In the evolving landscape of industrial processes, the demand for high-performance materials capable of operating under extreme conditions is constantly increasing. Among these, sintered felt stands out as a revolutionary material, offering unparalleled filtration efficiency, mechanical strength, and chemical resistance. This comprehensive guide explores its intricate world, from manufacturing marvels to diverse applications, empowering you with the knowledge to harness its full potential.

Industry Trends and the Growing Demand for Advanced Filtration Solutions

The global market for high-performance filtration media is experiencing robust growth, driven by stringent environmental regulations, increasing industrial automation, and the need for greater operational efficiency. Industries such as petrochemical, pharmaceutical, automotive, and aerospace are continuously seeking advanced materials that can withstand high temperatures, corrosive environments, and provide superior separation capabilities. This demand fuels innovation in materials like sintered metal fiber felt, which offers a durable, cleanable, and highly efficient alternative to traditional filtration media.

Key trends influencing the adoption of sintered felt include:

- Sustainability Initiatives: Industries are moving towards reusable and long-lasting filter media to reduce waste and environmental impact, making cleanable sintered felt highly attractive.

- High-Temperature Processes: The expansion of industries requiring processes at elevated temperatures (e.g., hot gas filtration, catalyst recovery) necessitates materials like stainless steel fiber felt that can maintain integrity and performance.

- Precision Filtration: The need for absolute filtration down to sub-micron levels in critical applications (e.g., sterile filtration in pharma, precision fluid control) is pushing the boundaries of filter design.

- Cost Efficiency: While initial investment might be higher, the extended lifespan, reusability, and reduced downtime offered by sintered fiber felt lead to significant long-term cost savings.

According to a report by Grand View Research, the global metal fiber market size was valued at USD 1.54 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 6.3% from 2023 to 2030, with filtration applications being a significant driver. This underscores the increasing reliance on advanced materials like sintered felt to meet complex industrial challenges.

Understanding the Core: Technical Parameters of Sintered Felt

The performance of any sintered felt product is defined by a set of critical technical parameters. Understanding these parameters is crucial for selecting the right material for a specific application. Here's a breakdown of the most important ones:

- Pore Size (Micron Rating): This indicates the smallest particle size that the filter can effectively capture. Sintered felts can achieve absolute filtration ratings from 0.5 microns up to 200 microns. A lower micron rating means finer filtration.

- Porosity: Represents the volume of voids (pores) within the material, expressed as a percentage. High porosity (typically 70-90%) in metal fiber felt allows for high flow rates with minimal pressure drop.

- Permeability: A measure of how easily fluids can pass through the felt. High permeability is desirable for efficient filtration and reduced energy consumption.

- Thickness: Influences the dirt-holding capacity and overall strength. It can range from 0.2 mm to several millimeters.

- Tensile Strength: The material's ability to withstand pulling forces without breaking, crucial for durability under pressure.

- Temperature Resistance: The maximum temperature the felt can withstand without degradation. For stainless steel fiber felt, this can exceed 600°C (1112°F), making it ideal for high-temperature gas filtration.

- Corrosion Resistance: The ability to resist chemical attack, determined by the material composition (e.g., various grades of stainless steel, Hastelloy, Inconel).

- Cleanability/Regenerability: The ease with which accumulated particles can be removed, allowing for repeated use and extended lifespan. This is a major advantage of sintered felt over disposable media.

Typical Sintered Felt Technical Specifications

Below is a table illustrating common parameters for various types of sintered felt, demonstrating the versatility and precision offered by this material:

| Parameter |

Standard Range (Stainless Steel) |

Typical Performance Benefits |

| Material Grades |

316L, 304L, 904L, Hastelloy, Inconel |

High corrosion and temperature resistance, bio-compatibility |

| Pore Size (Absolute) |

0.5 - 200 microns |

Precise particle capture, high efficiency filtration |

| Porosity |

70% - 90% |

High flow rates, low pressure drop, excellent dirt holding capacity |

| Thickness |

0.2 mm - 5.0 mm |

Customizable for specific mechanical and filtration needs |

| Operating Temperature |

-200°C to 700°C (or higher for special alloys) |

Suitable for cryogenic to extreme high-temperature environments |

| Permeability |

Adjustable, typically very high |

Energy efficiency, rapid processing |

| Tensile Strength |

Up to 300 MPa (for compacted forms) |

Robustness, structural integrity under stress |

| Cleanability |

Excellent (back-flushing, ultrasonic cleaning) |

Extended service life, reduced operating costs |

Polymer Sintered Felt: A Closer Look

Our flagship product, Polymer Sintered Felt, exemplifies the advanced capabilities of sintered felt technology. Engineered for demanding industrial applications, it leverages the unique properties of carefully selected metal fibers to deliver superior performance.

