- Introduction: Overview of types of expanded metal

and their market importance

- Understanding Types and Specifications of Expanded Metal Mesh

- Technical Advantages and Benefits

- Global Manufacturer Comparison

- Customization Options and Process Guidance

- Real-World Application Cases and Industry Impact

- Conclusion: Choosing the Right Types of Expanded Metal for Your Needs

(types of expanded metal)

Introduction: Exploring Types of Expanded Metal and Market Relevance

Expanded metal represents a versatile class of engineered materials featuring a lattice pattern created by slitting and stretching sheet metal. Recognized for their outstanding strength-to-weight ratio, types of expanded metal play key roles in myriad industrial, architectural, and security applications worldwide. Market research from the Global Market Insights firm reports that the expanded metal market surpassed $2.5 billion in 2023 and is projected to achieve a compound annual growth rate (CAGR) of over 4% through 2030, propelled by increasing demand in construction, transportation, and filtration sectors. Understanding the nuances among types of expanded metal mesh enables engineers, procurement specialists, and end-users to maximize performance while optimizing budget and function.

Types and Specifications of Expanded Metal Mesh

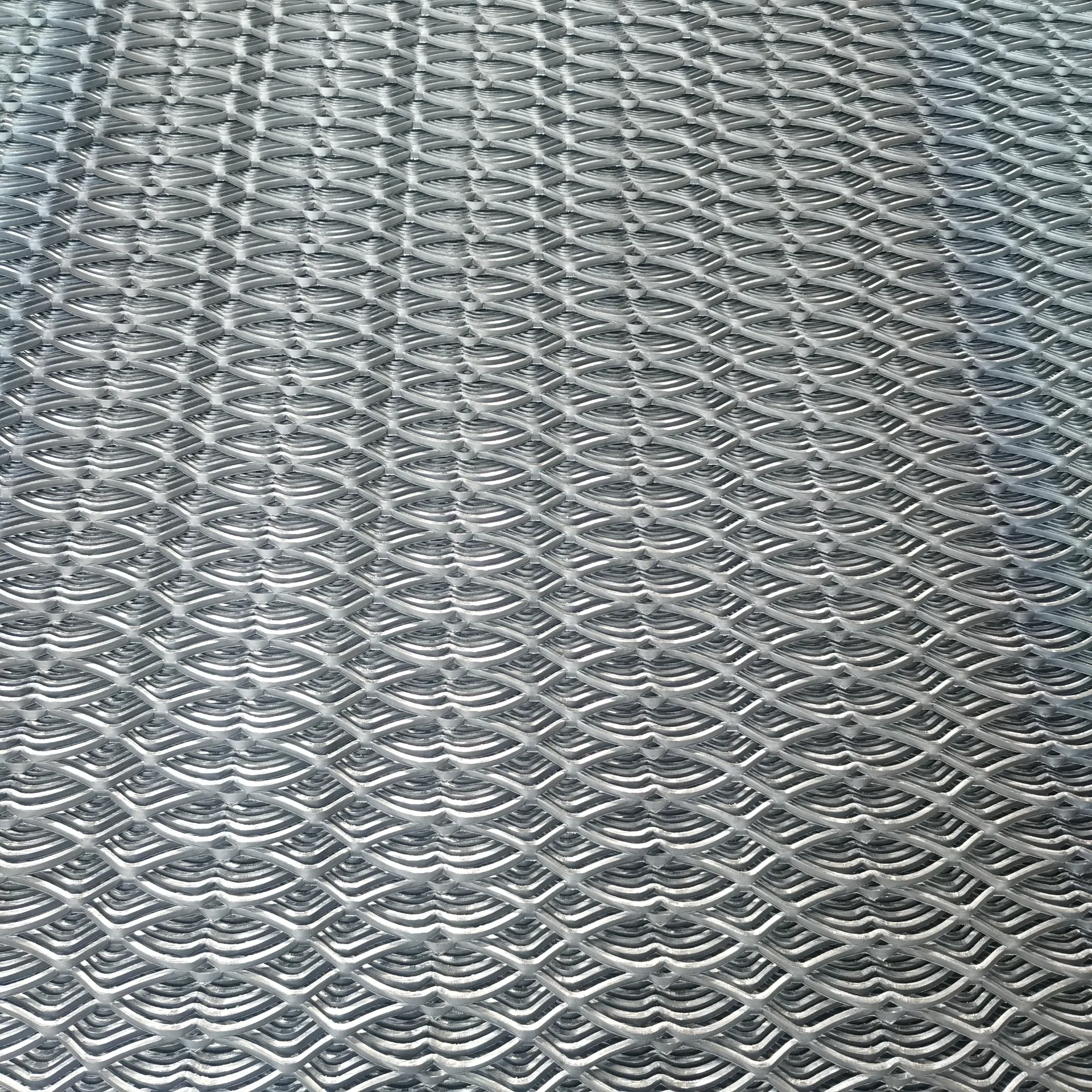

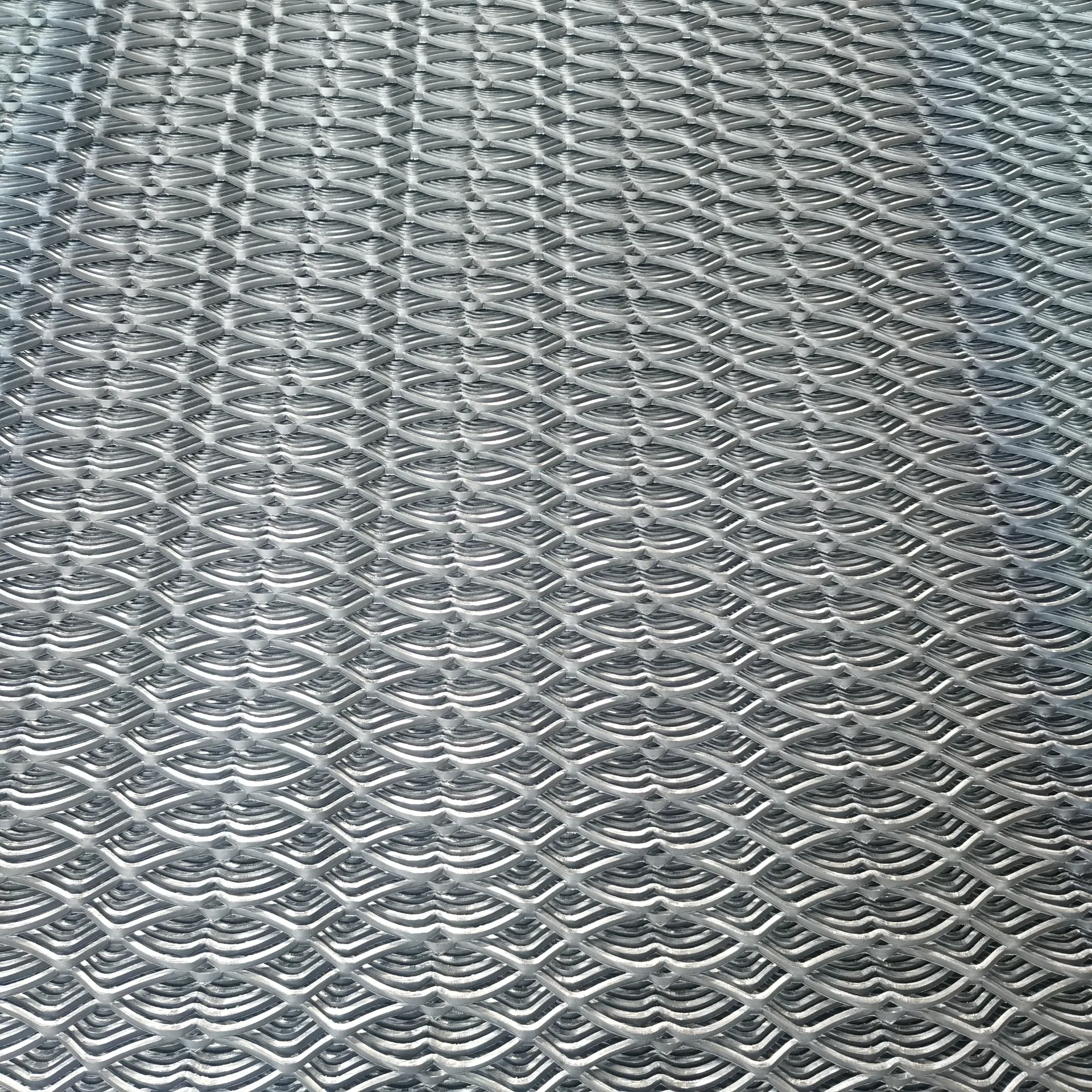

Expanded metal mesh is typically classified by material, mesh pattern, strand thickness, and finish. Common base metals include mild steel, stainless steel, aluminum, copper, and titanium. The most prevalent mesh patterns are raised (standard) and flattened configurations, where the former offers pronounced texture for slip resistance while the latter provides a smoother appearance.

Mesh openings are defined by the short way of diamond (SWD) and long way of diamond (LWD). These dimensions, combined with strand width and gauge, determine structural integrity and airflow. Key parameters are measured in inches or millimeters, tailored for applications such as fencing, walkways, architectural facades, acoustic panels, and filtration screens. For instance:

- Standard Expanded Metal: Classic diamond shape, ideal for walkways and fencing.

