Stainless Perforated Sheets play an increasingly important role in the fields of architecture, industry, and decoration due to their excellent physical performance, versatility, and aesthetics, and are gradually becoming an ideal choice. The wide range of its applications and the multitude of industries it benefits from all demonstrate its unique value and irreplaceability.

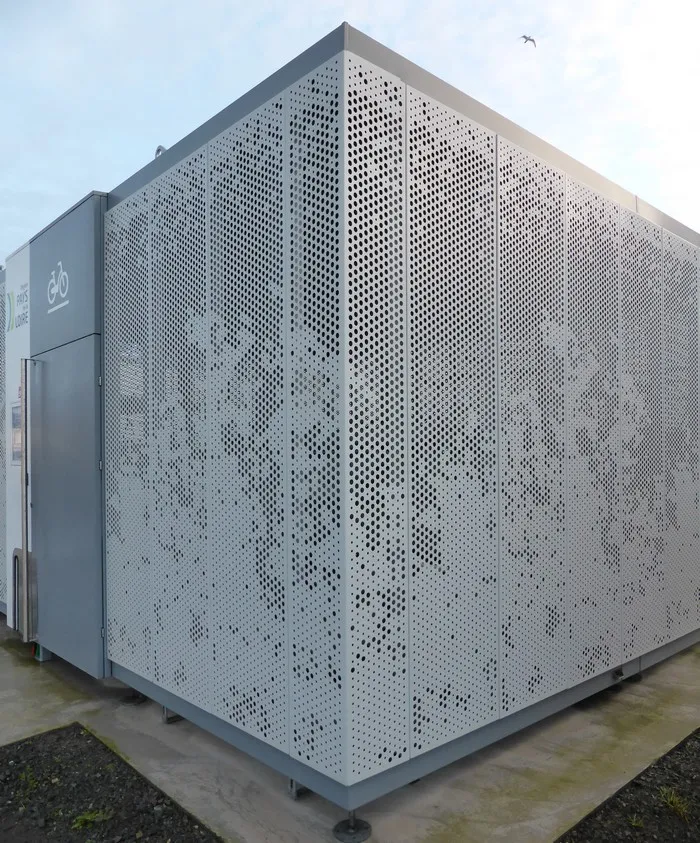

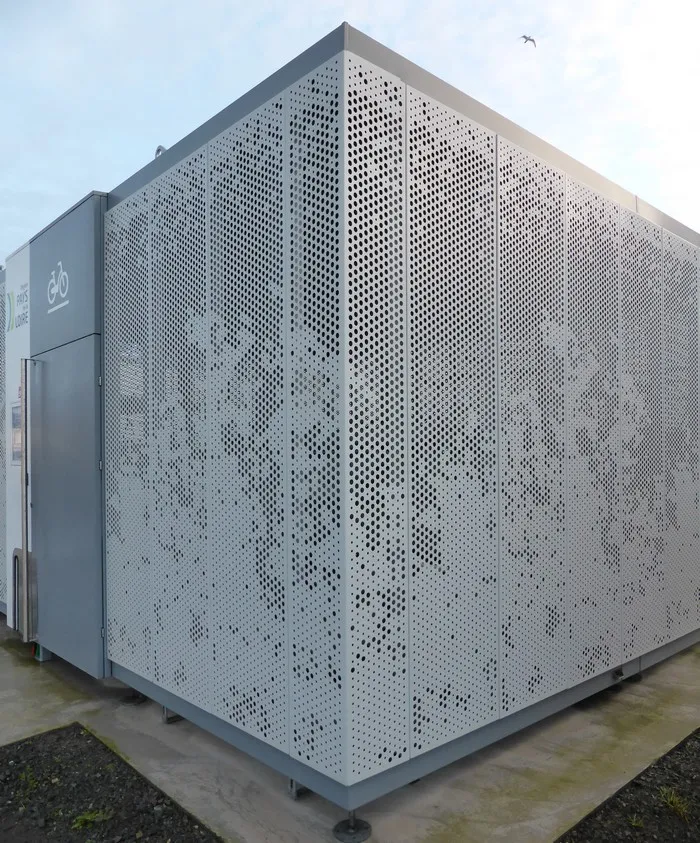

In the field of architecture, the application of Stainless Perforated Sheets is becoming increasingly widespread

