Unlocking Industrial Efficiency with Advanced Perforated Sheet Technology

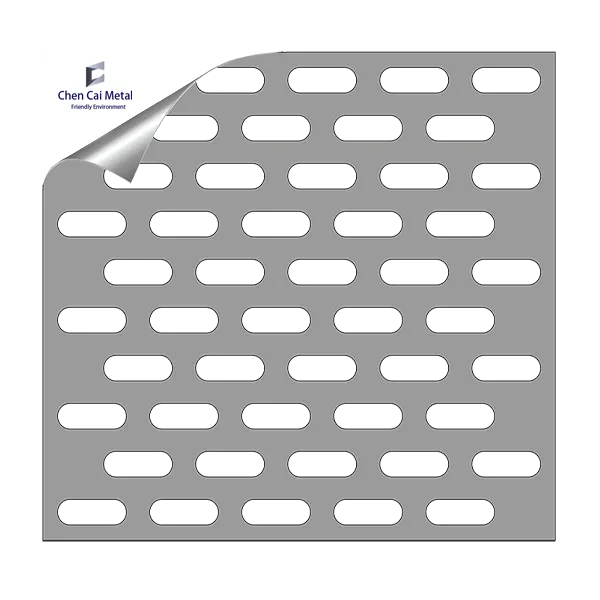

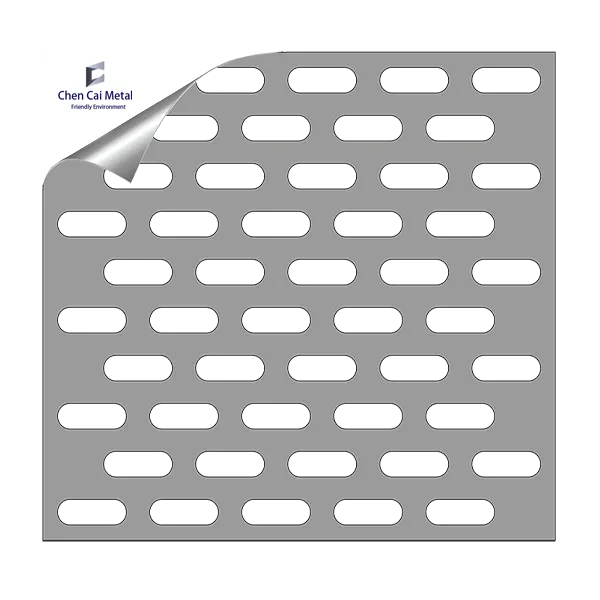

In the intricate landscape of modern industrial applications, the demand for precise, durable, and highly efficient materials is paramount. Among these, the slot hole perforated sheet stands out as a foundational component, offering unparalleled versatility and performance across a myriad of sectors. Unlike traditional round or square perforations, slotted patterns, particularly those with a 45° orientation, are engineered to optimize flow rates, enhance separation efficiency, and provide superior structural integrity under demanding conditions. This specialized design allows for the targeted filtration, screening, and ventilation of materials, making it indispensable in industries ranging from petrochemical and mining to food processing and architectural design. The precise engineering involved ensures uniform distribution of apertures, which is critical for consistent performance, whether dealing with granular solids, viscous liquids, or gaseous media. Our commitment to innovation in the field of advanced metal mesh solutions positions us at the forefront of providing these essential components, designed to meet the rigorous demands of contemporary industrial processes, thus ensuring enhanced operational efficiency and significantly reduced maintenance overheads for our clients worldwide. The ability to customize dimensions, material composition, and finish further augments their adaptability, making them a cornerstone of modern industrial infrastructure.

The Precision Behind the Product: Manufacturing Process of Slot 45° Perforated Sheets

The creation of a high-quality slot hole perforated sheet involves a meticulously controlled manufacturing process, ensuring both precision and durability. It commences with the careful selection of premium raw materials, typically stainless steel (e.g., 304, 316, 316L for superior corrosion resistance), carbon steel, galvanized steel, aluminum, or specialized alloys, chosen based on the intended application's environmental and operational demands. The journey begins with large coils or flat sheets, which undergo rigorous inspection to meet strict material composition and surface finish standards. Following material preparation, the sheets are fed into advanced CNC punching machines or laser cutting systems. These state-of-the-art machines are programmed with precise schematics to create the elongated, angled slots – in our flagship product, specifically at a 45° orientation. This specific angle is engineered to enhance flow characteristics and separation efficiency, particularly in applications requiring optimized material passage with minimal clogging. The punching process involves high-speed, high-pressure strikes, ensuring clean, burr-free edges, critical for both performance and safety. For thinner gauges or intricate patterns, laser cutting offers exceptional precision, minimizing material distortion and allowing for complex designs.

