(aluminum expanded metal suppliers)

The global market for architectural and industrial metal solutions grew 7.2% CAGR from 2020-2023, with aluminum expanded metal suppliers

meeting 34% of this demand. This material's 68% weight reduction compared to steel alternatives drives adoption in aerospace and transportation sectors. Manufacturers now prioritize suppliers offering both standard and customized patterns to accommodate complex design requirements.

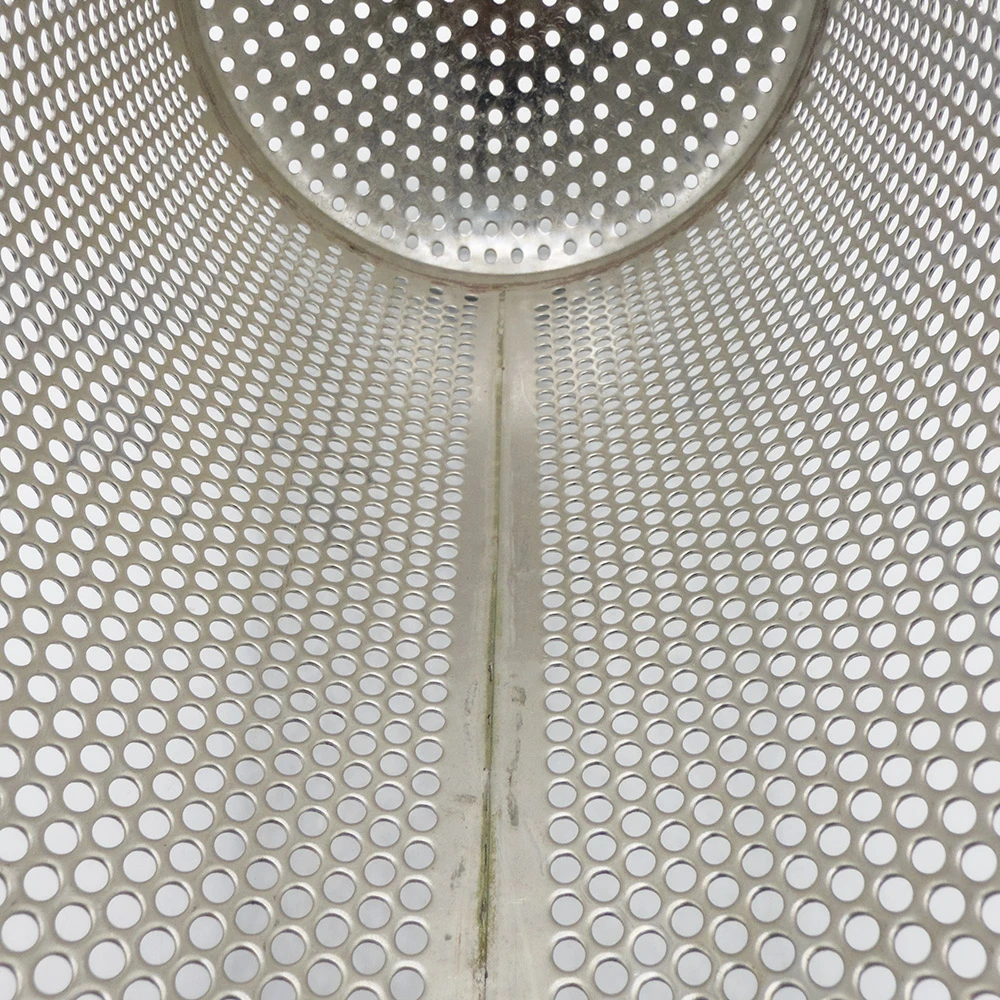

Advanced CNC punching systems achieve ±0.15mm dimensional accuracy, enabling production of 0.5-8mm thickness sheets with 20-80% open area ratios. Proprietary anodizing treatments enhance corrosion resistance by 4X compared to untreated surfaces. Leading aluminum perforated sheets suppliers utilize real-time thickness monitoring to maintain 99.3% consistency across production batches.

