11111

Stainless Expanded Metal, as an important metal material, plays an increasingly important role in modern industrial and construction fields with its unique design and excellent performance. The combination of multifunctionality and cost-effectiveness makes Stainless Expanded Metal an ideal choice for many engineering projects. This article will focus on exploring the prominent advantages of Stainless Expanded Metal in terms of functionality and economy.

The multifunctionality of Stainless Expanded Metal is reflected in its wide range of application areas

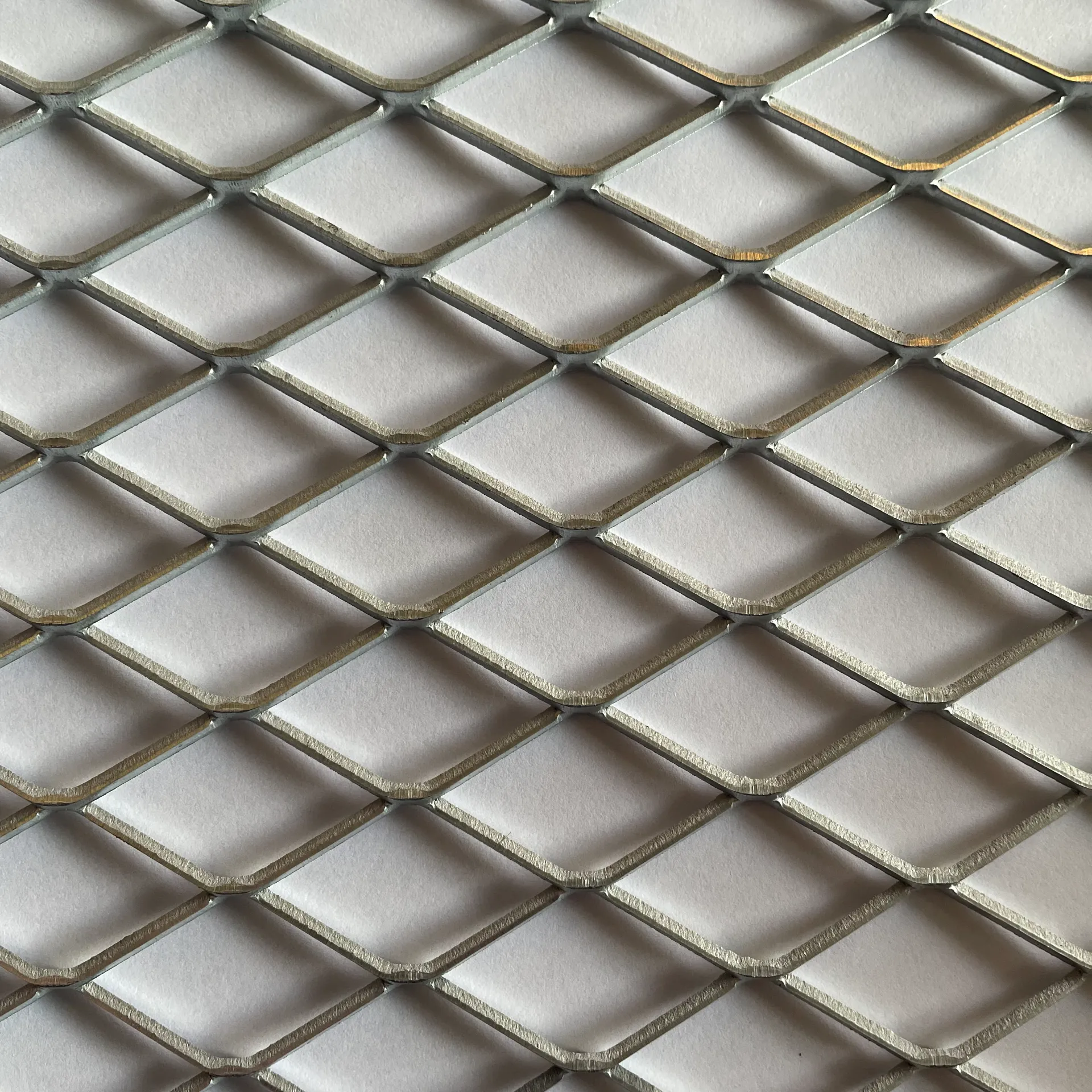

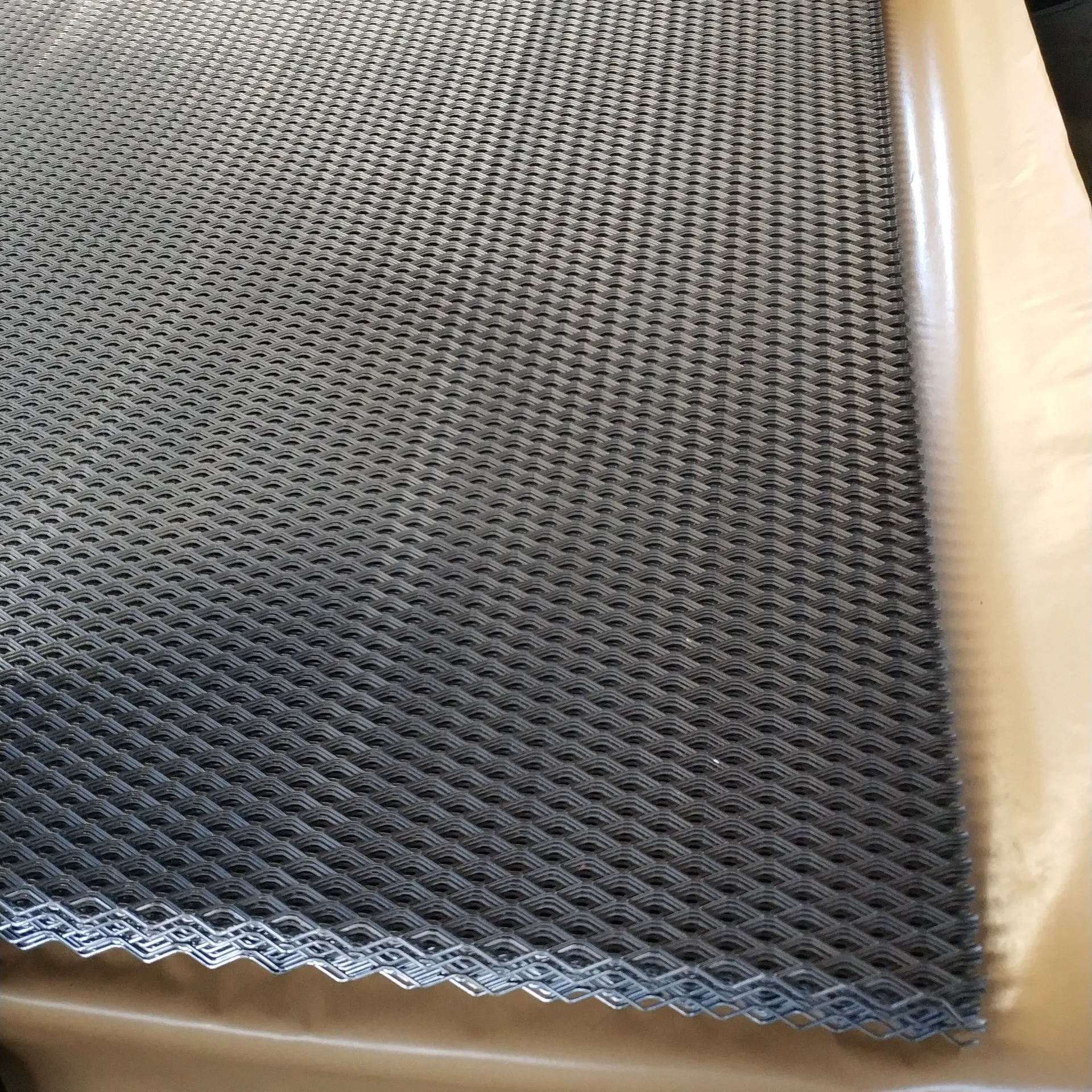

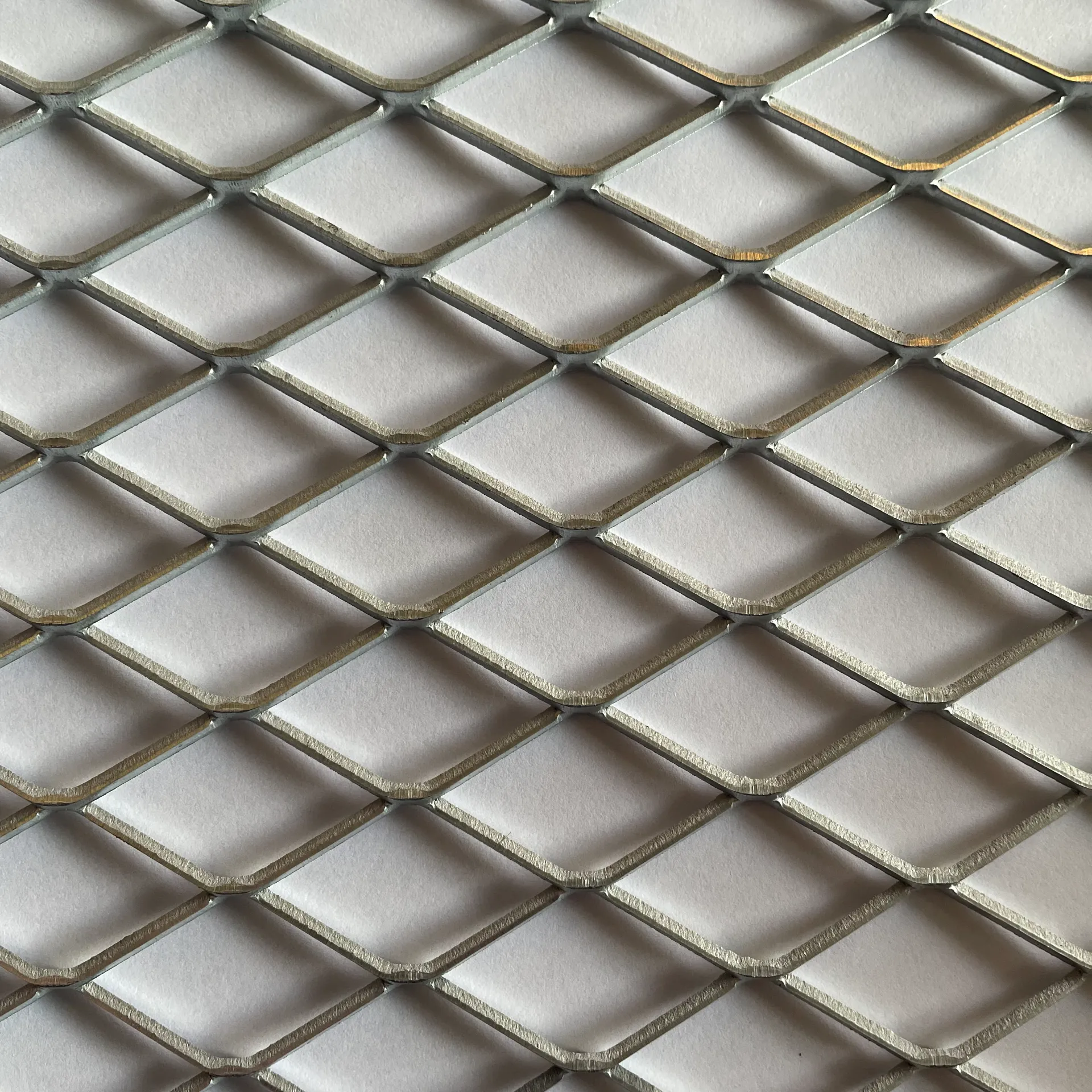

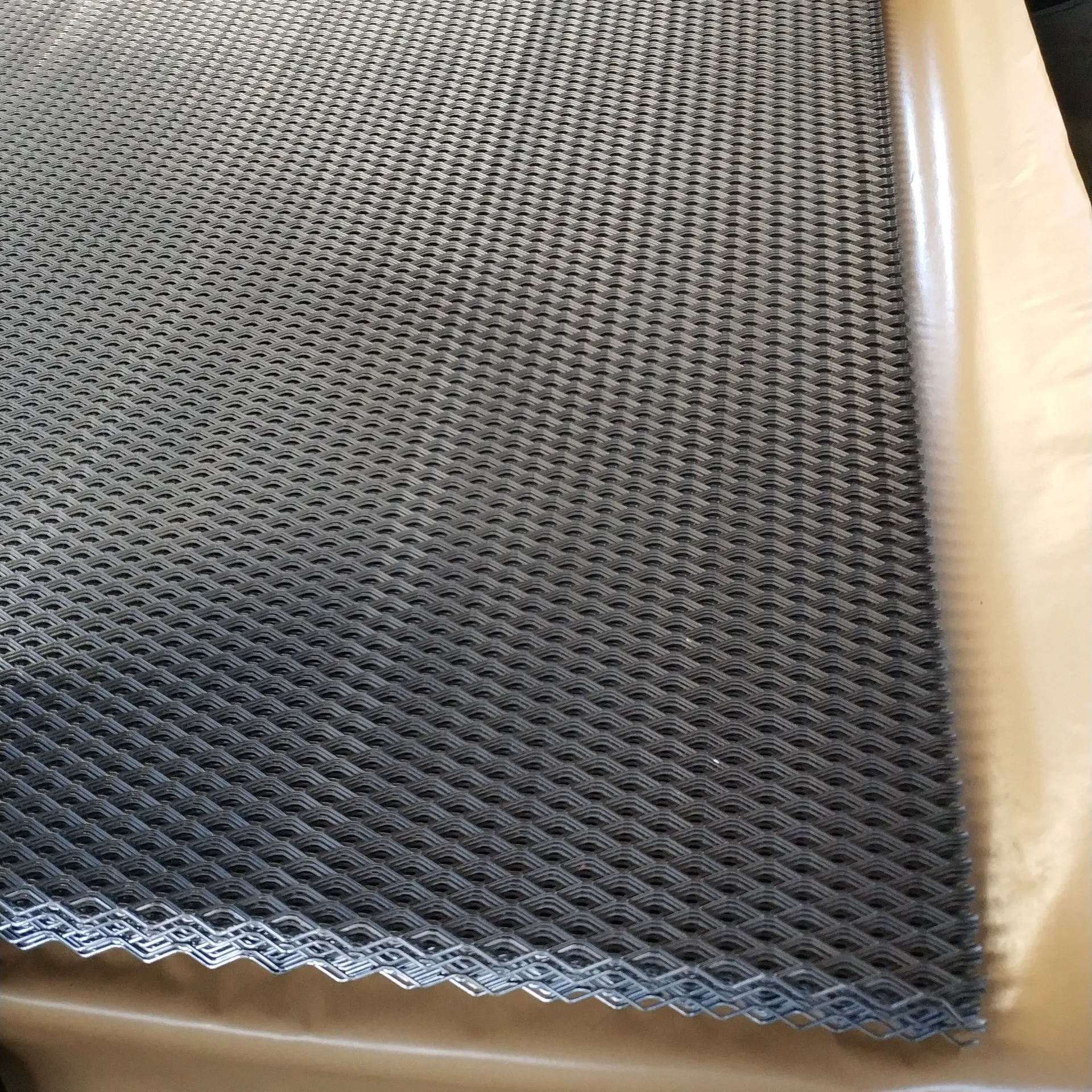

The unique diamond or hexagonal mesh structure of expanded mesh provides excellent ventilation, light transmission, and anti slip performance. Therefore, in the field of architecture, it is often used for curtain walls, ceilings, fences, and decorative components. It is not only aesthetically pleasing, but also effectively improves the air circulation and lighting effect inside the building. In the