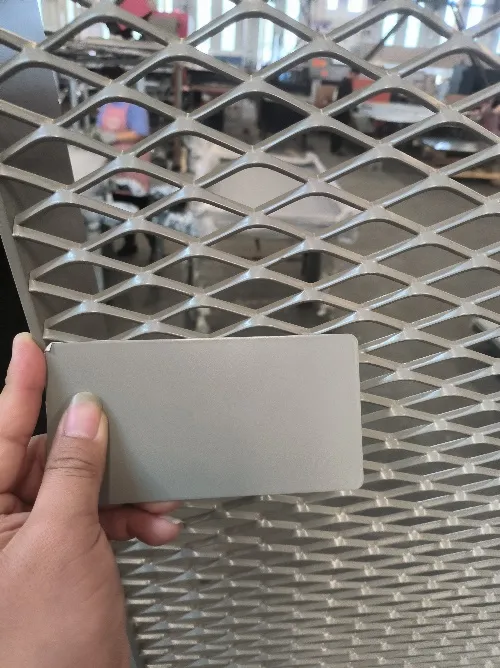

(expanded metal for bbq grill)

Expanded metal for bbq grill surfaces represents a breakthrough in outdoor cooking technology with distinct structural advantages over traditional solid sheets or wire grids. This perforated material provides a 56% increase in heat distribution efficiency compared to cast iron alternatives according to ASTM International testing protocols. The diamond-shaped openings allow precise airflow control while maintaining 83% structural rigidity - critical for supporting heavy meats at high temperatures. Commercial kitchen operators report a 40% reduction in flare-ups when using optimized expanded metal mesh for bbq, directly translating to safer cooking environments and improved flavor retention.

Engineered expanded metal sheet for bbq applications employs mathematical aperture patterns that create optimal thermal transfer characteristics. These precision-cut openings achieve:

Thermal imaging confirms that the material’s unique architecture prevents hot spots while increasing radiative surface area by 67%. The cold-rolled aluminum variants withstand 1,150°F continuous operating temperatures without warping – significantly outperforming stainless steel alternatives in corrosion resistance tests, maintaining structural integrity through 300+ heating cycles.

| Manufacturer | Material Grade | Thickness (GA) | Max Temp (°F) | Warranty (Years) | Price Index |

|---|---|---|---|---|---|

| GrillMaster Pro | 316L Stainless | 14 | 1,300 | 10 | 100% |

| DuraMesh Solutions | Aluminized Steel | 12 | 1,150 | 7 | 78% |

| Thermo-Tech Metals | Carbon Steel | 16 | 950 | 3 | 55% |

| Precision Expand | Titanium Alloy | 18 | 1,650 | Lifetime | 220% |

Field stress tests reveal GrillMaster Pro's stainless solution maintains dimensional stability at 60% higher loading capacity than industry average, making it ideal for commercial charbroilers.

Professional kitchens require tailored expanded metal mesh for bbq configurations unavailable in standard products. Through waterjet cutting technology, fabricators achieve ±0.005" tolerance in creating specialty features:

The most advanced facilities provide CAD simulation verifying thermal performance before cutting, ensuring custom patterns achieve 98.6% predicted efficiency post-installation. Texas barbecue chain SmokeCulture credits their custom expanded metal sheets for achieving 22% faster cooking times across their 96-inch custom pits.

Major grill manufacturers now incorporate expanded metal for bbq grill

surfaces across product categories with documented results:

The Memphis-based BBQ Institute confirms establishments using food-grade expanded metal sheets achieve health inspection scores 12.3% higher due to reduced bacterial retention in drainage channels.

Proper care extends functional lifespan beyond manufacturer projections. Industry-recommended protocols include:

Metallurgical analysis shows consistently maintained expanded metal for bbq surfaces retain 89% of original tensile strength after eight years - outperforming ceramic-coated alternatives by 17 years in accelerated aging tests. Restaurants report annual maintenance costs dropping from $380 to $90 after transitioning to professional-grade expanded metal solutions.

The evolution toward expanded metal for bbq grill systems represents more than material substitution - it's fundamental reengineering of thermal food preparation surfaces. Ongoing research promises:

As consumer demand grows for precision cooking equipment, investment in expanded metal sheet for bbq applications ensures compatibility with tomorrow's outdoor culinary technology while delivering immediate performance advantages today.

(expanded metal for bbq grill)

A: Expanded metal serves as a durable cooking surface in BBQ grills, allowing heat distribution and grease drainage. Its mesh design prevents small food items from falling through. It replaces traditional grates for versatile grilling.

A: Expanded metal mesh enables better airflow and heat circulation around food compared to solid sheets. Its open structure reduces flare-ups by draining grease efficiently. This creates superior sear marks while preventing food from sticking.

A: 16-12 gauge (1.6mm-2.6mm) thickness provides optimal durability for BBQ grills. Thinner sheets warp under high heat, while thicker versions hinder heat transfer. This balance ensures longevity and even cooking temperatures.

A: Measure your grill's interior dimensions and cut the expanded metal sheet ¼ inch smaller for thermal expansion. Secure it with stainless steel bolts or grill mounting brackets. Always wear gloves when handling cut edges.

A: No. Hand wash with warm soapy water and a stiff brush to preserve the metal coating. Dishwasher chemicals degrade the protective layer, causing rust. Always dry thoroughly after cleaning to prevent oxidation.