Process Flow: Crafting Polymer Sintered Felt

The manufacturing of sintered felt is a sophisticated process that transforms fine metal fibers into a highly porous, robust filter medium. While specific details may vary, the general process for producing high-quality metal fiber felt like our Polymer Sintered Felt involves several critical stages, ensuring exceptional material integrity and performance:

1. Fiber Preparation:

➤

Fiber Drawing/Shredding: High-quality metal wires (e.g., 316L stainless steel, titanium, nickel alloys) are drawn into extremely fine fibers, often with diameters ranging from 1 to 50 microns. For certain applications, fibers might be shredded from thin foils.

➤

Cleaning: Fibers undergo rigorous cleaning processes to remove any contaminants, oils, or oxides that could impair the sintering process or product purity.

2. Felt Formation (Web Laying):

➤

Non-Woven Web Formation: The clean metal fibers are uniformly dispersed and laid into a loose, non-woven web or mat. This can be achieved through various methods, including air-laying, wet-laying, or carding, to control the fiber distribution and initial density. The goal is to create a highly porous structure with a tortuous path for filtration.

➤

Pre-Compaction (Optional): In some cases, the felt might undergo a light compaction process to achieve a desired initial density or thickness before sintering.

3. Sintering Process:

This is the most critical step, transforming the loose fiber web into a rigid, self-supporting structure.

➤

High-Temperature Furnace: The felt is placed in a precisely controlled high-temperature furnace, typically under a protective or reducing atmosphere (e.g., hydrogen, vacuum, inert gas like argon) to prevent oxidation.

➤

Diffusion Bonding: The temperature is raised to just below the melting point of the metal fibers. At this temperature, atomic diffusion occurs at the contact points between individual fibers. This causes the fibers to metallurgically bond together, forming strong, permanent connections without melting. This process results in a stable pore structure and high mechanical strength.

➤

Cooling: After the sintering dwell time, the felt is slowly cooled in the controlled atmosphere to prevent thermal shock and maintain structural integrity.

4. Post-Processing & Quality Control:

➤

Compaction/Rolling (Optional): The sintered felt may be further rolled or compacted to achieve precise thickness, density, and pore size distribution for specific applications. This enhances mechanical strength and can refine filtration characteristics.