industrial field, Stainless Expanded Metal is widely used in filtering equipment, safety nets, and various mechanical equipment components, providing reliable protection and filtering functions. In addition, due to its excellent strength and corrosion resistance, Stainless Expanded Metal is often used to make vehicle grilles, sidewalks, and even some special art installations. This wide applicability fully demonstrates the powerful functionality of Stainless Expanded Metal.

The economic efficiency of Stainless Expanded Metal is also significant

Compared to expanded aluminum sheet metal, punching and stretching technology can maximize the use of raw materials in the production process. By cutting and stretching metal sheets, the expanded metal grating surface area can be expanded, thereby covering a larger area under the same weight. This means that the use of raw materials can be reduced and production costs can be lowered. In addition, the installation and maintenance of Stainless Expanded Metal are relatively simple and convenient, reducing maintenance costs in the later stage. The durability and corrosion resistance of Stainless Expanded Metal also mean a longer service life, reducing replacement frequency and further lowering overall costs. Therefore, considering multiple aspects such as raw material costs, production costs, installation and maintenance costs, and service life, Stainless Expanded Metal exhibits extremely high economic efficiency.

In summary, разширена стоманена мрежа has gained widespread market recognition for its perfect combination of the versatility and cost-effectiveness of Stainless Expanded Metal. It can not only meet the functional requirements of materials in different fields, but also effectively control costs and achieve maximum resource utilization. With the continuous development of technology, we believe that Stainless Expanded Metal will play a more important role in the future industrial and construction fields, and make greater contributions to the development of society.

Stainless Expanded Metal FAQs

What is Stainless Expanded Metal?

Stainless Expanded Metal is a mesh material formed by cutting and stretching stainless steel plates (such as 304, 316, etc.). The characteristics of Stainless Expanded Metal include corrosion resistance, high strength, and high temperature resistance, making it suitable for harsh environments.

