In the dynamic landscape of modern industry, the demand for materials that offer both functional performance and aesthetic versatility is ever-increasing. Among these, the custom perforated sheet stands out as a critical component, engineered to meet precise specifications across a myriad of applications. From enhancing architectural designs to optimizing industrial processes, its adaptability makes it indispensable.

This comprehensive guide delves into the intricate world of Customized Perforated Sheets, exploring their technical facets, manufacturing excellence, diverse applications, and the competitive advantages offered by leading manufacturers. We aim to provide a deep understanding for engineers, designers, and procurement specialists seeking optimal solutions.

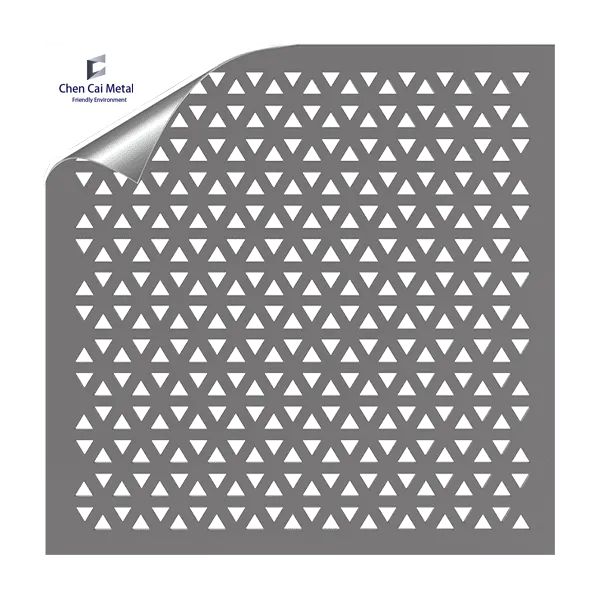

A custom perforated sheet is a metal panel (or other material) that has been mechanically punched with a series of holes or patterns. These perforations can vary widely in shape (round, square, slotted, hexagonal, decorative), size, and arrangement (staggered, straight row), offering a unique blend of structural integrity, aesthetic appeal, and functional properties such as light diffusion, sound absorption, ventilation, and fluid filtration.

The market for custom perforated metal panels is experiencing robust growth, driven by several key trends:

The effectiveness and suitability of a custom perforated sheet metal hinge on a precise understanding of its technical specifications. These parameters are crucial for design, manufacturing, and application:

The versatility of custom perforated metal panels translates into an incredibly diverse range of applications across numerous industries:

The production of a high-quality custom perforated sheet is a testament to precision engineering and advanced manufacturing processes. Unlike casting or forging which form bulk shapes, perforated sheets are primarily produced through precise punching or stamping, ensuring accuracy and consistency.

Description: The process begins with selecting the appropriate raw material (e.g., stainless steel, aluminum, carbon steel coil or sheet) based on client specifications for application, environment, and budget. The material is then cut to initial dimensions if not already in sheet form, and thoroughly cleaned to remove impurities that could affect perforation quality or subsequent finishing.

Expert Insight: Material selection is critical. For instance, for highly corrosive environments in petrochemical or marine applications, Grade 316L stainless steel offers superior resistance due to its molybdenum content compared to 304. For lightweight applications like custom perforated aluminum sheet, alloys like 3003 or 5052 are preferred for their excellent formability and strength-to-weight ratio.

➔Description: Precision tooling (punches and dies) is designed or selected based on the specified hole shape, size, and pattern. Modern CNC-controlled punching machines allow for rapid tool changes and complex pattern programming. Tooling accuracy is paramount for achieving consistent hole quality and precise pitch.

Expert Insight: Tooling materials are often high-strength tool steels (e.g., D2, M2) to withstand repetitive impact. The clearance between the punch and die, typically 5-10% of the material thickness, is crucial. Incorrect clearance can lead to burrs, uneven holes, or excessive tool wear. CNC programming ensures that even intricate custom perforated metal screen patterns are executed flawlessly across large sheets.

