Strainer Mesh

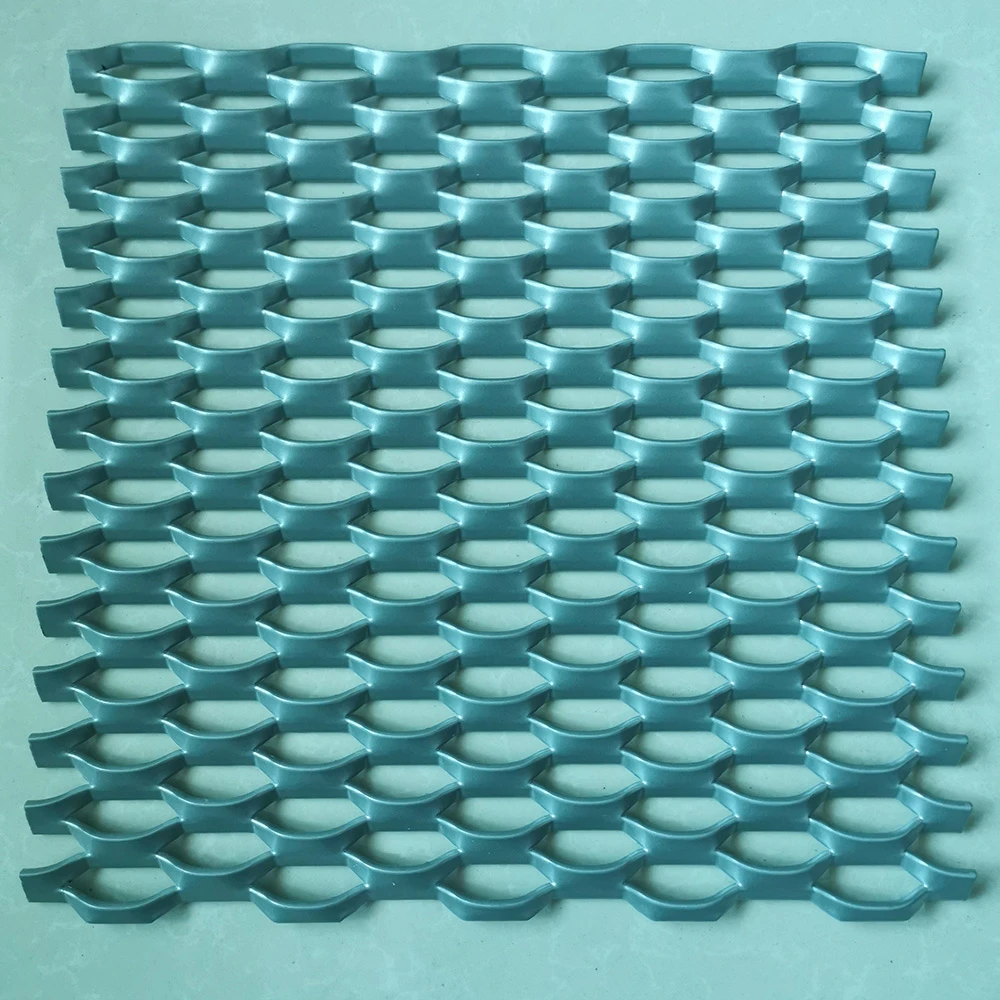

1. Material testing: Check if the mesh materials meet customer requirements, such as stainless steel, galvanized steel, aluminum alloy, or other corrosion-resistant materials.