Post-perforation, the sheets undergo a series of finishing processes. This may include deburring to remove any sharp edges, flattening to ensure dimensional stability, and cleaning to eliminate lubricants or debris. For enhanced corrosion resistance or aesthetic purposes, additional treatments like galvanization, powder coating, or anodizing might be applied. Every batch of slotted perforated sheet is subjected to stringent quality control, adhering to international standards such as ISO 9001 for quality management and ASTM standards (e.g., ASTM A240 for stainless steel) for material properties and dimensional tolerances. Our in-house testing includes visual inspection, dimensional checks using precise calipers and laser scanners, and sometimes even material composition analysis using X-ray fluorescence (XRF) spectrometry. These comprehensive checks ensure that each Slot 45° Perforated Sheet not only meets but often exceeds industry benchmarks for hole size accuracy, pitch consistency, open area percentage, and flatness. This meticulous approach guarantees an extended service life and reliable performance in even the most demanding environments, reflecting our unwavering commitment to delivering components that contribute directly to the efficiency and longevity of our clients' systems across petrochemical, metallurgical, and water treatment industries, among others.

Key Technical Parameters and Performance Metrics

Understanding the specific technical parameters of a slotted perforated sheet metal is crucial for optimal application. Key parameters include the slot dimensions (length and width), the pitch (distance from the center of one slot to the center of the next), the material gauge (sheet thickness), and the overall sheet dimensions. The "open area percentage" is a critical metric, representing the ratio of the total area of the holes to the total area of the sheet. For Slot 45° Perforated Sheets, this percentage is meticulously calculated to balance flow capacity with structural integrity, typically ranging from 20% to 50% depending on the specific application and desired filtration level. For instance, in dewatering applications, a higher open area facilitates faster liquid removal, while in fine screening, a lower open area might be preferred for precise separation of smaller particles. The 45° angle of the slots significantly influences flow dynamics, minimizing blinding and enhancing self-cleaning properties, which translates directly into reduced maintenance and increased operational uptime.

Our standard product range for Slot 45° Perforated Sheet typically includes a variety of slot sizes and material thicknesses to cater to diverse industrial needs. For example, common slot widths might range from 0.5mm to 10mm, with lengths varying from 5mm to 100mm, all precisely aligned at a 45-degree angle relative to the sheet's edge. Material gauges commonly span from 0.8mm (22 gauge) to 6.0mm (3 gauge), providing options for light-duty filtration up to heavy-duty structural support. The choice of material, such as 316L stainless steel, significantly enhances resistance to aggressive chemicals and high temperatures, making these sheets ideal for applications in corrosive environments found in chemical processing or marine industries. Performance data indicates superior particle separation efficiency due to the elongated slot design, which minimizes the passage of oversized particles while maximizing flow throughput. Furthermore, the inherent strength and rigidity of these sheets, even with high open areas, contribute to exceptional longevity, often exceeding conventional wire mesh or woven screens in harsh industrial settings, thereby offering a superior return on investment through prolonged operational periods and consistent performance.

