11111

In the realm of industrial and architectural materials, expanded metal products have gained significant traction for their unique properties and wide - ranging applications. The versatility of materials like stainless steel expanded metal 4x8, expanded wire, brass expanded metal, stretch metal, and expanded mesh panels makes them indispensable in various sectors, from construction to manufacturing. This exploration delves into their characteristics, uses, and the factors that contribute to their popularity.

The Durability and Utility of Stainless Steel Expanded Metal 4x8

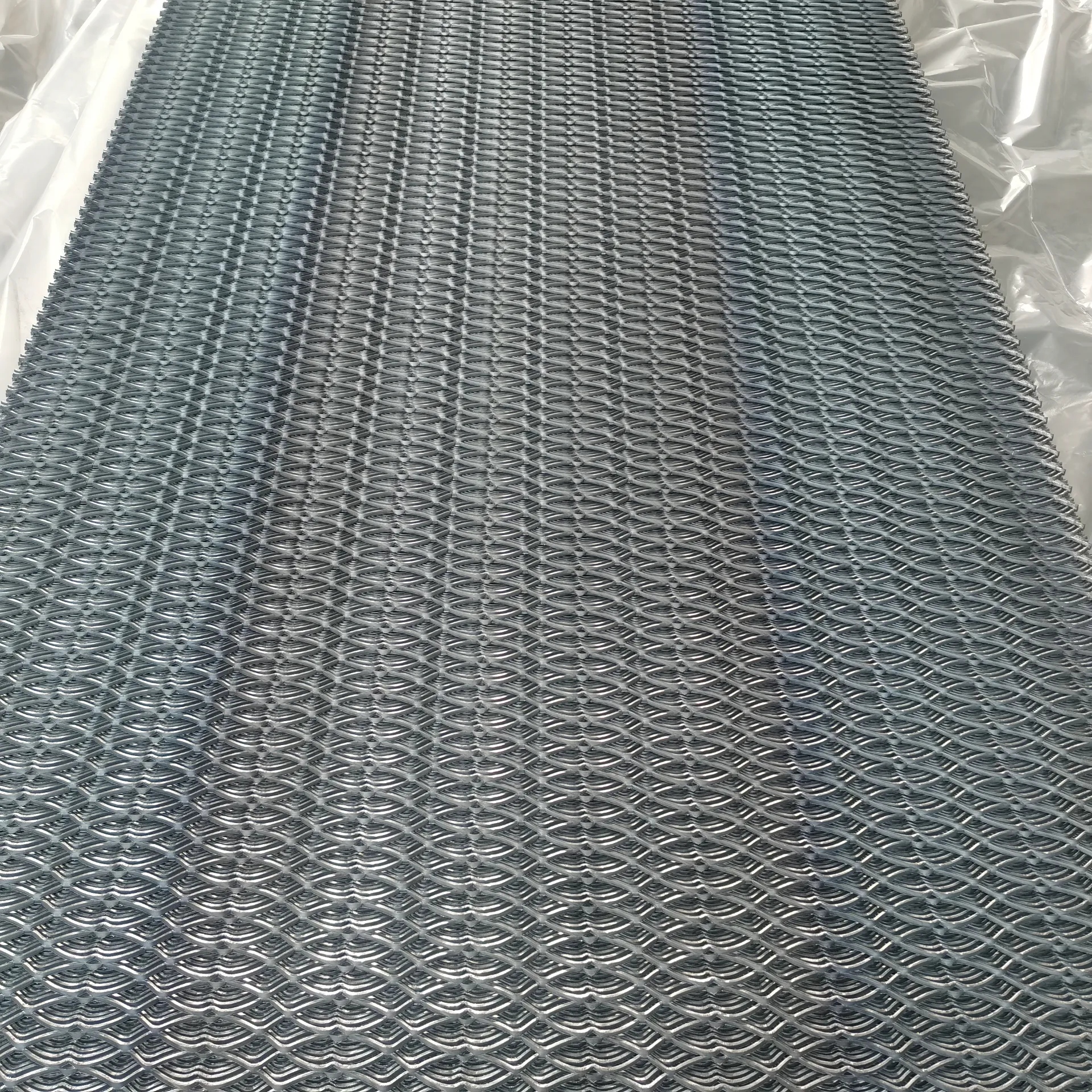

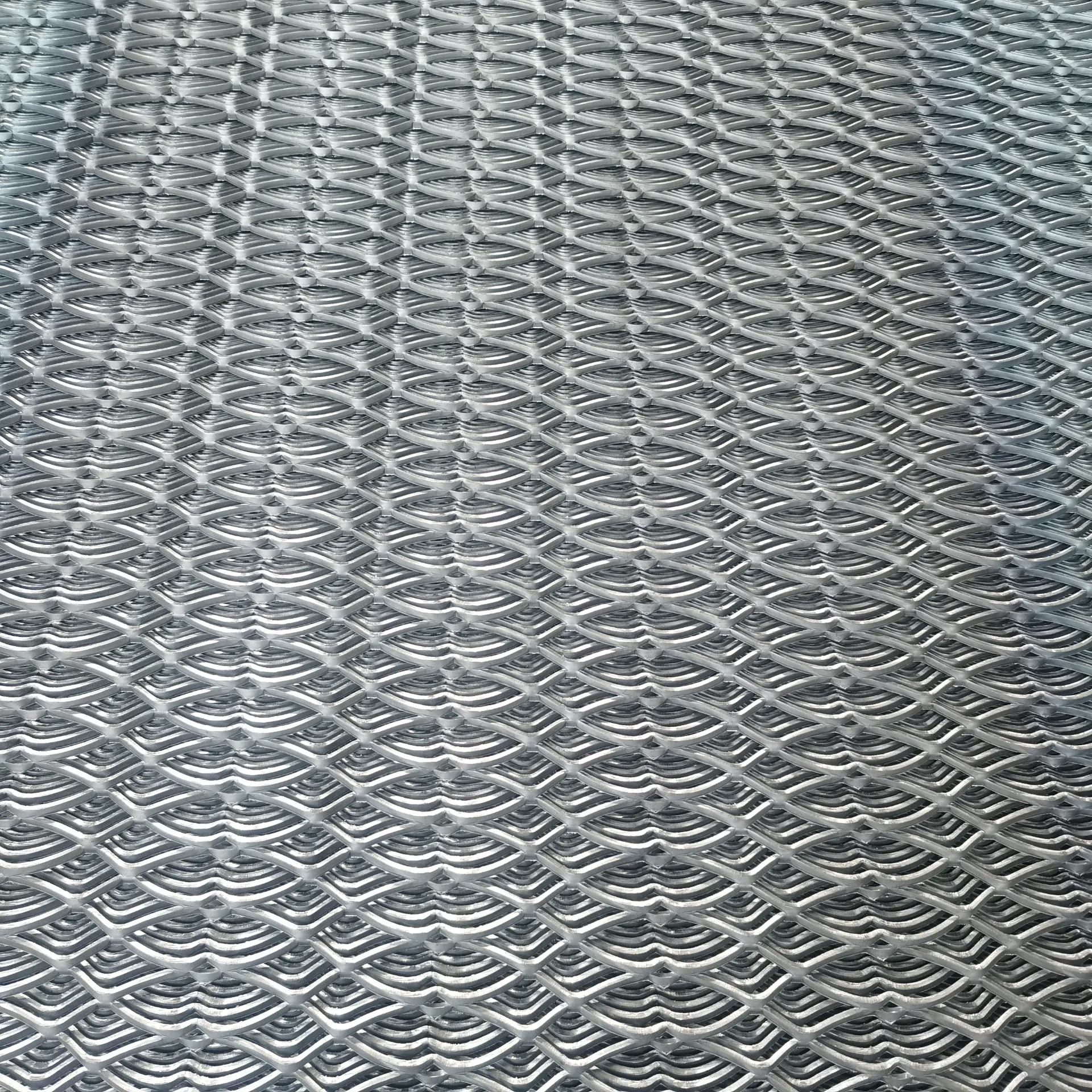

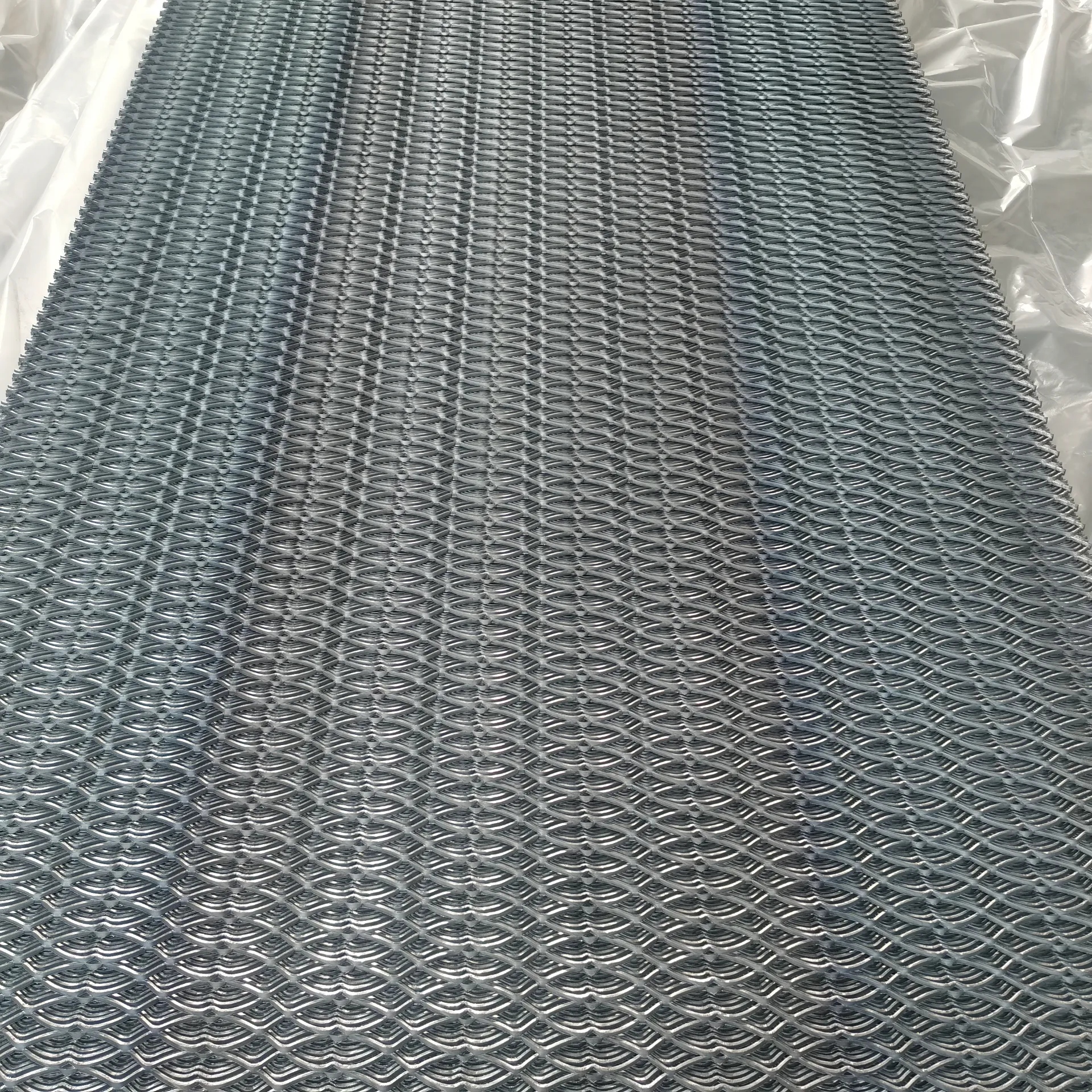

