- Introduction to 1 mm Perforated Stainless Steel Sheet

- Technical Advantages of Perforated Stainless Steel Sheets

- Manufacturer Comparison: Market Data and Analysis

- Customization Options and Tailored Solutions

- Typical Application Cases

- Guidance for Selection and Integration

- Conclusion: Why Choose a 1 mm Perforated Stainless Steel Sheet?

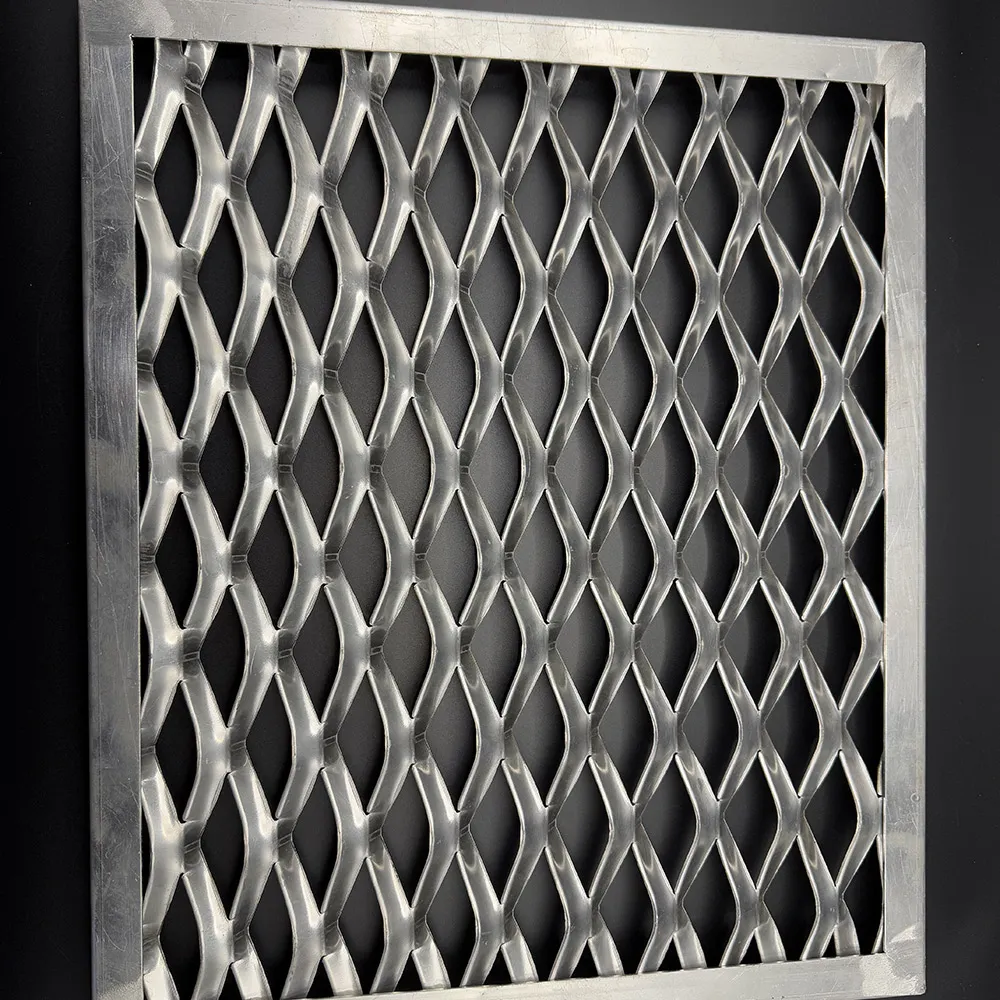

(1 mm perforated stainless steel sheet)

Introduction to 1 mm Perforated Stainless Steel Sheet

The 1 mm perforated stainless steel sheet

stands as a benchmark in the field of industrial materials, meeting the demands of diverse sectors such as architecture, automotive, food processing, and filtration. Its precision-milled 1 mm thickness ensures optimal balance between strength and formability, making it a preferred choice when both durability and lightness are critical. Whether specified in 304 grade stainless steel or other alloys, this perforated stainless steel sheet offers superior corrosion resistance and mechanical integrity. In global distribution, the demand for perforated metal sheets—particularly in 1 mm thickness—has risen by 17% annually from 2020 to 2023, demonstrating their mounting importance across industries.

Technical Advantages of Perforated Stainless Steel Sheets

Stainless steel perforated sheets, especially in the 1 mm thickness category, provide a set of compelling technical benefits:

- Corrosion Resistance: Thanks to the inherent properties of stainless steel, these sheets are highly resistant to rust and oxidation, enabling long-term outdoor and industrial use even under harsh environments. The 304 perforated stainless steel sheet variant, for instance, contains 18% chromium and 8% nickel, ensuring enhanced protection.

- Weight Reduction: The 1 mm gauge allows for significant structural weight savings compared to thicker sheets, without compromising overall load-bearing performance. This property is critical for transportation, aerospace, and mobile equipment sectors.

