11111

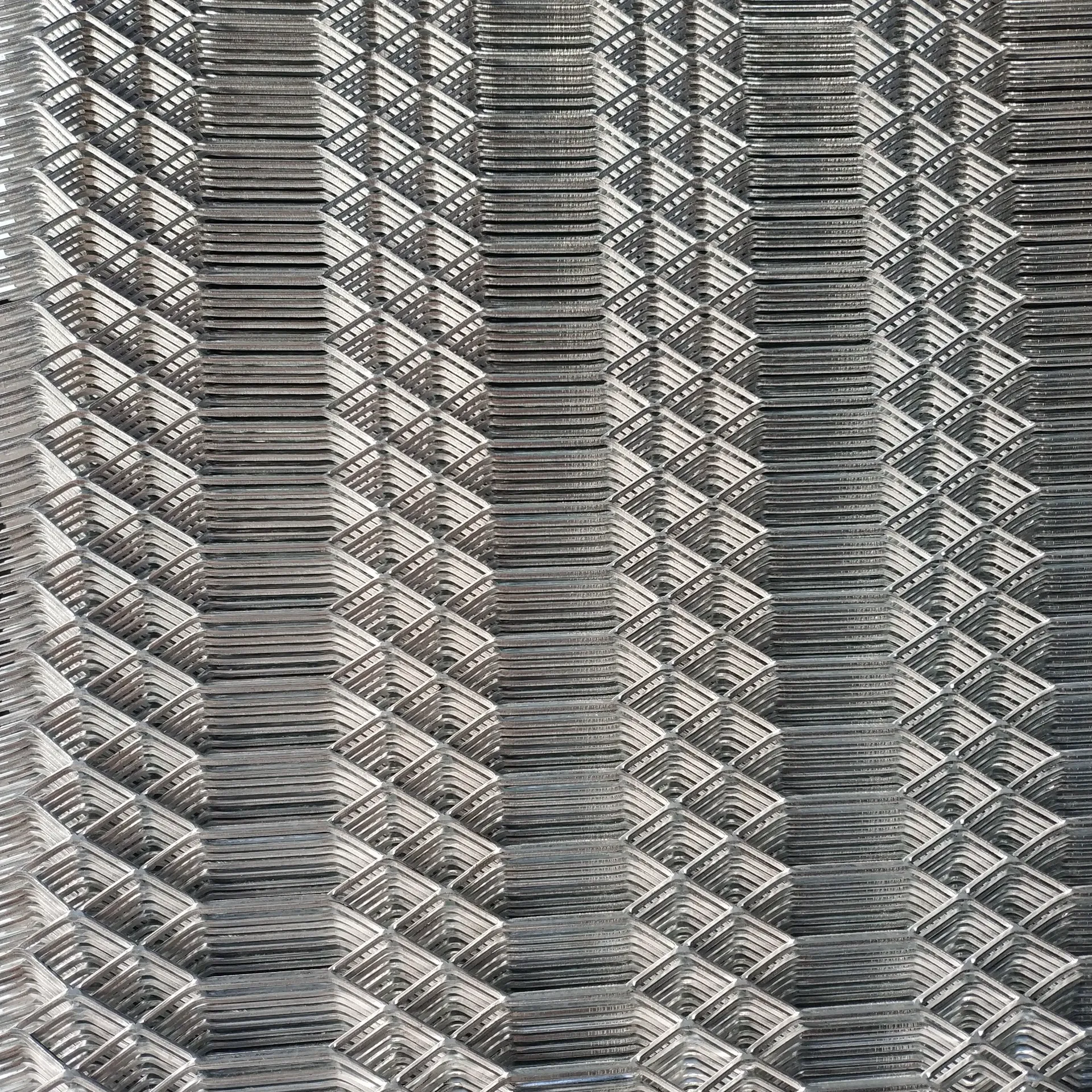

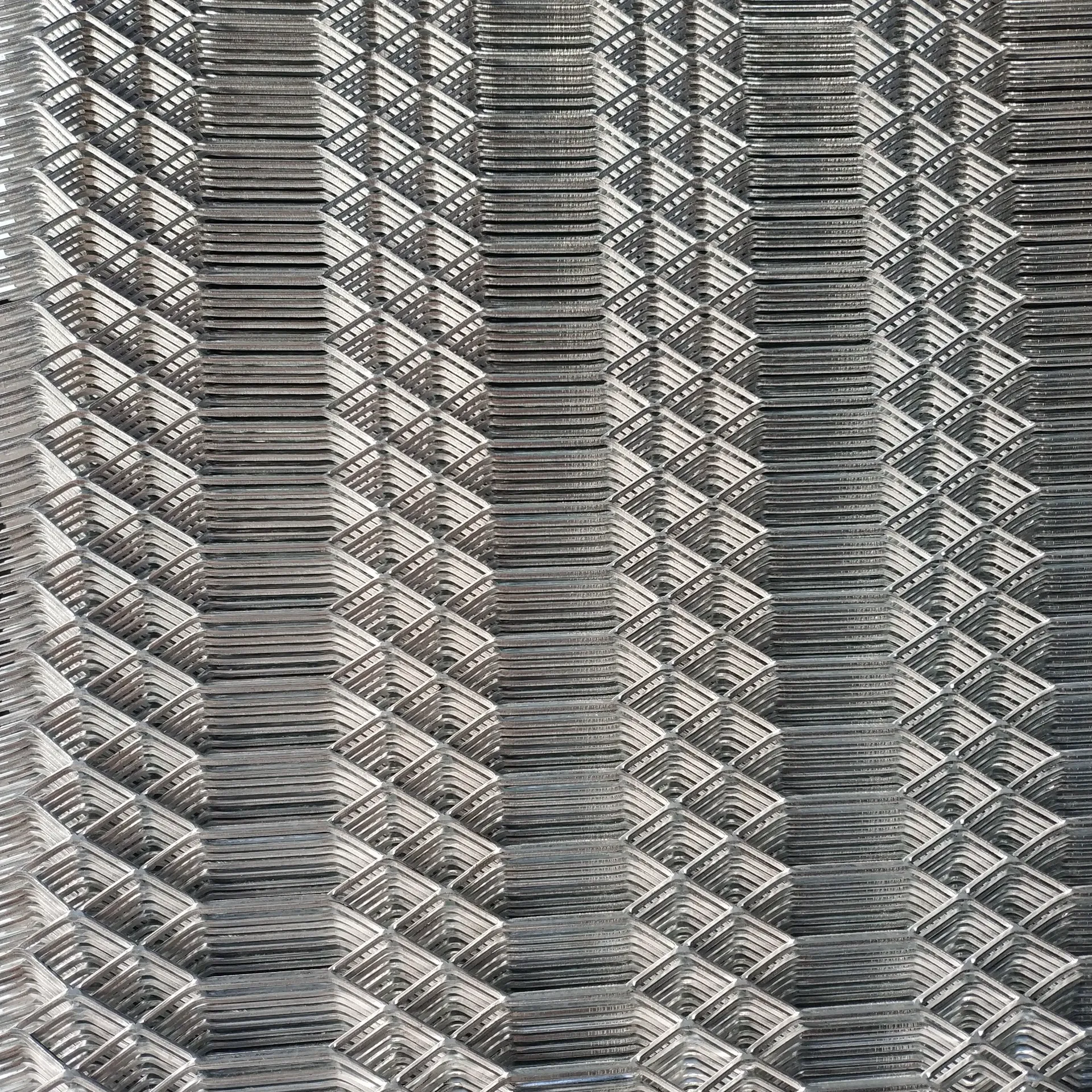

Expanded metal products have emerged as indispensable components in various industries, offering a balance of strength, durability, and design flexibility. From industrial walkways to kitchen appliances and architectural elements, the versatility of expanded metal makes it a go - to material for numerous applications. This exploration delves into the uses and characteristics of expanded metal catwalk grating, 4x8 expanded aluminum sheet, expanded metal for grill, 13 expanded metal, and coated expanded metal, highlighting their roles in different sectors.