Typical Slot Hole Perforated Sheet Specifications

| Parameter |

説明 |

Typical Range/Value |

| Material Grade |

Common alloys for specific environments |

SS304, SS316, SS316L, Carbon Steel, Aluminum, Galvanized Steel |

| Slot Width |

The narrower dimension of the slot opening |

0.5mm to 10mm |

| Slot Length |

The longer dimension of the slot opening |

5mm to 100mm |

| Angle of Slot |

Orientation of the slot relative to sheet edge |

45° (Standard for Slot 45° Perforated Sheet) |

| Sheet Thickness (Gauge) |

Material thickness before perforation |

0.8mm - 6.0mm (Approx. 22 to 3 Gauge) |

| Open Area Percentage |

Ratio of hole area to total sheet area |

20% - 50% (Customizable) |

| Standard Sheet Sizes |

Common panel dimensions |

1000x2000mm, 1220x2440mm, 1250x2500mm, or Custom |

Diverse Applications Across Critical Industries

The inherent versatility and robust performance of a slot hole perforated sheet make it an indispensable component across a broad spectrum of industrial applications. In the petrochemical industry, these sheets are widely utilized in catalyst support grids, reactor internal components, and various filtration units where high temperatures and corrosive media are common. Their ability to maintain structural integrity while allowing for precise fluid or gas flow is critical for optimizing reaction efficiency and preventing material bypass. Similarly, within the metallurgical sector, particularly in mineral processing and mining operations, slotted perforated sheet metal serves as crucial screening and dewatering media. The elongated slots are highly effective in separating ores from slurries, classifying aggregates, and ensuring efficient drainage, which significantly contributes to reduced processing times and improved yield rates. The resistance to abrasion and impact provided by high-quality materials like abrasion-resistant steel or hardened stainless steel ensures longevity in these demanding environments, minimizing downtime and replacement costs.

Beyond heavy industries, the application extends to areas like water treatment and environmental protection. Here, the slotted hole perforated sheet excels in various filtration stages, from primary screening of raw water intakes to support for filter media in wastewater treatment plants. The design minimizes clogging by allowing larger particles to pass without accumulation, thereby reducing backwash frequency and energy consumption. This translates directly into more energy-efficient operations and lower operational expenditure for municipal and industrial water facilities. Furthermore, in architectural and aesthetic applications, perforated sheets are employed for sun shading, facade cladding, and acoustic panels, offering a unique blend of functionality and modern design. The 45° angled slots can create captivating visual effects, controlling light and air flow while maintaining privacy. Other notable applications include sugar processing for juice filtration, grain drying equipment for airflow distribution, and even in specialized automotive components for sound damping or airflow management. The adaptability of these sheets to different environments and functional requirements underscores their critical role in driving efficiency and innovation across countless sectors worldwide, proving their value as a multifaceted engineering solution.

Technical Advantages and Core Benefits

The distinct advantages of a slotted perforated sheet, particularly the Slot 45° variant, stem from its engineered design which addresses common challenges faced by traditional perforated metals. A primary technical advantage is its superior flow optimization. The elongated and angled slots reduce surface tension and create a more direct path for fluid or granular material passage, minimizing turbulence and pressure drop. This leads to higher throughput rates and more efficient processing in applications like dewatering, screening, and material separation, directly contributing to energy savings by reducing the load on pumps or conveyors. For instance, in a typical industrial filtration system, a properly designed slot hole perforated sheet can achieve a 15-20% improvement in flow rate compared to a circular hole pattern with a similar open area, leading to significant operational cost reductions over time due to lower energy consumption and faster processing cycles. The design also inherently resists blinding and clogging. The self-cleaning effect, facilitated by the angled slots, prevents fine particles from lodging within the apertures, maintaining consistent open area and reducing the frequency of cleaning cycles.

Furthermore, the robust construction, typically from materials like stainless steel or high-strength alloys, provides exceptional corrosion resistance and mechanical strength. This ensures a prolonged service life, even in highly aggressive chemical environments or under constant abrasive wear, characteristic of mining and chemical processing industries. For example, a 316L stainless steel slotted perforated sheet can resist chlorides and other corrosive agents far better than standard carbon steel, extending lifespan by several fold in marine or acidic environments. The ability to customize slot dimensions, material thickness, and overall sheet size means these sheets can be precisely tailored to specific application requirements, ensuring optimal performance and cost-effectiveness. This bespoke engineering capability allows for fine-tuning parameters such as particle retention, flow rate, and structural load-bearing capacity, delivering a highly optimized solution that outperforms generic alternatives. The overall result is enhanced operational efficiency, reduced maintenance intervals, and a substantial increase in system reliability, solidifying the position of these advanced perforated sheets as a critical investment for industries aiming for peak performance and longevity.