➤

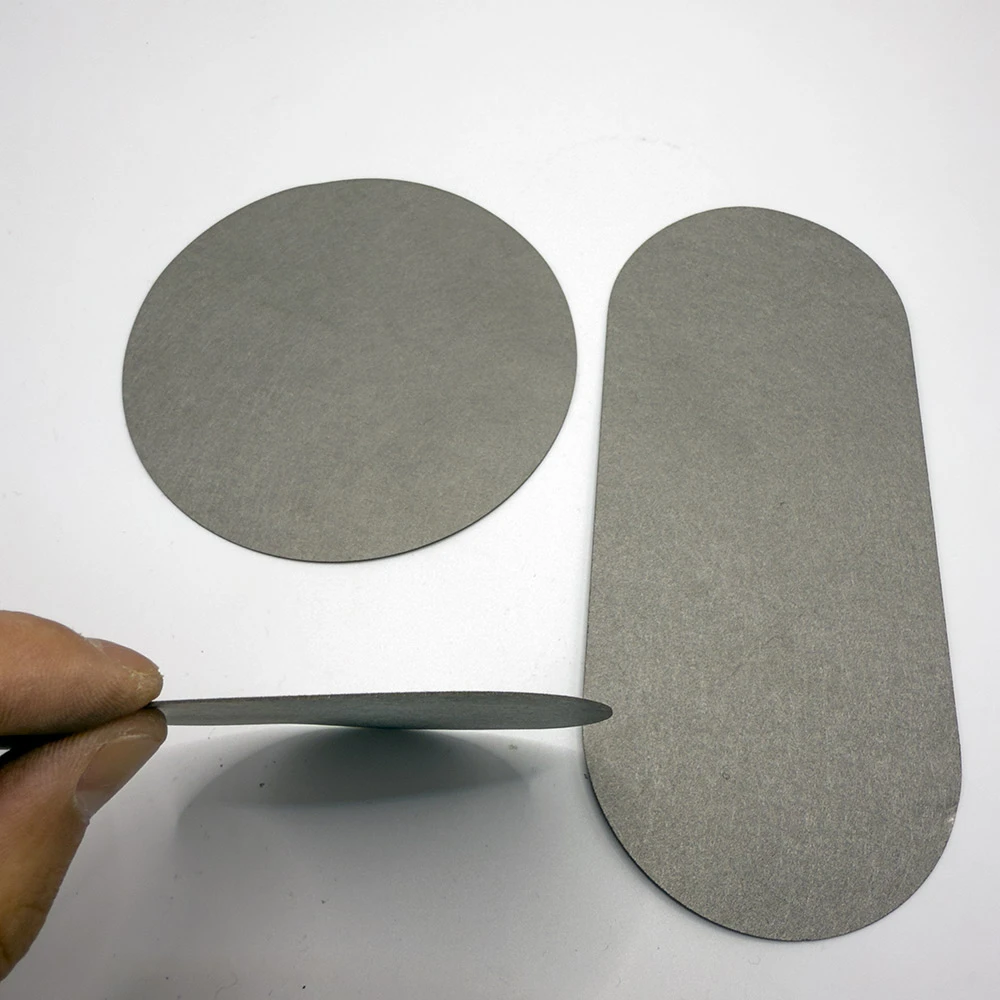

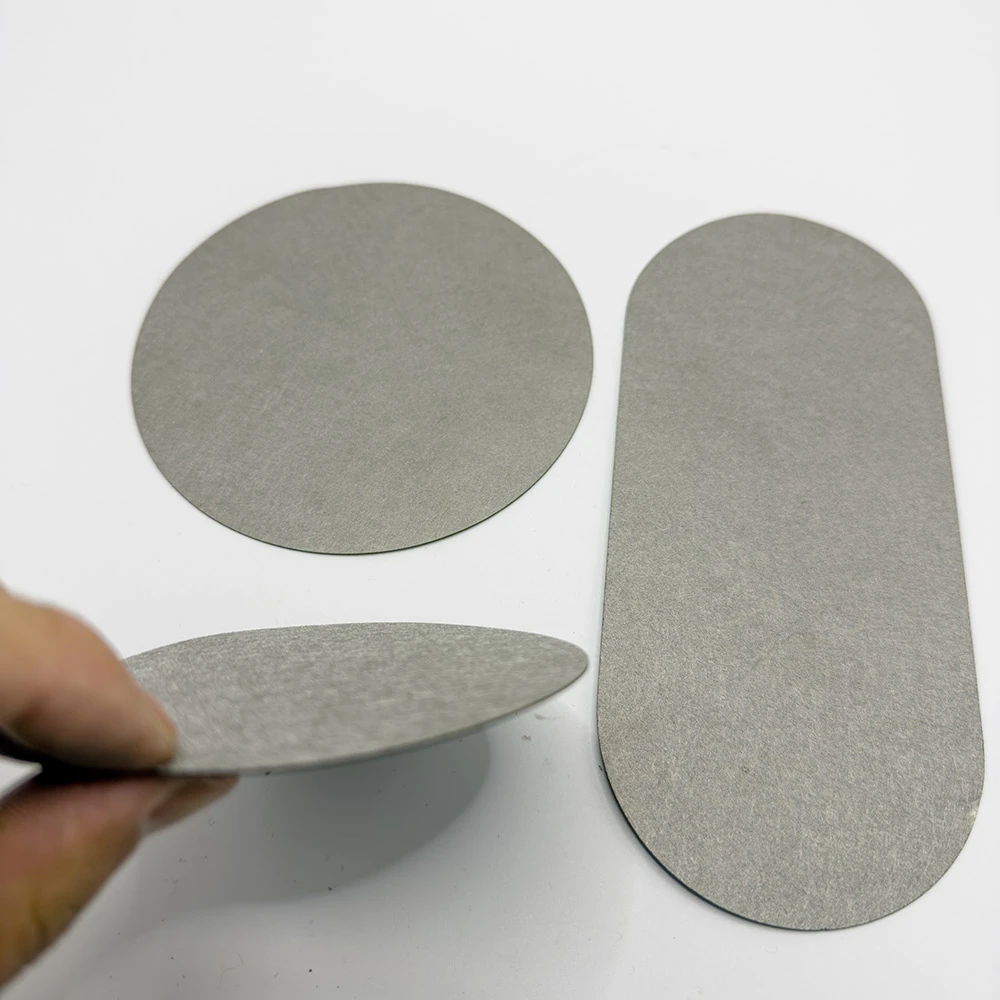

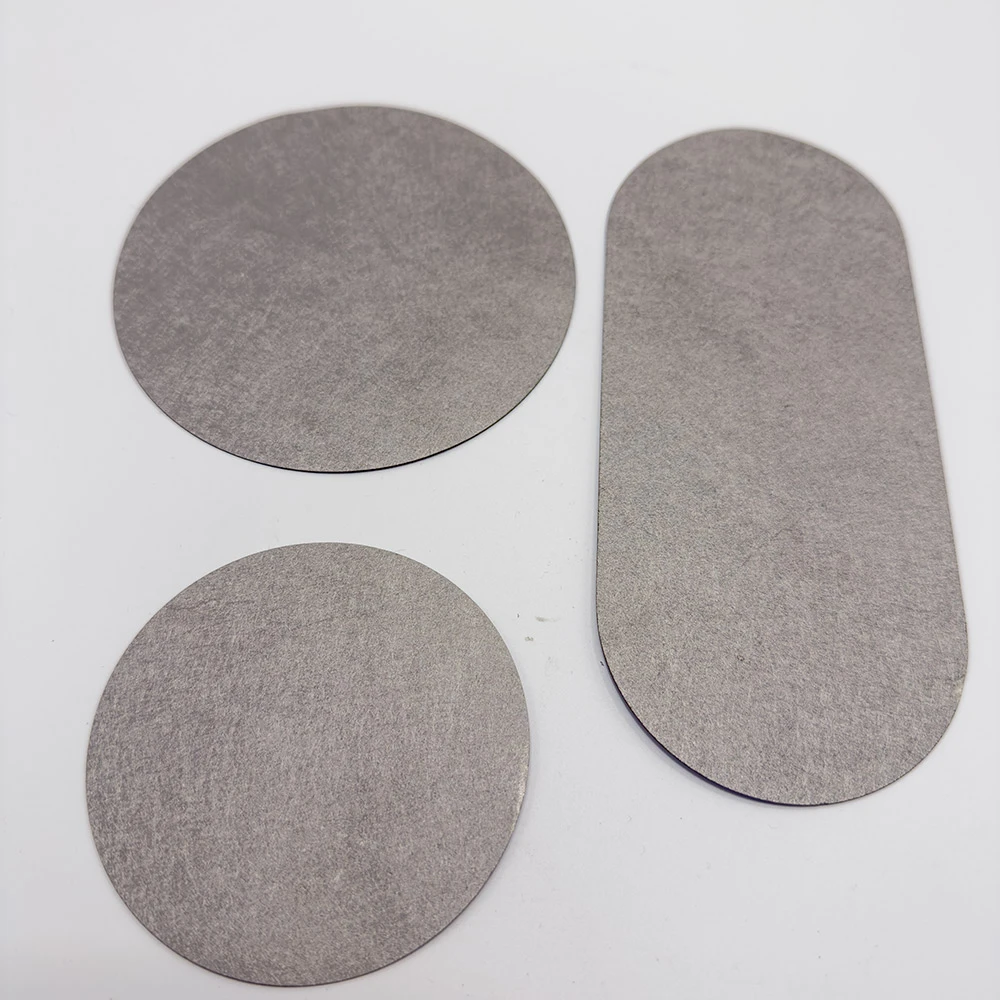

