11111

Expanded metal products have revolutionized various industries by offering a blend of strength, versatility, and cost - effectiveness. This overview explores the uses and features of expanded steel mesh sheet, 9 gauge expanded metal, heavy duty expanded metal mesh, metal sheet mesh, and galvanized expanded metal mesh, highlighting their roles in different sectors.

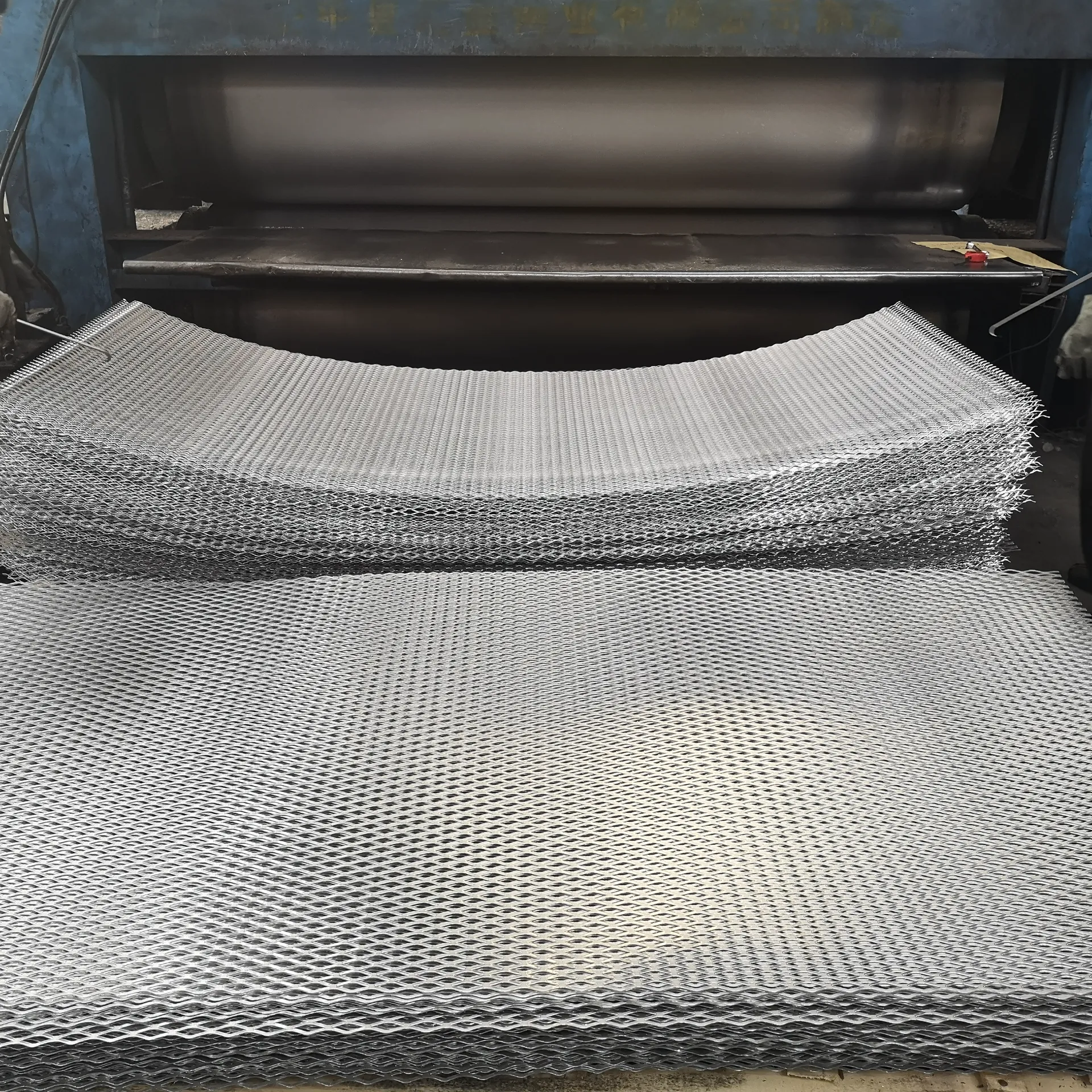

Industrial and Structural Uses of Expanded Steel Mesh Sheet

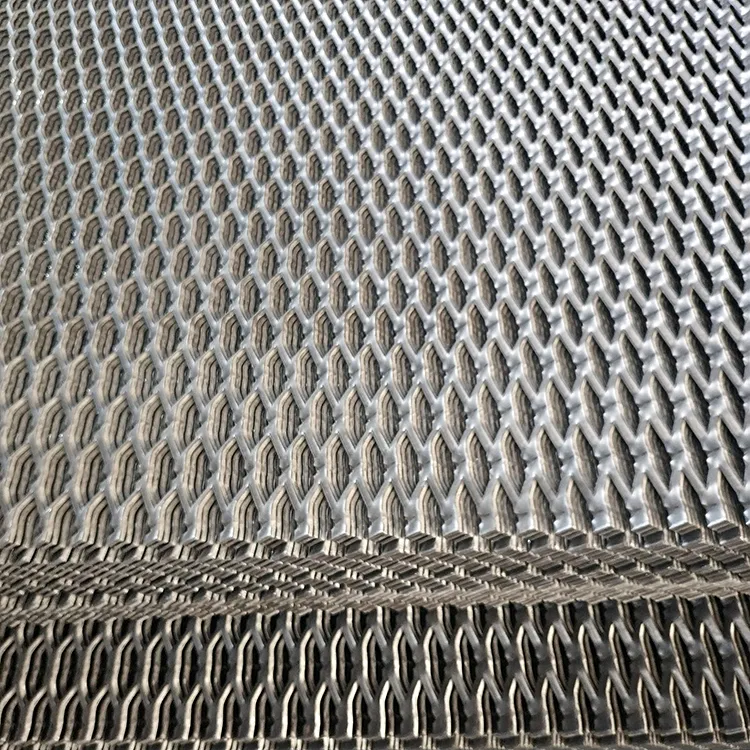

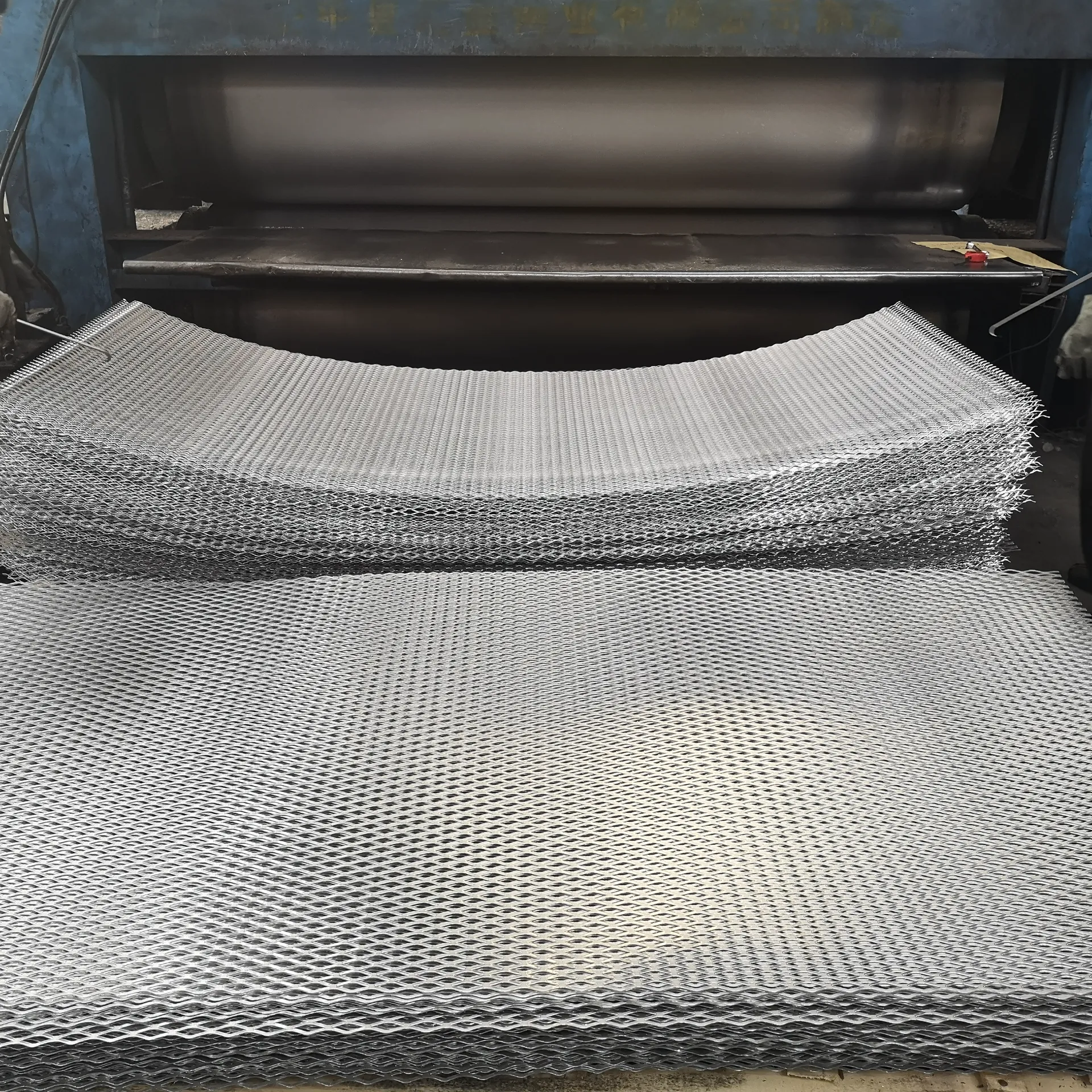

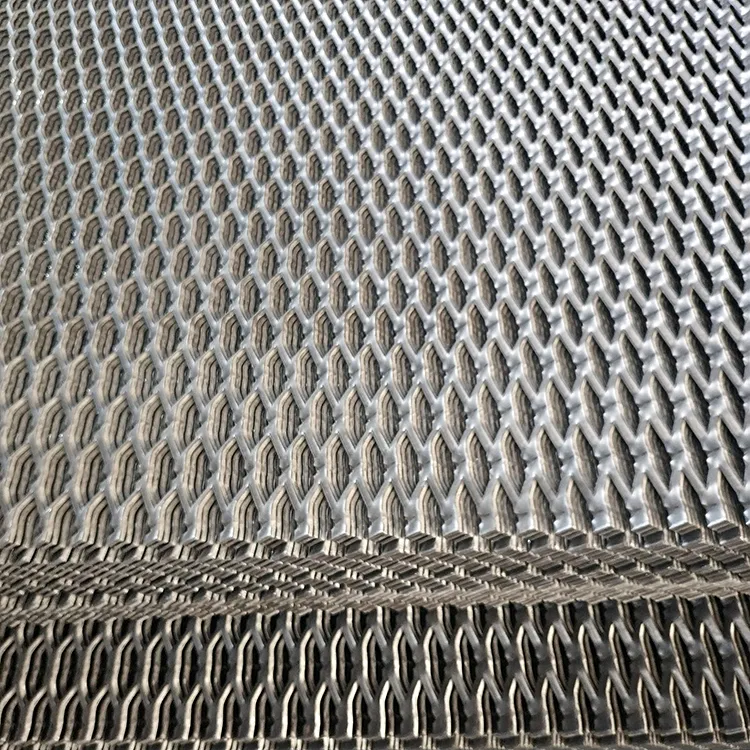

In industrial environments, expanded steel mesh sheet is a preferred choice for creating robust flooring, fencing, and safety barriers. Its interconnected metal strands form a durable lattice that can withstand heavy loads and frequent use. For example, in manufacturing plants, expanded steel mesh sheet is often installed as walkway flooring, providing both traction and visibility while allowing liquids and debris to pass through. The inherent strength of steel makes these sheets suitable for high - traffic areas where durability is non - negotiable.

