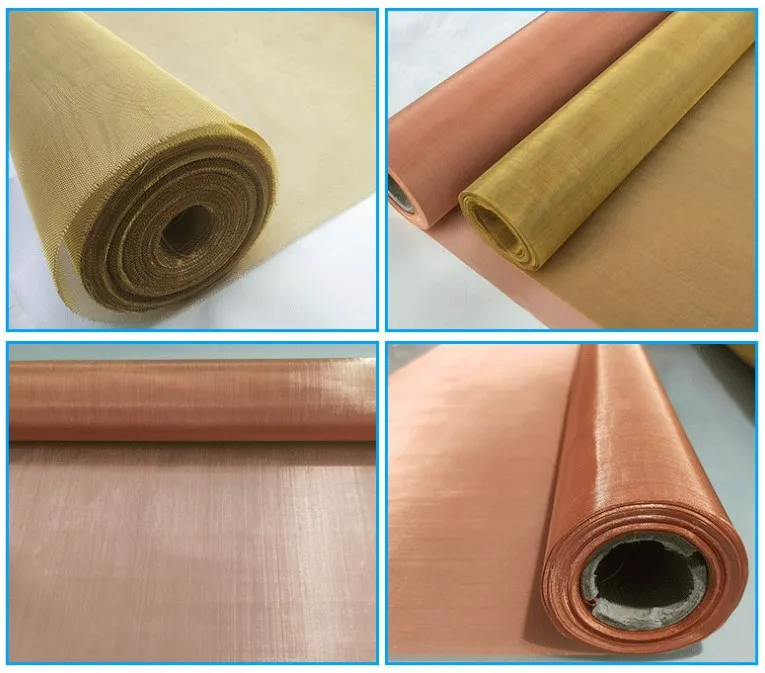

Chen Cai Metal Co. produces stainless steel screen, stainless steel woven wire cloth and filter mesh in various specifications, from large pore spacing to very fine pore size. Therefore, we provide various grades of stainless steel products to effectively meet the needs of different industrial applications, such as filtration, sieve and protection, etc.

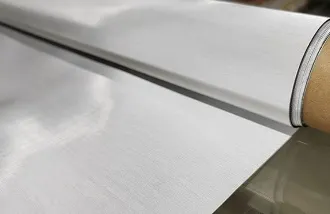

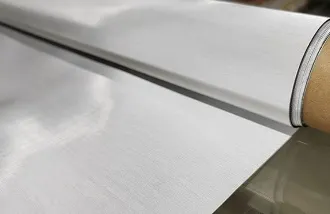

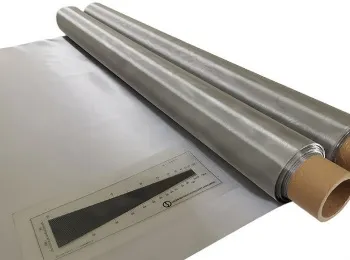

Chen Cai Metal Co. offers flexible purchasing options, whether you require coils or cut-to-length sheets, slit coils, filters, heavy-duty woven mesh, or custom woven mesh, we can meet your needs. Most standard specifications are in stock for quick delivery.

We also accept customized orders for OEM & ODM, ensuring the best price and on-time delivery service every time.

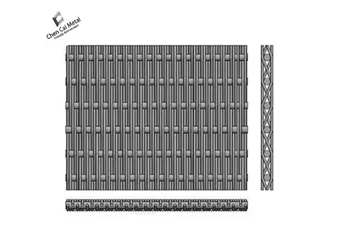

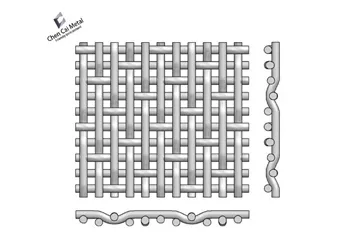

Weave Wire Mesh Types

-

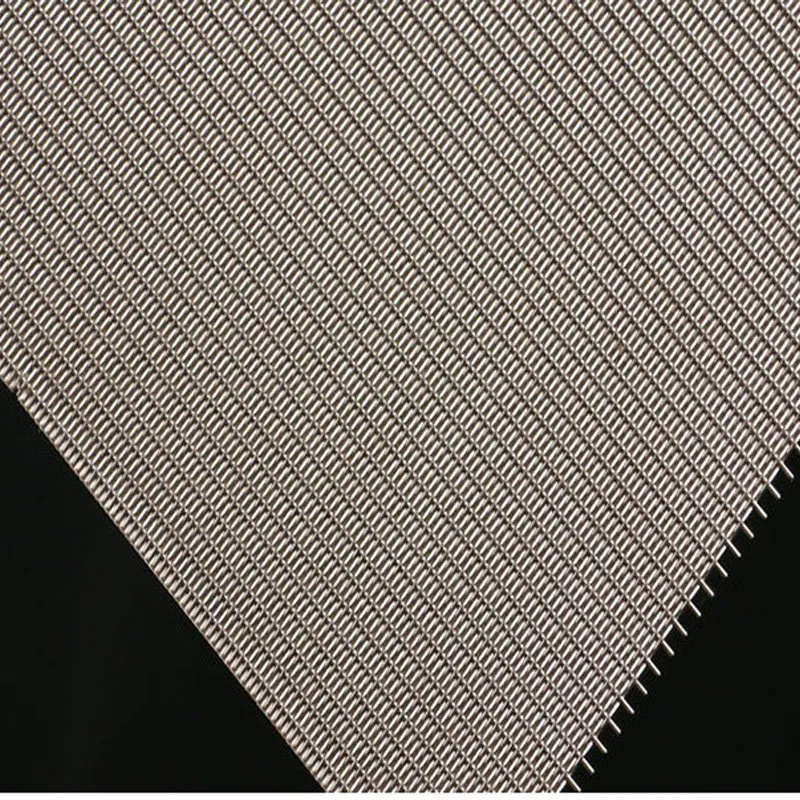

Dutch Twilled Weave Wire Mesh

-

Reverse Dutch Weave Wire Mesh

-

Five Shed Twill Weave Wire Mesh

What is Stainless Steel Weave Wire Mesh (Also Known as Stainless Steel Screen / Cloth)?