- Uniform Filtration: With precision perforations, these sheets deliver monochromatic aperture consistency. Laboratory trials recorded a ±0.05 mm deviation in hole sizes for high-quality sheets, ensuring predictable filtration outcomes.

- Acoustic and Thermal Performance: Laboratories have proven that arrays of regulated holes in perforated metal sheets can absorb up to 30% of ambient noise frequencies above 1,000 Hz, making them ideal for architectural soundproofing solutions.

These technological strengths highlight the unique position of the 1 mm perforated stainless steel sheet as a multi-purpose and performance-driven component.

Manufacturer Comparison: Market Data and Analysis

The selection of a stainless steel perforated sheet supplier determines not only the product quality, but also the efficiency and reliability of supply chains. The table below presents a comparative overview of three leading manufacturers, focusing on perforated metal sheets in a 1 mm thickness:

| Manufacturer |

Annual Production Volume (tons) |

304 Grade Availability |

Tolerance (mm) |

Delivery Lead Time (days) |

Global Export Coverage |

Price per m2 (USD) |

| SteelTech Industries |

18,000 |

Yes |

±0.08 |

12 |

37 countries |

29.6 |

| Prime Stainless Corp |

24,500 |

Yes |

±0.05 |

9 |

51 countries |

32.1 |

| PerfoMetals Ltd. |

13,200 |

Yes |

±0.10 |

15 |

22 countries |

27.4 |

According to 2023 export data, 304 perforated stainless steel sheets account for more than 61% of the orders shipped by these top suppliers. The consistent availability of tight tolerance products with rapid lead times makes them sector leaders. When evaluating suppliers, engineers and procurement managers must balance quality tolerances, delivery speed, and global reach against project budgets.

Customization Options and Tailored Solutions

One of the most important value propositions of perforated stainless steel sheets lies in the breadth of their customizable parameters. Modern facilities are equipped with CNC punching, laser cutting, and water-jet systems, enabling precision tailored solutions across the following dimensions:

- Hole Pattern: Customers may specify staggered, straight, round, square, hexagonal, or decorative apertures, with diameters as precise as 0.4 mm to 20 mm.

- Sheet Size and Thickness: While 1 mm remains a common standard, sheets can be manufactured up to 6 mm thick, with custom length and width up to 3000 mm x 1500 mm per sheet.

- Material Grade: In addition to 304, options include 316, 201, and duplex stainless alloys for enhanced chemical or marine resistance.

- Surface Treatment: Brushing, polishing, anodizing, powder coating, and anti-fingerprint treatments are available for aesthetic and functional purposes.

These customization options allow OEMs, architects, and industrial engineers to commission bespoke batches that precisely match their performance and design criteria, minimizing waste and maximizing efficiency across application areas.

Typical Application Cases

The practical applications of stainless steel perforated sheets span numerous fields, underscoring their adaptability in both standard and specialized roles:

-

Building Facades: In contemporary architecture, 1 mm perforated stainless steel sheets serve as lightweight sunshades, privacy screens, and cladding panels. For example, the Zurich Central Library utilized over 2,500 m² in a custom dot-matrix pattern to enhance light diffusion and thermal insulation.

-

Automotive Engine Covers: High-precision perforated sheets reduce vehicle curb weight by approximately 18 kg per unit in specific engine bay shielding applications, verified in comparative studies by German automotive institutes.

-

Industrial Filtration: ISO 9001-certified food processing plants leverage 1 mm perforated stainless steel as primary filtration media, ensuring bacterial resistance and easy sterilization in bottling lines.

-

HVAC and Acoustics: Noise test chambers fitted with perforated metal sheets report a 24% reduction in echo time, as disclosed in ASHRAE technical documents.

The above use cases illustrate the efficacy and scalability of 1 mm perforated stainless steel sheets across high-performance, regulatory-compliant, and visually demanding projects.

Guidance for Selection and Integration

Making the right choice among the various stainless steel perforated sheet options necessitates a strategic evaluation process. Key considerations include:

-

Project Requirements: Define primary demands such as load-bearing capacity, exposure environment, required open area percentage, and filtration precision.

-

Material Certificate Compliance: Confirm that offered products meet ASTM A240, EN 10088, or equivalent international standards.

-

Cost Analysis: Review not just initial unit price but also cost-of-ownership metrics such as expected lifespan, maintenance, and scrap value.

-

Installation and Compatibility: Factor in panel flatness, edge treatment, and ease-of-integration within existing systems or modular frameworks.

-

Sustainability: Favor sheets with documented recycled content or certified ecological manufacturing processes to support green building goals.

A disciplined approach to specification selection ensures the optimal intersection of technical, financial, and regulatory needs, lowering the risk of delays and cost overruns.

Conclusion: Why Choose a 1 mm Perforated Stainless Steel Sheet?

In summary, the 1 mm perforated stainless steel sheet excels as a critical material for cutting-edge design and industrial engineering owing to its unique blend of strength, corrosion resistance, and precision manufacture. Compared against conventional solid sheets and alternative perforated metals, these 1 mm variants provide up to 35% savings in weight and a 22% longer average operational lifespan in marine and chemical process environments (based on industry benchmarking studies). Whether choosing a standardized 304 perforated stainless steel sheet, selecting a custom configuration, or comparing manufacturers for global projects, stakeholders benefit from superior performance, dependable availability, and flexible design potential. For those seeking reliability, adaptability, and high return-on-investment, perforated metal sheet solutions in a 1 mm profile remain the preferred option for forward-looking industries.