Choosing Your Partner: Manufacturer Comparison and Custom Solutions

Selecting the right manufacturer for your slot hole perforated sheet requirements is as critical as the product itself. A discerning buyer must look beyond mere price and consider factors such as manufacturing precision, material quality consistency, adherence to international standards, and the breadth of customization capabilities. Leading manufacturers distinguish themselves through state-of-the-art production facilities, employing advanced CNC punching and laser cutting technologies that ensure millimeter-level accuracy for slot dimensions, pitch, and sheet flatness. Certification to ISO 9001, which signifies a robust quality management system, is a fundamental indicator of reliability and consistent product quality. Furthermore, experienced suppliers often have a proven track record, evidenced by long-term partnerships with major industrial players and positive customer feedback regarding product performance and service responsiveness. They should also demonstrate deep technical expertise, offering consultative support to help clients select the optimal material, slot configuration, and finishing treatments for their unique application challenges. This level of partnership is invaluable, particularly when dealing with complex industrial processes where precise material specifications directly impact operational efficiency and safety.

Customization is a cornerstone of our offering, recognizing that off-the-shelf solutions rarely fit every unique industrial scenario. We excel in providing tailor-made slotted perforated sheet solutions, adapting parameters such as specific slot dimensions, specialized material alloys (e.g., Duplex Stainless Steel for extreme environments, Monel for marine applications), unique sheet sizes, and custom finishing options like painting, anodizing, or specialized coatings for enhanced chemical resistance or non-stick properties. Our engineering team collaborates closely with clients from the initial concept phase through to final production, utilizing CAD/CAM software for precise design and simulation. This allows us to rapidly prototype and refine designs, ensuring the final product integrates seamlessly into existing systems and delivers optimal performance. Whether it's a large-scale order for a new refinery project or a small batch of highly specialized screens for a research facility, our agile manufacturing capabilities and commitment to precision ensure that every custom solution meets the most stringent requirements for quality, functionality, and cost-effectiveness. This bespoke approach minimizes waste, optimizes performance, and ultimately provides a superior return on investment for our clients by delivering solutions perfectly aligned with their operational demands.

Real-World Impact: Application Case Studies

The tangible benefits of a well-engineered slot hole perforated sheet are best illustrated through real-world applications where they have demonstrably improved efficiency and reliability. Consider a major chemical processing plant that faced recurring issues with catalyst fouling in their reactors, leading to frequent shutdowns for cleaning and catalyst replacement. By replacing their existing support grids with custom-designed Slot 45° Perforated Sheets made from high-grade 316L stainless steel, precisely engineered for optimized flow and reduced particle entrapment, the plant witnessed a significant reduction in fouling incidents. This led to a 25% increase in operational uptime and a 10% reduction in catalyst consumption over a two-year period, resulting in millions of dollars in savings from reduced maintenance and increased production capacity. This example highlights how the specialized design and material properties directly contribute to enhanced process stability and economic gains, validating the investment in superior perforated metal technology.

Another compelling case comes from a large-scale municipal wastewater treatment facility that struggled with inefficient dewatering of sludge, causing bottlenecks in their purification process. Their conventional screens were prone to rapid clogging, necessitating frequent manual cleaning and leading to increased labor costs and energy consumption. After implementing a pilot project with our slotted perforated sheet tailored for wastewater applications, featuring specific slot sizes and a high open area at a 45° angle, they observed a remarkable transformation. The unique slot geometry dramatically improved dewatering efficiency by 30%, allowing for faster processing of sludge and reducing the overall energy required for pumping. Furthermore, the self-cleaning properties of the sheets led to a 70% decrease in manual cleaning interventions, freeing up staff for other critical tasks and significantly lowering operational expenses. These quantifiable improvements underscore the profound impact that precision-engineered Slot 45° Perforated Sheets can have on large-scale industrial operations, demonstrating their capacity to deliver substantial long-term value through enhanced performance, reduced operational costs, and improved environmental outcomes.

Ensuring Trust: FAQs, Delivery & Support

Building trust with our B2B partners is paramount, and it's achieved through transparency, reliability, and robust support systems. We understand that purchasing critical industrial components like a slot hole perforated sheet involves significant investment and requires confidence in the supplier's capabilities. Our commitment to trustworthiness extends beyond product quality to encompass every aspect of the customer journey. We maintain stringent internal quality control procedures, backed by third-party certifications like ISO 9001, ensuring that every sheet leaving our facility meets the highest global standards. Our average lead time for standard products is typically 2-4 weeks, depending on order volume and material availability, while custom orders are quoted with precise timelines after design finalization, ensuring predictable project planning for our clients. We offer flexible shipping options, including expedited delivery for urgent requirements, coordinating closely with logistics partners to ensure timely and secure arrival of products to their destination worldwide.