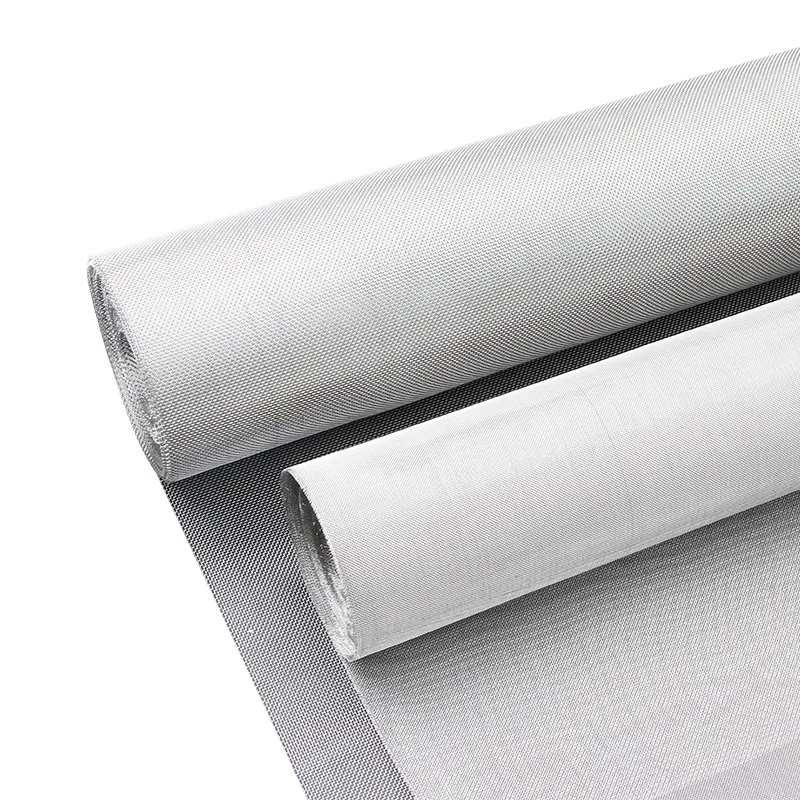

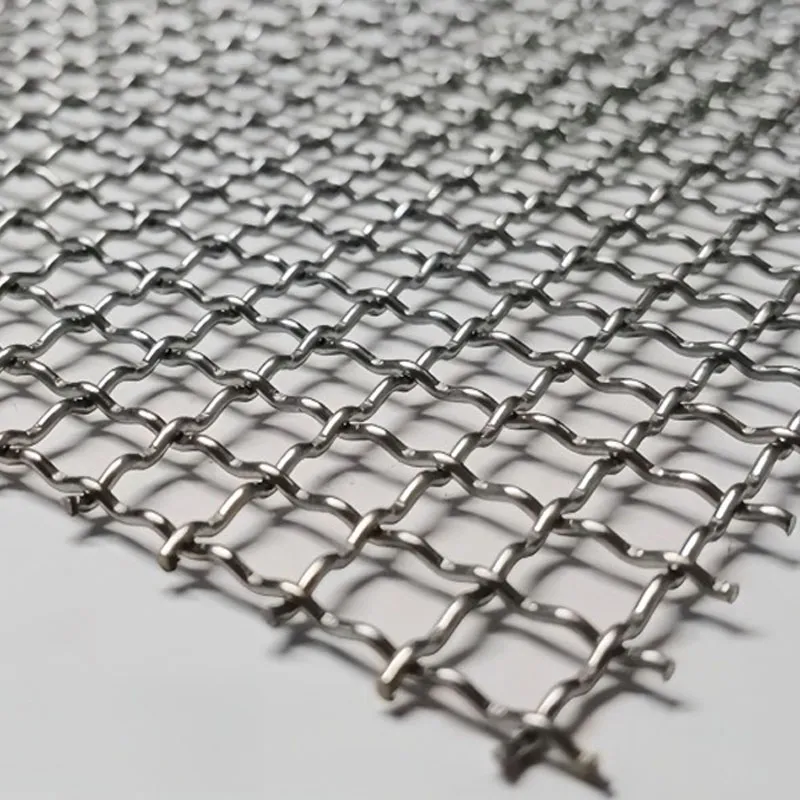

Stainless Steel Weave wire mesh is also called stainless steel screen or stainless steel cloth. They are made by weaving stainless steel into a mesh in the form of a woven type and are selected as industrial materials. Stainless steel woven wire mesh is durable and corrosion-resistant. Woven mesh is widely used in filtering, screening, separation, drying and door and window protection.

Although the terms "wire mesh" and "wire cloth" are often used interchangeably, they are technically slightly different.

