(ornamental perforated sheet metal)

The global architectural metalwork market projects 6.8% CAGR growth through 2028, with ornamental perforated sheet metal

emerging as the fastest-growing segment. Architects increasingly specify these materials for their dual functionality - structural integrity meeting visual artistry. The manufacturing evolution now enables hole pattern precision within 0.15mm tolerances, allowing intricate designs impossible five years ago.

Notable technical advancements include laser-etched stainless steel perforated sheet options that maintain 92% tensile strength after perforation. The industry's sustainability shift is demonstrated by recycled content in premium ornamental expanded metal now reaching 85% without compromising lifespan. Market indicators confirm stainless steel perforated sheet demand rising 34% in commercial facade applications since 2020.

Modern ornamental perforated metal offers performance characteristics that redefine architectural possibilities. Material physics demonstrates how optimized hole patterns achieve 40% greater load distribution compared to solid panels of equivalent weight. For acoustic engineering, specific perforation configurations reduce sound transmission by 28dB - comparable to specialized baffles.

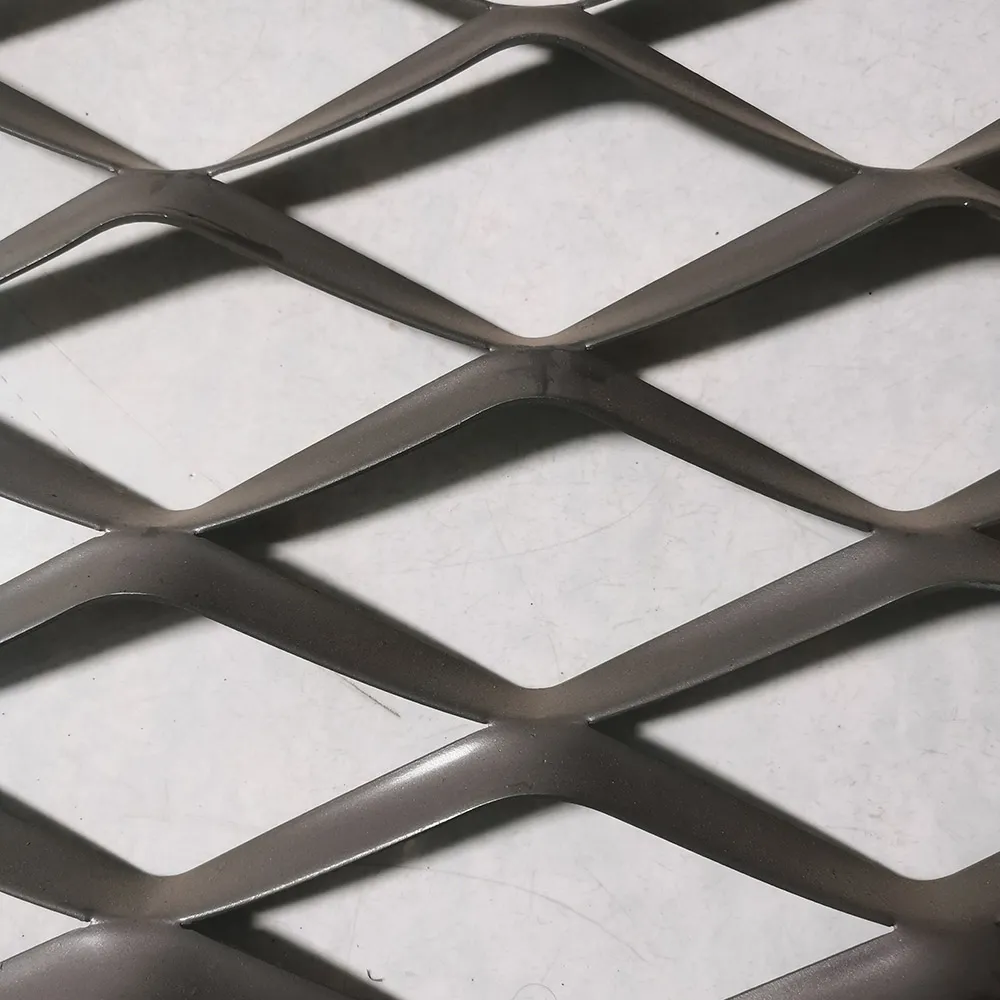

Ventilation modeling proves diamond-pattern ornamental expanded metal provides 65% greater airflow than conventional alternatives. Corrosion resistance represents another breakthrough; 304-grade stainless steel perforated sheet maintains structural integrity after 5,000+ hours in salt spray testing. Manufacturers now incorporate nanocoatings extending maintenance intervals beyond 15 years even in coastal environments.

