11111

In industrial and architectural contexts, expanded metal materials have emerged as versatile solutions for diverse needs. The stainless steel expanded metal mesh, expansion metal, heavy duty expanded metal, expanded aluminum mesh, and expanded mesh sheets offer unique combinations of strength, durability, and functionality. This exploration delves into their roles across various sectors and the factors that make them indispensable.

The Versatility of Stainless Steel Expanded Metal Mesh

Industries often turn to stainless steel expanded metal mesh for its corrosion resistance and structural integrity. In marine environments or chemical processing plants, this mesh is used for walkways, platforms, and fencing, as its stainless steel composition withstands harsh conditions. For example, in wastewater treatment facilities, stainless steel expanded metal mesh filters and supports heavy loads while resisting rust from constant moisture exposure. Its open design also allows for efficient drainage and ventilation, making it suitable for flooring in areas prone to liquid accumulation.

Understanding Expansion Metal and Its Core Uses

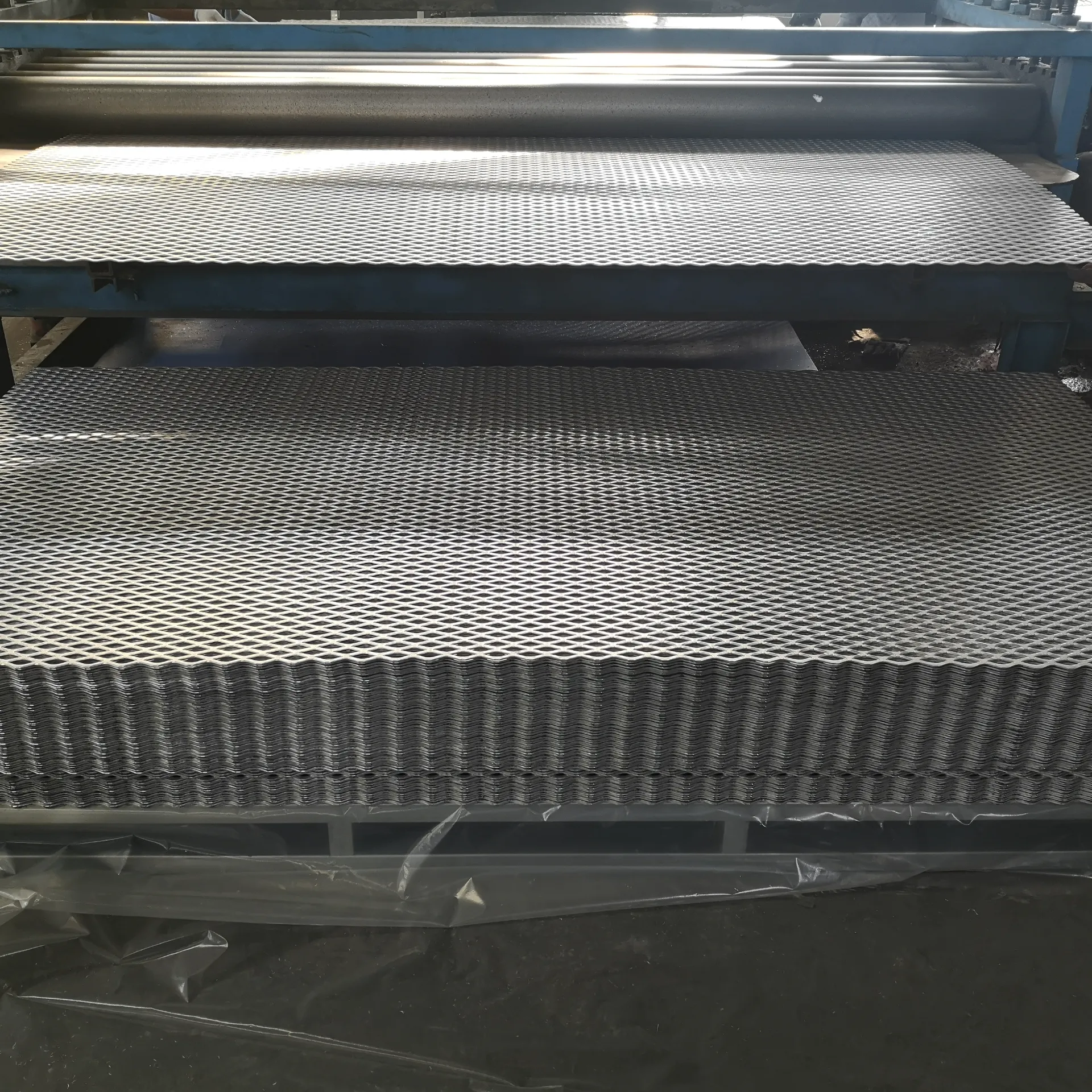

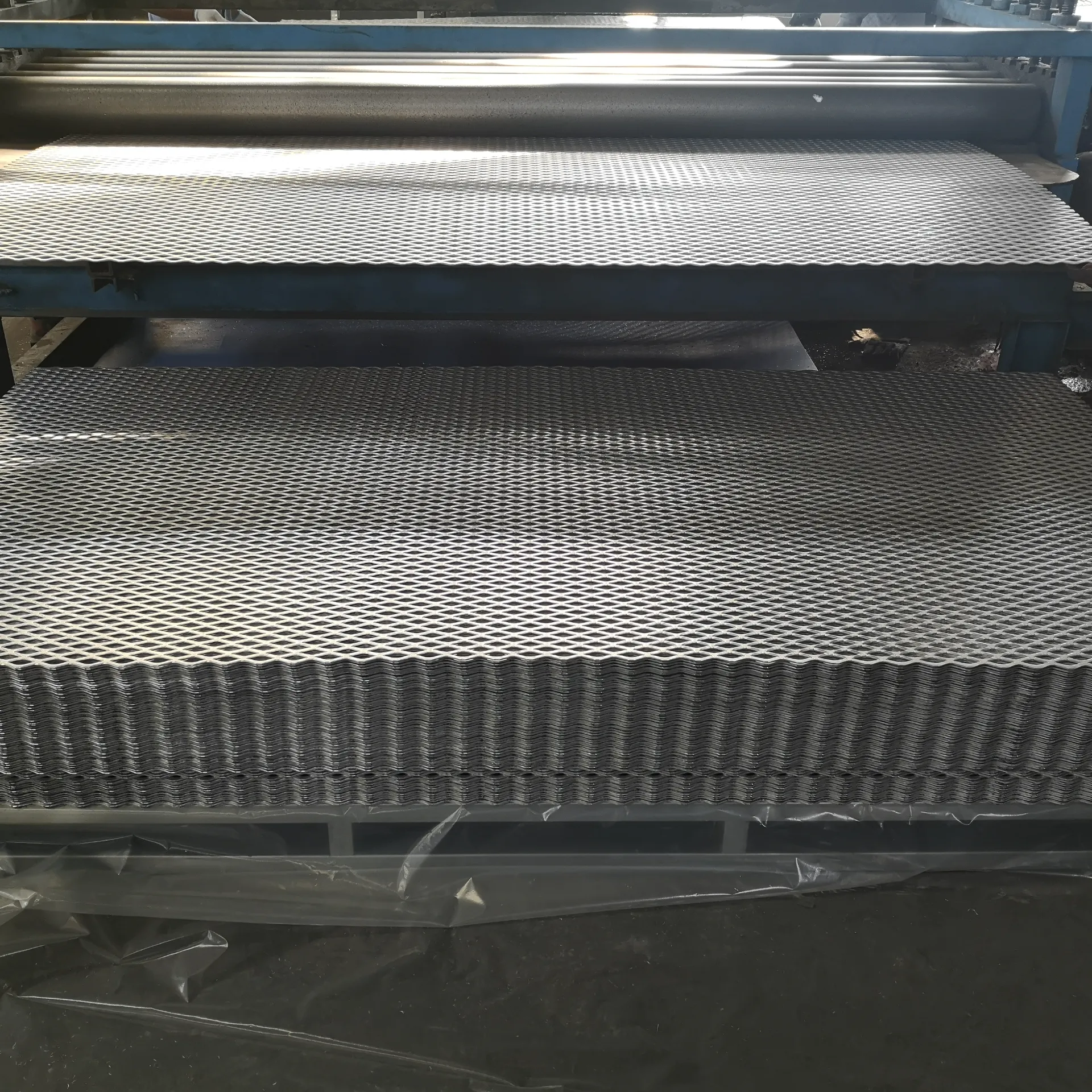

Expansion metal, a category that includes various metal types expanded into lattice patterns, is valued for its cost - effectiveness and adaptability. In construction, it serves as reinforcement for concrete or plaster, providing stability without adding excessive weight. For instance, in wall partitions or ceiling systems, expansion metal sheets distribute stress evenly, preventing cracks. Its manufacturing process—where a metal sheet is slit and stretched to form diamond or rectangular openings—creates a strong, lightweight material ideal for both load - bearing and decorative applications.

Heavy Duty Expanded Metal: Built for Intense Applications