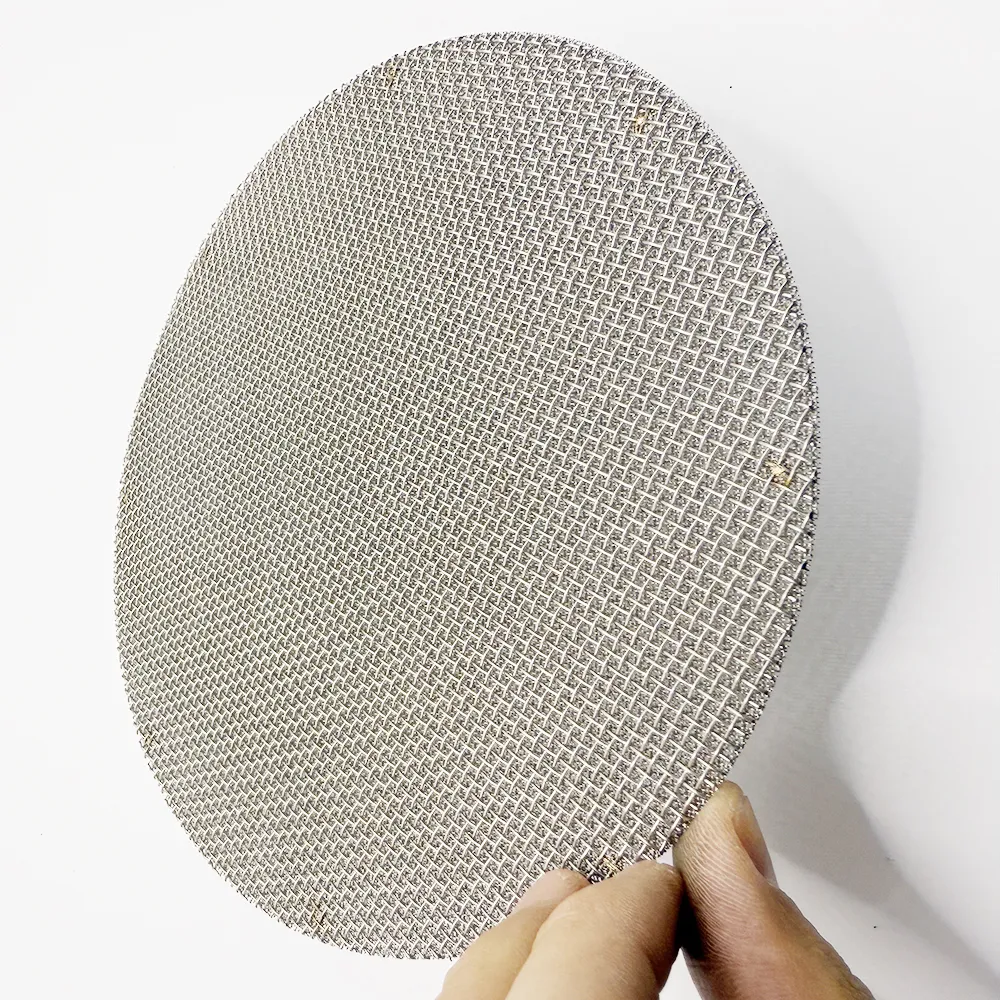

However, in ordinary commercial and industrial communication, these two terms are worth the same product category: stainless steel weave wire mesh. Stainless Steel Weave Wire Mesh can be processed into sintered filter mesh, which has more uniform mesh.

If you are looking for a high-quality supplier to help achieve filtering, protection or structural reinforcement materials, we can provide stainless steel screen to help you solve the problem, stainless steel weave mesh is a wise choice.

Stainless Steel Weave Wire Mesh Fabrications

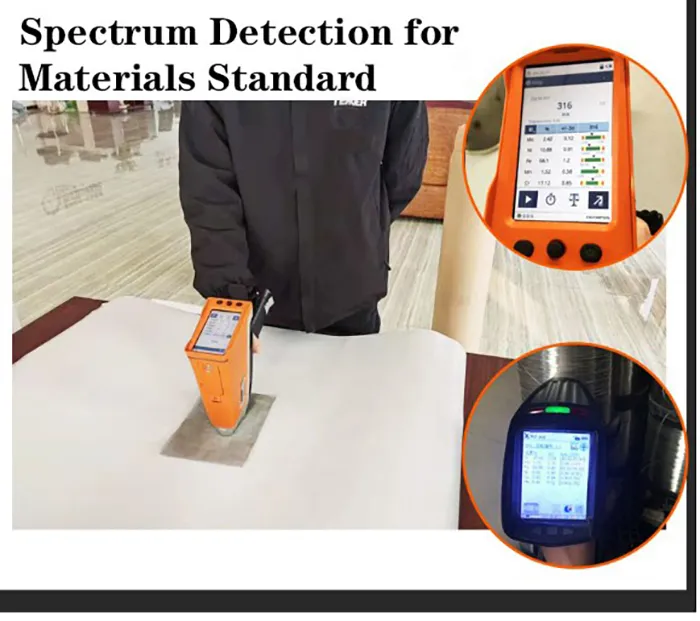

1. Raw Materials Preparation: Select the corresponding raw materials according to customer requirements, and then test and inspect the raw materials to ensure that the raw materials meet the weaving standards.

2. Weaving preparation: The warp (longitudinal) and weft (cross-directional) yarns are prepared and loaded into the machine in proportion. The raw materials are then threaded into the reed teeth of the weaving machine, thus setting the width of the weave.

3. Weaving into a net: Plain Weave, Twill Weave, Dutch Weave. During the weaving process, the weaving machine automatically crosses the warp and weft threads to form a net.

4. Inspection and trimming: Check whether the weaving is uniform, whether there are broken wires, skipped wires, and inconsistent hole diameters.

5. Cutting and sizing: Cut the large roll of weave screen mesh into specified length and width according to customer requirements.

6. Surface treatment: The woven mesh is pickled, cleaned, dried and other processes are carried out to remove oil and impurities from the weave wire mesh, thereby improving the anti-corrosion quality.