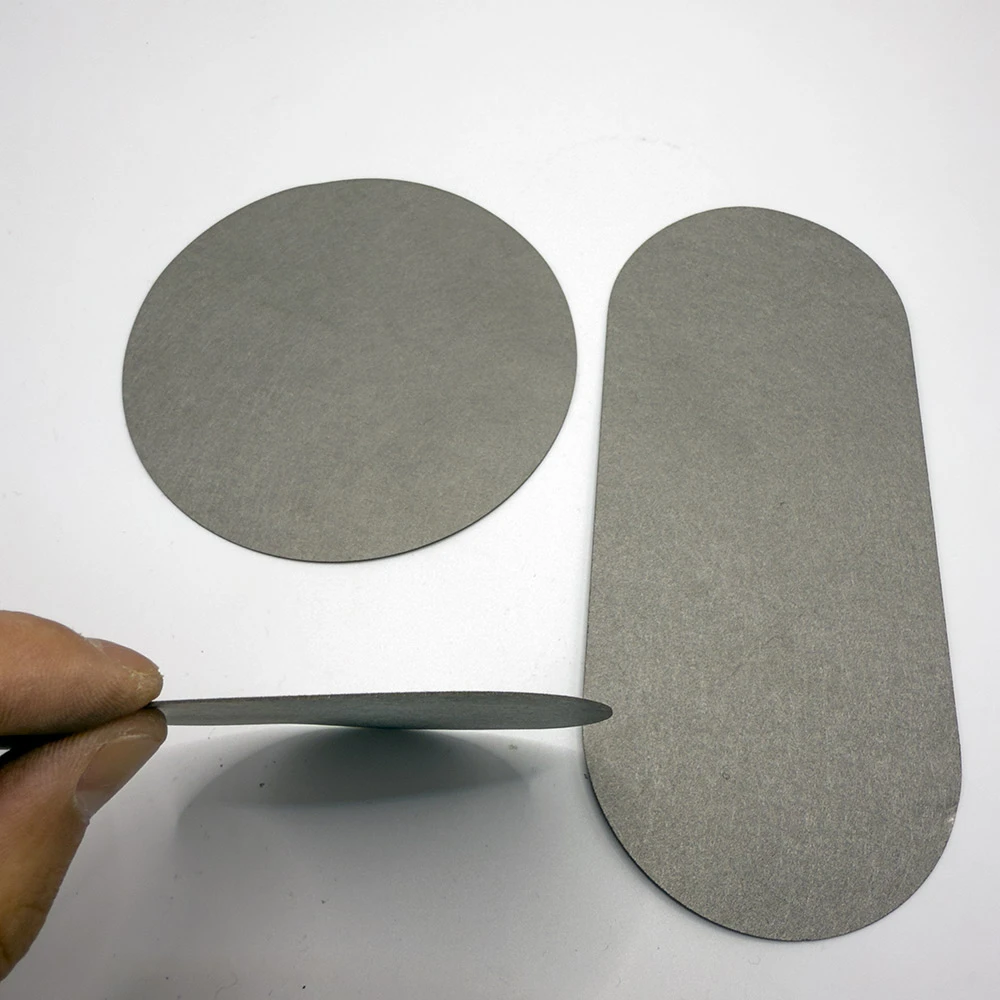

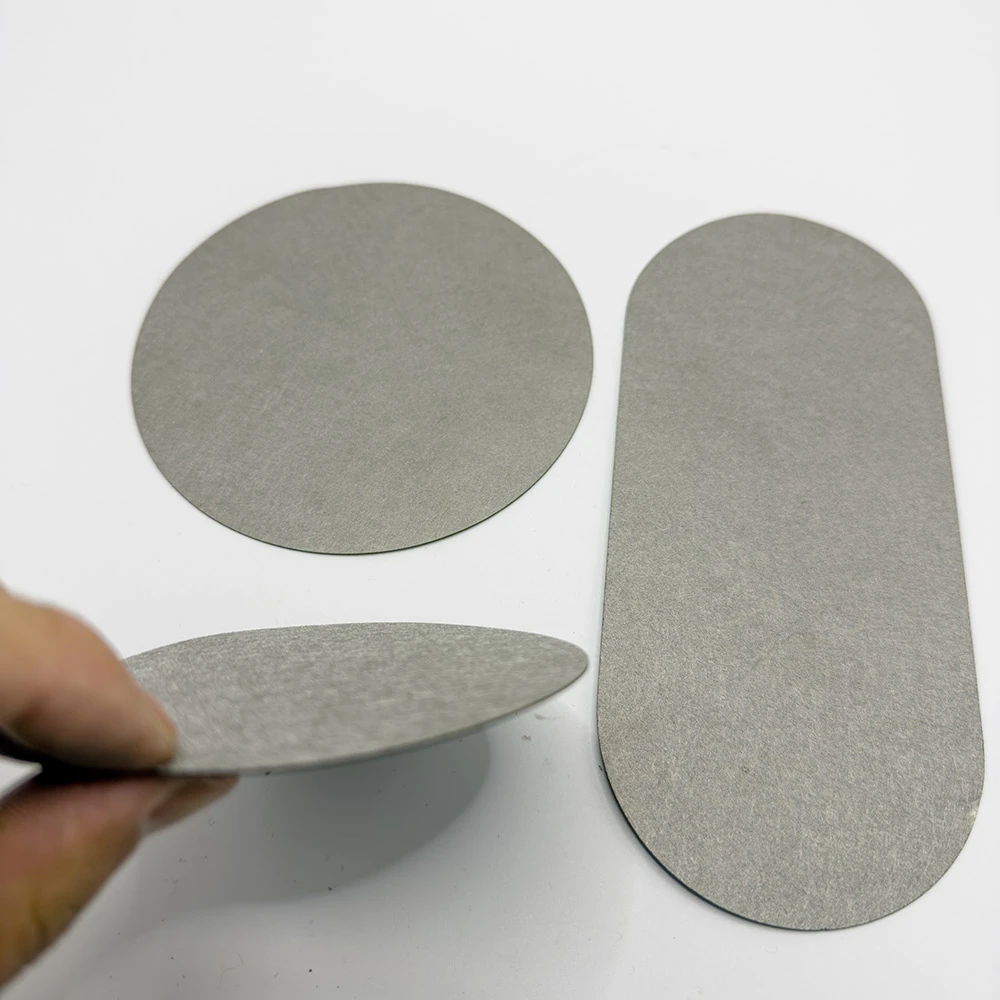

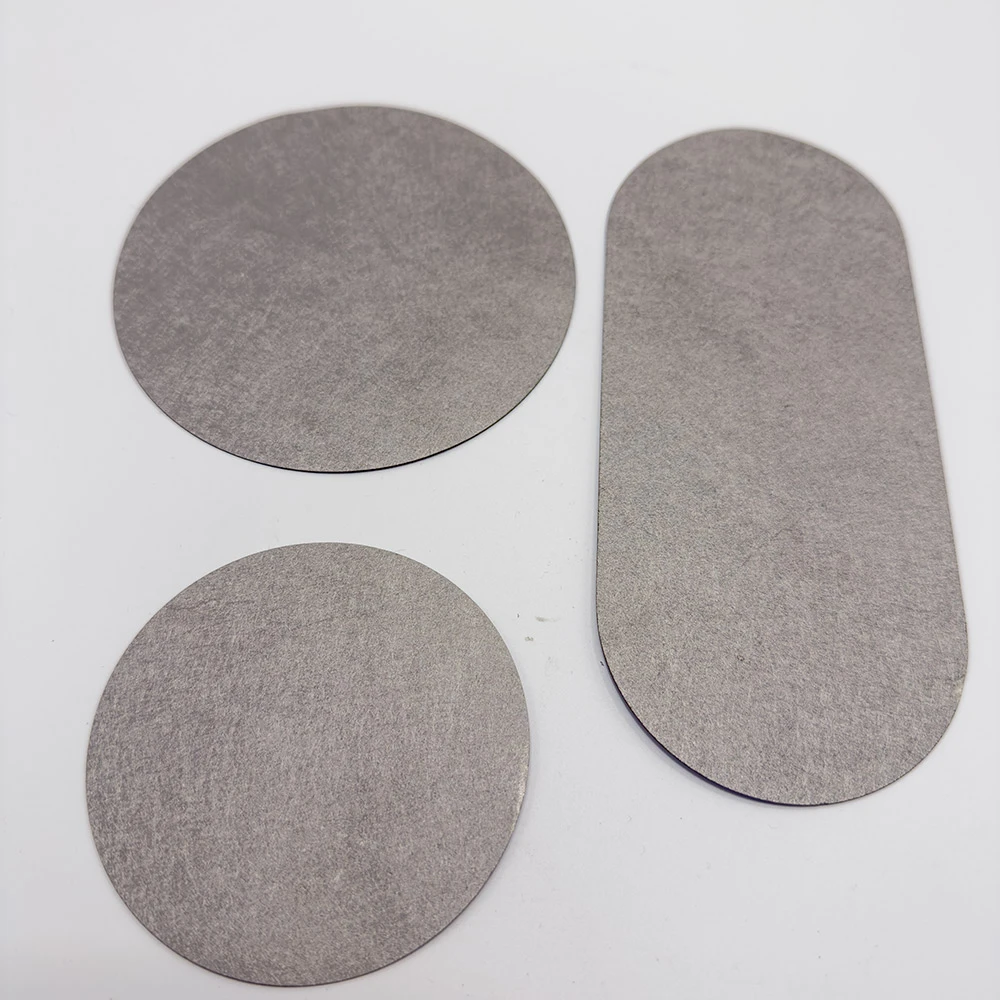

Cutting & Forming: The felt sheets are cut, welded, or formed into desired shapes and sizes, such as filter cartridges, discs, cones, or seamless tubes, using techniques like laser cutting, deep drawing, or special welding.

