11111

In the realm of industrial and architectural materials, expanded metal products have emerged as versatile solutions for a wide range of needs. From reinforcing structures to enhancing aesthetics, materials like expanded metal lath, expanded aluminum sheet, expanded steel sheet, expanded stainless steel mesh, and 9 expanded metal (often referring to specific gauges or types) offer unique properties that cater to diverse sectors. This exploration delves into their characteristics, applications, and the factors that make them essential in contemporary design and construction.

Exploring the Utility of Expanded Metal Lath

Expanded metal lath is a key component in construction, particularly for plaster and stucco applications. This material features a grid of interconnected metal strips formed by cutting and stretching a metal sheet, creating a durable, open - weave pattern. In residential and commercial builds, expanded metal lath is installed beneath plaster to provide mechanical adhesion, preventing cracks and improving the longevity of the finish. For example, in renovating old walls, contractors often use expanded metal lath to reinforce weak surfaces before applying new plaster, ensuring a smooth and stable result. Its lightweight yet sturdy design also makes it suitable for curved or irregular surfaces, offering flexibility without compromising strength.

Understanding Expanded Aluminum Sheet

Expanded aluminum sheet stands out for its corrosion resistance and lightweight properties, making it ideal for outdoor and marine applications. The expansion process creates a lattice of diamond - shaped openings, which reduces weight while maintaining structural integrity. In coastal areas, expanded aluminum sheet is frequently used for fencing, walkways, or ventilation covers, as its aluminum composition resists rust from salt exposure. Additionally, in automotive and aerospace industries, this material is employed for lightweight panels or heat - dissipation components, leveraging its high strength - to - weight ratio. The versatility of expanded aluminum sheet extends to decorative uses, such as architectural screens or signage, where its modern aesthetic and durability are highly valued.

