(types of expanded metal mesh)

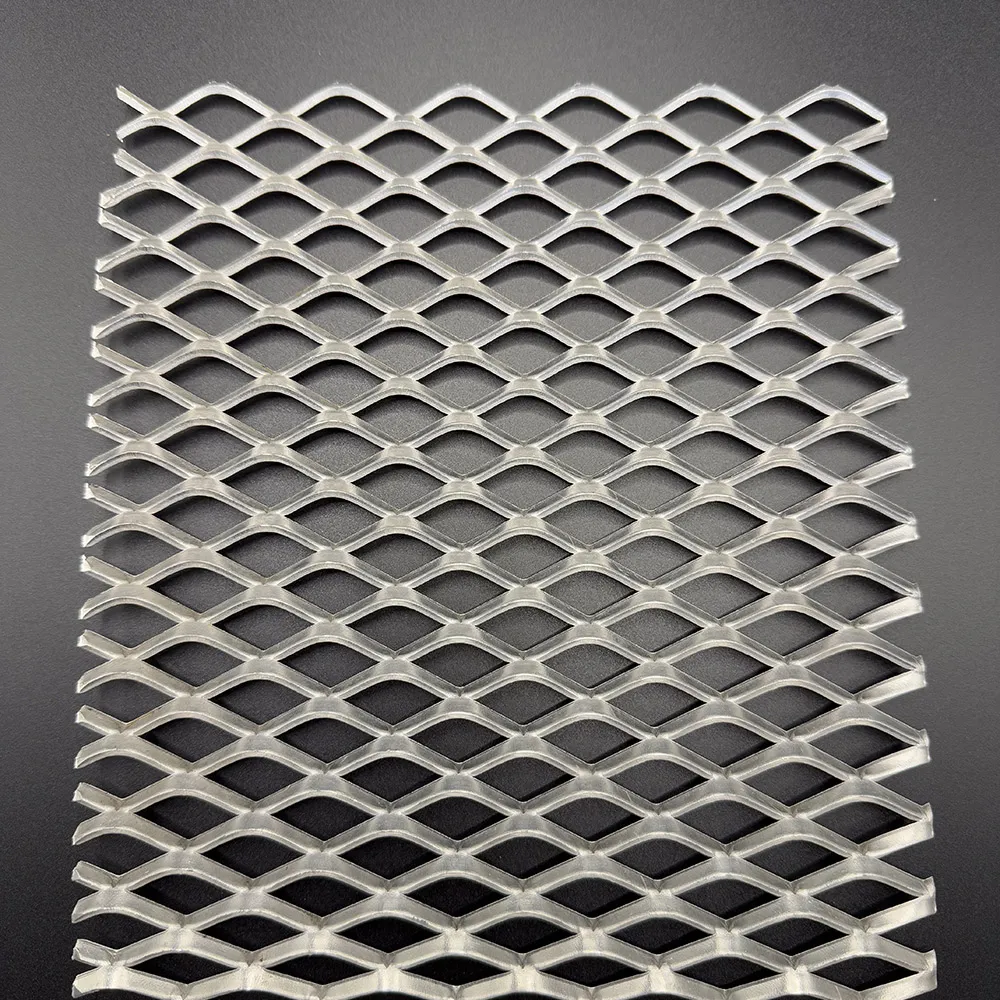

Expanded metal mesh, a versatile material manufactured through cutting and stretching metal sheets, serves critical roles in construction, filtration, and architectural design. With a global market projected to grow at a 5.8% CAGR from 2023 to 2030, demand varies across stainless steel, aluminum, and carbon steel variants. Standard, flattened, and micro-expanded meshes dominate 72% of industrial applications due to their balance of strength (up to 650 MPa tensile strength) and weight efficiency.

Advanced manufacturing techniques enable expanded metal meshes to achieve:

Recent innovations include anti-corrosion coatings extending product lifespan by 15–20 years in marine environments.

| Manufacturer | Material Options | Thickness Range (mm) | Lead Time | Price per m² ($) |

|---|---|---|---|---|

| Metalex | Stainless Steel, Aluminum | 0.5–12 | 10 days | 85–220 |

| Dexmet | Titanium, Copper Alloys | 0.3–8 | 21 days | 310–950 |

| Nilex | Carbon Steel, Galvanized | 1–15 | 7 days | 45–180 |

Customization parameters include:

A recent automotive project required meshes with 0.05 mm tolerance for battery shielding, achieving 99.2% EMI reduction.

Case 1: A refinery installed stainless steel expanded metal walkways (3 mm thickness) reducing maintenance costs by 40% annually. Case 2: Architectural aluminum meshes (65% open area) enabled 30% energy savings in a Dubai high-rise through optimized airflow.

Accelerated aging tests show:

Emerging technologies like laser-expanded hybrid meshes combine sub-millimeter precision with 98% material utilization. The sector is adopting AI-driven pattern optimization, reducing prototyping costs by 67% while enabling meshes with gradient porosity for aerospace applications.

(types of expanded metal mesh)

A: The primary types include standard expanded metal mesh, flattened expanded metal mesh, and specialty designs like hexagonal or diamond patterns. These differ in thickness, strand width, and application suitability.

A: Expanded metal meshes are commonly made from stainless steel, aluminum, carbon steel, or copper. Material choice depends on factors like corrosion resistance, strength, and environmental conditions.

A: Heavy-duty flattened expanded metal is ideal for structural support, while lighter aluminum meshes suit facades or walkways. Perforated or decorative types are used for aesthetics and ventilation.

A: Thickness ranges from fine meshes (e.g., 0.5mm) to heavy gauges (6mm+). Strand designs vary between raised/standard (for grip) and flattened (smoother surfaces), impacting durability and functionality.

A: Stainless steel offers superior corrosion resistance and strength, ideal for harsh environments. Unlike carbon steel or aluminum, it requires minimal maintenance and is common in food processing or marine applications.