11111

In the realm of materials engineering, expanded metal products have emerged as versatile solutions for both functional and aesthetic needs. From lightweight meshes to heavy-duty gratings, these materials offer durability, flexibility, and cost-effectiveness across various sectors. The keywords small expanded metal, 3 expanded metal grating, eml mesh sheets, heavy gauge expanded metal, and catwalk expanded metal represent specific types of expanded metal that cater to diverse requirements in industries such as construction, manufacturing, and architecture.

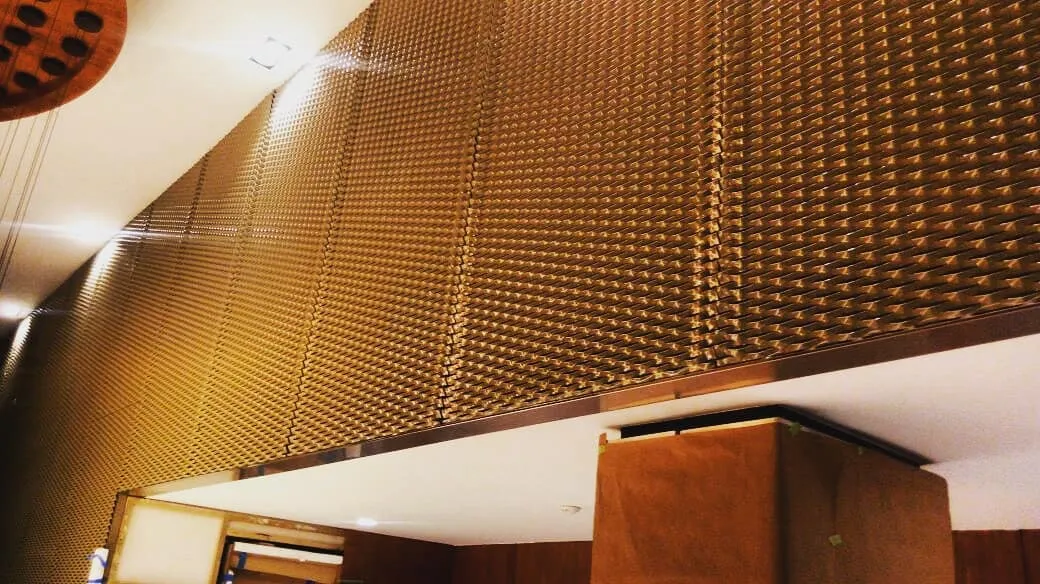

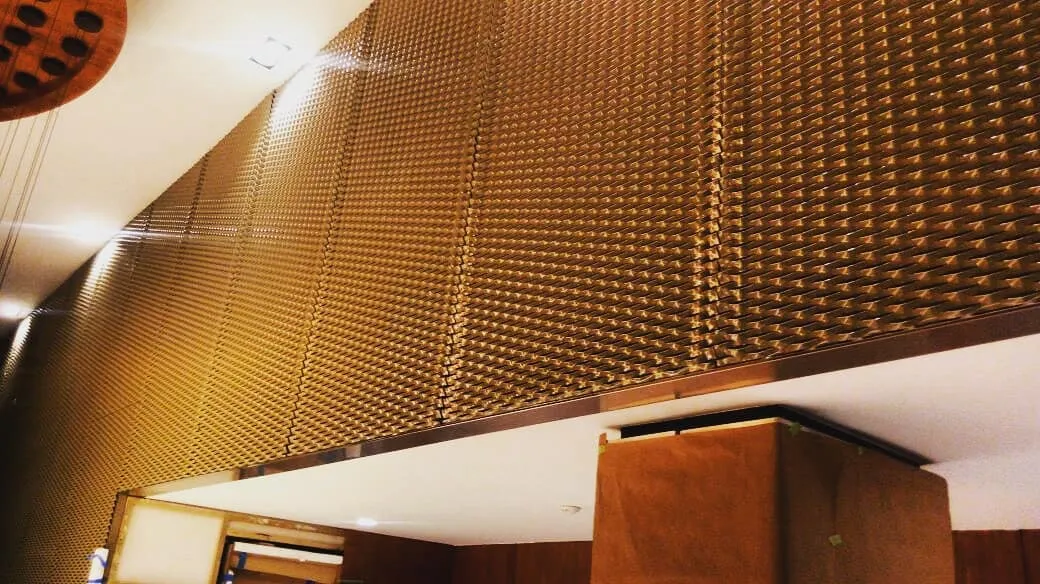

The Versatility of Small Expanded Metal

Small expanded metal is valued for its fine mesh structure, making it ideal for applications that require both strength and precision. In architectural projects, this material is often used for decorative panels, window guards, or ventilation screens. For instance, small expanded metal with its intricate mesh pattern is frequently used in interior design to create visually appealing partitions or ceiling installations. Its lightweight nature also makes it suitable for portable barriers or temporary fencing in events or construction sites. Additionally, in the automotive industry, small expanded metal can be found in air filters or radiator guards, where its durability and resistance to corrosion are essential.