Understanding Gauge and Strength in 9 Gauge Expanded Metal

The specification of 9 gauge expanded metal refers to the thickness of the metal used, with lower gauge numbers indicating thicker material. This type of expanded metal is valued for its balance of strength and permeability. In construction, 9 gauge expanded metal may be used as reinforcing mesh in concrete projects or as a base for plaster and stucco applications. Its robust structure ensures that it can handle the stresses of building movements while maintaining an open design that allows for proper adhesion and ventilation.

Heavy Duty Expanded Metal Mesh for Demanding Environments

Heavy duty expanded metal mesh is engineered to meet the toughest requirements, making it ideal for industrial and commercial applications that involve heavy machinery, vehicles, or extreme weather conditions. In(warehousing) and logistics, this mesh is used to create secure enclosures for storage areas or as protective barriers around equipment. The reinforced design of heavy duty expanded metal mesh resists impact, corrosion, and wear, ensuring long - term reliability in harsh environments such as outdoor construction sites or coastal facilities.

Versatility of Metal Sheet Mesh in Design and Function

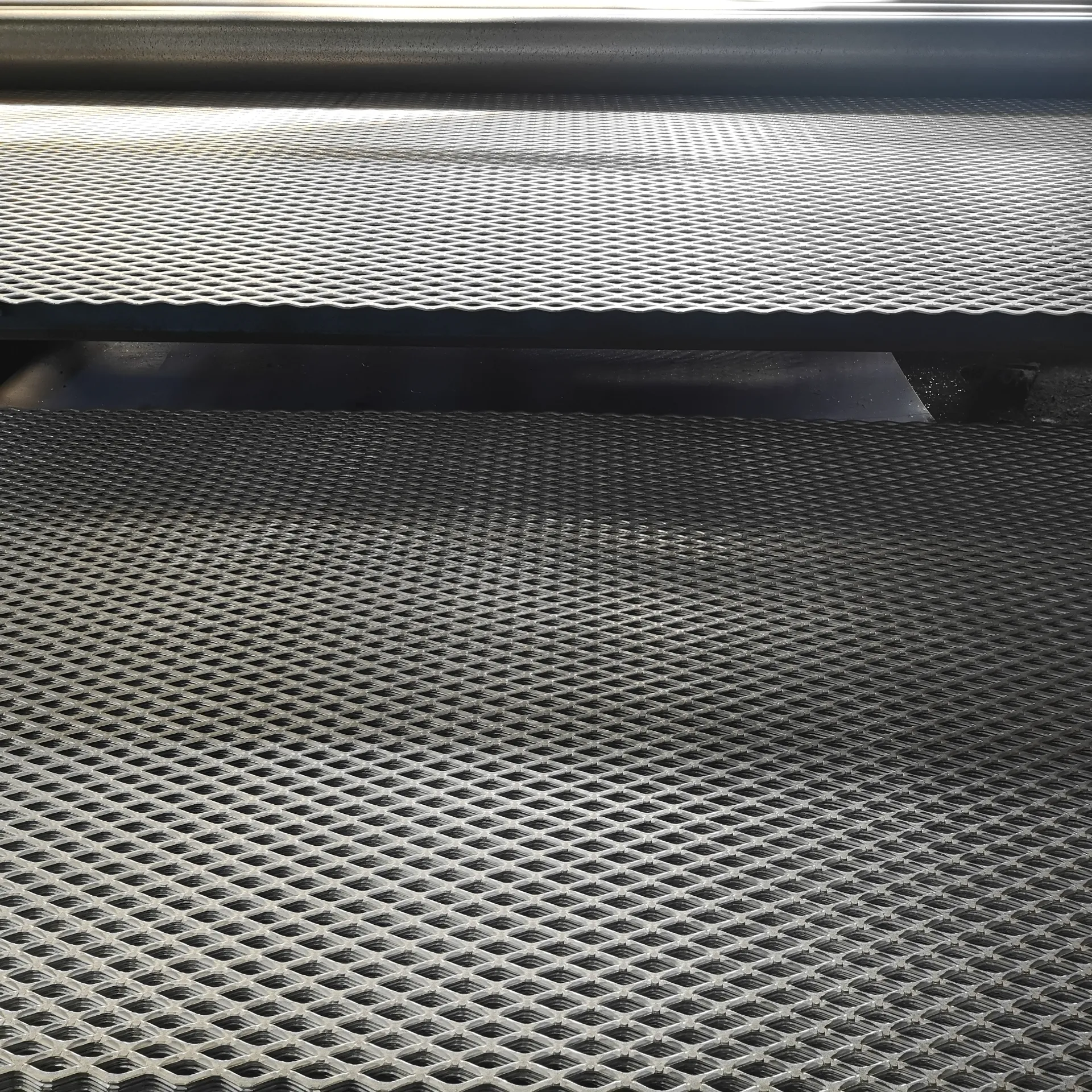

Metal sheet mesh encompasses a wide range of expanded metal products, varying in material, gauge, and mesh pattern. Architects and designers often use metal sheet mesh to create decorative panels, room dividers, or facade cladding, leveraging its unique textures and light - filtering properties. In agricultural settings, the same mesh may be used as fencing or animal enclosures, providing visibility and airflow while keeping livestock secure. The adaptability of metal sheet mesh allows it to serve both functional and aesthetic purposes across diverse industries.