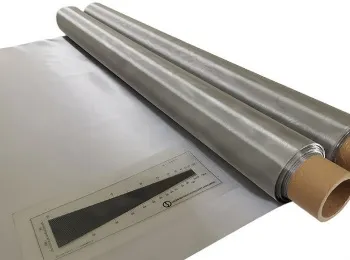

7. Packing, warehousing and shipment: Roll the stainless steel weave wire mesh into rolls or sheets, and pack them with Kraft Paper and wooden boxes to ensure transportation safety

General Specification

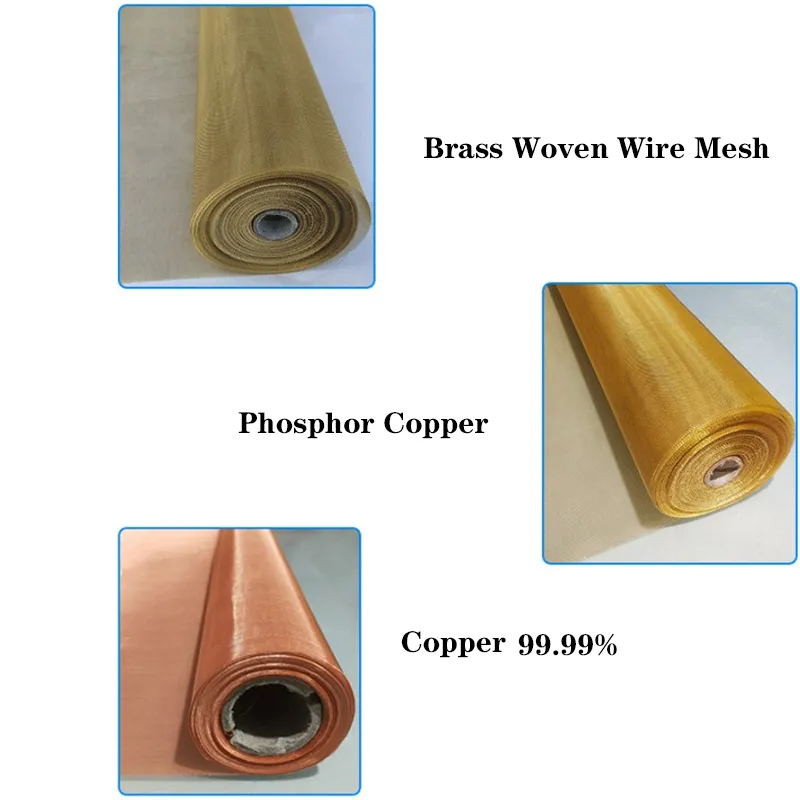

1. Wire Materials: 1.1. Stainless Steel-304,304L, 316, 316L, 321, 310, 310S.

1.2. Duplex stainless steel 2205, super duplex stainless steel 2507

1.3. Nickel Wire Mesh

1.4. Nickel-chromium alloy wire mesh

1.5. Hastelloy Wire Mesh

1.6. Monel 400 etc...

2. Hole Mesh Size: 0.02mm (20 Micron) to 50mm

3. Wire Diameter: ≥ 0.02 mm

4. Width: Some specifications can be to 6 m.

Stainless Steel Weave Screen for General Applications

Stainless Steel Woven Wire Mesh has excellent acid resistance, alkali resistance, heat resistance and corrosion resistance. Stainless steel weave screen is used in chemical industry, petroleum, aerospace, sewage system, medicine, automobile, industrial field, etc. Stainless steel woven wire mesh has become a widely used material.

The hygiene standards and chemical resistance of Stainless Steel Woven Screen are crucial, so it plays an important role in the screening and filtration of solids, liquids and gases in various industrial fields.

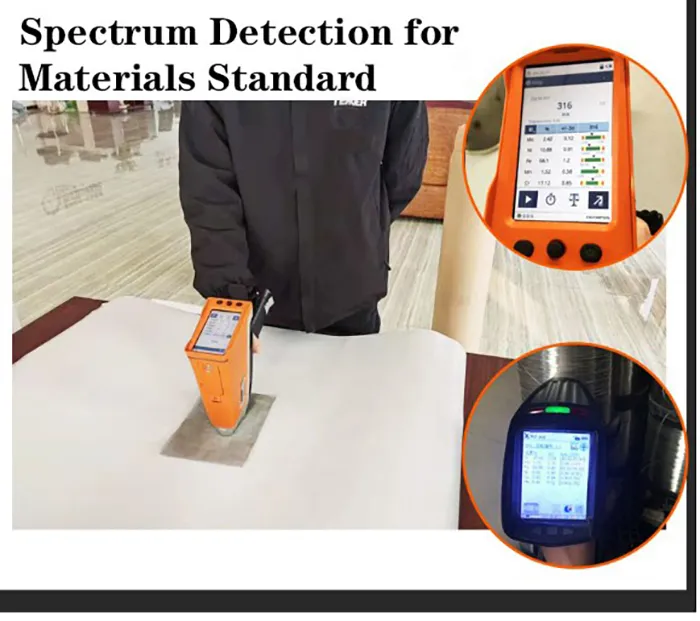

Stainless Steel Woven Wire Mesh Standards

Chen Cai Metal Co. is ISO-9001:2015 certified. Based on the ISO 9001:2015 standard, we strictly require high-quality stainless steel products that meet international standards. Every batch of metal mesh produced by our company is strictly inspected to ensure that it meets customer standards and global quality requirements.