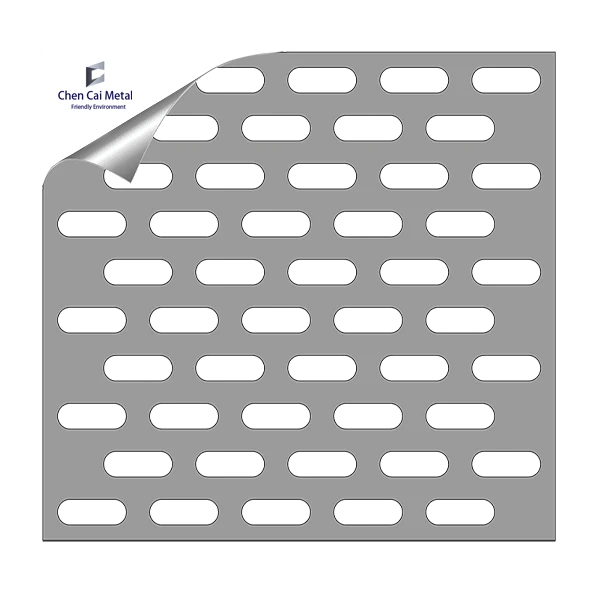

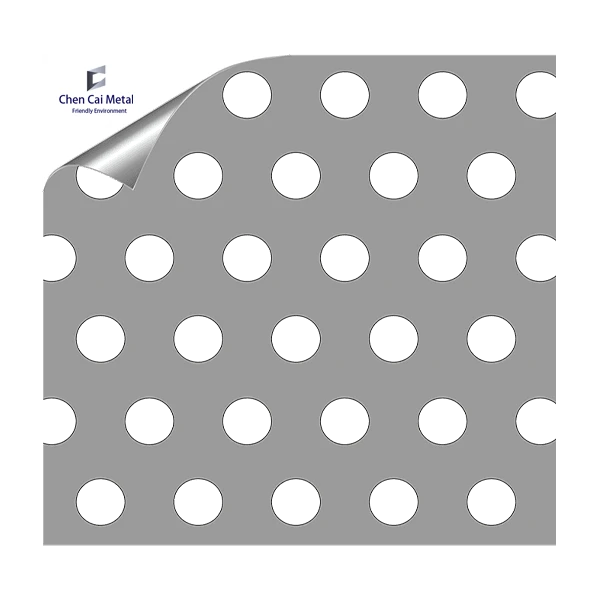

2. Mesh size: Measure whether the mesh size of the product meets the standard of filtration accuracy, to avoid particles that cannot be filtered beyond the standard or cannot be filtered through.

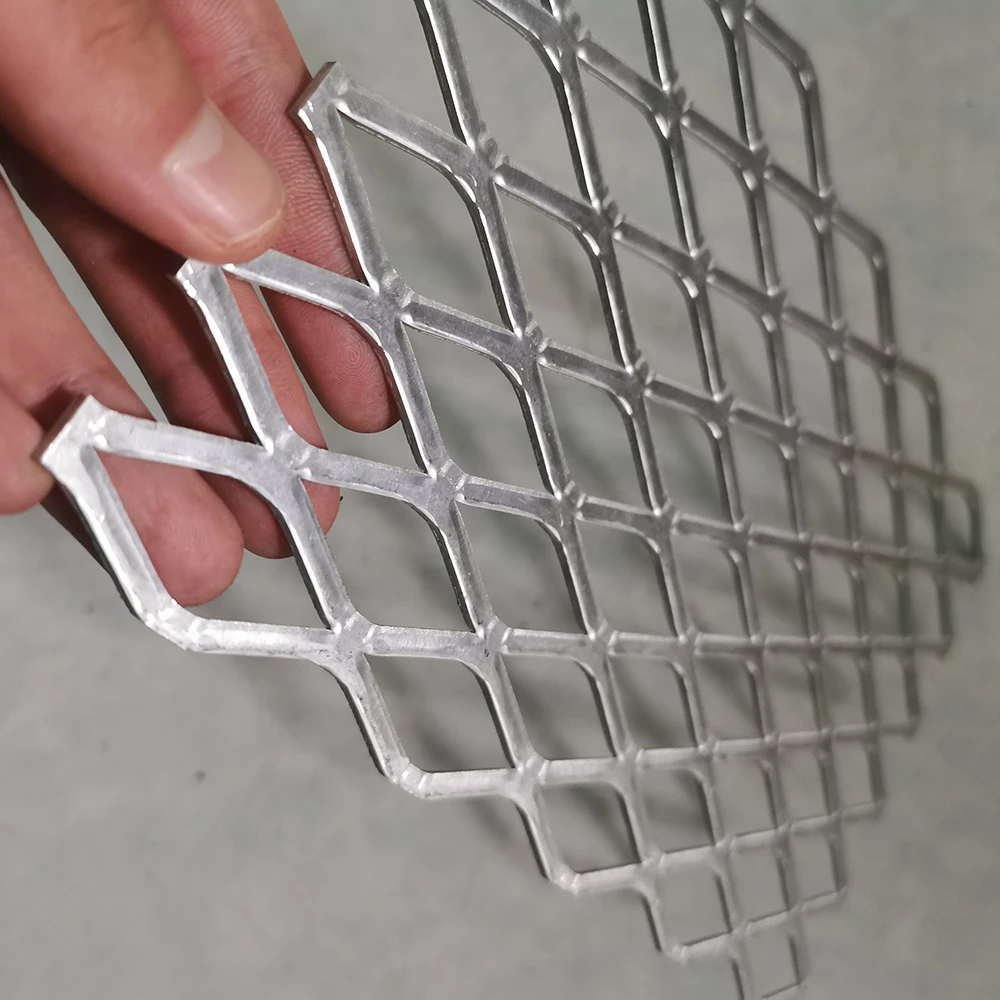

3. Detection of wire diameter and thickness: Use professional measuring tools to check whether the metal wire meets the standard wire diameter or whether the plate meets the standard thickness to ensure customer requirements.

4. Quality of welding and connection points: Check whether the welding points at each point are uniform, firm, and whether there are any virtual welds, fractures, or burrs, to ensure that the customer receives the product without detachment or leakage during use.

5. Surface treatment: Check whether the product surface has been treated as required, such as electroplating, polishing, spraying, or electrolysis, etc.

6. Pressure testing and durability testing: measuring the compressive strength of the product through professional instruments to ensure that the filter can work under specific pressure fluids

7. Cleanliness check: Check the product for oil stains, impurities, or other contaminants.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)