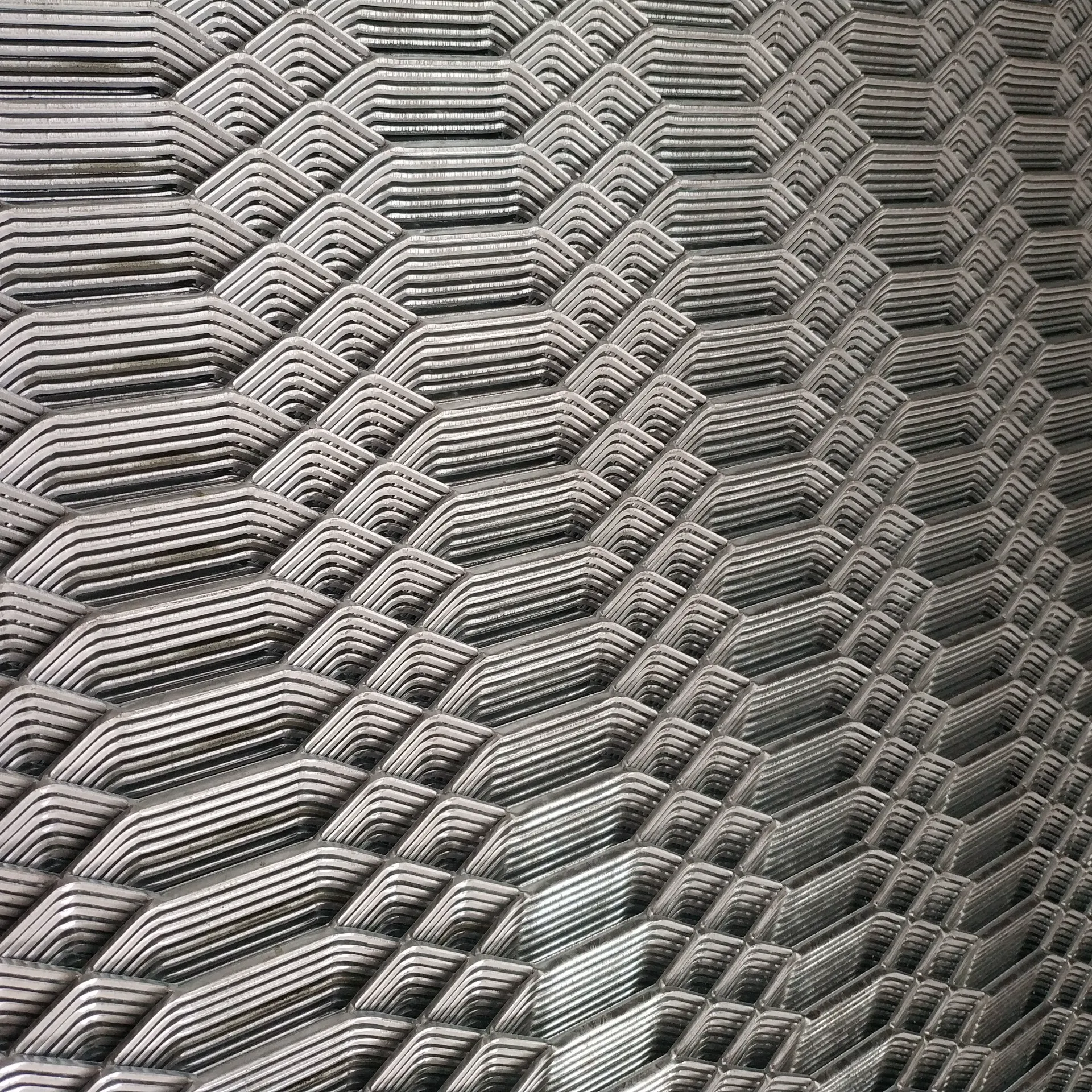

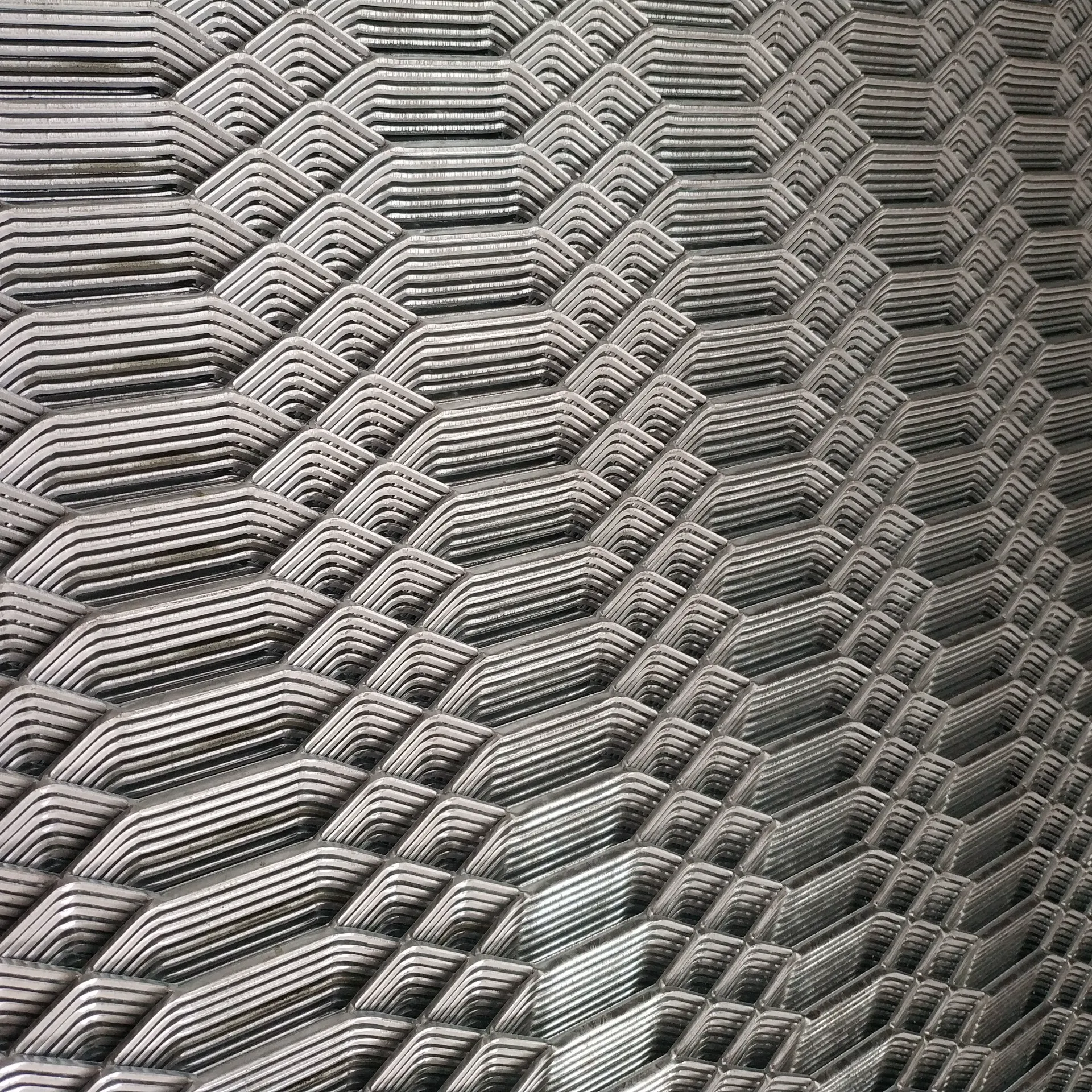

The Robustness of Expanded Steel Sheet

Expanded steel sheet is prized for its strength and durability, making it a go - to choice for heavy - duty industrial and commercial applications. Constructed from carbon steel, this material can withstand high loads and harsh environments, such as factories, warehouses, or construction sites. For instance, expanded steel sheet is often used as flooring in mezzanines or catwalks, providing a non - slip surface that is both safe and easy to clean. Its rigid structure also makes it suitable for security barriers or machine guards, offering protection against impacts and unauthorized access. Galvanized variants of expanded steel sheet further enhance corrosion resistance, ensuring longevity in outdoor or moisture - rich settings.

Examining Expanded Stainless Steel Mesh

Expanded stainless steel mesh combines the strength of steel with the corrosion resistance of stainless steel, making it suitable for high - hygiene or chemically harsh environments. In food processing facilities, pharmaceutical plants, and laboratories, this mesh is used for drains, filters, or partitions, as its non - porous surface resists bacterial growth and chemical stains. The precise expansion process of expanded stainless steel mesh creates uniform openings, making it ideal for applications requiring consistent airflow or liquid filtration, such as ventilation systems or wastewater treatment plants. Additionally, in architectural designs, this mesh can be used for decorative facades or sunscreens, offering both functionality and a sleek, modern look.

Demystifying 9 Expanded Metal

The term 9 expanded metal typically refers to a specific 规格 (gauge) or type of expanded metal, often denoting the size of the openings or the thickness of the material. In construction and manufacturing, the “9” might correspond to a standard mesh size, such as 9mm openings, or a gauge thickness that balances strength and weight for specific uses. For example, in agricultural settings, 9 expanded metal could be used for livestock fencing, where the mesh size prevents animals from escaping while allowing proper visibility and airflow. In industrial applications, this type of expanded metal might be chosen for conveyor belts or screening materials, where the specified opening size ensures efficient separation of particles or debris.

