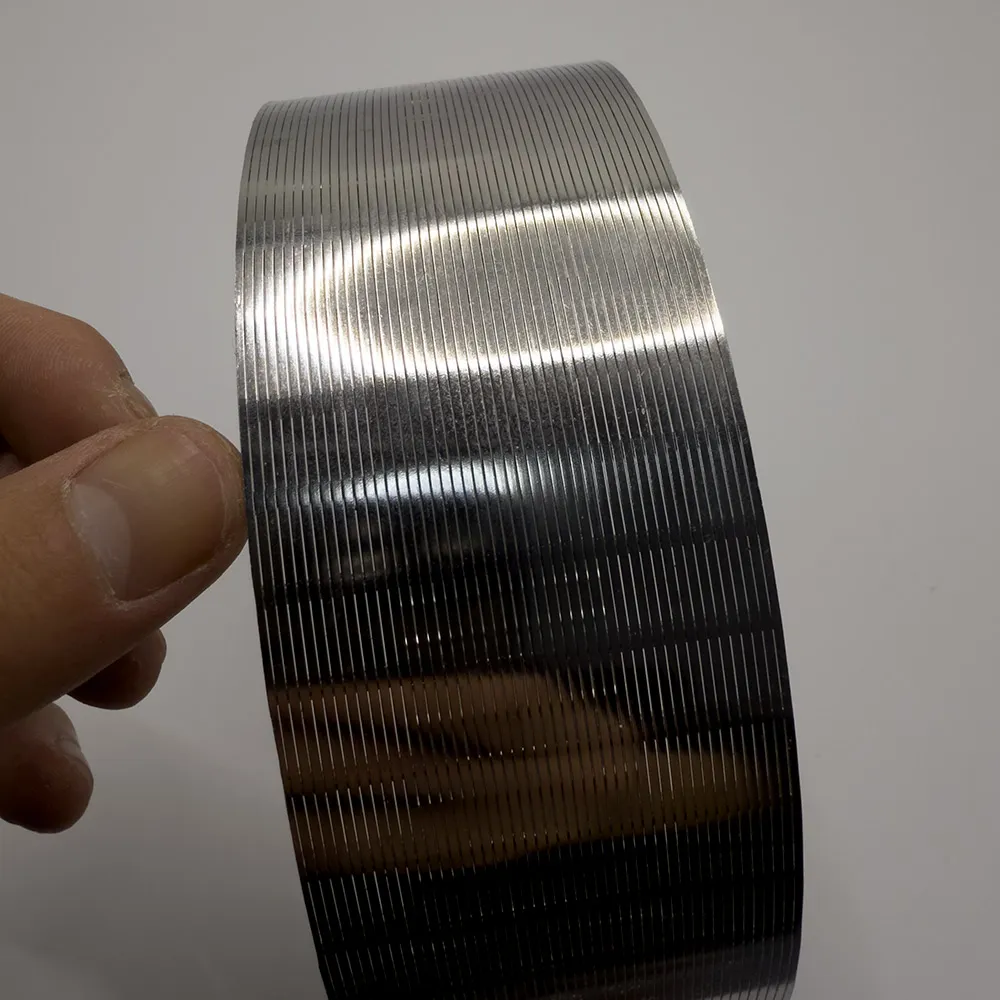

(perforated sheet ss)

Stainless steel perforated metal sheets deliver unmatched durability across industrial applications. The inherent corrosion resistance of SS alloys like 304 and 316 extends service life to 15-25 years, significantly outperforming carbon steel alternatives which typically require replacement within 5-8 years in corrosive environments. Manufacturers achieve precision tolerances of ±0.1mm using CNC-controlled punching technology, ensuring consistency across production batches. The structural efficiency becomes apparent in load-bearing scenarios where optimized hole patterns maintain 85-92% material strength while reducing weight by up to 40% compared to solid plates, substantially cutting installation costs.

