Industry Overview and Trends in Perforated Sheet Technology

The demand for advanced material solutions continues to drive innovation across numerous industrial sectors. Among these, square hole perforated sheet stands out as a versatile and high-performance material, crucial for applications ranging from architectural design to precision filtration. The market for perforated metals is experiencing steady growth, fueled by increasing industrialization, infrastructure development, and a heightened focus on efficiency and sustainability. Key trends include the adoption of lighter, stronger alloys like aluminum, enhanced customization capabilities, and the integration of smart manufacturing processes to achieve tighter tolerances and superior surface finishes. End-users are increasingly seeking solutions that offer not only functional superiority—such as optimal open area for airflow or filtration—but also aesthetic appeal and long-term durability in challenging environments. This shift necessitates materials like square hole perforated sheet metal that can meet stringent performance specifications while offering design flexibility.

Technological advancements in punching and stamping equipment, coupled with sophisticated CAD/CAM software, allow for the production of increasingly complex perforation patterns and precise hole geometries. This precision is critical in industries such as HVAC for air distribution, acoustic panels for sound dampening, and various components in the automotive and aerospace sectors. Furthermore, the emphasis on energy efficiency and environmental regulation is prompting a greater adoption of materials that can contribute to reduced operational costs and extended product lifespans, making square perforated aluminum sheet a particularly attractive option due to its lightweight nature and corrosion resistance.

Detailed Manufacturing Process Flow for Square Hole Perforated Sheet

The production of metal sheet with square holes is a highly precise and multi-stage process designed to ensure product integrity and performance. Our manufacturing facility adheres strictly to international standards, including ISO 9001:2015 for quality management.

-

1. Material Selection and Preparation:

We begin with carefully selected raw materials, which typically include stainless steel (e.g., 304, 316L), galvanized steel, carbon steel, and aluminum alloys (e.g., 1050, 3003, 5052). Each material is chosen based on the specific application requirements, considering factors such as corrosion resistance, strength-to-weight ratio, and formability. Material thickness can range from 0.5mm to 10mm. All incoming materials undergo rigorous quality checks to verify chemical composition and mechanical properties against ASTM or EN standards.

-

2. Precision Perforation:

This critical stage involves using advanced CNC punching machines. These machines are equipped with precision tooling to create square holes with exacting dimensions and patterns. The hole size, pitch (distance between hole centers), and staggering angle (often 45° for optimal open area and strength) are programmed into the CNC system. Our high-speed punch presses can achieve perforation rates of up to 600 strokes per minute, ensuring efficient production while maintaining superior hole quality. Tolerances are typically held to ±0.1mm for hole size and pitch, aligning with ANSI/NAAMM standards.

-

3. Leveling and Deburring:

After perforation, the sheet metal may exhibit some curvature or burrs around the holes. Our multi-roll leveling machines flatten the sheets to ensure a perfectly planar surface. Deburring processes, using either mechanical brushes or vibratory finishing, remove any sharp edges or burrs, ensuring safe handling and optimal aesthetic appeal. This step is crucial for applications requiring high aesthetic quality or where smooth surfaces are essential for preventing snagging or injury.

-

4. Cutting and Forming:

The perforated sheets are then cut to the specified dimensions using precision shearing or laser cutting equipment. For specific applications, sheets can also undergo further forming processes such as bending, rolling, or welding to create complex components or finished products. Our hydraulic press brakes and rolling machines handle these operations with exceptional accuracy.

-

5. Surface Treatment (Optional):

Depending on the material and end-use environment, various surface treatments can be applied. These include powder coating for enhanced corrosion resistance and aesthetic finish, anodizing for aluminum to increase hardness and create decorative colors, galvanizing for steel to add a sacrificial zinc layer, or polishing for stainless steel to achieve a bright, reflective surface. These treatments extend the service life of the square hole perforated sheet and enhance its performance in corrosive or demanding conditions.

