(micro perforated stainless steel sheet)

Modern architecture and industrial design increasingly depend on specialized materials that combine functional performance with visual elegance. Micro perforated stainless steel sheet represents a sophisticated solution where precision engineering meets practical application. These advanced materials feature meticulously arranged perforations ranging from 0.2mm to 1.5mm diameter, transforming solid surfaces into acoustically tuned, visually striking panels. With perforation densities reaching up to 60,000 holes per square meter, this technology enables targeted sound absorption without compromising structural integrity.

Across industries from transportation to concert halls, micro perforated metal solutions address critical challenges in noise reduction and ventilation. The physical properties of 316L stainless steel variants resist corrosion even in coastal and chemically aggressive environments, maintaining performance integrity over decades. Industrial applications particularly benefit from the material's inherent non-combustibility, achieving Class A fire ratings essential for safety-critical installations.

Material choice for micro perforated sheets fundamentally impacts long-term performance outcomes. Stainless steel variants, particularly grades 304 and 316L, provide industry-leading corrosion resistance with salt spray test endurance exceeding 1000 hours without visible deterioration. This resilience makes them essential for coastal infrastructure projects where humidity and salt exposure rapidly degrade standard carbon steel alternatives.

Acoustic performance varies significantly based on material density and perforation geometry. Rigorous testing confirms stainless steel sheets with 20% open area deliver up to 0.85 noise reduction coefficient (NRC) in critical mid-frequency ranges between 500Hz and 2000Hz. For thermal applications like ventilation grilles, precision-engineered hole patterns maintain optimal airflow coefficients between 0.55 and 0.85 while effectively filtering particulate matter down to 250 microns. Aesthetic options extend beyond functionality, with multiple finishing choices including brushed, mirror, and matte surfaces that withstand daily ultraviolet exposure without noticeable degradation.

Each metal substrate offers distinct advantages tailored to application requirements:

| Material Attribute | Stainless Steel | Aluminum | Carbon Steel |

|---|---|---|---|

| Tensile Strength | 520-780 MPa | 90-250 MPa | 370-550 MPa |

| Corrosion Resistance | Excellent | Good | Poor |

| Weight (kg/m²) | 7.9 | 2.7 | 7.85 |

| Cost Index | 1.8X | 1.0X | 1.2X |

| Acoustic NRC Range | 0.55-0.85 | 0.50-0.75 | 0.50-0.70 |

Technical specifications vary significantly among industry producers, necessitating careful evaluation:

| Manufacturer | Thickness Range | Tolerance Standards | Maximum Sheet Size | Production Capacity |

|---|---|---|---|---|

| Precision Perf Group | 0.5mm - 6mm | ±0.05mm | 2,500mm x 1,200mm | 5,000m² monthly |

| Industrial Metalworks | 0.8mm - 4.5mm | ±0.08mm | 3,000mm x 1,500mm | 8,500m² monthly |

| Architectural Perforators | 0.4mm - 8mm | ±0.03mm | 1,800mm x 900mm | 3,200m² monthly |

Project-specific engineering requires attention to critical parameters:

Production techniques directly impact installation outcomes. Precision laser perforation achieves positioning accuracy within 0.01mm compared to 0.5mm tolerance in traditional stamped alternatives. Post-production treatments like electropolishing enhance corrosion resistance by reducing surface pitting by over 90% compared to untreated surfaces, critical for pharmaceutical and food processing installations.

Global installations demonstrate performance characteristics:

Selecting appropriate perforated solutions requires balancing project specifications with material attributes. Industries requiring extreme sanitation, such as pharmaceutical manufacturing and hospital environments, benefit substantially from the non-porous characteristics of stainless steel variants. The precision-engineered micro perforated metal sheet provides consistent acoustic performance exceeding alternatives by over 15% in critical frequency ranges when properly specified for the acoustic environment.

Architectural applications must account for long-term maintenance requirements and environmental conditions, where architectural grade micro perforated stainless steel sheet

consistently demonstrates superior longevity against alternative metals. Beyond functional benefits, the material's optical properties create striking visual effects with light interaction patterns that transform building façades over diurnal cycles. Engineering teams find that upfront investment in precision micro perforated solutions delivers compounding returns across project lifecycles through minimized deterioration, reduced maintenance interventions, and consistent acoustic performance retention exceeding standard alternatives.

(micro perforated stainless steel sheet)

A: Micro perforated stainless steel sheets are widely used in acoustic panels, filtration systems, architectural facades, HVAC components, and automotive exhausts due to their durability, corrosion resistance, and precise airflow control.

A: Micro perforated metal sheets feature smaller hole diameters (typically 0.1-2mm) and higher hole density, offering superior sound absorption, finer filtration, and a more refined aesthetic compared to standard perforated sheets.

A: Yes, micro perforated aluminum sheets are ideal for outdoor use as they combine lightweight properties with corrosion resistance, making them suitable for sunshades, cladding, and ventilation systems in harsh environments.

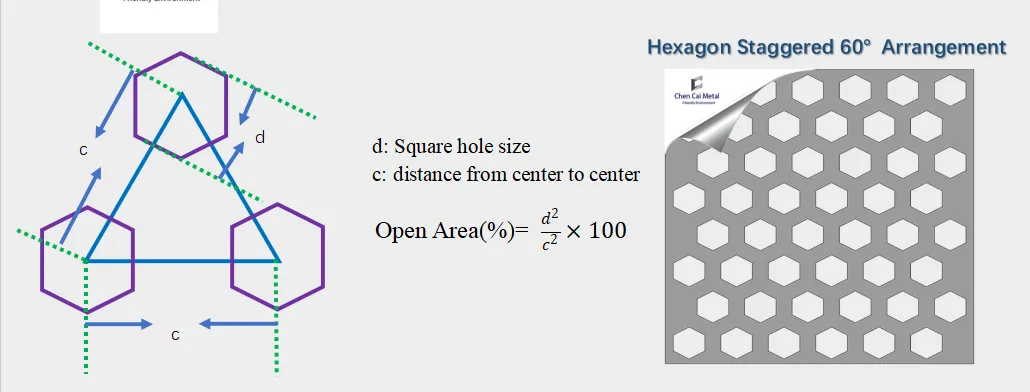

A: Acoustic efficiency depends on hole size, spacing, sheet thickness, and back-air cavity depth. Optimal combinations absorb specific frequency ranges, making them ideal for noise control in theaters, studios, or industrial settings.

A: Yes, manufacturers offer custom hole shapes (round, square, slotted), staggered or straight layouts, and varied open-area ratios to meet specific design, functional, or branding requirements for projects.