Foarbyld fan Filterprecision (μm) :

|

Aperture Grutte (mm)

|

Filterprecision (μm)

|

Application

|

|

5.0

|

5000

|

grutte particle removal

|

|

2.0

|

2000

|

geskikt foar grutte ôffal opheffing

|

|

1.0

|

1000

|

it fuortheljen fan gruttere fêste ûnreinheden

|

|

0.5

|

500

|

it fangen fan floeibere dieltsjes

|

|

0.1

|

100

|

Ultrafine filtraasje

|

|

Foar hegere presyzje filtraasje (1-50μm), an ekstra fyn filter tas of ynderlike lining kin wurde yntegrearre mei it roestfrij stiel perforearre gaas om superieure prestaasjes te berikken.

Wolle jo in oanbefelling foar de optimale diafragmagrutte en materiaal basearre op jo applikaasje? Lit my witte jo fereaske filtraasje standert (μm)!

|

Customized Filter Mesh Fabrications & Strainers Capabilities

We can customize precision filter screens according to your required filtration accuracy. Chen Cai Metal Manufacture Co. can provide micron-level filtration to industrial large particle filters. We support OEM & ODM and various other material alloy processing customization.

How to Select the Suitable Filter Mesh Strainer Type and Materials for your demand of Applications:

Considering the flowability, micron level, mechanical load and compatibility of the filter material, the correct filter can be selected. The following are application examples:

Explore the Types of Filter Mesh Strainer Capabilities we offer:

Provides filter mesh components with diverse structures, suitable for water filtration, seawater filtration, pump protection and fine sand screening.

1、Seawater Strainer Basket: Mainly used in the ocean and near the seaside environment, because it is necessary to consider the corrosion resistance of seawater and large-capacity filtration.

2、Y Strainer Filter Mesh: This is a compact, in-line filter mesh design, which is used to clear debris in the pipeline through the Y type design, and to protect springs and valves, etc.

3、Screen Filter Mesh: This is mostly flat or curved design, mainly used for filtration in liquid or air systems.

