11111

In the realm of industrial and architectural materials, expanded metal solutions have gained prominence for their durability, versatility, and unique structural properties. Key variants such as rubber coated expanded metal, expanded sheet metal 4x8, 1 2 expanded metal, expanded metal decking, and ss expanded metal cater to diverse needs across sectors like construction, manufacturing, and design. Each type offers distinct advantages, blending functionality with adaptability to meet specific project requirements.

Exploring the Versatility of Rubber Coated Expanded Metal

Rubber coated expanded metal combines the robustness of expanded metal with the protective benefits of a rubber layer. This hybrid material is often used in environments requiring both strength and resistance to corrosion, impact, or abrasion. For instance, in industrial settings, rubber coated expanded metal can line machinery guards or walkways, absorbing vibrations and reducing noise while preventing metal - on - metal contact. The rubber coating, typically made from materials like neoprene or EPDM, adds a layer of weather resistance, making it suitable for outdoor applications such as fencing or decorative screens. The coating also enhances grip, making it a preferred choice for stair treads or ramps where slip resistance is critical.

Understanding Dimensions and Sizing with Expanded Sheet Metal 4x8

Expanded sheet metal 4x8 refers to expanded metal panels measuring 4 feet by 8 feet, a standard size that balances practicality with ease of transportation and installation. This dimension is widely used in construction and fabrication projects, such as wall cladding, roof decking, or ventilation covers. The 4x8 size minimizes waste during cutting and allows for efficient coverage of large areas. For example, in commercial buildings, expanded sheet metal 4x8 can be installed as exterior facades, providing both aesthetic appeal and structural support. The sheets can be further customized through processes like punching, bending, or coating to meet specific design or functional needs.