➔Description: The prepared material sheet is fed into a high-speed automatic punching machine. Under precise CNC control, a series of punches rapidly pierce the material, creating the desired hole pattern. For very specific or intricate designs, laser cutting may be employed, offering unparalleled precision but at a higher cost.

Expert Insight: High-speed mechanical presses are common for volume production. The punching force can range from several tons to hundreds of tons. Maintaining consistent punch speed and pressure is essential to prevent material deformation or tearing. For thinner gauges or delicate materials, advanced servo-driven presses provide finer control, minimizing distortion. The process adheres to industry standards such as ASTM A666 for stainless steel and ASTM B209 for aluminum sheets, ensuring material integrity post-perforation.

➔Description: After perforation, the sheet may exhibit some bowing or warping due to the stresses introduced during punching. A leveling machine flattens the sheet to ensure it is perfectly planar. Deburring removes any sharp edges or burrs around the perforations, enhancing safety and aesthetic appeal.

Expert Insight: Roller levelers are commonly used for flattening. Deburring can be done mechanically (brushing, tumbling) or thermally. For applications requiring extremely smooth edges, like those in food processing or medical equipment, specialized deburring techniques or even electropolishing may be applied to meet stringent standards such as FDA guidelines for surface finish.

➔Description: The perforated sheet is then cut to the final specified dimensions. This can involve shearing, guillotining, or laser cutting, ensuring precise edges and angles according to the design.

Expert Insight: Shearing is efficient for straight cuts, while laser cutting offers flexibility for complex shapes or precise cut-outs that integrate with the perforated pattern. Adherence to tight dimensional tolerances, often within ±0.5mm, is crucial, especially for architectural panels that need to fit seamlessly into structures.

➔Description: Depending on the application, the custom perforated sheet metal may undergo various finishing processes. This includes powder coating for color and enhanced corrosion resistance, anodizing for aluminum, galvanizing for steel, polishing for aesthetic shine, or painting.

Expert Insight: Powder coating offers excellent durability and a wide range of colors, suitable for exterior architectural applications. Anodizing creates a hard, corrosion-resistant, and aesthetically pleasing oxide layer on aluminum. Hot-dip galvanizing provides robust corrosion protection for steel by creating a zinc coating, ideal for outdoor industrial settings. These processes comply with standards like ASTM B117 for salt spray testing (corrosion resistance) and AAMA 2605 for high-performance architectural coatings.

➔Description: The finished custom perforated sheet undergoes rigorous quality inspection. This includes dimensional checks, hole accuracy verification, open area calculation, surface finish evaluation, and material conformity testing. Once approved, the sheets are carefully packaged to prevent damage during transit.

Expert Insight: Inspections adhere to international standards like ISO 9001 for quality management systems. Specific product standards such as ANSI/NAAMM HMMA 861 for hollow metal doors and frames (where perforated panels might be used) or relevant ASTM specifications for material and perforation quality are applied. Digital measuring tools, optical inspection systems, and even CMM (Coordinate Measuring Machine) can be used for high precision. Proper packaging, often involving protective films, wooden crates, or steel pallets, ensures products arrive in pristine condition, critical for maintaining client satisfaction.

Product Name: Customized Perforated Sheet

Product URL: https://www.ccmetalmesh.com/customized-perforated-sheet.html

| Parameter | Description | Typical Range/Value | Industry Standard Reference |

|---|---|---|---|

| Material Thickness (Gauge) | Sheet material thickness prior to perforation. | 0.5 mm - 10 mm (24 Gauge - 3/8 inch) | ASTM A480/A480M (Stainless Steel), ASTM B209 (Aluminum) |

| Hole Shape | Geometry of the perforations. | Round, Square, Slotted, Hexagonal, Decorative, etc. | Custom specification |

| Hole Size (Aperture) | Diameter for round holes; side length for square, etc. | 0.8 mm - 100 mm (0.031 inch - 4 inch) | ISO 3310-1 (Test Sieves), Custom tolerance (e.g., ±0.05 mm) |