Our customer support is designed to be highly responsive and technically proficient. A dedicated account manager is assigned to each client, providing a single point of contact for all inquiries, from technical specifications to order tracking. We offer comprehensive pre-sales consultation to help define precise requirements and post-sales support for installation guidance or troubleshooting. Our products come with a standard 12-month warranty against manufacturing defects, underscoring our confidence in their durability and performance. This warranty covers material flaws and workmanship issues, providing peace of mind to our clients. For any concerns or issues, our technical support team is available via phone, email, and online portal to provide prompt and effective solutions. Additionally, we maintain a comprehensive FAQ section addressing common questions regarding material selection, installation best practices, maintenance, and potential performance optimizations for slotted perforated sheet metal. Our aim is to foster long-term partnerships built on mutual trust, delivering not just products, but complete solutions and unwavering support throughout the lifespan of our perforated sheets in their critical applications.

Frequently Asked Questions (FAQs)

- Q: What is the typical lifespan of a Slot 45° Perforated Sheet?

A: The lifespan varies significantly based on the material, application environment (e.g., presence of corrosive agents, abrasion), and operational stresses. However, with proper material selection and design, our sheets can last from 5 to 20+ years in typical industrial settings. For instance, a 316L stainless steel sheet in a non-abrasive chemical environment could easily exceed 15 years, while a carbon steel sheet in a highly abrasive mining application might need replacement in 5-7 years.

- Q: Can these sheets be welded or fabricated on-site?

A: Yes, our slot hole perforated sheet products are designed for ease of fabrication. Depending on the material, they can be readily welded, cut, bent, and formed using standard industrial techniques. We recommend consulting our technical team for specific material welding guidelines to ensure optimal structural integrity and avoid material degradation. For instance, stainless steel requires specific welding procedures to maintain its corrosion resistance.

- Q: How does the 45° slot angle improve performance?

A: The 45° angle provides several advantages: it promotes a "self-cleaning" action by reducing particle entrapment and blinding, especially with fibrous or irregular materials. It also optimizes flow dynamics, reducing turbulence and pressure drop, leading to higher throughput and energy efficiency. This design is particularly beneficial in applications involving viscous liquids or materials prone to sticking, ensuring continuous and efficient operation.

- Q: What inspection standards do you follow for quality assurance?

A: We strictly adhere to international quality standards, including ISO 9001 for our quality management system. For material specifications and dimensional tolerances, we comply with relevant ASTM standards (e.g., ASTM A240 for stainless steel, ASTM B209 for aluminum, etc.) and ANSI standards where applicable. Each batch undergoes rigorous in-house testing and inspection before shipment, and third-party inspections can be arranged upon request.

Conclusion: The Future of Industrial Perforation

The evolution of industrial processes demands materials that are not only robust but also intelligently designed for optimal performance. The slot hole perforated sheet, particularly with its advanced 45° angled slot configuration, represents a pinnacle in this technological progression. Its proven capabilities in enhancing flow efficiency, resisting corrosion and abrasion, and facilitating precise separation position it as an indispensable component across vital sectors such as petrochemical, metallurgy, water treatment, and countless others. The ability to customize these sheets to exact specifications, coupled with rigorous quality assurance and comprehensive customer support, ensures that our Slot 45° Perforated Sheets deliver exceptional value, leading to significant operational savings and improved system longevity for our clients worldwide. As industries continue to strive for greater sustainability, efficiency, and resilience, the role of precisely engineered perforated metals will only become more critical, serving as a fundamental element in achieving these ambitious goals.

References

- American Society for Testing and Materials (ASTM) International Standards.

- International Organization for Standardization (ISO) 9001:2015 Quality Management Systems.

- ASM Handbook, Vol 14A: Metalworking: Perforating and Punching.

- Chemical Engineering Journal, Article on Fluid Dynamics in Perforated Plates.

- Journal of Materials Processing Technology, Research on Advanced Sheet Metal Forming.

![$item[タイトル] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)