The Significance of 1 2 Expanded Metal in Design and Function

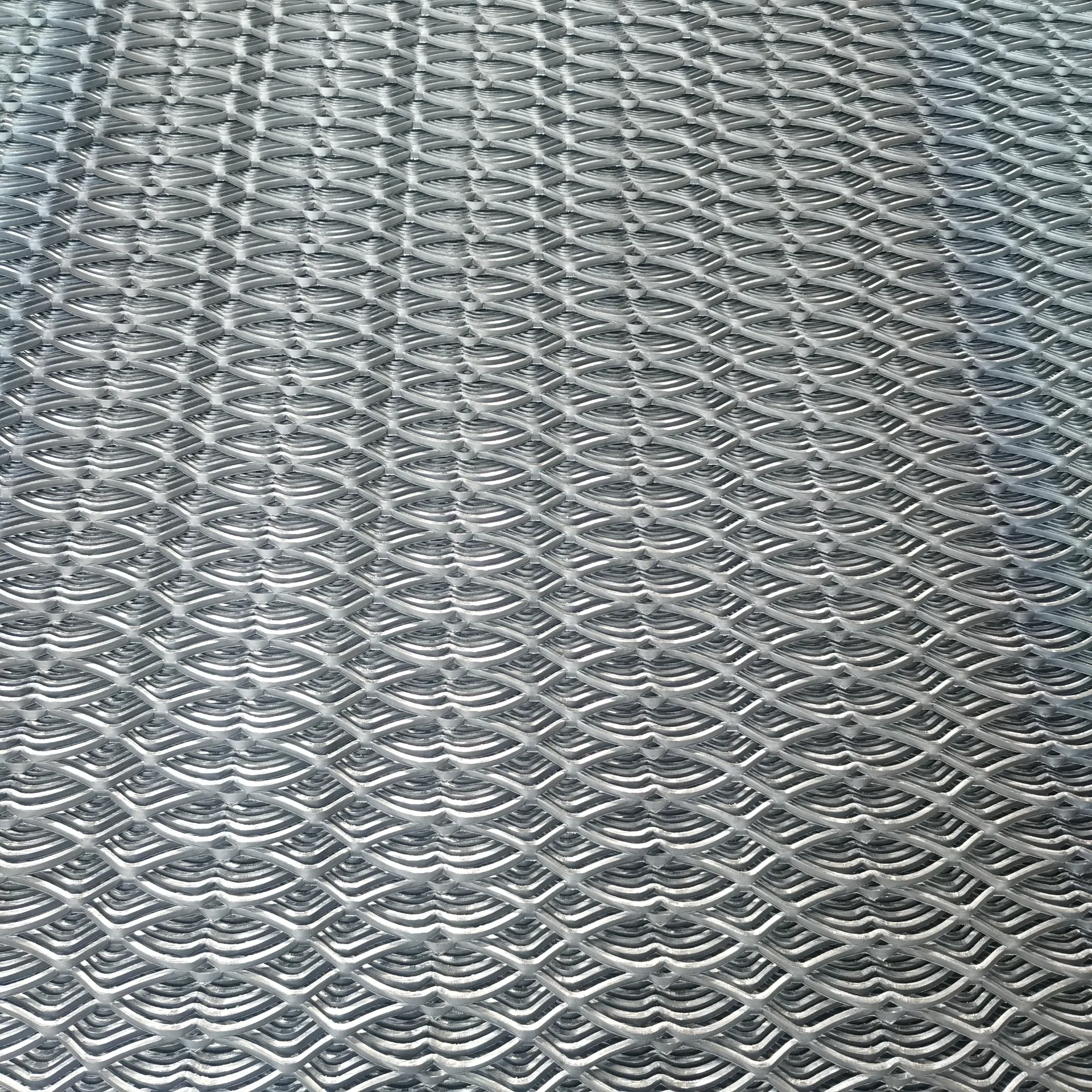

1 2 expanded metal—often referring to expanded metal with a 1/2 - inch mesh opening—offers a balance between openness and structural integrity. This mesh size is ideal for applications requiring moderate visibility and airflow while maintaining strength. In agricultural settings, 1 2 expanded metal is used for livestock fencing, allowing animals to be visible while preventing escape. In automotive applications, it can serve as radiator guards or engine bay screens, protecting components from debris while ensuring proper cooling. The 1/2 - inch openings also make this variant suitable for decorative purposes, such as room dividers or architectural screens, where a balance of privacy and light transmission is desired.