| Pitch (Center Distance) | Distance from center of one hole to the next. | Minimum: Hole size + 0.5 mm; Max: Varies by pattern | Custom specification, often 60-degree staggered, 90-degree straight |

| Open Area (%) | Percentage of total sheet area that is open (perforated). | Typically 20% - 65% (Can range from 8% to 80%+) | Calculated based on hole size and pitch |

| Margin/Unperforated Area | Solid border around the perforated area. | Customizable, often 10-20 mm or as required | Client specific or manufacturing standard |

| Sheet Size | Overall dimensions of the perforated panel. | Standard: 1000x2000mm, 1220x2440mm (4x8 ft), Custom up to 2m x 6m+ | Varies by manufacturer capability and transport limits |

| Material Grades | Specific alloy or material designation. | Stainless Steel (304, 316, 316L), Aluminum (1100, 3003, 5052), Carbon Steel, Galvanized Steel, Copper, Brass, etc. | ASTM, EN, JIS, AISI standards depending on material |

| Surface Finish | Post-perforation treatments. | Mill finish, Polished, Anodized, Powder Coated, Galvanized, Painted | ISO 12944 (Corrosion Protection), AAMA 2605 (Architectural Coatings) |

Compared to other materials or manufacturing methods, custom perforated sheets offer distinct advantages:

In a major industrial water treatment facility, the replacement of traditional mesh screens with custom perforated stainless steel sheets led to a significant improvement in filtration efficiency. The precise, consistent hole patterns (e.g., 2mm round holes with 4mm staggered pitch, 316L Stainless Steel) ensured finer particle separation, reducing downstream pump maintenance by 15% and extending filter media life by 25%. The inherent corrosion resistance of the material also meant the screens required replacement only every 7-10 years, dramatically decreasing operational downtime and associated costs, demonstrating a clear return on investment.

Similarly, for a commercial building in a warm climate, implementing custom perforated aluminum sheet sunshades (3mm thick, 10mm square holes, 50% open area, anodized finish) on the facade resulted in a 12% reduction in cooling energy consumption during peak summer months. The calculated ROI for these sunshades was estimated at 5 years, purely from energy savings, not to mention the enhanced aesthetic appeal.

Selecting the right manufacturer for your custom perforated sheet needs is as critical as the product itself. A reliable supplier embodies expertise, experience, and trustworthiness.

When comparing manufacturers, consider these vital aspects:

At CC Metal Mesh, we pride ourselves on being a leading provider of high-quality Customized Perforated Sheets. With over two decades of dedicated experience in metal mesh and perforation, our expertise is built on a foundation of precision engineering and client-centric solutions.

The essence of a custom perforated sheet lies in its ability to be precisely tailored. Our custom solution process is designed to translate your unique vision into a tangible, high-performance product.

Our commitment to excellence is underpinned by adherence to rigorous international standards. CC Metal Mesh operates under an ISO 9001:2015 certified quality management system, demonstrating our consistent ability to provide products and services that meet customer and regulatory requirements. Our materials sourcing is meticulously managed, with full traceability to original mill certificates for all metal alloys (e.g., verifying compliance with ASTM A240 for stainless steel sheet, plate, and strip). We frequently work to project-specific standards such as those from ASTM, ANSI, and local building codes, ensuring our products integrate seamlessly and safely into diverse applications globally.

Our average lead time for custom perforated sheet orders typically ranges from 2 to 4 weeks for standard materials and patterns, following design approval. For highly complex designs, very large volumes, or specialized materials/finishes, lead times may extend to 6-8 weeks. We maintain transparent communication throughout the production cycle, providing regular updates on order status and estimated delivery dates. For urgent requirements, expedited production options may be available upon request and feasibility assessment.

Every custom perforated sheet from CC Metal Mesh is backed by a comprehensive quality assurance program. We perform multi-stage inspections, from raw material incoming to final product packaging. This includes dimensional verification using calibrated instruments (micrometers, calipers, optical comparators), visual inspection for surface finish and hole integrity, and mechanical property testing if required by specification. We offer a standard 5-year warranty on material and workmanship, covering any defects arising from our manufacturing process under normal use conditions, underscoring our confidence in product durability and performance.

