(16 gauge perforated sheet metal)

Understanding gauge thickness is fundamental when selecting perforated sheet metal. The 16 gauge designation represents a thickness of 0.0598 inches (1.52 mm), positioning it between lighter 18 gauge materials and heavier 14 gauge alternatives. This specific thickness delivers an optimal balance of structural integrity and material economy for industrial applications.

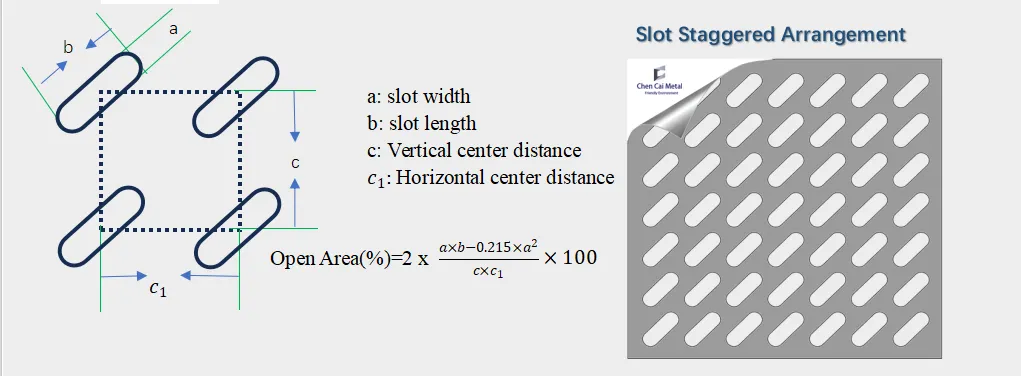

Perforation patterns significantly influence functional performance with common configurations including round holes (60% open area), staggered slots (45-50% open area), and custom designs tailored to specific flow requirements. Hole diameters typically range from 1/16" to 2", with precision tolerances maintained at ±0.005". Manufacturers control pattern consistency using CNC punching technology that achieves positional accuracy within 0.001" across production runs.

16 gauge perforated stainless steel sheet delivers exceptional corrosion resistance due to the chromium oxide layer that forms naturally on its surface. Austenitic grades like 304 and 316L provide tensile strength between 70-85 ksi while maintaining elongation properties of 40-50%, allowing significant forming capability without cracking. The material's passive layer demonstrates self-repairing qualities when damaged, maintaining integrity in chloride-rich environments.

Thermal properties include maximum operating temperatures of 1600°F (870°C) for continuous exposure with thermal expansion coefficients of 9.6 µin/in-°F. Electrical conductivity ranges between 2-3% IACS (International Annealed Copper Standard), significantly lower than carbon steel alternatives but sufficient for grounding applications. The perforation process increases surface area by up to 65% compared to solid sheets, enhancing heat dissipation efficiency in thermal management applications.

Mechanical testing verifies that 16 gauge perforated steel withstands point impacts up to 95 ft-lbs before deformation occurs, outperforming lighter gauges by 45%. The strategic hole patterns function as controlled stress points, distributing energy across the panel during high-force events. Vibration damping efficiency increases by 30% compared to solid sheets, minimizing resonance in industrial machinery guards.

When comparing perforated vs. expanded metal configurations, 14 gauge expanded metal panels demonstrate 27% greater vertical load capacity but offer only 40% open area maximum. For filtration applications requiring particulate separation, the precision perforations in 16 gauge sheets achieve filtration accuracy within ±0.05 mm compared to expanded metal's variable opening geometry.

| Manufacturer | Lead Time | Hole Tolerance | Material Certification | Max Width | Custom Pattern Cost Premium |

|---|---|---|---|---|---|

| MetalTech Global | 3-5 weeks | ±0.003" | ASTM A480 | 60" | 15-20% |

| Perforated Steel Solutions | 2-3 weeks | ±0.006" | ASME SA240 | 48" | 25-30% |

| Industrial Perforators Inc. | 4-6 weeks | ±0.002" | EN 10088-2 | 72" | 10-15% |

| Precision Perforating Co. | 1-2 weeks | ±0.008" | ASTM A666 | 48" | 30-40% |

Global suppliers demonstrate significant variation in technical capabilities, with European manufacturers typically offering tighter dimensional tolerances while North American producers deliver faster turnarounds. Third-party certification differences impact application suitability for regulated industries including food processing (FDA/NSF compliance) and structural applications requiring AISC certification.

Beyond standard hole patterns, advanced customization includes tapered perforations for gradient filtration and offset punching strategies that maintain 85% material integrity while increasing open area. Modern waterjet cutting supplements traditional punching for complex geometries achieving kerf widths as narrow as 0.030" (0.76mm). Surface treatments like passivation enhance corrosion resistance by removing free iron particles from stainless steel surfaces.

For specialized applications including pharmaceutical processing, manufacturers can apply electropolishing treatments that reduce microscopic surface roughness from 32 μin to 8 μin Ra. This creates a non-porous surface that resists bacterial colonization and meets USP Class VI requirements. Edge treatments including hemming and laser-cut welding preparations maintain dimensional stability during thermal cycling.

A major automotive manufacturer utilized 16 gauge perforated stainless sheets for thermal management in EV battery compartments, achieving 35°C reduction in operating temperatures while reducing component weight by 22 lbs per vehicle. The optimized perforation pattern directed airflow through critical heat zones without compromising structural safety ratings.

In architectural applications, the Denver Art Museum installed custom 16 gauge sheets with varying perforation densities that create shifting visual effects throughout the day. The panels maintained dimensional stability during seasonal temperature fluctuations exceeding 100°F. For water treatment facilities, stacked perforated stainless screens with progressively smaller apertures achieved 99.8% particulate removal while operating at flow rates of 500 gallons/minute with minimal pressure drop.

Current R&D initiatives focus on laser-perforated hybrid materials incorporating micro-encapsulated corrosion inhibitors between composite layers. These next-generation panels autonomously release protective compounds when detecting pH changes from corrosive agents. Manufacturers are developing adaptive perforation patterns using shape-memory alloys that dynamically alter open area percentages based on ambient temperature fluctuations.

Production advancements now enable precision in-line punching at feed rates exceeding 60 ft/min while maintaining dimensional tolerances within 0.001" throughout continuous runs. Industry forecasts predict 12% annual growth for specialized 16 gauge stainless solutions in renewable energy applications including hydrogen production equipment and tidal power filtration systems.

(16 gauge perforated sheet metal)

A: 16 gauge perforated sheet metal typically has a thickness of 0.0598 inches (1.52 mm). This measurement is standardized for industrial and construction applications.

A: 16 gauge perforated stainless steel sheet offers superior corrosion resistance and durability compared to carbon steel. It is ideal for harsh environments like marine or chemical industries.

A: 14 gauge expanded metal is often used for walkways, fencing, and protective barriers. Its diamond-shaped openings provide strength and slip resistance.

A: Yes, 16 gauge perforated sheet metal can be customized with round, square, or hexagonal holes. Patterns vary based on project requirements for airflow, filtration, or aesthetics.

A: Yes, its corrosion-resistant properties make it ideal for outdoor applications like architectural facades or HVAC systems. Regular maintenance can further extend its lifespan.