Chen Cai Metal Co. tests Stainless Steel Woven Wire Mesh according to internationally recognized standards:

ASTM A580/A580M-18 – Standard Specification for Stainless Steel Wire

ISO 9044:1999 – Industrial Woven Wire Mesh – Technical Requirements and Tests

ASTM E2016-15 – Standard Specification for Industrial Woven Wire Mesh

ASTM E2814-11 – Standard Guide for Industrial Woven Wire Mesh Filter Cloth

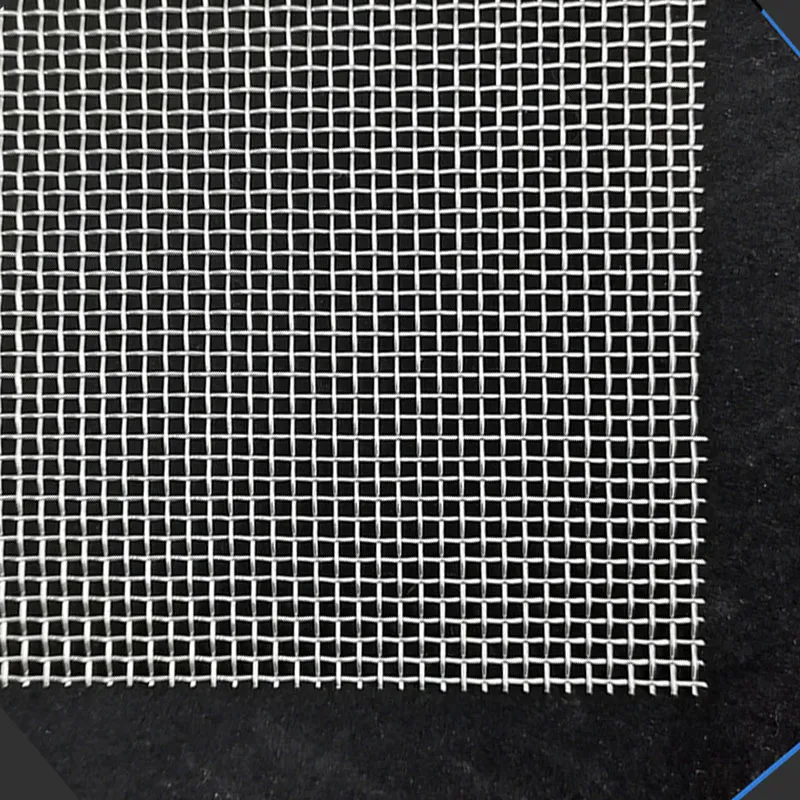

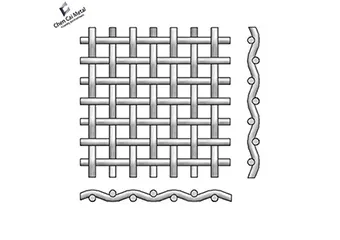

Plain Weave Wire Mesh & Twill Plain Weave Screen

Plain Weave Wire Mesh & Twill Plain Weave Screen is also called stainless steel square hole, mesh range is from 1 mesh to 635 mesh, wire diameter is from 0.02mm to 4mm. The specifications in the following table are all in stock, welcome to consult:

|

Table 1: Stainless Steel Plain Weave Wire Mesh & Twill Weave Screen Specification

|

|

Mesh Range

|

Wire Diameter(mm)

|

Hole Opening(mm)

|

Materials

|

|

1 x 1

|

2.000

|

23.370

|

SS/Nickel/Monel

|

|

2 x 2

|

1.600

|

11.100

|

SS/Nickel/Monel

|

|

3 x 3

|

1.370

|

7.090

|

SS/Nickel/Monel

|

|

4 x 4

|

1.600

|

4.750

|

SS/Nickel/Monel

|

|

4 x 4

|

1.190.