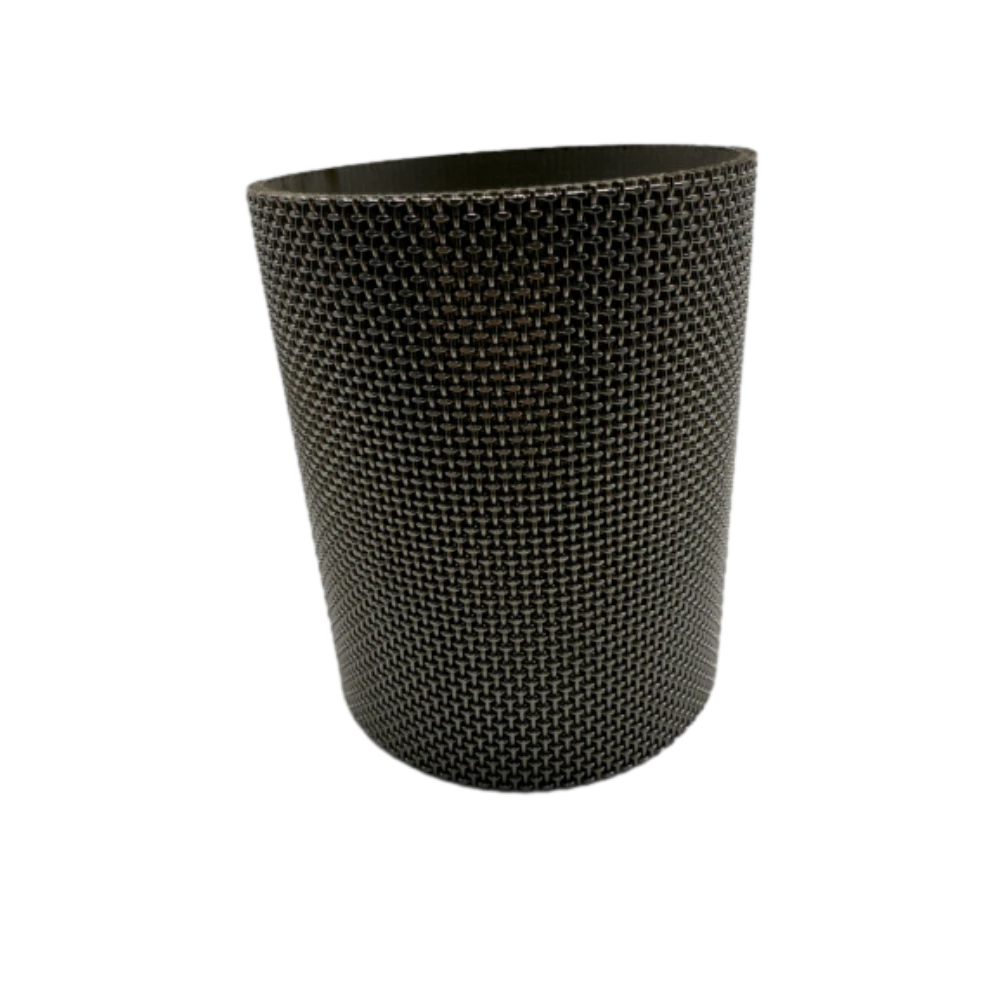

4、Wire Mesh Filter Tube: This is a cylindrical design, with a multi-layer filter mesh design, mainly used for continuous flow filtration in water, oil, and gas pipes.

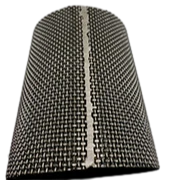

5、Conical Strainer/Cone Filter: A temporary or permanent conical filter made by combining a woven mesh and a punched mesh. Most of them are used before the pipeline is started or flushed.

Filter Mesh Materials and Construction Techniques

The material and structure of the filter mesh determine the weather resistance, corrosion resistance, temperature resistance and filtration accuracy of the filter.

1、Sintered Stainless Steel Filter: The multi-layer metal mesh is bonded together by a sintering machine to form a screen filter mesh with high rigidity and precise micron filtration.

2、Stainless Steel Knitted Wire Mesh: This product is made by interweaving annular filter mesh, with high elasticity and surface area on the surface, mainly used for gas-liquid separation. Also called gas-liquid filter mesh

3、Welded Mesh Filter Elements: The perforated metal tube or expanded metal tube is welded with the woven wire mesh to form a high-performance screen filter mesh strainer, the main purpose of which is to achieve structural strength.

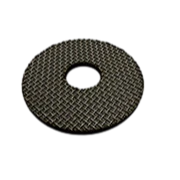

4、Extruder Screen & Drum Filter: The metal mesh is welded into a disc or cylinder for plastic extrusion and filtration equipment.

5、Wedge Wire Filter: The V-shaped metal mesh is welded on the metal support rod, the main purpose of which is to achieve long-term use and repeated cleaning.

Micron Filter Mesh Selection from 10μm to 500μm

Different particle sizes provide different filtration options.

1、100 Micron Filter Mesh: Mainly used for coarse particle filtration of water, oil and hydraulic oil.

2、Inlet Filter & Pump Strainer: Inlet filter is installed at the inlet of pump or valve to filter impurities, prevent clogging and reduce wear.

3、Wire Mesh Filter Disc & Screen Gasket: Mainly used for filtration inside valves, nozzles or gaskets to achieve sealed filtration.

4、Stainless Steel Basket: Designed in the shape of a basket, the sturdy and durable structure is reusable and can filter different micron contaminants.

Application Areas of Filter Mesh Strainers

Ensure the reliable operation and filtration efficiency of mechanical equipment, filter mesh covers the needs of a wide range of industries

1、Water Treatment Systems: Filter and desalinate seawater, drinking water and irrigation systems.

2、Pump and HVAC Systems: Protect equipment and machinery from being damaged by impurities, thereby greatly effectively filtering out impurities.

3、Air Filtration & Ventilation: Stainless Steel can filter air and resist the high temperature and humidity in industrial air.

4、Oil, Gas & Petrochemical: Sintered Mesh and Conical Strainer Mesh are often used for corrosive pipeline filtration under high pressure.

Frequently Asked Questions About Mesh Filters

1、What is a 100 micron filter mesh used for?

100 micron filter mesh can filter particles as small as 0.1mm and is suitable for general water and oil filtration.

2、Can you customize a stainless steel filter basket?

Sure, we provide customized services, customized shapes: round, square, conical, etc., as well as micron-level filtration.

3、How do sintered filters differ from woven ones?

Sintered filters are usually made of 5 layers of sintered bonding, using a hot melt process, which is durable; while Woven ones have good flexibility, but poor structural rigidity.

4、What’s the benefit of wedge wire vs. perforated screen?

Wedge wire filter has a higher open surface connection and overall structural performance, which is very suitable for continuous flow filtration of heavy objects.

![$item[titel] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)