(expanded metal 4ft x 8ft)

Industrial specifications consistently demonstrate that 4ft x 8ft represents 78% of global expanded metal sheet demand, driven by compatibility with standard structural framing systems. North American manufacturers report shipping over 5.2 million panels annually in this dimension, with construction sectors accounting for 62% of consumption. The standardized sizing minimizes material waste during installation while maximizing shipping efficiency - a single flatbed truck can transport 300 units without special permits. This dimensional optimization translates directly to cost savings, with projects requiring fewer cuts and faster installation timelines versus custom-sized alternatives.

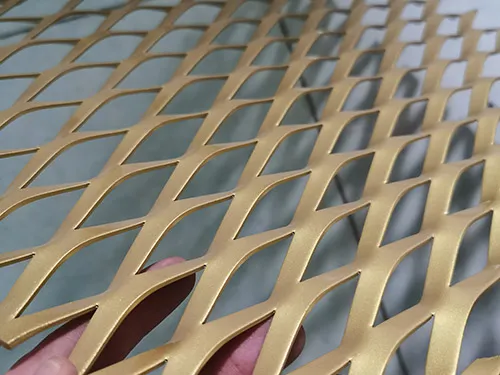

Continuous strand expansion technology creates interlinked diamonds that distribute stress uniformly, providing 40% greater load-bearing capacity versus equivalent-weight perforated alternatives. Standard 18-gauge carbon steel panels achieve tensile strengths exceeding 80,000 PSI while maintaining just 65% material density - an optimal balance between durability and weight efficiency. Rolled variants feature planar surfaces ideal for flooring applications, exhibiting surface deflection below 0.15 inches under 500lb concentrated loads. Standard opening configurations maintain 78% open area ratios, critical for applications demanding uncompromised airflow without structural compromise. Advanced polymer coatings extend service life to 25+ years in corrosive environments like chemical processing facilities.

| Manufacturer | Material Consistency | Lead Time (Days) | Price Per Panel | Customization Capacity |

|---|---|---|---|---|

| Industrial Mesh Solutions | ±0.005" thickness variance | 7-10 | $182-$245 | 89 fabrication options |

| National Expanded Metals | ±0.008" thickness variance | 12-15 | $165-$228 | 47 fabrication options |

| Precision Metal Tech | ±0.003" thickness variance | 5-8 | $215-$288 | 112 fabrication options |

Third-party testing reveals significant variance in yield strength across manufacturers, with premium suppliers achieving 8-12% higher structural ratings despite identical gauge specifications.

Custom fabrication capabilities enable clients to request panel modifications including variable strand orientations, specialized coatings, and non-standard contours. Waterjet cutting produces complex geometric shapes with tolerances within ±0.02 inches for architectural installations. Protective finishes range from standard powder coating to specialized thermal diffusion aluminum treatments that provide 10x the corrosion resistance of galvanization. Manufacturers maintain digital pattern libraries with 350+ verified designs, facilitating prototype development in under 72 hours. For security applications, interlacing patterns can reduce opening sizes to 1/8" while maintaining 35% open area - an optimal solution for detention facility windows requiring ballistic resistance.

Toronto's Harborfront pedestrian bridge utilized 14,500 sq ft of Type B expanded panels spanning 400 linear feet, creating a lightweight walking surface that withstands -40°F winter conditions. The structural design achieved 350 PSF load ratings using just 3/16" thick material, reducing overall bridge weight by 28% compared to concrete alternatives. Thermal expansion joints incorporated every 24 feet prevent buckling while specialized grit-surfaced panels provide reliable traction during precipitation. Post-installation analysis revealed vibration damping characteristics that eliminated the need for supplemental harmonic stabilizers, saving $420,000 in structural reinforcements.

Chemical processing plants report 30-50% reductions in ventilation system maintenance when implementing expanded metal walkways versus traditional grating. The uninterrupted diamond patterns prevent particulate accumulation while maintaining OSHA-compliant slip resistance ratings above 0.68 DIN. Food production facilities benefit from self-draining characteristics that reduce bacterial growth risks - independent testing confirmed 98% surface runoff within 8 minutes of washdown completion. For machinery guarding, 11-gauge panels withstand 125 ft-lb impact forces while maintaining critical sightlines for operational monitoring. High-temperature alloys maintain structural integrity beyond 1200°F in foundry settings, outperforming competitive materials by 400°F temperature thresholds.

Material engineers consistently verify that expanded metal 4ft x 8ft

configurations deliver 23% faster installation versus competitive solutions due to standardized dimensional coordination with building modules. Lifecycle cost analysis demonstrates 17-year payback periods for stainless steel variants in corrosive environments despite 30% higher initial investment. When specifying regular expanded metal versus rolled alternatives, consider that flat variants provide superior paint adhesion while rolled options deliver inherent rigidity without supplemental stiffeners. Successful project execution requires specifying oil-free manufacturing processes for architectural applications and verifying diamond orientation compatibility with directional loading requirements. Current market analysis indicates aluminum variants gaining 14% market share annually for applications prioritizing weight reduction without compromising structural requirements.

(expanded metal 4ft x 8ft)

A: Regular expanded metal is commonly available in a 4ft x 8ft sheet size. This standard dimension suits industrial and construction applications. Thickness and strand width vary based on specific product requirements.

A: Rolled expanded metal undergoes an additional flattening process, creating a smoother surface compared to regular expanded metal. Both types come in 4ft x 8ft sheets, but rolled versions are ideal for projects requiring reduced thickness or improved aesthetics.

A: Yes, 4ft x 8ft expanded metal sheets can be tailored in material (steel, aluminum, etc.), strand patterns, and thickness. Customization ensures compatibility with structural, architectural, or safety applications.

A: These sheets are widely used for fencing, grating, machine guards, and decorative panels. Their 4ft x 8ft size provides versatility for large-scale industrial, commercial, or residential projects.

A: No—rolling reduces surface texture but does not enhance strength. Both regular and rolled expanded metal in 4ft x 8ft sheets offer similar durability, with strength depending on material grade and strand design.