|

5.160

|

SS/Nickel/Monel

|

|

5 x 5

|

1.000

|

4.040

|

SS/Nickel/Monel

|

|

6 x 6

|

0.890

|

3.350

|

SS/Nickel/Monel

|

|

8 x 8

|

0.710

|

2.460

|

SS/Nickel/Monel

|

|

10 x 10

|

0.640

|

1.910

|

SS/Nickel/Monel

|

|

12 x 12

|

0.580

|

1.520

|

SS/Nickel/Monel

|

|

12 x 12

|

0.500

|

1.60

|

SS/Nickel/Monel

|

|

14 x 14

|

0.230

|

1.220

|

SS/Nickel/Monel

|

|

14 x 14

|

0.500

|

1.300

|

SS/Nickel/Monel

|

|

16 x 16

|

0.450

|

1.130

|

SS/Nickel/Monel

|

|

18 x 18

|

0.430

|

0.980

|

SS/Nickel/Monel

|

|

20 x 20

|

0.400

|

0.870

|

SS/Nickel/Monel

|

|

24 x 24

|

0.350

|

0.700

|

SS/Nickel/Monel

|

|

30 x 30

|

0.330

|

0.520

|

SS/Nickel/Monel

|

|

30 x 30

|

0.300

|

0.540

|

SS/Nickel/Monel

|

|

30 x 30

|

0.230

|

0.620

|

SS/Nickel/Monel

|

|

35 x 35

|

0.280

|

0.450

|

SS/Nickel/Monel

|

|

40 x 40

|

0.250

|

0.380

|

SS/Nickel/Monel

|

|

40 x 40

|

0.230

|

0.400

|

SS/Nickel/Monel

|

|

50 x 50

|

0.230

|

0.280

|

SS/Nickel/Monel

|

|

60 x 60

|

0.180

|

0.230

|

SS/Nickel/Monel

|

|

70 x 70

|

0.165

|

0.200

|

SS/Nickel/Monel

|

|

70 x 70

|

0.120

|

0.240

|

SS/Nickel/Monel

|

|

80 x 80

|

0.165

|

0.200

|

SS/Nickel/Monel

|

|

80 x 80

|

0.140

|

0.150

|

SS/Nickel/Monel

|

|

90 x 90

|

0.120

|

0.160

|

SS/Nickel/Monel

|

|

100 x 100

|

0.110

|

0.140

|

SS/Nickel/Monel

|

|

100 x 100

|

0.100

|

0.150

|

SS/Nickel/Monel

|

|

100 x 100

|

0.090

|

0.170

|

SS/Nickel/Monel

|

|

120 x 120

|

0.090

|

0.120

|

SS/Nickel/Monel

|

|

150 x 150

|

0.063

|

0.110

|

SS/Nickel/Monel

|

|

180 x 180

|

0.053

|

0.090

|

SS/Nickel/Monel

|

|

200 x 200

|

0.053

|

0.070

|

SS/Nickel/Monel

|

|

250 x 250

|

0.040

|

0.063

|

SS/Nickel/Monel

|

|

300 x 300

|

0.040

|

0.044

|

SS/Nickel/Monel

|

|

325 x 325

|

0.035

|

0.043

|

SS/Nickel/Monel

|

|

350 x 350

|

0.030

|

0.042

|

SS/Nickel/Monel

|

|

400 x 400

|

0.030

|

0.033

|

SS/Nickel/Monel

|

|

450 x 450

|

0.028

|

0.028

|

SS/Nickel/Monel

|

|

500 x 500

|

0.025

|

0.026

|

SS/Nickel/Monel

|

|

635 x 635

|

0.020

|

0.020

|

SS/Nickel/Monel

|

Plain Dutch Weave Wire Mesh / Screen

Plain Dutch Weave Wire Mesh / Screen is designed to handle high flow rates while maintaining a relatively low pressure drop. In the plain Dutch weave process, each warp and weft thread passes over and under a wire diameter. The warp threads are thicker and the weft threads are thinner, allowing them to be closely packed together. This structure creates a dense mesh that is ideal for filtering fine impurities.

|

Table 2: Plain Dutch Weave Wire Mesh & Screen / Cloth Specification

|

|

Mesh Range

|

Wire Diameter(mm)

|

Hole Opening(μm)

|

Materials

|

|

7 x 44

|

0.71 x 0.63

|

315

|

SS 304 or 316 etc

|

|

8 x 60

|

0.63 x 0.45

|

300

|

SS 304 or 316 etc

|

|

14 x 88

|

0.50 x 0.40

|

200

|

SS 304 or 316 etc

|

|

22 x 64

|

0.58 x 0.40

|

280

|

SS 304 or 316 etc

|

|

24 x 110

|

0.36 x 0.25

|

150

|

SS 304 or 316 etc

|

|

30 x 150

|

0.23 x 0.18

|

100

|

SS 304 or 316 etc

|

|

40 x 200

|

0.18 x 0.13

|

80

|

SS 304 or 316 etc

|

|

50 x 250

|

0.14 x 0.11

|

60

|

SS 304 or 316 etc

|

|

80 x 400

|

0.10 x 0.065

|

40

|

SS 304 or 316 etc

|

|

78 x 700

|

0.11 x 0.08

|

30

|

SS 304 or 316 etc

|

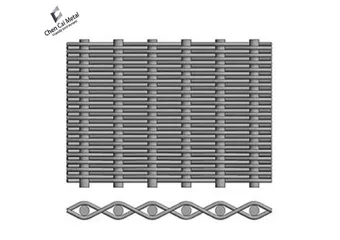

Twill Dutch Weave Wire Mesh / Screen

Twill Dutch Weave Wire Mesh / Screen / Cloth is specially designed to filter fine impurities due to the fusion of "twill" and "Dutch" weaving techniques. In this woven structure, the warp and weft threads alternately pass through two warp threads. The thicker warp threads are paired with the thinner weft threads, resulting in a lightweight and compact durable effect. The weft threads are woven at an extremely high density, completely covering the warp threads, forming a high-density, compact and durable mesh structure. This weave provides complex flow channels that can maintain reasonable flow rates while ensuring the performance of retaining particles.

|

Table 3: Twill Dutch Weave Wire Mesh & Screen / Cloth Specification

|

|

Mesh Range

|

Wire Diameter(mm)

|

Hole Opening(μm)