Heavy duty expanded metal is engineered to handle extreme loads and rigorous environments. In mining and heavy machinery industries, this type of metal is used for safety barriers, conveyor belts, and protective guards. Its thick gauge and robust structure make it capable of withstanding impacts, abrasions, and high - pressure conditions. For example, in quarry operations, heavy duty expanded metal screens separate aggregates of different sizes, enduring constant friction from heavy stones. Additionally, in industrial flooring for factories with heavy equipment, it provides a stable surface that resists deformation under continuous use.

The Lightweight Strength of Expanded Aluminum Mesh

Expanded aluminum mesh offers a balance of lightness and durability, making it popular in aerospace, automotive, and architectural fields. In aircraft interiors, this mesh is used for overhead compartments and ventilation panels, as its low weight contributes to fuel efficiency while maintaining strength. In building facades, expanded aluminum mesh creates decorative screens that allow natural light to filter through while providing privacy. Its corrosion resistance also makes it suitable for outdoor applications, such as garden fences or balcony railings, where it withstands weathering without rusting.

Expanded Mesh Sheets: Customizable Solutions for Diverse Needs

Expanded mesh sheets are available in various metals and patterns, offering flexibility for customization. In agricultural settings, these sheets are used as animal enclosures or ventilation panels in barns, with mesh sizes tailored to contain specific livestock. In art and design, artists use expanded mesh sheets to create sculptures or room dividers, leveraging the unique textures and light - filtering effects of different expansions. Manufacturers can also alter the sheet thickness, opening size, and metal type to meet precise project requirements, from lightweight decorative elements to heavy - duty industrial components.

FAQ: Key Insights on Expanded Metal Products

What factors should be considered when selecting expanded mesh sheets?