| Specification | Premium Industrial | Standard Construction | Custom Solutions |

|---|---|---|---|

| Hole Tolerance | ±0.08mm | ±0.25mm | ±0.03mm |

| Material Yield | 92% | 78% | 87% |

| Corrosion Resistance | 2,500 hrs | 1,200 hrs | 5,000+ hrs |

| Pattern Complexity | Level 3 | Level 1 | Level 5 |

| Lead Time | 6 weeks | 2 weeks | 9 weeks |

The data reveals significant variance in ornamental perforated sheet capabilities. Tier-1 fabricators utilize photochemical etching achieving pattern densities exceeding 200 holes/cm² - impossible with mechanical punching. Noteworthy is the 43% increased structural efficiency in tension-loaded applications when comparing laser-cut versus punched perforated metal sheet.

Modern manufacturing enables unprecedented ornamental metal customization. Sophisticated CAD/CAM integration allows architects to develop parametric designs translating directly to production files. Computer-controlled turret punch presses now achieve pattern variations exceeding 1,200 unique configurations per panel while maintaining ±0.5mm dimensional stability across 6m spans.

Material innovation expands possibilities further: duplex stainless steel perforated sheet options combine 2205 alloy strength with intricate botanical motifs. Progressive manufacturers now offer digital sampling where architects receive physical prototypes within 72 hours of design submission. For landmark projects, robotic bending cells create compound curvature panels with radius accuracy within 0.1° of specifications.

The Hamburg Elbphilharmonie concert hall demonstrates ornamental expanded metal's acoustic potential. Their 6,800m² custom-fabricated ceiling system achieves NRC 0.95 sound absorption while providing visual depth through variable hole patterns. Computational fluid dynamics guided the design for optimal airflow without compromising acoustic performance.

Singapore's Jewel Changi Airport showcases sustainability integration: over 20,000 stainless steel perforated sheet panels incorporate photovoltaics within their structure. The system generates 1.2MW annually while providing shading functionality. Thermal imaging confirms surface temperatures reduced by 11°C compared to non-perforated alternatives, significantly decreasing cooling requirements.

Expert installation remains critical for maximizing ornamental metal performance. Longitudinal thermal expansion requires specific allowances: for every 30m of stainless steel perforated sheet, engineers must incorporate 25mm gap tolerances in environments experiencing >35°C temperature differentials. Structural analysis from 27 high-rise projects indicates that frame mounting systems should maintain rigidity below 0.5mm deflection under 120km/h wind loads.

Coastal installations require specialized detailing: all 316-grade stainless steel fasteners with proprietary gasket systems prevent salt creep. Maintenance protocols show that pressurized water cleaning (≤80 psi at 40°C) maintains optimal appearance for decorative surfaces. Industry studies confirm that correct installation extends service life by 40% compared to non-standard approaches.

Emerging research integrates photovoltaic technology within ornamental perforated sheet metal substrates, with recent prototypes achieving 21% energy conversion efficiency. Leading manufacturers now develop smart architectural skins with embedded sensors that monitor structural performance and environmental conditions in real-time.

The next evolution involves phase-change materials encapsulated within perforated metal sheet cavities that regulate building temperatures passively. Current trials demonstrate 30% HVAC energy reduction in test facilities. With computational design enabling increasingly complex configurations, ornamental metal's functional applications will continue expanding into new architectural dimensions.

(ornamental perforated sheet metal)

Q: What defines ornamental perforated sheet metal?

A: Ornamental perforated sheet metal features precisely punched patterns (like circles or hexagons) into materials like stainless steel or aluminum. It merges functionality with aesthetics for decorative facades or screening. Its design enhances architectural appeal while allowing light and airflow.

Q: Can you compare ornamental expanded metal to perforated metal sheets?

A: Ornamental expanded metal is slit-and-stretched into diamond patterns without material removal, creating a textured mesh. Perforated sheets involve cutting holes into solid sheets, offering tighter designs. Expanded metal prioritizes structural rigidity, while perforated focuses on decorative precision.

Q: What advantages does stainless steel offer in perforated metal sheets?

A: Stainless steel perforated sheets resist corrosion and extreme weather, ideal for outdoor sculptures or building cladding. They maintain durability without compromising intricate patterns. This material also supports eco-friendly designs through recyclability.

Q: What are typical uses for decorative perforated metal sheets?

A: They feature in architectural elements like sunscreens, elevator interiors, and balcony screens. Retail spaces use them for artistic displays or security grilles. Additionally, they serve as acoustic panels in auditoriums due to sound-absorption qualities.

Q: How customizable are ornamental perforated metal patterns?

A: Yes! Hole shapes (stars, waves), sizes, and layouts can be tailored digitally. Materials range from stainless steel to colored aluminum for branding. Custom designs transform functional sheets into unique art pieces.