Industrial and Structural Applications of Expanded Metal

In industrial settings, expanded metal catwalk grating is widely used to create safe and sturdy walkways, platforms, and mezzanines. The open design of this grating allows for proper drainage of liquids and debris while providing excellent traction, reducing the risk of slips and falls. For example, in manufacturing facilities or warehouses, workers rely on expanded metal catwalk grating to navigate elevated areas safely. The grating’s durability ensures it can withstand heavy foot traffic and the occasional impact from equipment, making it a reliable choice for industrial environments.

Architectural and Construction Uses of Expanded Metal Sheets

The 4x8 expanded aluminum sheet is a popular choice in architectural and construction projects due to its lightweight nature and corrosion resistance. Architects often incorporate these sheets into building facades, room dividers, or decorative screens, leveraging their unique patterns to add visual interest. In construction, 4x8 expanded aluminum sheets can be used as reinforcing materials in concrete structures or as ventilation panels in walls and ceilings. Their standard 4x8 size makes them easy to handle and install, reducing labor costs and time on the job site.

Expanded Metal in Kitchen and Outdoor Grill Setups

For culinary and outdoor enthusiasts, expanded metal for grill offers practical benefits. The evenly spaced openings in the metal allow for optimal heat distribution, ensuring that food cooks evenly on barbecues or grills. This type of expanded metal is often made from stainless steel, which is resistant to high temperatures and corrosion, making it suitable for frequent use. Whether used as a grill grate or as a protective screen around outdoor cooking areas, expanded metal for grill combines functionality with durability, enhancing the overall cooking experience.

Understanding Expanded Metal Specifications and Grades

The term 13 expanded metal typically refers to a specific mesh size or gauge, indicating the number of openings per linear inch and the thickness of the metal. This specification is crucial in determining the strength and permeability of the material. For instance, a 13 expanded metal with smaller openings may be used in applications requiring fine filtration or security, such as window guards or machinery covers. Larger mesh sizes, on the other hand, are ideal for applications where visibility and airflow are more important, like ventilation grilles or decorative panels.

The Advantages of Coated Expanded Metal

Coated expanded metal offers enhanced protection and aesthetic appeal through various surface treatments. Common coatings include powder coating, galvanization, and paint, which can improve the metal’s resistance to rust, chemicals, and UV rays. In outdoor applications, such as fences or signage, coated expanded metal maintains its appearance and functionality even in harsh weather conditions. Additionally, the coating allows for a wide range of colors and textures, making it suitable for decorative purposes in both residential and commercial settings.

FAQ: Key Questions About Expanded Metal Products

How do I choose the right expanded metal for my project?

Selecting the appropriate expanded metal depends on factors such as the intended use, load requirements, and environmental conditions. For industrial applications like expanded metal catwalk grating, prioritize strength and slip resistance. For architectural projects, consider the aesthetic appeal and corrosion resistance of materials like 4x8 expanded aluminum sheet. Always review the mesh size, material type, and coating options to ensure the product meets your specific needs.

Can expanded metal sheets be cut to custom sizes?

Yes, most expanded metal sheets, including 4x8 expanded aluminum sheets, can be cut to custom sizes using appropriate tools such as tin snips, saws, or plasma cutters. It is essential to wear protective gear during cutting and to follow safety guidelines to avoid injury. Some suppliers also offer pre - cut or fabricated solutions for added convenience.

What maintenance is required for coated expanded metal?

Maintaining coated expanded metal is relatively simple. Regularly clean the surface with a mild detergent and water to remove dirt and debris. Avoid using abrasive cleaners or tools that could damage the coating. Inspect the coating periodically for signs of wear or damage, and touch up any areas as needed to preserve the metal’s protection and appearance.

Is expanded metal suitable for high - temperature applications like grills?

Yes, expanded metal for grill is designed to withstand high temperatures, especially when made from heat - resistant materials like stainless steel. However, it is important to ensure that the metal’s coating, if any, is also rated for high temperatures to prevent damage or release of harmful substances during cooking.

What does the "13" in 13 expanded metal signify?

The "13" in 13 expanded metal typically refers to the mesh count or the number of openings per linear inch, though exact specifications may vary by manufacturer. This measurement helps determine the density and strength of the expanded metal, making it easier to select the right product for applications ranging from security screens to ventilation systems. Always consult the manufacturer’s technical data for precise details about mesh size and gauge.

![$ element [ady] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)