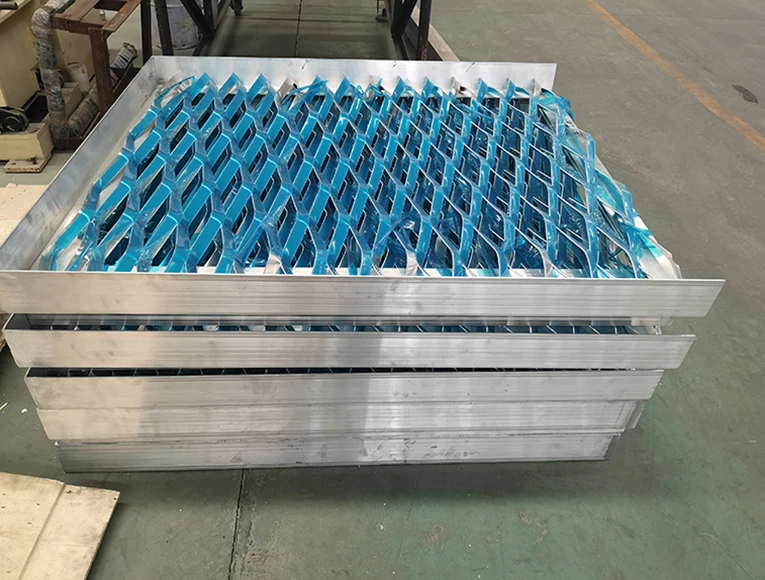

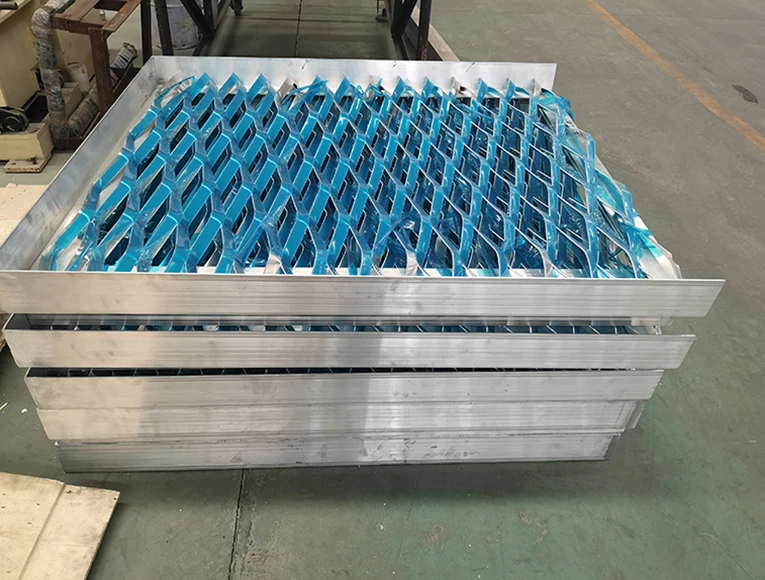

- Flattened Expanded Metal: Post-process rolled for uniform thickness, often used in screens and guards.

- Micro Expanded Metal: Finer mesh suitable for filtration, audio grilles, and decorative panels.

- Heavy Type Expanded Metal: Manufactured from thicker sheets for load-bearing infrastructure.

Compliance with standards such as ASTM F1267 and EN 10347 ensures reliability and safety across global projects.

Technical Advantages and Functional Benefits

Different types of expanded metal deliver distinctive technical strengths, making them the material of choice for industrial designers and architects. Key advantages include:

- High Strength-to-Weight Ratio: Expanded metal’s open grid improves load distribution and resists deformation without significant weight increase.

- Non-slip Surface: Raised mesh patterns enhance traction, maximizing safety on platforms and walkways.

- Excellent Airflow and Light Transmission: Its geometry allows for ventilation, cooling, and illumination without sacrificing security.

- Material Optimization: No waste is generated in the expansion process, making it more sustainable compared to perforated metals.

- Cost Effectiveness: Durable and long-lasting, requiring less maintenance and replacement over time.

Data shows that in transportation infrastructure, utilizing expanded metal mesh panels can reduce structural weight by up to

35% compared to conventional grating systems while maintaining, or even exceeding, required load-bearing capacities.