Examining Applications in Construction with Expanded Metal Decking

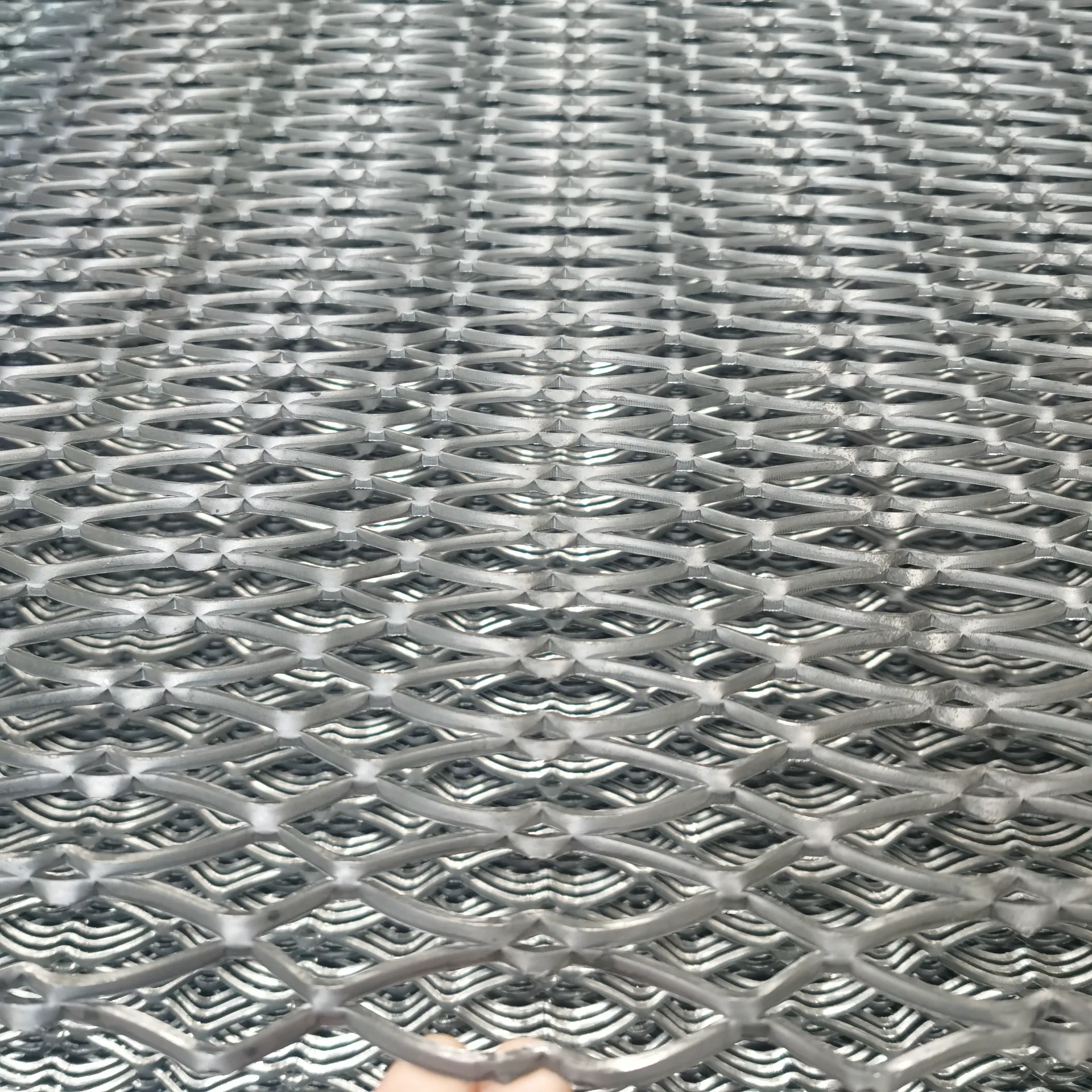

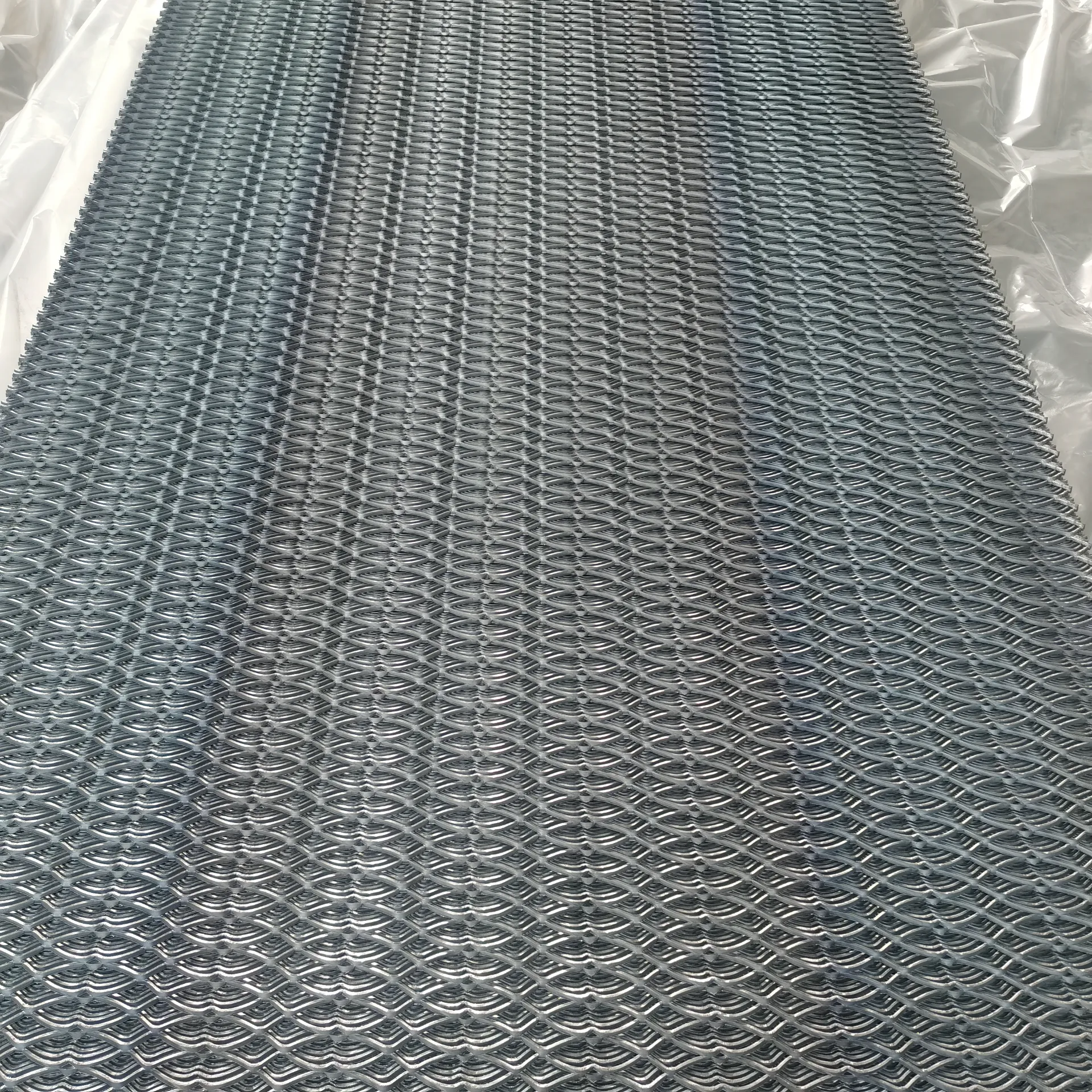

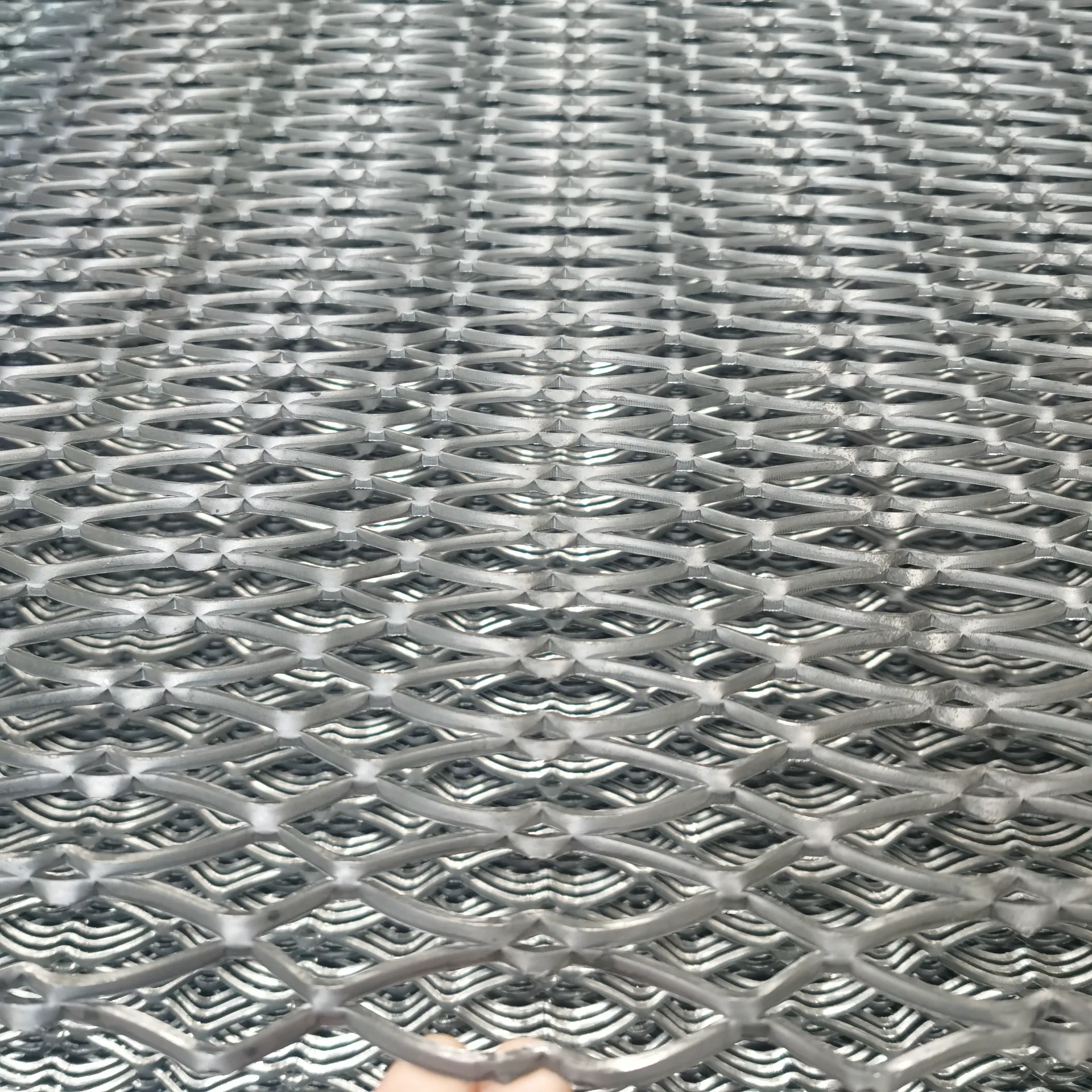

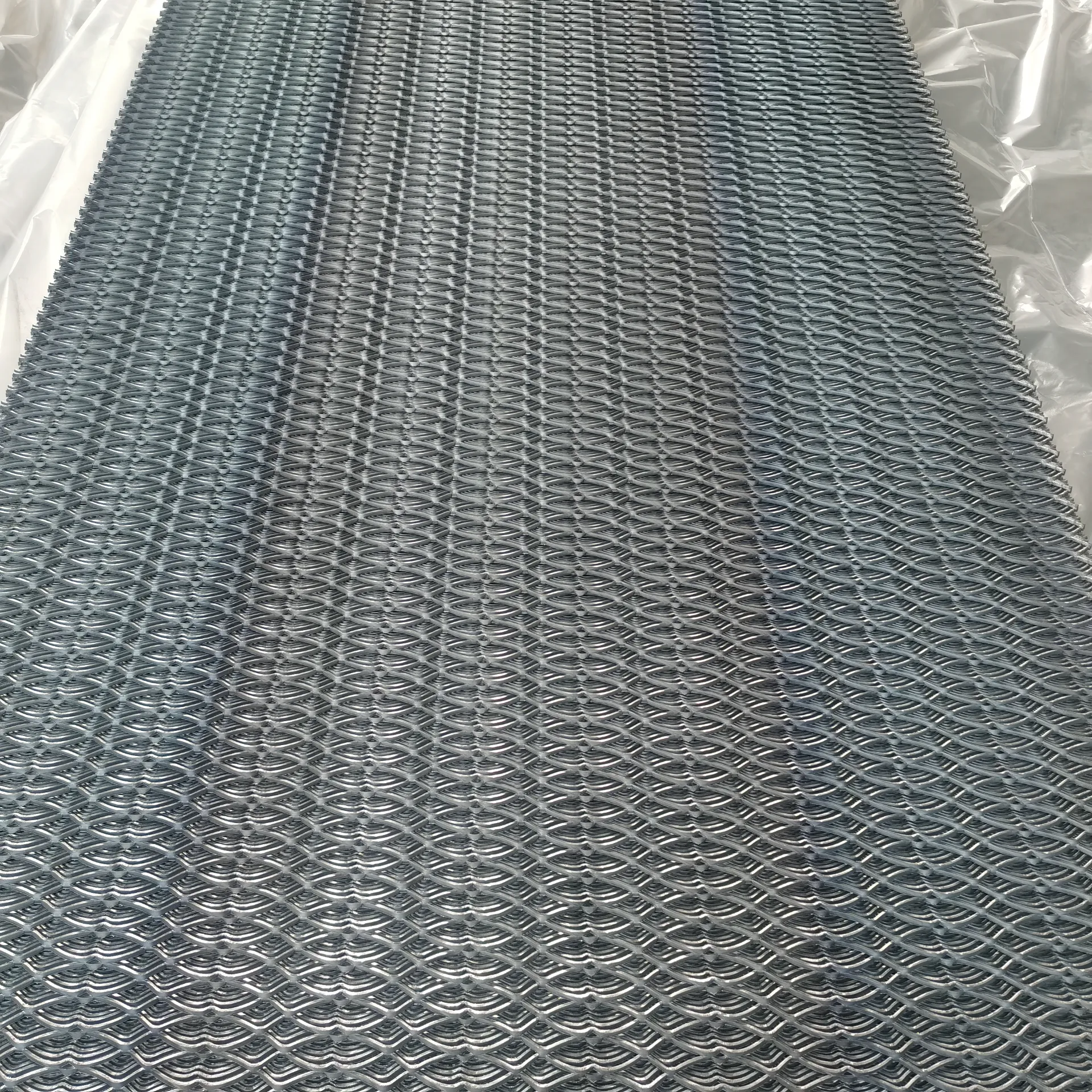

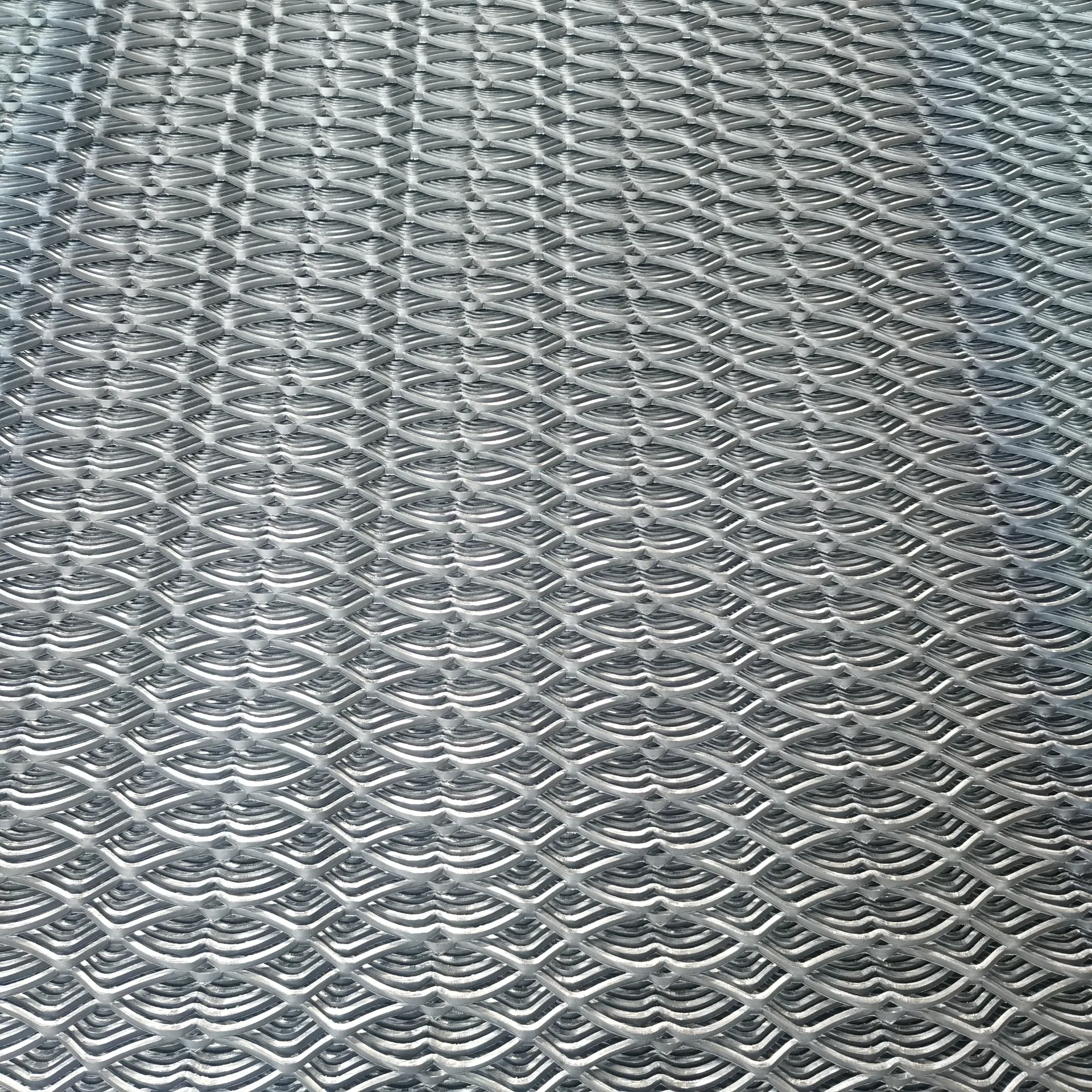

Expanded metal decking is a specialized form of expanded metal designed for load - bearing applications in construction. Typically used as flooring or roofing decks, this material features a raised pattern that enhances traction and drainage. In industrial warehouses or parking garages, expanded metal decking provides a durable surface that can withstand heavy foot or vehicle traffic while allowing water and debris to pass through. The decking’s