-

6. Quality Control and Packaging:

Every batch undergoes a final comprehensive quality inspection, checking for dimensional accuracy, hole integrity, flatness, and surface finish. We utilize optical measurement tools and manual inspections to ensure adherence to customer specifications and international quality standards. Products are then carefully packaged to prevent damage during transit, typically using wooden pallets or crates, with protective interleaving between sheets.

Target industries for our square hole perforated sheet include petrochemical (for filters and screens), metallurgy (for sieves and heat exchangers), water supply & drainage (for filtration and screens), food processing (for drying and sorting trays), and architectural design (for facades and sunscreens). Our products offer significant advantages in energy saving through optimized airflow and lightweight construction, and superior corrosion resistance due to material selection and advanced surface treatments, ensuring a long service life.

Technical Specifications: Square 45° Perforated Sheet

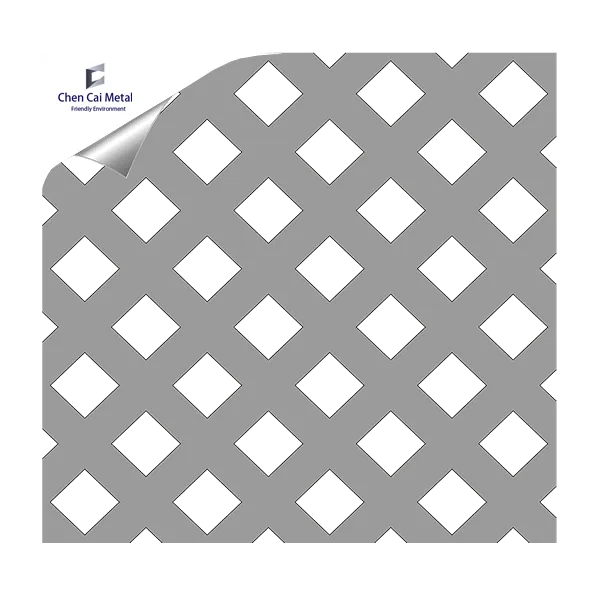

Understanding the precise technical parameters is paramount for selecting the optimal square hole perforated sheet for industrial applications. Our Square 45° Perforated Sheet is engineered for superior performance and durability, featuring a diagonal perforation pattern that maximizes open area while maintaining structural integrity.

Typical Product Specification Table: Square 45° Perforated Sheet

| Parameter |

Specification Range / Typical Values |

Industry Standard / Benefit |

| Material Options |

Stainless Steel (304, 316L), Galvanized Steel, Carbon Steel, Aluminum (1050, 3003, 5052), Copper, Brass |

Versatility for diverse environments (corrosion resistance, strength) |

| Sheet Thickness |

0.5 mm to 10 mm (0.02" to 0.394") |

Tailored to load-bearing and structural requirements |

| Hole Size (Side Length) |

3 mm x 3 mm to 50 mm x 50 mm (0.118" to 1.97") |

Customizable for filtration, screening, or aesthetic needs |

| Pitch (Center-to-Center) |

Typically 1.5 to 2.5 times hole size |

Optimal balance between open area and structural integrity |

| Perforation Pattern |

45° Staggered Square Holes |

Maximizes open area, improves aesthetic appeal, uniform strength |

| オープンエリア |

30% to 70% (typical range) |

Efficient flow rate for air, liquid, light; sound absorption properties |

| Standard Sheet Sizes |

1000x2000mm, 1220x2440mm, 1250x2500mm, 1500x3000mm |

Common sizes for ease of integration and cost-efficiency |

| Finish |

Mill finish, Polished, Galvanized, Powder Coated, Anodized |

Enhanced durability, corrosion resistance, aesthetic versatility |

| Manufacturing Standard |

ISO 9001:2015, ASTM E2773, ANSI/NAAMM |

Ensures consistent quality, performance, and reliability |

These specifications underscore our commitment to providing high-quality square hole perforated sheet metal engineered to meet the stringent requirements of modern industrial and architectural applications. Our technical team is available to discuss custom specifications and material selections to perfectly match your project's demands.