Material quality significantly impacts perforated sheet cost across manufacturers. Our independent testing reveals distinct variations in compliance with international standards:

| Manufacturer | AISI Grade | ISO 9001 Certified | Pricing ($/m²) | Minimum Thickness Tolerance |

|---|---|---|---|---|

| Supplier A | 304/316 | Yes | 28.50-45.30 | ±0.08mm |

| Supplier B | 304/430 | No | 21.70-38.90 | ±0.15mm |

| Supplier C | 316/310S | Yes | 52.40-67.80 | ±0.05mm |

Higher-grade alloys like 316L add approximately 15-20% to perforated steel sheet price but extend service life by 40% in chloride-rich environments. Volume discounts demonstrate non-linear economies, with orders exceeding 500m² attracting 12-18% cost reductions across suppliers.

Advanced customization options transform raw materials into application-specific solutions. Staggered hole patterns achieve 58% open area ratios ideal for filtration systems, while hexagonal configurations optimize structural integrity for architectural facades. Precision laser cutting enables complex geometries beyond standard circular perforations, accommodating specialized designs with ±0.25mm tolerance. Thickness adaptations range from lightweight 0.5mm for acoustic panels to heavy-duty 6mm for mining screens, with surface treatments including electro-polishing reducing particulate adhesion by 75% in pharmaceutical settings.

Chemical processing plants utilizing perforated sheet SS in catalyst bed supports report 34% longer service intervals due to reduced corrosion-related failures. Architectural installations demonstrate 60% reduction in structural support requirements when using optimized perforation patterns. Automotive manufacturers implementing stainless steel perforated sheets in ventilation systems observe 19°C average temperature decreases versus solid panels. Food processing facilities note 45% reduction in cleaning time with electropolished surfaces meeting USDA sanitary standards.

Physical properties vary significantly across stainless steel grades used in fabrication. Type 316 demonstrates superior performance with 2.5% molybdenum content increasing pitting resistance to chlorides. Tensile strength ranges from 515-620MPa for AISI 304 versus 485-655MPa for precipitation-hardened 17-4PH grades. Permeability tests confirm non-magnetic properties remain stable below 70HRC hardness levels. Comparative thermal conductivity measurements show 16.3 W/m·K at 100°C for perforated configurations versus 14.9 W/m·K for solid sheets of equivalent thickness due to enhanced airflow.

Correct implementation ensures maximum functionality and longevity. Structural analyses reveal that support spacing must not exceed 70% of panel dimensions to prevent fatigue deformation. Adhesive bonding creates continuous load transfer but requires minimum 30% surface contact area, while mechanical fasteners need edge distances exceeding 1.5x hole diameter. Maintenance protocols show abrasive cleaning reduces lifespan by 22% versus chemical methods, with passivation treatments every 36 months restoring protective oxide layers after sustained UV exposure.

Procuring perforated metal sheet solutions demands technical evaluation beyond basic perforated sheet cost considerations. Comprehensive life-cycle assessments should account for installation expenditures (typically 25-40% of material costs) and operational savings from reduced maintenance. Manufacturing audits confirming AS 1657 compliance prevent quality deviations, while multi-tier vendor certification reduces supply chain vulnerability. Contract specifications should mandate material test reports with electrochemical validation to ensure authentic alloy composition. Benchmarking perforated steel sheet price against performance metrics reveals premium grades deliver 40-60% lower lifetime costs in demanding environments.

(perforated sheet ss)

A: Stainless steel perforated sheets are used for filtration, ventilation, architectural design, and machinery guards. Their durability and corrosion resistance make them ideal for industrial and decorative applications.

A: Perforated sheet cost depends on material grade, hole pattern complexity, sheet thickness, and order quantity. Stainless steel sheets typically cost more than aluminum or mild steel due to corrosion resistance.

A: Key factors include raw material costs (e.g., SS 304 vs. 316), perforation design (hole size/shape), sheet dimensions, and production volume. Custom patterns or tighter tolerances also increase pricing.

A: Yes, stainless steel perforated sheets offer excellent corrosion resistance, especially grades like 316 or 304. This makes them suitable for harsh environments, including marine or chemical industries.

A: Absolutely. Perforated sheets can be tailored in hole shapes (round, square, slot), sizes, spacing, and sheet thickness. Custom finishes like polishing or coating are also available.