open design also reduces weight compared to solid metal sheets, making it easier to install and transport. Additionally, its structural rigidity eliminates the need for additional support beams in some applications, streamlining construction processes.

The Advantages of SS Expanded Metal in Corrosive Environments

SS expanded metal—short for stainless steel expanded metal—stands out for its exceptional resistance to corrosion, rust, and chemical damage. This makes it indispensable in harsh environments such as marine settings, chemical plants, or food processing facilities. For example, in coastal areas, SS expanded metal can be used for seawall barriers or offshore platform walkways, enduring saltwater exposure without degradation. In food production lines, its non - porous surface and resistance to bacteria make it suitable for conveyor belts or safety guards. The inherent strength and longevity of stainless steel also reduce maintenance costs over time, making SS expanded metal a cost - effective choice for high - demand applications.

FAQ: Key Insights into Expanded Metal Products

How to select the right expanded metal for outdoor use?

For outdoor applications, prioritize materials like SS expanded metal or rubber coated expanded metal for their corrosion resistance. Consider factors such as weather conditions (e.g., humidity, salt exposure), load requirements, and aesthetic goals. A mesh size like 1 2 expanded metal may be suitable for airflow, while solid coatings add protection.

Can expanded sheet metal 4x8 be cut to smaller sizes?

Yes, expanded sheet metal 4x8 can be easily cut using tools like tin snips, saws, or plasma cutters to fit specific project dimensions. Always wear protective gear during cutting and ensure the edges are deburred to prevent injury.

What maintenance is required for rubber coated expanded metal?

Regularly inspect rubber coated expanded metal for signs of wear, such as peeling or cracking in the rubber layer. Clean with a mild detergent and water to remove debris, and avoid using abrasive cleaners that could damage the coating. Replace damaged sections promptly to maintain performance.

Is expanded metal decking suitable for residential use?

Yes, expanded metal decking can be used in residential settings for applications like balconies, terraces, or garden pathways. Its slip - resistant surface and modern aesthetic make it a practical choice, though ensure it meets local building codes for load capacity and safety.

How does ss expanded metal differ from galvanized expanded metal?

SS expanded metal offers superior corrosion resistance in extreme environments due to its chromium - nickel alloy composition. Galvanized expanded metal, coated with zinc, is more budget - friendly but less durable in highly corrosive conditions like marine or industrial zones.

![$item[titel] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)