Versatile Application Scenarios and Technical Advantages

The unique properties of square hole perforated sheet, particularly its balance of open area, strength, and aesthetic appeal, make it indispensable across a multitude of industries. Its geometric precision allows for predictable performance in diverse functional roles.

- Acoustic Panels and Sound Dampening: In architectural and industrial settings, perforated sheets serve as effective components in acoustic ceiling tiles, wall panels, and machinery enclosures. The precisely engineered square perforations disrupt sound waves, significantly reducing noise pollution. The 45° staggered pattern provides excellent sound absorption coefficients.

- Filtration and Separation: From water treatment plants to petrochemical refineries, metal sheet with square holes is vital for screening, straining, and filtration. Its uniform apertures ensure consistent particle separation, essential for fluid processing, solid waste management, and industrial air filtration systems. The durability of materials like stainless steel ensures longevity in corrosive filtering environments.

- Architectural Facades and Sunscreens: Architects leverage the aesthetic versatility of square perforated aluminum sheet for building facades, balustrades, and sunshades. The material offers a modern, high-tech appearance, allows for natural light diffusion while controlling glare, and provides ventilation. Its lightweight nature minimizes structural load, making it ideal for large-scale external applications.

- HVAC and Enclosure Ventilation: Essential for efficient airflow and heat dissipation in heating, ventilation, and air conditioning systems, as well as in electronic enclosures. The precise open area facilitates optimal air exchange, preventing overheating and ensuring system longevity.

- Security and Safety Guards: Used extensively for machine guards, stair treads, and fencing, providing a strong physical barrier without completely obstructing visibility or airflow.

Key Technical Advantages:

- Optimized Open Area & Flow Dynamics: The 45° staggered square pattern maximizes the open area ratio, enabling superior airflow, liquid flow, and light transmission compared to traditional patterns, while maintaining sufficient strength. This translates to energy savings in ventilation and pumping systems.

- High Strength-to-Weight Ratio: Especially evident with aluminum and certain stainless steel alloys, perforated sheets offer significant structural integrity for their weight, reducing overall material consumption and shipping costs.

- Corrosion and Wear Resistance: Through material selection (e.g., SS316L for marine environments) and optional surface treatments (e.g., galvanizing, powder coating), the service life of the square hole perforated sheet metal is significantly extended, even in harsh chemical or environmental conditions.

- Aesthetic Versatility: The uniform and geometric patterns provide a modern, industrial, and clean aesthetic, highly valued in contemporary design. Various finishes further enhance visual appeal.

- Thermal Management: Efficient heat dissipation properties make these sheets ideal for heat shields, engine covers, and electronic enclosures, contributing to the longevity and performance of enclosed components.

These combined advantages underscore why square hole perforated sheet remains a preferred choice for engineers and designers seeking reliable, high-performance, and cost-effective material solutions.

Customized Solutions and Vendor Comparison

In the specialized B2B market for perforated metals, the ability to provide tailored solutions is a critical differentiator. We pride ourselves on offering extensive customization options for square hole perforated sheet, enabling our clients to achieve precise functionality and integration for their unique projects.

Our Customization Capabilities Include:

- Material Variants: Beyond standard options, we can source specialty alloys (e.g., Monel, Inconel) for extreme temperature or highly corrosive applications.

- Custom Hole Configurations: While our Square 45° Perforated Sheet is a flagship, we can adjust square hole dimensions, pitch, margin, and even integrate blind areas (unperforated sections) as per design specifications.

- Unique Sheet Sizes & Forms: Producing non-standard sheet dimensions, as well as complex formed components (e.g., cylinders, cones, bent panels) directly from perforated stock.

- Specialized Surface Finishes: Beyond standard treatments, we can arrange for electropolishing, specific paint systems, or anti-microbial coatings.

- Additional Fabrication: Including welding, notching, rolling, and further machining to deliver semi-finished or ready-to-install components.

Our engineering team collaborates closely with clients from conceptualization to production, using advanced simulation software to optimize designs for performance and manufacturability.