| Parameter | Supplier A | Supplier B | Supplier C |

|---|---|---|---|

| Max Sheet Width | 2500mm | 3000mm | 2000mm |

| Minimum Hole Size | 0.8mm | 1.2mm | 0.5mm |

| Alloy Options | 5 grades | 3 grades | 7 grades |

| Lead Time | 10 days | 15 days | 7 days |

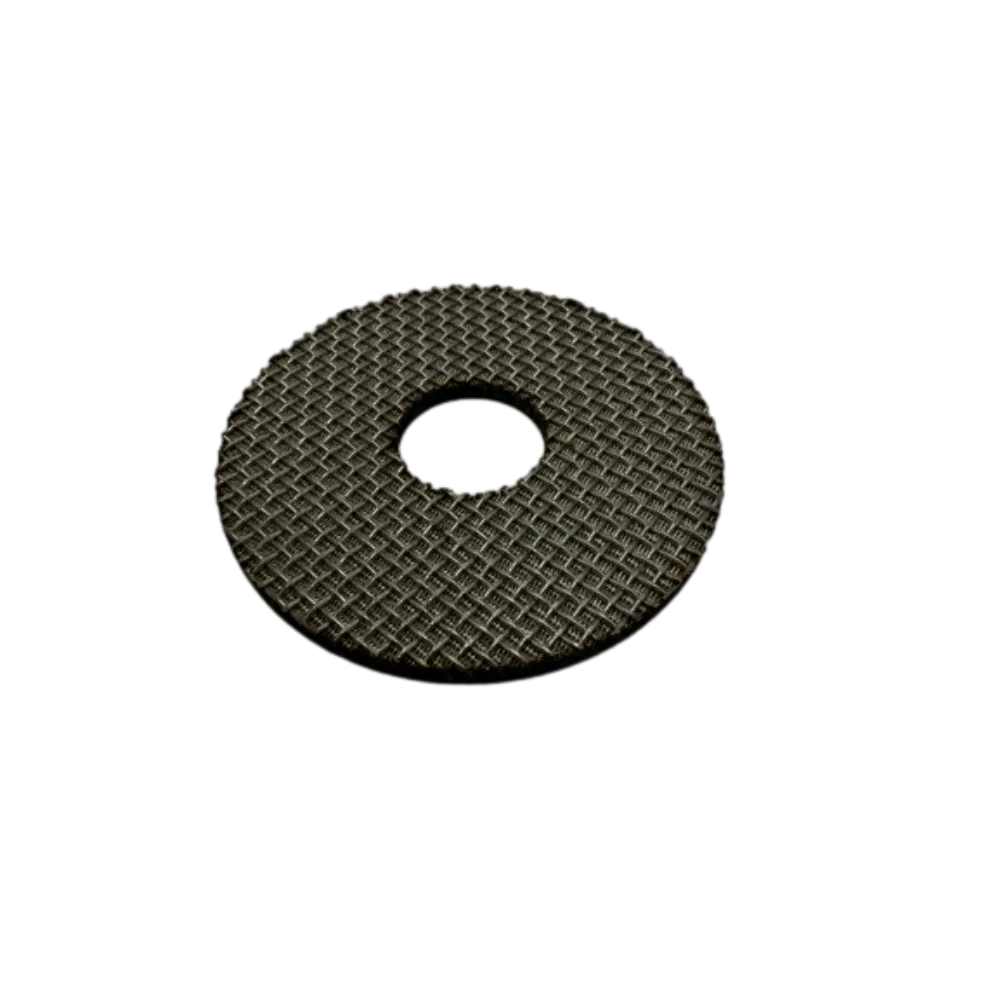

Custom patterns account for 42% of orders processed by expanded metal mesh suppliers. Anti-slip variants demonstrate 0.78 friction coefficients (ASTM D1894 standard), while EMI shielding versions achieve 85dB attenuation from 1-10GHz frequencies. Architectural clients frequently request powder-coated finishes matching RAL color charts with 98% accuracy.

ISO 9001-certified mills supply raw materials with full traceability documentation. Third-party testing verifies:

A recent airport canopy project required 1,850m² of Type 5052 expanded panels with 3.2mm strand width. The solution reduced structural load by 2.3 tons while maintaining 75kg/m² snow load capacity. Automotive manufacturers have adopted hexagonal perforation patterns showing 18% better airflow than traditional designs.

Top-tier suppliers maintain 97.6% on-time delivery rates through vertically integrated facilities handling sheet metal processing from alloy selection to final inspection. When evaluating aluminum perforated sheets suppliers, prioritize those offering CAD pattern validation and material certification traceability. The most reliable partners provide 24-month performance warranties on structural applications.

(aluminum expanded metal suppliers)

A: Prioritize suppliers with certifications (e.g., ISO), industry experience, and customizable options. Ensure they provide material specifications, such as strand thickness and mesh size, and offer timely delivery.

A: Expanded metal mesh is created by stretching slit aluminum sheets, offering durability and airflow, while perforated sheets feature punched holes for filtration or aesthetics. Suppliers may specialize in one or both products.

A: Construction, automotive, HVAC, and aerospace industries use it for grating, screens, and reinforcement. Suppliers catering to these sectors often provide corrosion-resistant and lightweight solutions.

A: Look for ISO 9001 for quality management and ASTM/EN standards compliance. Suppliers with OSHA-compliant safety practices and material traceability are preferable for industrial projects.

A: Pricing depends on material grade (e.g., 3003 or 5052 aluminum), sheet thickness, and order volume. Custom patterns or coatings may increase costs but add functional value.