The excellent corrosion resistance and strength of stamped metal sheets enable them to withstand various harsh environmental conditions, whether it is exterior wall decorations exposed to wind and rain or structural supports that require heavy pressure. Meanwhile, by controlling the aperture, arrangement, and surface treatment, various visual effects can be created, providing great flexibility for architectural design. The use of punched plates to control lighting, ventilation, and noise can significantly improve the comfort of buildings. For example, in curtain wall design, Stainless Perforated Sheet can effectively shade the sun, reduce indoor temperature, and thus reduce energy consumption. In addition, its lightweight characteristics also reduce the load on the building structure and improve the safety of the building.

In the industrial field, Stainless Perforated Sheets are widely used in multiple industries due to their excellent filtration, screening, and protection performance

In industries such as food processing, chemical engineering, and pharmaceuticals, punched plates can be used to filter solid impurities, separate materials with different particles, and ensure the purity and efficiency of the production process. In the field of mechanical manufacturing, punched plates can serve as protective covers for equipment, preventing foreign objects from entering and ensuring the safe operation of the equipment. In terms of noise control, සිදුරු සහිත රැලි සහිත ලෝහය can be used to manufacture mufflers, soundproof screens, etc., reducing industrial noise pollution. In addition, the high temperature resistance and corrosion resistance of stainless steel also make it perform well in extreme environments such as high temperature and high pressure, ensuring the stability and safety of industrial production.

In the field of decoration, Stainless Perforated Sheet has won the favor of designers with its modernity and diversity

Through different hole designs and surface treatments, rich visual effects can be created to meet the decorative needs of different styles. From simple and modern indoor partitions to artistic wall decorations, සිදුරු සහිත මල නොබැඳෙන වානේ දැලක් can showcase its unique charm. In addition, its easy to clean and maintain characteristics make it an ideal choice for decorative materials, which can maintain its beauty and functionality for a long time.

In summary, perforated metals have shown great potential for application in the fields of architecture, industry, and decoration due to their excellent physical properties, multifunctionality, and aesthetics. Its excellent corrosion resistance, strength, and plasticity enable it to meet various demanding requirements, while its lightweight, easy to clean, and maintenance characteristics also make it more practical. With the continuous advancement of technology and the expansion of application fields, Stainless Perforated Sheets will undoubtedly play a more important role in the future fields of architecture, industry, and decoration, becoming a truly ideal choice.

Stainless Perforated Sheet FAQs

What is a Stainless Perforated Sheet?