Manufacturer Comparison: Global Suppliers at a Glance

Assessing leading manufacturers is critical for sourcing high-performance types of expanded metal suited to specific project needs. Below is a comparative analysis of three renowned suppliers based on key criteria:

| Manufacturer |

Product Range |

Key Markets |

Certifications |

Minimum Order |

Lead Time |

Customization |

| McNichols Company (USA) |

Standard, Flattened, Micro, Heavy |

Construction, Security, Industrial |

ISO 9001:2015, ASTM |

1 sheet/panel |

2-4 weeks |

Full (size, material, finish) |

| Metafence (UK) |

Raised, Flattened, Anti-climb |

Utilities, Rail, Perimeter Security |

ISO 14001, CE, BS EN |

20 sheets/panels |

3-6 weeks |

Partial (pattern, coating) |

| Aneka Tata (Indonesia) |

Standard, Flattened, Decorative |

Architecture, Automotive, Filtration |

ISO 9001, JIS |

variable |

4-8 weeks |

Full (design, thickness, color) |

This overview highlights both the diversity of products and the breadth of supplier capabilities, informing selection based on certification, customization, and delivery.

Customization and Specification Guidance

Selecting the optimal type of expanded metal mesh depends on a nuanced understanding of application requirements, environmental conditions, and project-specific challenges. Key steps in the customization process include:

- Material Selection: Choose from steel, aluminum, stainless steel, copper, or specialty alloys based on required corrosion resistance, weight, and cost.

- Pattern Configuration: Define mesh type (standard/raised, flattened, micro) for intended use such as anti-slip flooring, grills, or façade cladding.

- Dimension Specification: Accurately determine SWD, LWD, thickness, strand width, and sheet size to fulfill engineering criteria.

- Finish Options: Apply galvanizing, anodizing, or powder coating for durability, aesthetics, and added protection.

- Compliance & Testing: Seek compliance with ISO, ASTM, or EN standards where applicable for quality assurance and performance.

Many suppliers offer digital tools, design consultation, and samples, facilitating seamless coordination from concept to fabrication.

Case Studies: Expanded Metal in Action

The versatility of expanded metal mesh is illustrated in a diverse array of real-world applications. Below are select examples, underscoring how different types address unique challenges:

-

Architecture – Berlin Central Station, Germany: The façade incorporates aluminum flattened mesh panels for ventilation and striking visual effect. Over 25,000 square feet of material was precision-cut to ensure secure mounting and weather durability.

-

Transportation – New York City Subway Platforms: Utilization of heavy-duty raised expanded steel mesh enhances passenger safety. Laboratory testing confirmed a 30% reduction in slip incidents post-installation.

-

Oil & Gas – North Sea Rig Walkways: Corrosion-resistant stainless expanded mesh was chosen for its ability to withstand extreme marine environments. Maintenance costs fell by 18% over a three-year period compared to prior grating solutions.

-

Energy – Solar Farm Perimeter Fencing in Dubai: Hot-dip galvanized expanded mesh achieves both security and low maintenance in high-UV, saline conditions. Vandalism attempts decreased by 40%, contributing to uninterrupted operations.

These cases reaffirm the adaptability and performance of different types of expanded metal mesh in addressing safety, sustainability, and design innovation.

Conclusion: Selecting the Optimal Types of Expanded Metal for Diverse Applications

For specifiers, engineers, and procurement teams, understanding the breadth of available types of expanded metal and aligning their respective features with project objectives delivers powerful value. Whether the priority is load capacity, security, design flexibility, or sustainability, the array of expanded metal mesh types offers targeted yet adaptable solutions. In a marketplace where efficiency and performance are intertwined, selecting the optimal variation—from standard raised patterns for strength to micro mesh for fine filtration—strengthens both the integrity and success of industrial, architectural, and security ventures. Proper supplier vetting, detailed customization, and adherence to global quality standards ensure that every investment in expanded metal yields measurable, lasting results.

(types of expanded metal)

FAQS on types of expanded metal

Q: What are the main types of expanded metal?

A: The main types of expanded metal are standard (raised), flattened, and micro-expanded. Each type varies by mesh thickness and appearance. Their applications differ based on strength and ventilation needs.

Q: What are the differences between types of expanded metal mesh?

A: The differences between types of expanded metal mesh lie in the mesh size, thickness, and material. For example, fine mesh is used for filtration, while heavy mesh is used for security. Shape and pattern also affect their suitability for specific uses.

Q: How do I choose between different types of expanded metal?

A: Select the type of expanded metal based on your project's strength, ventilation, and appearance requirements. Consider the environment and load it will bear. Consulting with a supplier helps ensure the right mesh is chosen.

Q: What materials are used for various types of expanded metal?

A: Expanded metal is commonly made from steel, stainless steel, aluminum, and sometimes copper. The material chosen affects corrosion resistance and strength. Each type suits specific environments and applications.

Q: Are there special types of expanded metal for architectural applications?

A: Yes, architectural expanded metal mesh features unique designs and finishes. These types are used for facades, sunscreens, and decorative purposes. They combine aesthetics with functionality for building projects.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)