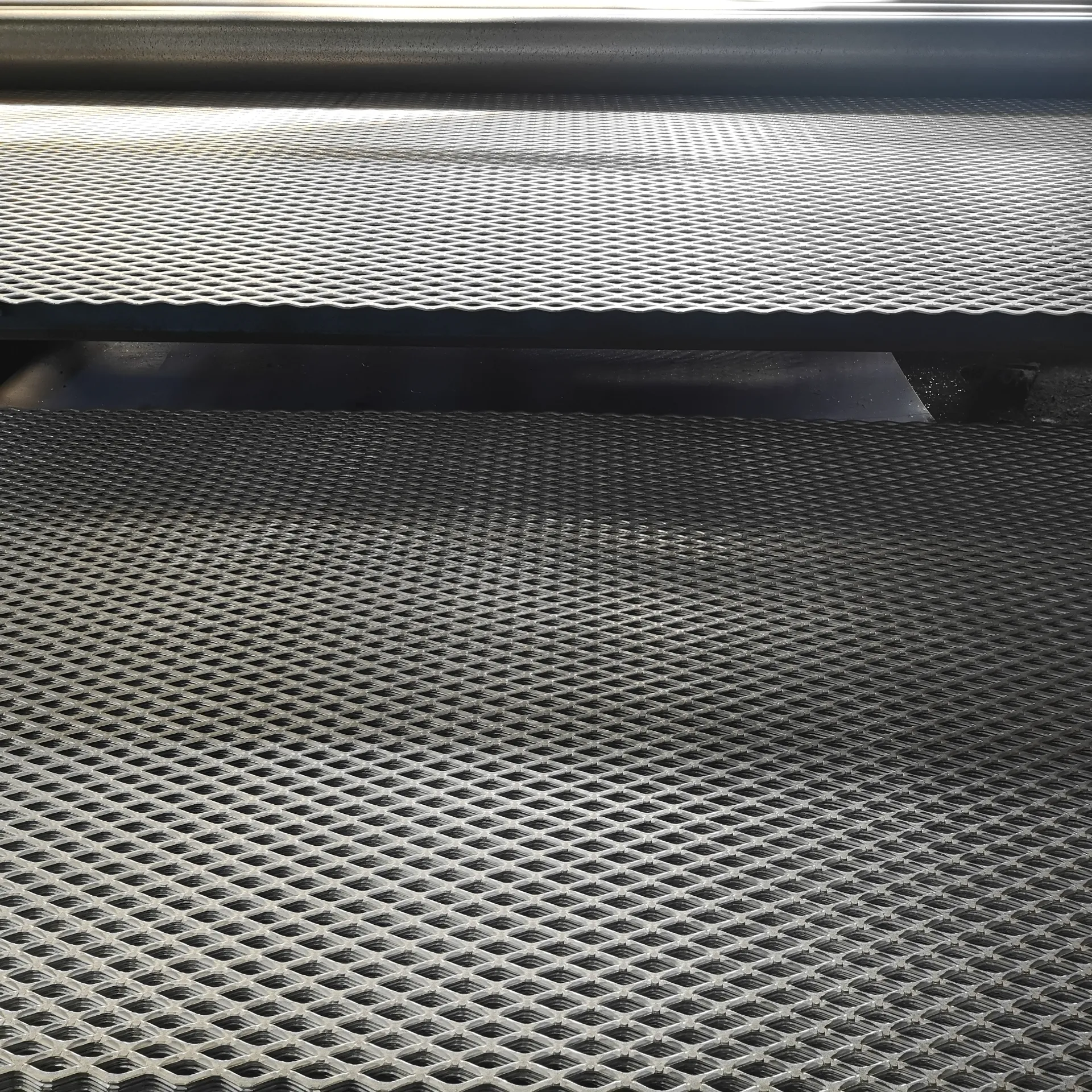

Corrosion Resistance with Galvanized Expanded Metal Mesh

Galvanized expanded metal mesh offers enhanced protection against rust and corrosion, thanks to a zinc coating applied to the metal surface. This makes it particularly suitable for outdoor applications, such as fencing, roofing, or drainage grates, where exposure to moisture and weather is constant. The galvanized coating not only extends the lifespan of the mesh but also maintains its structural integrity in humid or salt - air environments. For example, in coastal regions or areas with high rainfall, galvanized expanded metal mesh is a reliable choice for retaining walls or flood control structures.

FAQ: Key Considerations for Expanded Metal Products

How to select the right expanded metal for a specific project?

Choosing the appropriate expanded metal involves assessing factors like load capacity, environmental conditions, and aesthetic needs. For heavy - duty applications, prioritize heavy duty expanded metal mesh or expanded steel mesh sheet with thicker gauges. In outdoor settings, galvanized expanded metal mesh is ideal for its corrosion resistance. For decorative uses, explore the patterns and finishes available in metal sheet mesh.

Can expanded metal sheets be modified after production?

Yes, most expanded steel mesh sheet and metal sheet mesh products can be cut, bent, or welded to fit custom dimensions. However, it is essential to use proper tools and safety equipment during modification. For example, cutting 9 gauge expanded metal may require power tools like reciprocating saws or plasma cutters to ensure clean, precise edges.

What maintenance is required for galvanized expanded metal mesh?

Galvanized expanded metal mesh requires minimal maintenance due to its corrosion - resistant coating. Regularly inspect the mesh for signs of damage, such as scratches or peeling zinc, and clean it with a mild detergent and water to remove dirt or debris. In most cases, the galvanized coating provides long - lasting protection without frequent upkeep.

How does gauge affect the performance of expanded metal?

The gauge of expanded metal, such as 9 gauge expanded metal, directly impacts its strength and weight. Thicker gauges (lower numerical values) are stronger and more durable, making them suitable for load - bearing applications. Thinner gauges are lighter and more flexible, ideal for decorative or non - structural uses. Always refer to the manufacturer’s specifications to match the gauge with the project’s requirements.

Is heavy duty expanded metal mesh suitable for residential use?

Yes, heavy duty expanded metal mesh can be used in residential settings for applications that require extra strength, such as security gates, basement window guards, or industrial - style room dividers. Its robust design ensures enhanced security and durability, making it a practical choice for homeowners seeking both functionality and a modern aesthetic.

![$item[titel] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)