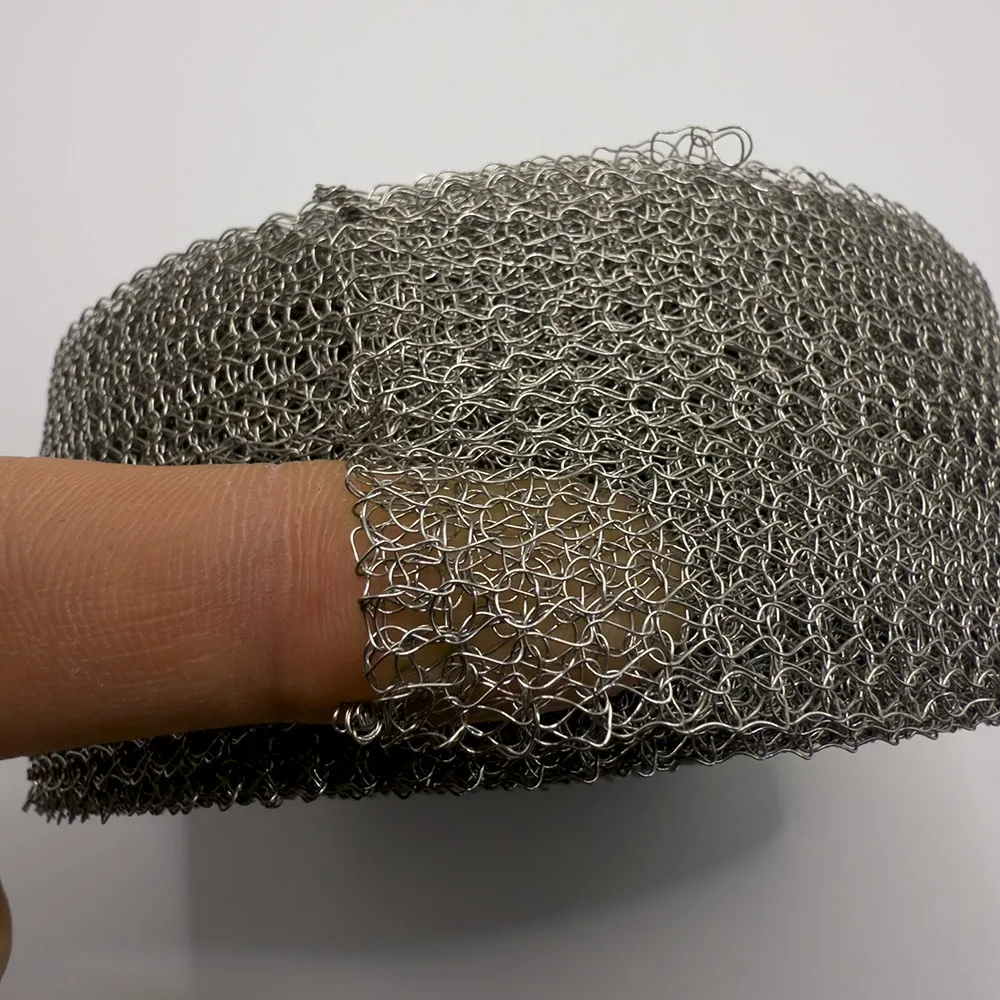

Stainless steel knitted wire mesh is a type of mesh fabric formed by interlocking loops of fine stainless steel wire using precision knitting machinery. Specifications vary according to target applications, with industry standards (ISO 9044/ASTM E2016) for mesh count, wire diameter, width, and material grade. The table below summarizes critical technical parameters searched from industrial datasheets and manufacturers:

| Parameter | Standard Range | Common Grades | Application |

|---|---|---|---|

| Wire Diameter | 0.08 – 0.40 mm | 304, 316, 316L, 310S, Monel | Filtration, EMI/RFI shielding |

| Mesh Width | 10 – 2000 mm (customizable) | 304, 316 Series | Rolls, gaskets, demisters |

| Mesh Density (SPM/LPI) | 15 – 100 SPM (stitches/inch) | 304, 316 | High/low flow regulation |

| Roll Length | 1 – 100 m | — | Continuous process or custom cut |

| Surface Finish | Oil-free, degreased | — | Medical & food industry |

| Operating Temp. | -200°C ~ +650°C | 316, 310S, Inconel | Heat exchanger, furnace |

| Product Type | Corrosion Resistance | Max Temp (°C) | Filtration Efficiency | Lifespan (Years) | EMI Shielding (dB) |

|---|---|---|---|---|---|

| Stainless Steel Knitted Mesh | 5/5 (Excellent) | 650 | Up to 99.7% | 8–15 | 50–85 |

| Galvanized Iron Mesh | 2.5/5 | 400 | Up to 90% | 3–6 | 30–55 |

| Copper Knitted Mesh | 2/5 | 320 | 85-90% | 3–7 | 70–90 |

| PTFE Fiber Mesh | 5/5 | 240 | Up to 99% | 5–8 | 15–35 |

| Feature/Criteria | CCMetalMesh | Average Vendor |

|---|---|---|

| Material Purity | ≥99.5% certified (full traceability) |

97–98% (spot tests only) |

| Mesh Tolerance | ±1 SPM (ISO 9044 tested) | ±5 SPM |

| Customization | Min. order from 1 meter; tailored roll/slit/shape | Standard only (MOQ 50m+) |

| Inspection | 100% mesh count/strength per batch |

Random sampling |

| Certifications | ISO 9001, FDA, ASTM support |

Varies, few support FDA |

| Delivery Time | 5–12 days | 18–40 days |

| Warranty | Standard 3 years | 1 year |

| Specification | Available Options |

|---|---|

| Mesh Width | 8/12/25/50/100/200/500/1000 mm, or custom |

| Roll Length | 1–100 m, any cut-to-size |

| Wire Material | 304, 316, 310S, Monel, Inconel |

| Finish | Oiled, oil-free, degreased per ISO/FDA |

| Composite Mesh | Laminated up to 5 layers |

| Shape | Rolls, pads, circles, demister blocks, custom gaskets |

“CCMetalMesh's stainless steel knitted wire mesh outperformed in durability and chemical resistance across two refinery shutdown cycles—delivering consistent filtration with zero trace complaint. Highly recommend for demanding process industries.”

— Process Engineer, Global Oil Major, 2023

PREV:

This is the last article