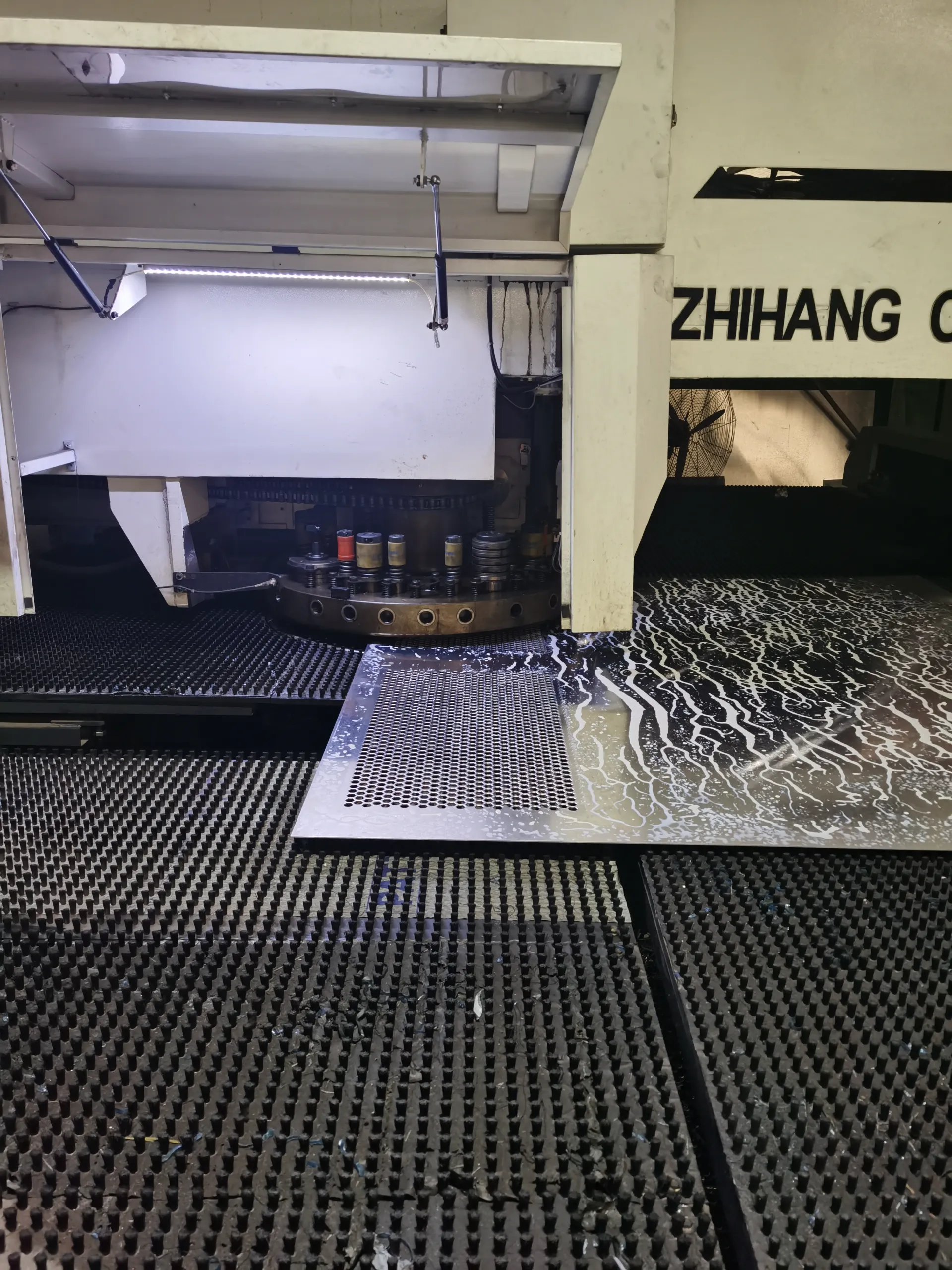

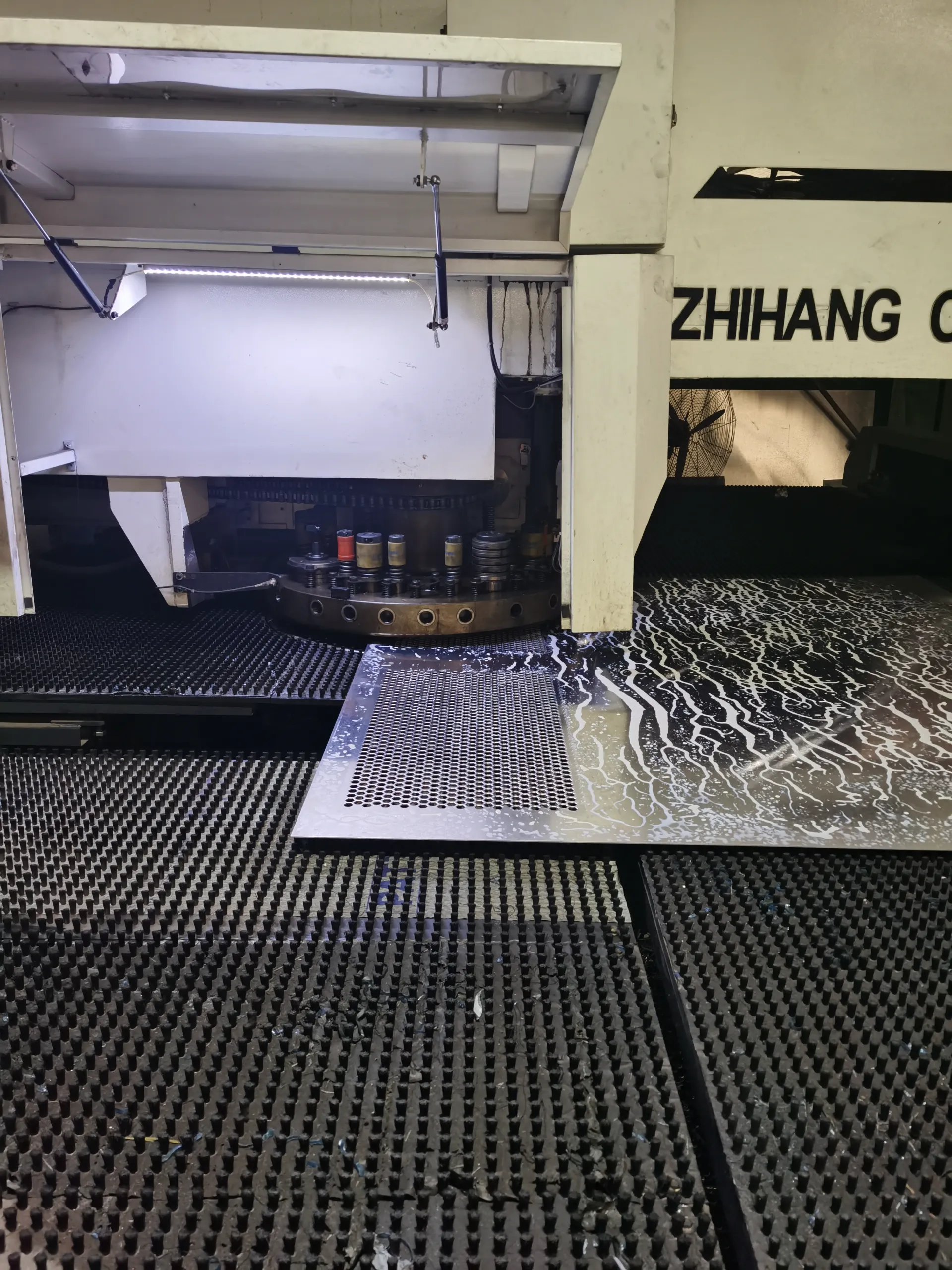

Stainless Perforated Sheet is a perforated metal sheet formed on stainless steel plates (such as 304, 316, etc.) through stamping, laser or plasma cutting processes. Its hole types are diverse (round holes, square holes, long holes, etc.), with characteristics such as corrosion resistance, high strength, and easy cleaning, suitable for harsh environments and high-end decoration.

What are the main materials of Stainless Perforated Sheet? How to choose?

Common materials include 304 stainless steel (universal type, acid and alkali resistant) and 316 stainless steel (high corrosion resistance, suitable for marine and chemical environments). When choosing, the usage scenario should be considered:

316 is preferred for outdoor or highly corrosive environments (such as coastal areas and chemical plants);

The decoration or food industry requires beauty and hygiene, and can choose 304 mirror or brushed treatment;

Cost sensitive projects can use 201 stainless steel (with slightly weaker corrosion resistance).

What are the applications of Stainless Perforated Sheet in the field of architectural decoration?

Stainless Perforated Sheet is commonly used for:

Curtain wall and exterior facade: such as sun visors, ventilation decorative panels, balancing functionality and artistry;

Interior design: partitions, ceilings, stair railings, creating a modern industrial style;

Acoustic engineering: sound-absorbing wall panels in cinemas and concert halls that adjust sound wave reflection through holes.

What are the core advantages of Stainless Perforated Sheet in the industrial field?

Corrosion resistance: Long term resistance to moisture, chemicals, or salt spray, with a lifespan far exceeding that of ordinary metals;

Health and safety: The surface is smooth and residue free, meeting the standards of the food and pharmaceutical industry (such as workbenches and filters);

High temperature adaptability: suitable for protection and ventilation of high-temperature equipment such as boilers and flues.

What are the processing precautions for Stainless Perforated Sheet?

Hole type design: The hole spacing and aperture need to balance strength and transparency (such as anti slip plates requiring close arrangement of small holes);

Edge treatment: After cutting, burrs need to be removed to prevent scratches (especially for food grade applications);

Installation method: Reserve thermal expansion and contraction gaps (for outdoor large-scale paving).

![$අයිතමය[මාතෘකාව] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)