|

Materials

|

|

80 × 700

|

0.110 × 0.080

|

30

|

SS 304, 316 etc

|

|

165 × 800

|

0.070 × 0.050

|

20

|

SS 304, 316 etc

|

|

165 × 1400

|

0.063 × 0.040

|

15

|

SS 304, 316 etc

|

|

200 × 600

|

0.050 × 0.032

|

10

|

SS 304, 316 etc

|

|

200 × 1400

|

0.050 × 0.032

|

10

|

SS 304, 316 etc

|

|

250 × 1600

|

0.050 × 0.032

|

8

|

SS 304, 316 etc

|

|

280 × 2200

|

0.050 × 0.032

|

7

|

SS 304, 316 etc

|

|

300 × 2100

|

0.036 × 0.025

|

6

|

SS 304, 316 etc

|

|

325 × 2300

|

0.035 × 0.025

|

4

|

SS 304, 316 etc

|

|

400 × 2800

|

0.030 × 0.018

|

3

|

SS 304, 316 etc

|

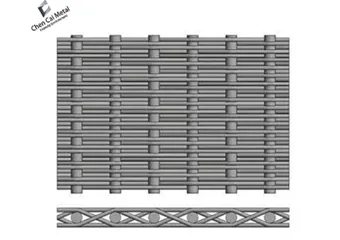

Reverse Dutch Weave Wire Mesh / Screen / Cloth

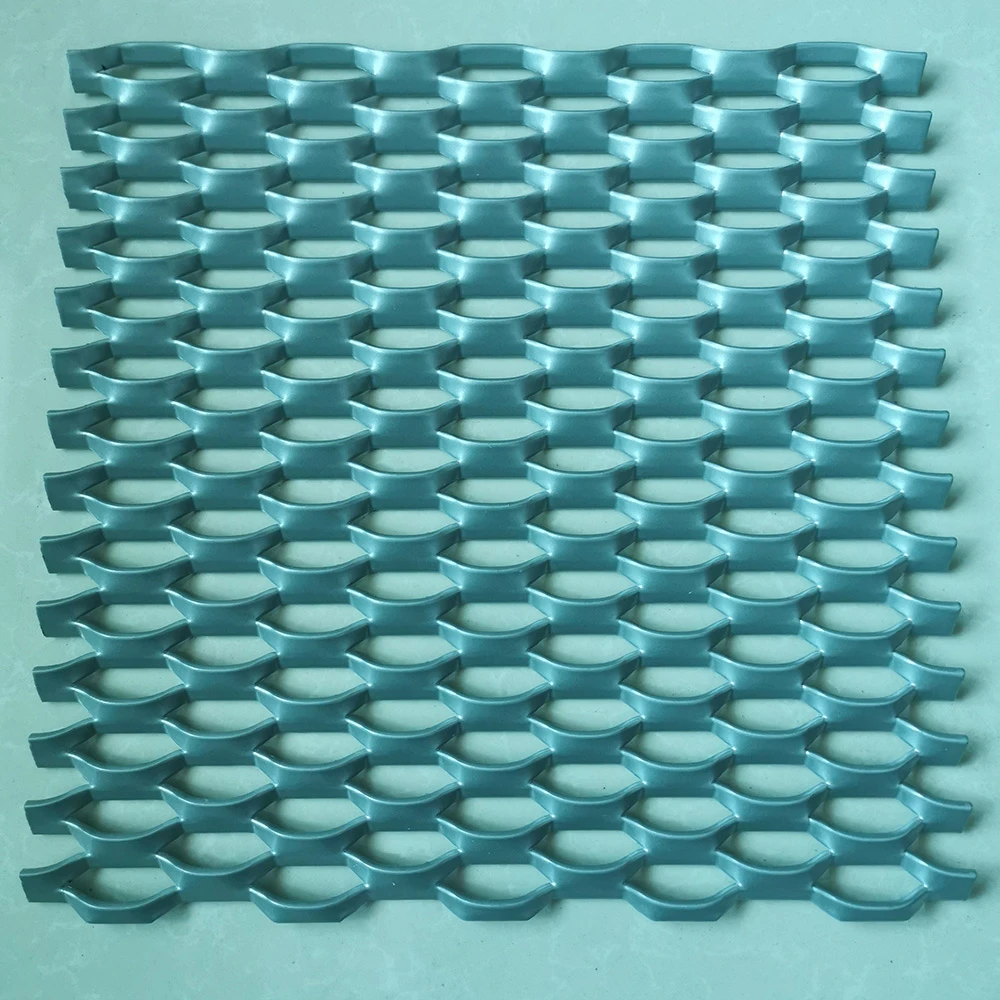

Reverse Dutch Weave Wire Mesh / Screen / Cloth is a special weave wire mesh that is commonly used for high-performance filtration applications, especially in plastics processing, chemical processing and pharmaceutical applications. Compared to the standard plain Dutch Weave Wire Mesh, Reverse Dutch Weave wire mesh uses thicker wefts and thinner warps, which is essentially the opposite of the typical weave structure, hence the name "Reverse Dutch Weave Wire Mesh".

The thinner warps form a delicate filter layer, while the thicker wefts provide strong support and maintain circulation. This allows Reverse Dutch Weave Wire Mesh to improve filtration efficiency, extend service life, increase pressure resistance and anti-clogging ability, making it a continuous and demanding filtration product.

|

Table 4: Reverse Dutch Weave Wire Mesh & Screen / Cloth Specification

|

|

Mesh Range

|

Wire Diameter(mm)