Vendor Comparison: Key Factors for Selecting a Supplier

Choosing the right supplier for square hole perforated sheet metal is crucial for project success. While several manufacturers offer perforated products, our commitment to quality, technical expertise, and customer service distinguishes us. Below is a comparison of key attributes:

Vendor Comparison for Perforated Metal Sheets

| Attribute |

Our Company (CC Metal Mesh) |

Typical Competitor |

| Technical Expertise & R&D |

20+ years experience, dedicated R&D team, material science specialists, ISO/ASTM compliance. |

Limited R&D, basic material knowledge, only common standards. |

| Customization Capabilities |

Extensive, full design support, material sourcing, advanced fabrication, prototyping. |

Standard patterns/sizes, limited custom tooling, basic cuts. |

| Quality Control & Certifications |

ISO 9001:2015, detailed batch testing, third-party inspection, traceable materials. |

Basic QC, self-certification, limited material traceability. |

| Lead Time & Fulfillment |

Streamlined production, efficient logistics, on-time delivery track record, urgent order flexibility. |

Standard lead times, potential delays, limited rush order capacity. |

| After-Sales Support |

Dedicated support team, technical assistance, warranty fulfillment, prompt issue resolution. |

Minimal support, difficult to reach, slow resolution. |

| Pricing Strategy |

Value-based, competitive for high quality & customization, long-term partnerships. |

Price-driven, often compromises quality/service for lower cost. |

Our reputation is built on delivering superior square perforated aluminum sheet and other perforated metal products, backed by unparalleled service and technical expertise. We have partnered with leading firms in petrochemical, environmental engineering, and construction sectors globally, a testament to our authoritativeness and trustworthiness in the market.

Application Case Studies

Real-world implementations demonstrate the transformative impact of high-quality square hole perforated sheet. Our experience spans decades, providing critical solutions to complex industrial challenges.

Case Study 1: Noise Abatement in a Manufacturing Plant

Client: Large-scale Automotive Component Manufacturer

Challenge: Excessive noise levels from high-speed stamping machinery caused discomfort for workers and exceeded occupational health and safety limits (OSHA standards of 85 dBA TWA). Traditional solid barriers were impractical due to ventilation requirements and access. The client needed a solution that would effectively reduce noise without hindering airflow or machine maintenance.

Solution: We supplied custom-fabricated acoustic panels utilizing 3mm thick square hole perforated sheet metal (304 stainless steel with 6x6mm holes on an 8mm 45° staggered pitch) backed by a high-density sound-absorbing mineral wool layer. The panels were designed for quick assembly and disassembly, allowing for easy access to machinery. The high open area (approximately 50%) of the perforation ensured adequate ventilation.

Results: Post-installation, noise levels were reduced by an average of 12-15 dBA in the immediate vicinity of the machinery, bringing the plant into compliance with safety regulations. Employee feedback indicated significantly improved working conditions and reduced fatigue. The stainless steel construction ensured excellent durability and corrosion resistance in the industrial environment, projecting a service life of over 15 years.

Case Study 2: Sustainable Architectural Facade for a Commercial Complex

Client: Leading Architectural Firm for a Green Building Project

Challenge: The project required an external facade material that would provide solar shading, allow for natural ventilation, and offer a striking modern aesthetic, all while contributing to the building's LEED certification. The material needed to be lightweight, highly durable against weather elements, and easily integrated into a modular design.

Solution: We collaborated with the architects to design and supply custom-sized square perforated aluminum sheet panels (5052-H32 alloy, 2mm thick, with 15x15mm holes on a 20mm 45° staggered pitch). The panels were finished with a durable, UV-resistant powder coating in a bespoke color. The 45% open area provided optimal solar shading while maintaining transparency and views from inside. The lightweight nature of aluminum significantly reduced the load on the building structure.

Results: The facade successfully reduced solar heat gain by an estimated 25%, leading to substantial energy savings on air conditioning. The striking visual appeal of the perforated panels became a signature feature of the building, receiving commendations for innovative design and sustainability. The aluminum panels are projected to last over 30 years with minimal maintenance, proving the long-term value of the investment.