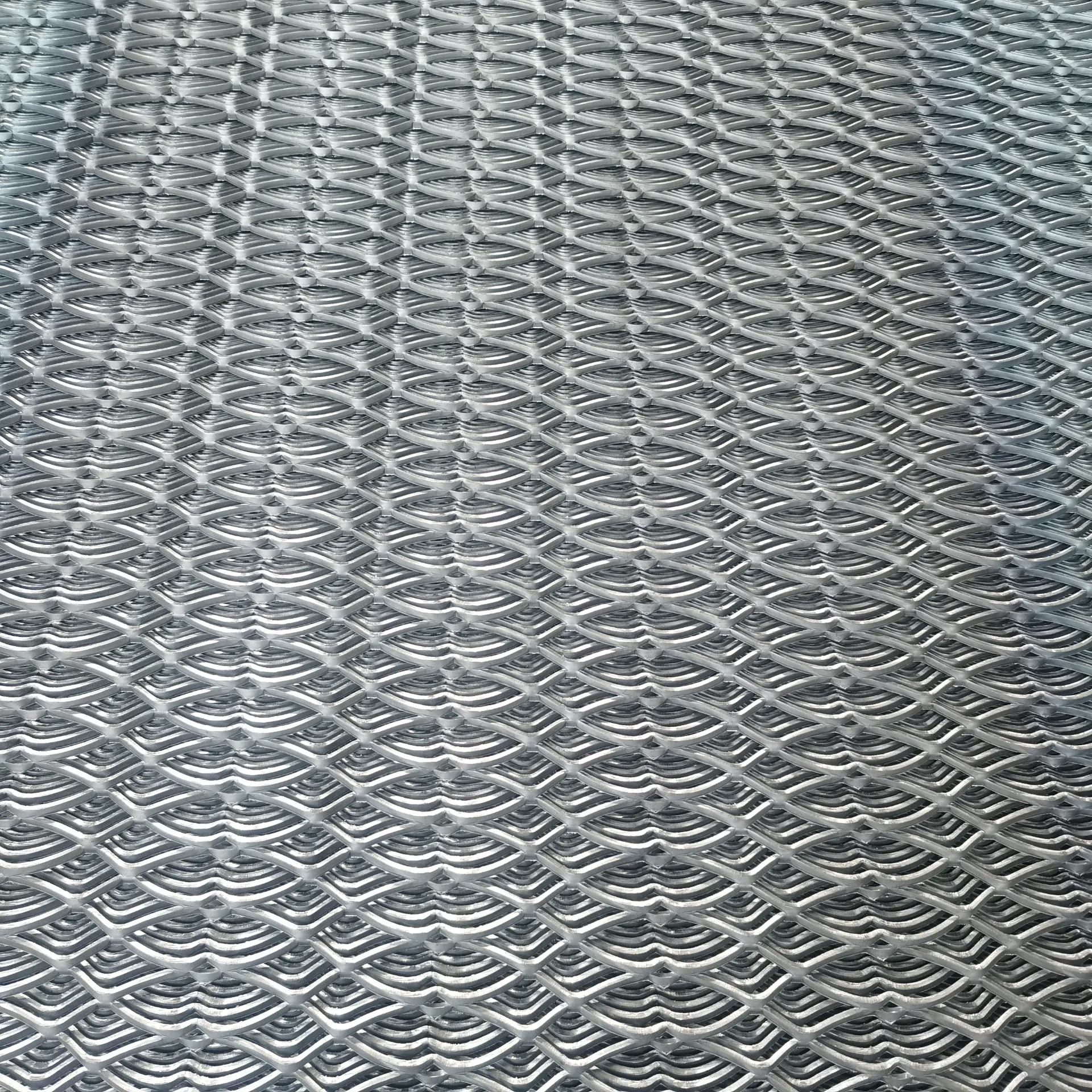

For industrial applications, stainless steel expanded metal 4x8 sheets are highly preferred. Their corrosion resistance and high tensile strength make them ideal for outdoor fencing, machine guards, and walkways in harsh environments. The 4x8 size offers a balanced surface area, providing optimal coverage while remaining easy to handle during installation. In food processing plants, these sheets are used as drain covers or ventilation panels, where resistance to moisture and chemicals is crucial. The open design of stainless steel expanded metal 4x8 allows for efficient airflow and liquid drainage, enhancing functionality in demanding settings.