|

Materials

|

|

75 × 15

|

0.45 × 0.50

|

SS 304, 316 etc

|

|

120 × 15

|

0.35 × 0.50

|

SS 304, 316 etc

|

|

132 × 17

|

0.32 × 0.45

|

SS 304, 316 etc

|

|

150 × 18

|

0.30 × 0.45

|

SS 304, 316 etc

|

|

152 × 24

|

0.28 × 0.40

|

SS 304, 316 etc

|

|

160 × 18

|

0.27 × 0.45

|

SS 304, 316 etc

|

|

180 × 18

|

0.26 × 0.45

|

SS 304, 316 etc

|

|

200 × 40

|

0.17 × 0.27

|

SS 304, 316 etc

|

|

260 × 40

|

0.15 × 0.27

|

SS 304, 316 etc

|

|

300 × 40

|

0.14 × 0.25

|

SS 304, 316 etc

|

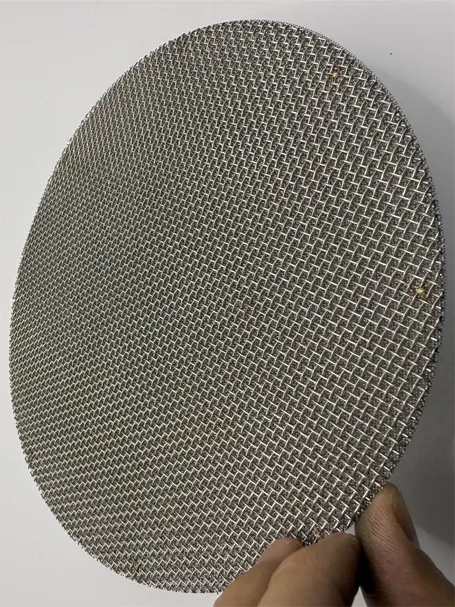

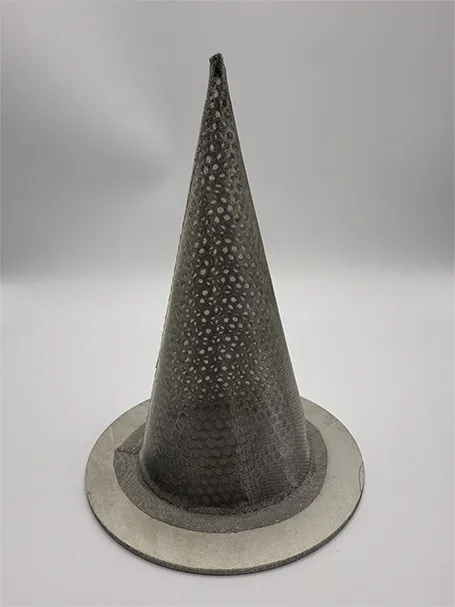

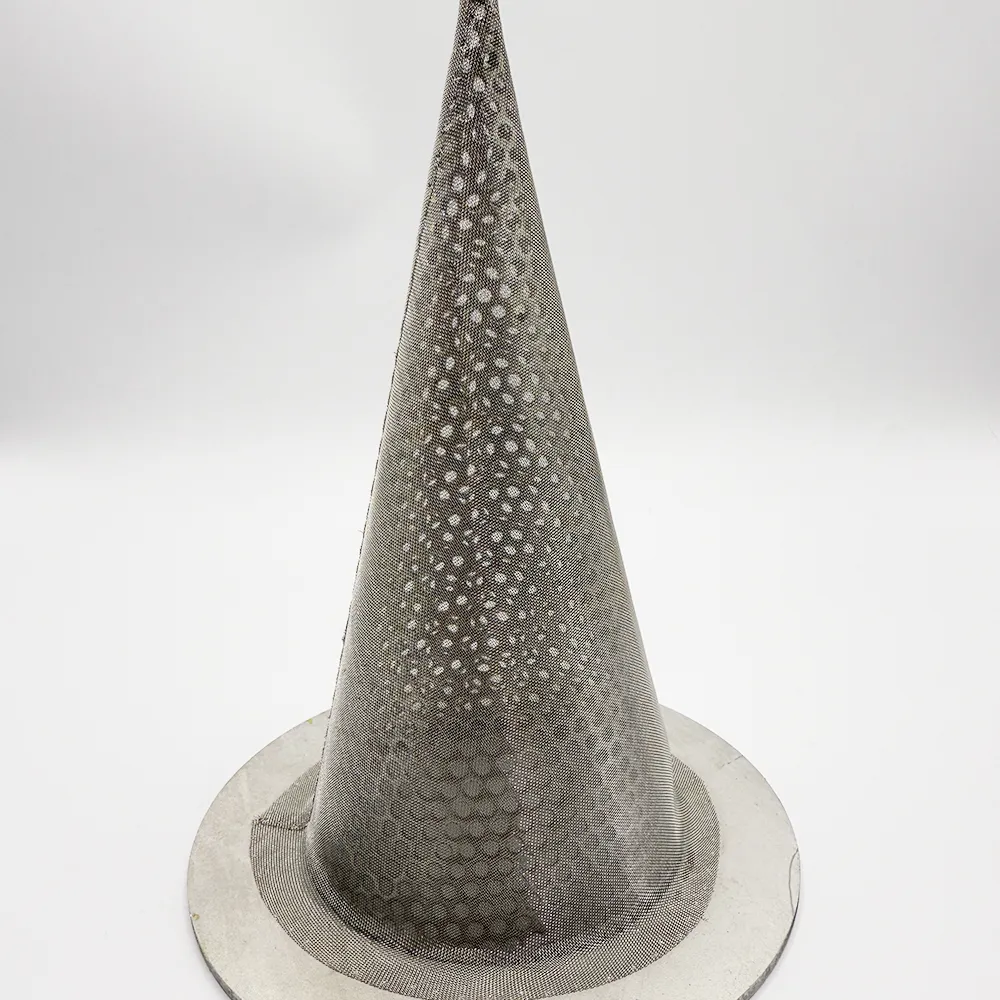

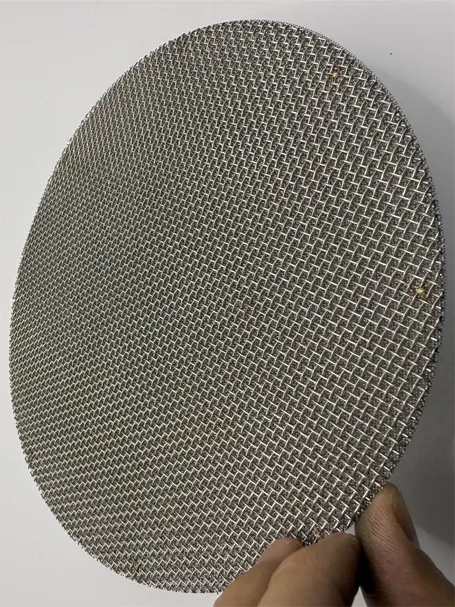

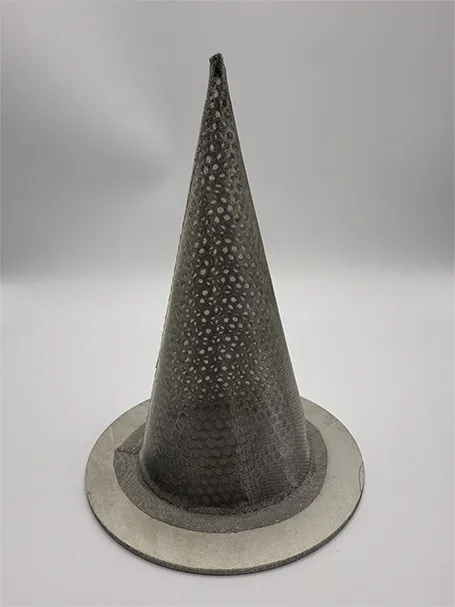

Products Case Exhibition

Below pictures is for our existed clients, stainless steel weave wire mesh help them solve a lot of issues in industry of filtration, sieve, chemical, industrial, oil etc.

We can cut any size of width according to clients’ request, making stainless steel screen mesh conveniently to use for clients. Before loading / delivery products, we will package stainless steel screen mesh by kraft paper, and then package into the wooden case. In order to Protect stainless steel from damage.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)