Our dedicated customer support team is available to assist you throughout your project lifecycle. From initial inquiry to post-delivery support, we offer:

A1: Open Area refers to the total percentage of the sheet that has been removed by perforation. It's calculated as (Area of one hole × Number of holes) / Total Sheet Area × 100%. This parameter is critically important as it directly impacts the sheet's functional properties: higher open areas allow for greater light transmission, airflow, and fluid filtration, while lower open areas provide more structural strength and privacy. For example, a filter screen requires a high open area, whereas a decorative facade might opt for a lower one for specific light effects.

A2: While perforated sheets offer good strength-to-weight ratios, they generally have reduced load-bearing capacity compared to solid sheets of the same material and thickness. Their suitability for structural load-bearing depends heavily on the specific design (material, gauge, hole size, and pattern) and the applied loads. For structural applications, a structural engineer should always be consulted to perform load calculations and ensure compliance with relevant building codes and safety standards (e.g., AISC specifications for steel structures).

A4: Margins refer to the unperforated border around the edges of the sheet. You specify them by indicating the width of each margin (e.g., 15mm top margin, 20mm bottom margin, 10mm side margins) or by stating "no margins" if the perforation extends to the very edge. Margins are crucial for mounting, framing, and maintaining structural integrity, especially if the sheet needs to be bent or welded. Clear communication of margin requirements prevents manufacturing issues and ensures proper fit in the final assembly.

A5: The service life of custom perforated aluminum sheet in outdoor environments is generally excellent due to aluminum's natural corrosion resistance, forming a protective oxide layer. Anodized or powder-coated aluminum can significantly extend this, often exceeding 20-30 years in typical atmospheric conditions. In very harsh environments (e.g., coastal areas with high salt spray or industrial areas with chemical pollutants), specific high-grade alloys (like 5052 or 6061) and robust finishes (like AAMA 2605 certified powder coatings) are recommended to achieve extended longevity, potentially 50+ years.

A6: In a straight-row pattern (also known as 90-degree pattern), the centers of the holes are aligned both horizontally and vertically, forming a grid. This pattern offers uniform appearance and consistent open area. In a staggered pattern, the centers of the holes in adjacent rows are offset, typically by half the pitch (e.g., 60-degree staggered or 45-degree staggered). Staggered patterns are generally preferred for their aesthetic appeal, improved structural stability (distributing stress more evenly), and often higher open area percentages for a given hole size and pitch, making them suitable for screens and filters.

A7: Yes, a custom perforated metal screen can be highly effective in noise reduction, particularly when combined with an acoustic absorbent material (like mineral wool or fiberglass batt) behind it. The perforations allow sound waves to pass through to the absorbent material, which then dissipates the sound energy. The specific hole size, open area, and thickness of the perforated sheet, along with the type and thickness of the acoustic backing, all contribute to the overall Sound Absorption Coefficient (SAC) and Noise Reduction Coefficient (NRC). This is widely applied in acoustic ceilings, wall panels, and machinery enclosures to meet standards like ASTM C423 for sound absorption.

The custom perforated sheet stands as a testament to engineering versatility and aesthetic potential. Its ability to be precisely tailored in terms of material, pattern, and finish makes it an unparalleled choice for architects, engineers, and industrial designers seeking functional efficiency, structural integrity, and visual appeal.

From controlling light and airflow in sustainable architecture to robust filtration in demanding industrial environments, the applications are as diverse as the designs themselves. By understanding the intricate manufacturing process, key technical parameters, and leveraging the expertise of a trusted manufacturer like CC Metal Mesh, you can unlock the full potential of these exceptional materials, ensuring optimal performance and long-term value for your projects.

Our commitment to quality, backed by ISO 9001 certification and decades of hands-on experience, ensures that every custom perforated sheet we produce is a benchmark of precision and reliability. Partner with us to transform your complex requirements into perfectly executed solutions.

References & Further Reading:

PREV:

This is the last article