➤

Quality Assurance: Each batch undergoes rigorous testing to ensure it meets strict performance specifications. This includes bubble point testing (for pore size), permeability testing, porosity measurement, and mechanical strength tests. Adherence to international standards like ISO 9001 and specific industry standards (e.g., ASTM F316 for bubble point, ISO 2942 for fabrication integrity) is paramount.

Material & Manufacturing Highlights of Polymer Sintered Felt:

- Material Composition: Primarily utilizes high-grade 316L stainless steel fiber felt, known for its exceptional corrosion resistance, high-temperature stability, and biocompatibility. Other exotic alloys like Hastelloy, Inconel, and Titanium are available for extreme chemical environments.

- Manufacturing Process: Our process does not involve traditional casting or forging. Instead, it relies on advanced fiber production, precision web laying, and a controlled vacuum/hydrogen sintering process to achieve the unique porous structure and mechanical robustness. CNC machining is used for precision cutting and forming of the final filter elements.

- Detection Standards: All Polymer Sintered Felt products adhere to stringent quality control standards, including ISO 9001 for manufacturing quality, ASTM F316 for filtration performance, and other relevant industry standards (e.g., FDA compliance for food/pharma grades, if applicable).

- Service Life: With proper cleaning and maintenance, Polymer Sintered Felt elements offer an exceptionally long service life, often several years, significantly reducing replacement costs and operational downtime compared to conventional filters.

- Applicable Industries: Our Polymer Sintered Felt is ideally suited for a wide range of critical industries:

- Petrochemical & Chemical: Catalyst recovery, hot gas filtration, polymer filtration, corrosive fluid filtration, solvent recovery. Its robust structure and chemical resistance make it indispensable.

- Metallurgy & Power Generation: High-temperature flue gas filtration, slag separation, molten metal filtration, protecting expensive downstream equipment.

- Water Treatment & Desalination: Pre-filtration for reverse osmosis (RO) systems, advanced wastewater treatment, deep well injection. Its high dirt holding capacity and cleanability ensure efficient water purification.

- Pharmaceutical & Food & Beverage: Sterilization filtration, clarification, active pharmaceutical ingredient (API) recovery, high-purity water filtration. FDA-compliant grades ensure safety and purity.

- Aerospace & Aviation: Hydraulic fluid filtration, fuel filtration, cabin air filtration, pneumatic systems, where reliability and performance are non-negotiable.

- Advantages in Typical Application Scenarios:

- Energy Saving: The high porosity and low pressure drop of Polymer Sintered Felt minimize pump energy consumption in fluid filtration systems.

- Corrosion Resistance: Utilizing materials like 316L stainless steel fiber felt ensures longevity and integrity even in highly aggressive chemical environments, preventing costly material degradation and system failures.

- Back-Flushable & Regenerable: Its robust structure allows for effective back-flushing, ultrasonic cleaning, and chemical cleaning, restoring original performance and significantly extending lifespan.

- High Contaminant Capacity: The unique three-dimensional porous structure provides excellent dirt-holding capacity, leading to longer service intervals.

Application Scenarios: Where Sintered Felt Excels

The versatility of sintered felt allows it to be deployed across a vast array of challenging applications, where conventional filter media often fail. Its unique combination of high porosity, controlled pore size, and mechanical strength makes it an ideal choice.

- Polymer Filtration (Chemical & Synthetic Fibers): In the production of polymers like PET, nylon, and polypropylene, micro-impurities can significantly degrade product quality. Sintered fiber felt elements provide precise and consistent filtration, ensuring a clean polymer melt, which is critical for high-quality fiber spinning and film extrusion. This direct application significantly impacts the final product's strength, clarity, and consistency.

- Hot Gas Filtration (Industrial Furnaces, Incinerators): Conventional fabric filters cannot withstand the extreme temperatures (up to 700°C) found in industrial furnaces, incinerators, and fluidized bed reactors. Sintered metal fiber felt is perfect for filtering particulate matter from hot exhaust gases, protecting downstream equipment like heat exchangers, and reducing air pollution. Its ability to withstand thermal shock and high differential pressures ensures reliable long-term operation.

