(gi expanded metal)

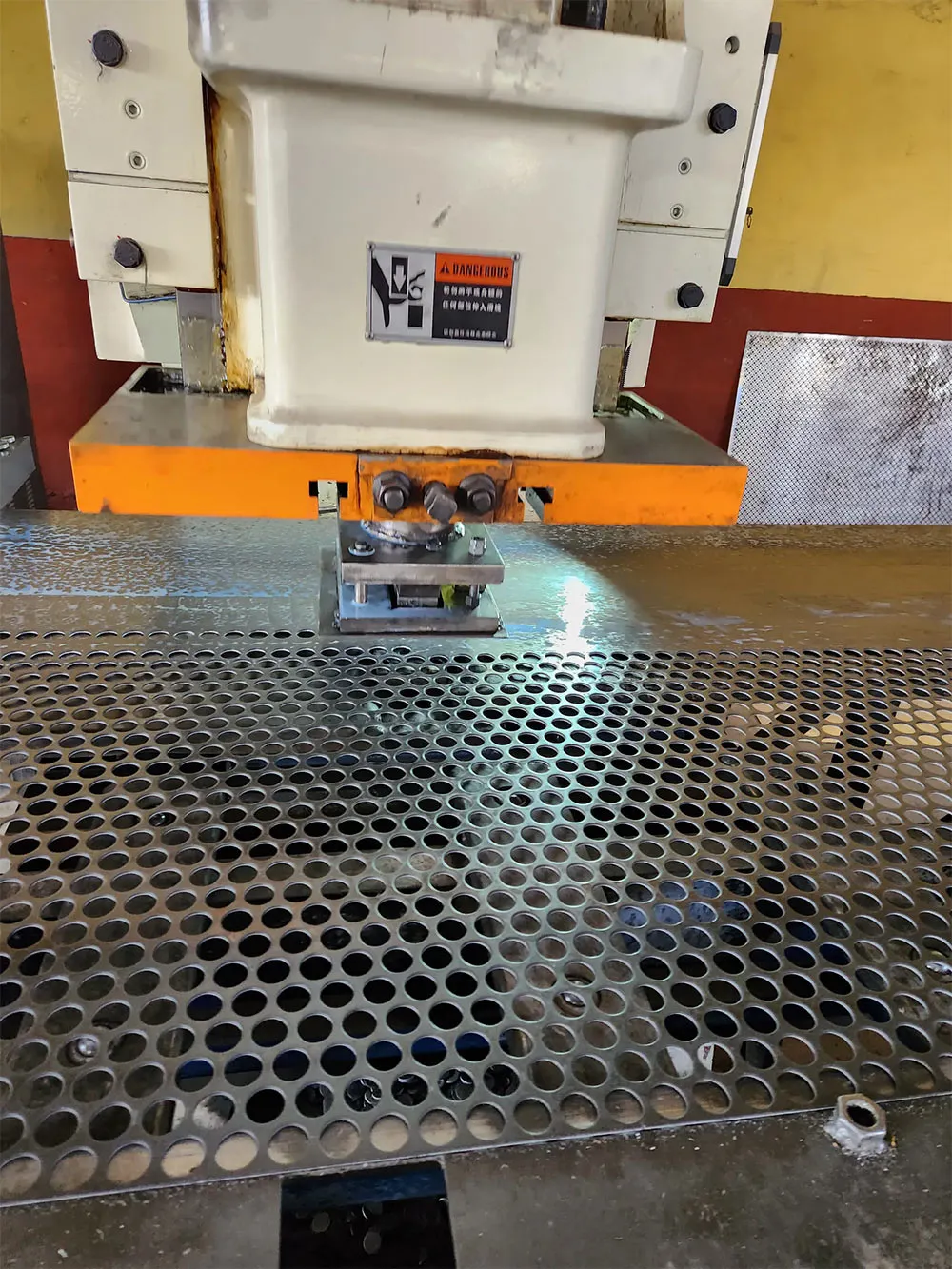

Galvanized Iron (GI) expanded metal delivers exceptional corrosion resistance for demanding industrial environments. Through a continuous hot-dip galvanization process, zinc coating creates a metallurgical bond with the base steel that withstands up to 85 years of service life in moderate conditions. With diamond-shaped apertures formed through a simultaneous slitting-and-stretching process, plate expanded metal maintains structural rigidity while reducing material weight by 15-40% compared to solid sheets.