When choosing expanded mesh sheets, consider the application’s load requirements, environmental conditions (e.g., moisture, chemicals), and aesthetic needs. For outdoor use, prioritize corrosion - resistant materials like stainless steel or aluminum. For heavy loads, opt for heavy duty expanded metal with a thicker gauge. Additionally, the mesh pattern (diamond, rectangular) and opening size affect functionality, such as airflow or visibility.

How does stainless steel expanded metal mesh differ from aluminum variants?

Stainless steel expanded metal mesh offers superior corrosion resistance and strength, making it ideal for harsh or high - load environments. Expanded aluminum mesh, while lighter and more cost - effective, is better suited for applications where weight reduction and moderate strength are priorities, such as architectural designs or automotive components.

Can heavy duty expanded metal be used for decorative purposes?

Yes, heavy duty expanded metal can serve decorative functions in addition to its industrial uses. Its robust structure can be incorporated into modern architectural designs, such as building facades or room partitions, where its unique texture and durability add visual interest. Powder coating or painting can further enhance its aesthetic appeal.

What maintenance is required for expanded metal products?

Maintenance varies by material. Stainless steel and aluminum expanded metal products typically require minimal upkeep, such as occasional cleaning with a mild detergent to remove debris. For steel variants in corrosive environments, inspect for rust and apply protective coatings as needed. Regularly check heavy duty expanded metal for signs of wear or damage in high - stress applications.

Are expanded metal products recyclable?

Yes, most expanded metal products, including stainless steel expanded metal mesh, expanded aluminum mesh, and steel - based expansion metal, are recyclable. This makes them a sustainable choice, as the metal can be melted down and reused, reducing environmental impact. Always check with local recycling facilities for specific guidelines.

![$item[titel] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)