The Versatility of Expanded Wire in Diverse Projects

Another variant, expanded wire, offers a balance of flexibility and strength. Made by slitting and stretching a metal sheet, this material features a uniform pattern of diamond - shaped openings. In agriculture, expanded wire is commonly used for livestock fencing, as its design prevents animals from getting stuck while providing a secure barrier. In the automotive industry, it serves as a component in air filters and radiator guards, where its mesh structure traps debris without restricting airflow. The affordability and ease of customization of expanded wire make it a popular choice for both small - scale DIY projects and large - scale industrial applications.

Brass Expanded Metal for Aesthetic and Functional Purposes

Brass expanded metal finds its niche in decorative and architectural projects. The warm, golden hue of brass adds an aesthetic appeal, making it suitable for interior design elements like room dividers, ceiling panels, and staircase railings. Beyond its visual appeal, brass offers moderate corrosion resistance, making it suitable for indoor and low - humidity outdoor settings. In musical instruments, such as speaker grilles, brass expanded metal provides a combination of sound diffusion and structural support. Its malleability allows for intricate designs, enabling designers to create unique patterns that blend functionality with style.

The Structural Advantages of Stretch Metal

Stretch metal, produced through a specialized stretching process, boasts unique structural properties. This method elongates the metal, creating a network of interconnected strands that offer high tensile strength with minimal material usage. In aerospace applications, stretch metal is used in lightweight panels for aircraft interiors, where reducing weight without compromising strength is critical. In the energy sector, it serves as a component in heat exchangers, allowing for efficient heat transfer while maintaining structural integrity. The ability to tailor the stretch ratio and opening size makes stretch metal adaptable to specific performance requirements.

The Practical Applications of Expanded Mesh Panels

Expanded mesh panels are versatile components used in various industries. In construction, they are employed as concrete reinforcement, providing stability to walls and floors while reducing the need for traditional rebar. In (warehousing), these panels serve as shelving units or partition walls, offering visibility and ventilation while maximizing storage space. For security applications, expanded mesh panels can be combined with other materials to create robust barriers that deter unauthorized access. Their modular design allows for easy installation and modification, making them a cost - effective solution for many projects.

FAQ: Key Considerations for Expanded Metal Products

Material Selection for Expanded Metal Products

When choosing between materials like stainless steel expanded metal 4x8, brass expanded metal, or expanded wire, consider the environment and purpose. Stainless steel is ideal for outdoor or corrosive settings, brass for decorative indoor use, and expanded wire for general - purpose applications requiring flexibility. Evaluate factors such as moisture exposure, load-bearing needs, and aesthetic requirements to select the most suitable material.

Maintenance Tips for Longevity

To maintain the performance of expanded metal products, regular cleaning is recommended. For stainless steel and brass, wipe with a mild detergent and water to remove dirt and prevent corrosion. Avoid using abrasive cleaners that could scratch the surface. Inspect stretch metal or expanded mesh panels for signs of wear, such as loose strands or bent sections, and repair or replace as needed to ensure continued functionality.

Customization Options for Unique Projects

Most expanded metal products, including stainless steel expanded metal 4x8 and brass expanded metal, can be customized in terms of sheet size, opening pattern, and thickness. Manufacturers often offer services like punching, cutting, and bending to meet specific project requirements. Whether for a custom fence design or a specialized industrial component, discussing your needs with suppliers can lead to tailored solutions.

Cost Comparison Between Materials

The cost of expanded metal products varies by material . Stainless steel tends to be more expensive than brass or expanded wire due to its superior corrosion resistance and strength. Brass is often priced higher than steel for decorative applications. Expanded mesh panels and stretch metal costs depend on factors like material type, sheet size, and production complexity. Comparing quotes from suppliers can help balance cost and performance for your project.

Installation Best Practices

Foar stainless steel expanded metal 4x8 or expanded mesh panels, ensure proper anchoring to the substrate. Use corrosion-resistant fasteners, such as stainless steel screws, to secure the panels. When installing in high - wind areas, reinforce the framework to prevent movement. For decorative applications like brass expanded metal, focus on precise cutting and fitting to achieve a seamless aesthetic. Always follow manufacturer guidelines for safe and effective installation.

![$item[titel] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)