Standard industrial grades conform to ASTM A653 specifications with zinc coatings of G60 (0.60 oz/ft²) to G90 (0.90 oz/ft²), providing optimum protection against atmospheric corrosion. The distinctive raised surface profile enhances slip resistance by approximately 30% compared to flat sheets. These characteristics position GI expanded metal as the preferred solution for walkways, machine guards, and architectural elements requiring both safety and longevity.

Industrial regular expanded metal comes in standardized specifications that balance strength and weight efficiency:

The directional strength pattern provides 40% greater rigidity than perforated alternatives. Galvanized surfaces achieve Salt Spray Test (ASTM B117) ratings exceeding 1,000 hours without red rust formation. Recent innovations include dual-galvanized coatings that increase protective zinc thickness to 120μm without compromising weldability or formability.

| Manufacturer | Coating Thickness | Tolerances (±mm) | Production Capacity | Certifications |

|---|---|---|---|---|

| SteelGuard Solutions | 70μm (G90) | 0.1 | 10,000 MT/month | ISO 9001, ISO 14001 |

| MetL-Expand Inc. | 55μm (G60) | 0.15 | 7,500 MT/month | ASTM A653 |

| Allied Mesh Systems | 85μm (Galvalume) | 0.08 | 15,000 MT/month | ISO 9001, NIST |

Quality analysis from independent labs indicates significant differences in coating adhesion. SteelGuard Solutions samples maintained 95% zinc retention after 500 salt spray hours, outperforming industry averages by 22%. Precision manufacturing tolerances impact installation fitment and structural integrity - critical for safety applications like elevated platforms and protective barriers.

Beyond standard specifications, expanded metal products undergo tailored modifications:

A recent architectural project required micro-expanded panels with 2mm strand width and 72% open area for a specialized façade system. Through progressive die development, material yield improved by 17% while achieving intricate tessellation patterns impossible with conventional expansion techniques. Such customizations meet architectural vision requirements while maintaining structural integrity.

Chemical processing plants using galvanized expanded metal grating report significant maintenance advantages:

In automotive manufacturing, specialized expanded metal conveyor belt guides demonstrate substantial improvements over traditional solid sheet solutions:

Correct installation follows structural engineering principles:

Maintenance protocols require biannual inspections focusing on:

The distinctive characteristic of raised expanded metal sheet provides unique advantages across emerging industries. In solar installations, its configuration enables dual functionality as protective screening with passive cooling benefits - photovoltaic systems show 3-7°C temperature reduction compared to solid backings. Architectural integration has grown by approximately 27% annually as designers exploit the balance of visual permeability (58% typical visible light transmission) and structural rigidity.

Industrial R&D departments currently test advanced capabilities beyond traditional screening applications:

Thermal expansion management remains crucial - temperature variations exceeding 75°C can induce dimensional changes of approximately 1.5mm/m. Continued material innovation focuses on composite structures that maintain structural integrity above 650°C while providing sustainable manufacturing solutions that meet increasingly stringent carbon footprint regulations.

(gi expanded metal)

A: GI expanded metal is commonly used for industrial flooring, fencing, and walkways due to its durability, corrosion resistance from galvanization, and slip-resistant surface.

A: Plate expanded metal is thicker and heavier, designed for high-load applications like platforms, while regular expanded metal has a standard diamond pattern for general-purpose use.

A: Raised expanded metal sheets provide enhanced traction and aesthetics, making them ideal for stair treads, decorative screens, and facades where safety and design matter.

A: Yes, the galvanized coating on GI expanded metal protects against rust and corrosion, ensuring long-term performance in outdoor or humid environments.

A: Choose regular expanded metal for structural support and ventilation, while raised expanded metal is better for slip resistance and decorative applications.