Applications of 3 Expanded Metal Grating

3 expanded metal grating refers to a specific (specification) of expanded metal with a 3-inch mesh opening, offering a balance between openness and structural integrity. This type of grating is commonly used in industrial flooring, walkways, and platforms. In factories or warehouses, 3 expanded metal grating provides a non-slip surface for workers, while allowing debris or liquids to pass through, simplifying cleaning and maintenance. It is also suitable for outdoor applications such as bridge decks or stair treads, where its resistance to heavy foot traffic and harsh weather conditions is crucial. The 3-inch mesh size makes it an excellent choice for applications that require visibility without compromising strength.

eml Mesh Sheets: Lightweight and Functional

eml mesh sheets (expanded metal lightweight mesh sheets) are designed for applications where weight reduction is a priority without sacrificing durability. These sheets are often used in agricultural settings for animal fencing or ventilation in livestock shelters. The open structure of eml mesh sheets allows for proper air circulation while preventing small animals from escaping. In the packaging industry, they can be used as protective inserts or trays to secure fragile items during transportation. The lightweight nature of these sheets also makes them easy to handle and install, reducing labor costs in construction or renovation projects.

The Robustness of Heavy Gauge Expanded Metal

Heavy gauge expanded metal is engineered to withstand extreme loads and harsh environments. Made from thicker metal sheets, this type of expanded metal is commonly used in industrial settings such as mining, oil and gas, or heavy machinery guarding. For example, heavy gauge expanded metal can be found in conveyor belts, safety barriers, or access platforms where high strength and impact resistance are non-negotiable. Its ability to resist deformation under heavy loads makes it a preferred choice for structural applications. Additionally, in outdoor security fencing, heavy gauge expanded metal provides a robust barrier against forced entry, ensuring the safety of perimeters in commercial or industrial facilities.

Catwalk Expanded Metal for Elevated Structures

Catwalk expanded metal is specifically designed for elevated walkways, gangways, and observation decks. This type of expanded metal offers a safe, non-slip surface for workers or pedestrians in elevated environments. The open mesh design of catwalk expanded metal reduces wind resistance, making it suitable for outdoor catwalks in tall buildings or industrial complexes. It also allows for easy inspection of the area below, which is crucial in maintenance or monitoring tasks. In architectural projects, catwalks made from expanded metal can add a modern, industrial aesthetic while ensuring compliance with safety standards for load-bearing structures.

FAQ: Key Insights into Expanded Metal Products

How to Choose the Right Expanded Metal Type for a Project

Selecting the appropriate expanded metal depends on factors such as load requirements, environment, and intended use. For lightweight, decorative purposes, small expanded metal or eml mesh sheets are suitable. For heavy-duty applications, heavy gauge expanded metal or 3 expanded metal grating is preferable. Consider the mesh size, metal thickness, and surface treatment (e.g., galvanized for corrosion resistance) to ensure the material meets project specifications.

What Maintenance Is Required for Expanded Metal Products

Most expanded metal products require minimal maintenance. Regularly inspect for signs of wear, such as rust or damage, especially in outdoor or high-moisture environments. Clean with a mild detergent and water to remove debris. For galvanized surfaces, touch up any scratches to prevent corrosion. In industrial settings, check for loose fasteners or structural integrity, especially in load-bearing applications like catwalk expanded metal.

Can Expanded Metal Be Customized for Specific Sizes or Shapes

Yes, expanded metal can be cut, bent, or welded to fit specific dimensions or design requirements. Manufacturers often offer customization services to create tailored solutions for unique projects. Whether it’s a curved architectural panel or a custom-sized grating for a catwalk, suppliers can adjust the mesh size, metal type, and shape to meet exact needs.

What Are the Cost Advantages of Using Expanded Metal

Expanded metal is cost-effective due to its efficient manufacturing process, which involves slitting and stretching a single metal sheet rather than weaving or welding multiple wires. This reduces material waste and production time. Additionally, its durability and low maintenance requirements offer long-term cost savings compared to other materials like traditional wire mesh or solid metal panels.

How Does Expanded Metal Contribute to Sustainability

Many expanded metal products are made from recycled metals, and the material itself is fully recyclable at the end of its lifecycle. Its open design also promotes energy efficiency by allowing natural light and air circulation, reducing the need for artificial lighting and ventilation in buildings. This makes expanded metal a sustainable choice for eco-conscious projects.

![$item[título] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)