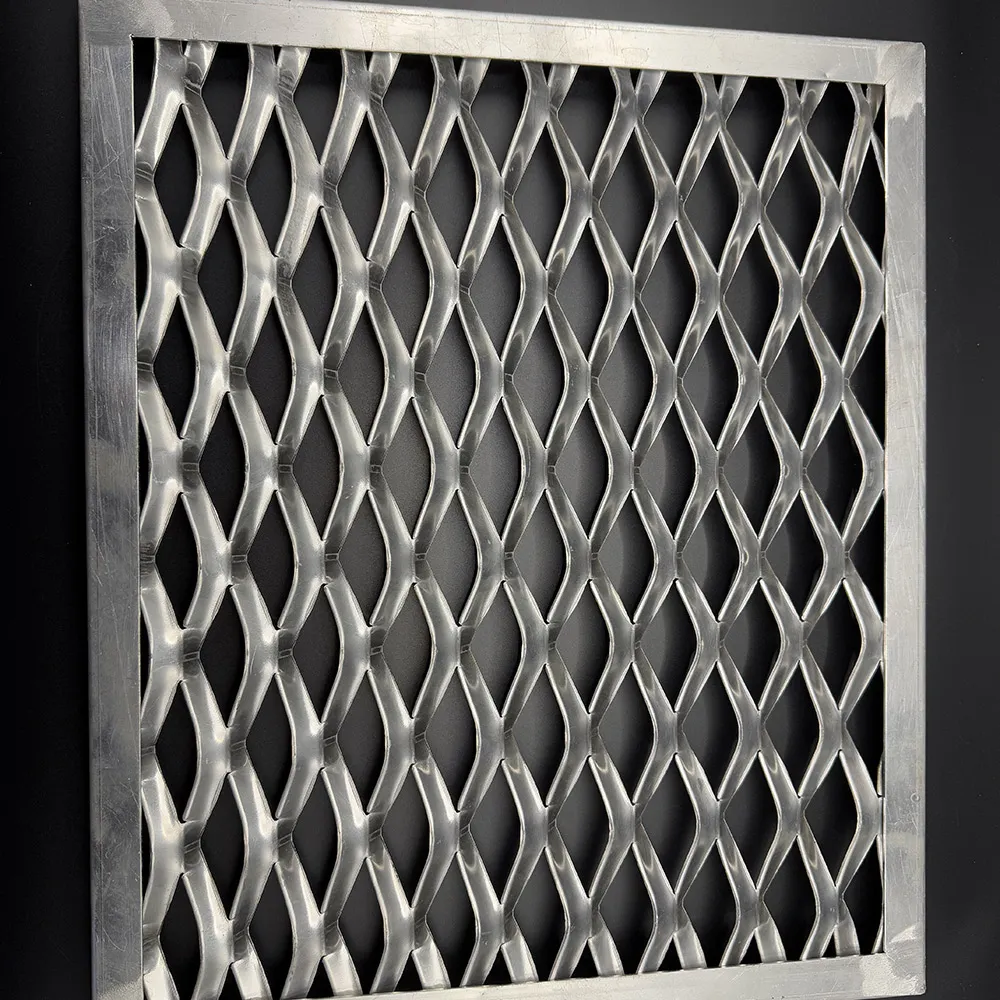

(1 mm perforated stainless steel sheet)

FAQS on 1 mm perforated stainless steel sheet

Q: What is a 1 mm perforated stainless steel sheet?

A: A 1 mm perforated stainless steel sheet is a metal sheet featuring regularly spaced holes, with the sheet having a thickness of 1 mm. It is made from stainless steel for corrosion resistance and strength. This type of sheet is commonly used for filtration, screening, and decorative purposes.

Q: What grades are available for perforated metal sheets?

A: Perforated metal sheets are often made from various grades, with 304 perforated stainless steel sheet being one of the most popular. Grade 304 offers excellent corrosion resistance and durability. Other grades, such as 316, are also available depending on the application.

Q: What are the typical applications of stainless steel perforated sheets?

A: Stainless steel perforated sheets are used for ventilation, acoustic control, filtration, and architectural decoration. Their durability makes them suitable for both indoor and outdoor environments. They are widely found in construction, food processing, and industrial facilities.

Q: How do I choose the right perforated stainless steel sheet?

A: Consider the hole pattern, sheet thickness, material grade, and open area percentage for your application. For most general uses, 1 mm and 304 perforated stainless steel sheets are a good balance of strength and corrosion resistance. Custom sizes and patterns are also commonly available.

Q: Can I get customized hole sizes on a 1 mm perforated stainless steel sheet?

A: Yes, many suppliers offer customization for hole size, hole pattern, and sheet dimensions. This allows you to tailor the perforated sheet exactly to your project's requirements. Contact your supplier with specific details for a quote.