FAQ: Key Insights into Expanded Metal Products

How to choose the right expanded metal for a specific project?

Selecting the appropriate expanded metal depends on factors like load requirements, environmental conditions, and aesthetic goals. For heavy loads, opt for expanded steel sheet or galvanized variants. In corrosive environments, expanded aluminum sheet or expanded stainless steel mesh are preferable. For decorative or lightweight applications, consider expanded metal lath or aluminum sheets with smaller mesh sizes. Always verify the mesh size, material thickness, and finish (e.g., galvanized, powder - coated) to meet project specifications.

What maintenance is required for expanded metal products?

Maintenance varies by material. Expanded steel sheet and lath may require periodic checks for rust, especially in wet environments; galvanized coatings can be touched up if damaged. Expanded aluminum sheet and stainless steel mesh are low - maintenance, needing only occasional cleaning with mild detergent to remove debris. Avoid using abrasive tools that could damage the surface finish or structural integrity.

Can expanded metal be customized for unique designs?

Yes, expanded metal can be cut, bent, or welded to fit custom shapes and sizes. Manufacturers often offer customization services, such as adjusting mesh patterns, adding coatings, or fabricating complex profiles. This makes it suitable for unique architectural features, curved walls, or specialized industrial components.

What’s the difference between expanded metal and perforated metal?

Expanded metal is created by cutting and stretching a metal sheet, resulting in a continuous, interconnected mesh. Perforated metal has holes punched into a sheet, leaving separate metal pieces around each hole. Expanded metal is generally stronger and more flexible, while perforated metal offers more design flexibility with hole shapes and sizes.

Is 9 expanded metal suitable for outdoor use?

Yes, 9 expanded metal can be used outdoors, depending on the material. If made from galvanized steel, aluminum, or stainless steel, it can withstand weathering. For example, a galvanized 9 expanded metal with a 9mm mesh might be used for outdoor fencing or drainage grates, providing durability and resistance to rust in outdoor environments.

![$ element [ady] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)