Frequently Asked Questions (FAQ)

-

Q1: What is the typical lead time for custom square hole perforated sheet orders?

A1: Lead times vary based on material availability, order complexity, and current production schedules. For standard materials and patterns, typical lead times range from 2-4 weeks. Highly specialized materials or complex fabrication may extend this to 6-8 weeks. We provide an estimated lead time with every quote and keep clients informed throughout the process.

-

Q2: What kind of warranty do you offer on your perforated products?

A2: We stand behind the quality of our square hole perforated sheet metal products. We offer a standard 1-year warranty against manufacturing defects in materials and workmanship from the date of purchase. Extended warranties or specific performance guarantees can be discussed for large-scale projects or particular application requirements.

-

Q3: Can you help with design and engineering for a specific application?

A3: Absolutely. Our experienced engineering team provides comprehensive technical support, from material selection and perforation pattern optimization to structural analysis and prototyping. We use advanced CAD/CAM software to translate your requirements into precise manufacturing specifications, ensuring the optimal metal sheet with square holes for your project.

-

Q4: What are your minimum order quantity (MOQ) requirements?

A4: While we primarily serve industrial and commercial clients, MOQs can vary depending on the material and customization required. For standard sheets, MOQs might be as low as 1-2 full sheets. For highly customized patterns or unique materials, there may be tooling charges or larger MOQs. Please contact our sales team with your specific needs for a detailed quotation.

-

Q5: What are the benefits of a 45° staggered square perforation pattern?

A5: The 45° staggered pattern offers several advantages. It allows for a higher open area percentage compared to straight-line patterns for the same hole size and pitch, which is beneficial for airflow, light transmission, and filtration. It also provides a visually appealing, uniform pattern, and can contribute to enhanced structural stability by distributing stress more evenly across the sheet. This makes our Square 45° square perforated aluminum sheet highly versatile.

Lead Time, Warranty, and Customer Support

Our commitment to client satisfaction extends beyond product delivery. We provide transparent communication, robust quality assurance, and responsive support throughout the project lifecycle.

Fulfillment and Lead Time Management:

We understand the critical nature of project timelines. Our production planning integrates lean manufacturing principles to optimize efficiency. For typical orders of square hole perforated sheet, expect lead times of 2-4 weeks. For urgent requirements or large-scale projects, we offer expedited options and phased deliveries, managed through dedicated project coordinators. Our logistics partners ensure secure and timely global shipping, with full tracking capabilities.

Warranty Commitments:

All our perforated metal products, including square perforated aluminum sheet, come with a standard 12-month limited warranty against manufacturing defects. This covers material flaws and workmanship under normal use conditions. Specific product lines or project agreements may include extended warranties or performance guarantees tailored to the application's demands. Our comprehensive quality control ensures that such instances are rare, but our commitment is to provide prompt and fair resolution should any issues arise.

Dedicated Customer Support:

Our multilingual customer support team is available from Monday to Friday, 8:00 AM to 5:00 PM (GMT+8). We provide technical assistance, order status updates, and post-sales support via phone, email, and live chat. For complex projects, clients are assigned a dedicated account manager to ensure seamless communication and personalized service. Our goal is to build long-term partnerships based on trust, reliability, and unparalleled product quality for every metal sheet with square holes we deliver.

References and Authoritative Sources

- ISO 9001:2015 Quality Management Systems – Requirements. International Organization for Standardization.

- ASTM E2773 Standard Test Method for Determining the Open Area of Perforated Plate. ASTM International.

- ANSI/NAAMM MBG 531-09 Metal Bar Grating Manual for Specifying and Purchasing. National Association of Architectural Metal Manufacturers.

- "Perforated Metal: A Material for Contemporary Architecture" by U. Zölffel. DETAIL, Edition, 2011.

- "Acoustic Properties of Perforated Panels" by C. G. S. Rao, Journal of Sound and Vibration, 2005.

![$item[タイトル] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)