What are the main materials of Stainless Expanded Metal? How to choose?

Common materials:

304 stainless steel: universal type, resistant to acid, alkali, and atmospheric corrosion, suitable for most indoor and outdoor scenarios.

316 stainless steel: containing molybdenum element, resistant to chloride ion corrosion, suitable for high corrosion environments such as marine and chemical industries.

Selection criteria: comprehensive consideration based on corrosiveness (such as choosing 316 in coastal areas), strength requirements (thickness), and budget.

What are the typical applications of Stainless Expanded Metal in the field of architectural decoration?

Curtain wall and facade decoration: As a translucent sunshade or artistic panel, it combines functionality and modernity.

Interior design: used for partitions, ceilings, stair handrails, etc., to enhance the industrial or minimalist style of the space.

Security protection: such as ventilation anti-theft windows and guardrails, which are both beautiful and durable.

What are the core advantages of Stainless Expanded Metal in the industrial field?

Corrosion resistance: It is not easy to rust when exposed to moisture, chemicals, or salt spray environments for a long time (such as chemical plants and coastal facilities).

High temperature resistance: suitable for protection of high-temperature equipment (such as boilers, flue gas filtration).

Easy to clean: The surface is smooth and suitable for the hygiene requirements of the food and pharmaceutical industries, such as workbenches and sieves.

-

Compared with ordinary carbon steel expanded metal mesh, what are the advantages and disadvantages of Stainless Expanded Metal?

Advantages:

Longer lifespan, maintenance free (no need for galvanizing or painting);

Hygiene and environmental protection, in compliance with food/medical standards;

Higher strength and weather resistance.

inferiority:

The cost is relatively high (the price may be 23 times that of carbon steel);

The processing difficulty is slightly higher (requiring specialized tools for cutting).

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)