- Catalyst Recovery (Petrochemical): In petrochemical processes, expensive and often hazardous catalysts need to be efficiently recovered from process streams. Sintered felt elements, especially those made from stainless steel fiber felt, are used in reactors and separators to achieve high recovery rates, minimizing waste and maximizing process efficiency. Their robust construction handles harsh chemical environments and high flow rates.

- Fluidized Bed Applications: Acting as gas distributors or support grids, sintered felt provides uniform gas flow in fluidized beds, crucial for processes like coal gasification, pyrolysis, and pharmaceutical granulations. Its uniform porosity ensures even fluidization, preventing channeling and improving reaction efficiency.

- Pharmaceutical and Food & Beverage Industries: For critical sterilization, clarification, and purification steps, sintered felt elements (often FDA-compliant grades) are used. Examples include sterile air filtration, removal of carbon fines from liquids, and product clarification. Their easy cleanability and non-shedding properties are essential for maintaining product purity and meeting stringent regulatory standards.

- Hydraulic and Lubrication Oil Filtration: Precision machinery relies on ultra-clean hydraulic and lubrication oils. Sintered felt filter elements provide excellent contaminant removal, protecting sensitive components from wear and extending equipment life. Their high dirt-holding capacity and resistance to collapse under high pressure are significant advantages.

Technical Advantages of Polymer Sintered Felt

Compared to conventional filter media such as woven wire mesh, paper, or ceramic filters, Polymer Sintered Felt offers a multitude of superior technical advantages:

- Precise Pore Size Distribution: The controlled sintering process creates a uniform pore structure, guaranteeing highly efficient and precise filtration, often with an absolute filtration rating, unlike some nominal rated media.

- High Porosity & Permeability: With porosity typically ranging from 70% to 90%, it offers significantly higher flow rates and lower pressure drop compared to solid media or less porous alternatives, leading to reduced energy consumption.

- Exceptional Strength & Durability: The diffusion-bonded fiber structure provides excellent mechanical strength and rigidity, making it resistant to high differential pressures, thermal shock, and vibration, ensuring a long service life.

- High Temperature & Corrosion Resistance: Made from alloys like 316L stainless steel fiber felt, it can withstand extreme temperatures (up to 700°C) and aggressive chemical environments where organic or ceramic filters would degrade.

- Superior Cleanability & Reusability: Its robust metallic structure allows for effective cleaning by back-flushing, ultrasonic cleaning, or chemical washing, restoring almost original performance. This reusability drastically reduces operational costs and waste.

- Non-Shedding Media: Unlike some fibrous or pleated paper filters, sintered felt does not shed fibers, ensuring absolute product purity in critical applications like pharmaceuticals or electronics manufacturing.

- Three-Dimensional Filtration: The complex, tortuous path created by the randomly oriented fibers provides depth filtration, trapping particles throughout the media, not just on the surface, leading to higher dirt-holding capacity.

Manufacturer Comparison: Choosing Your Partner

When selecting a supplier for sintered felt products, it's crucial to partner with a manufacturer who not only understands the material science but also prioritizes quality, customization, and customer support. Look for:

- Expertise & Experience: A manufacturer with years of experience in producing advanced metal filter media, possessing deep technical knowledge of metallurgy, fiber technology, and filtration principles. Our team at CC Metal Mesh has extensive experience in the field, ensuring expertly crafted solutions.

- Quality Control & Certifications: Adherence to international quality management systems like ISO 9001, and material/product testing standards (e.g., ASTM, DIN). This guarantees consistent product quality and reliability.

- R&D Capabilities: A commitment to research and development allows for innovation and the ability to develop customized solutions for unique challenges.

- Customization & Flexibility: The ability to tailor products in terms of material, pore size, dimensions, and configurations to precisely meet specific application requirements.

- Technical Support & After-Sales Service: Comprehensive support from initial consultation to installation and troubleshooting, ensuring optimal performance and customer satisfaction.

While direct comparisons can be complex without specific competitor data, our focus on precision manufacturing, extensive material selection, and rigorous quality control for our Polymer Sintered Felt positions us as a leader in delivering high-performance sintered felt solutions.

Custom Solutions and Tailored Polymer Sintered Felt

We understand that every industrial application has unique requirements. Therefore, we specialize in providing highly customized sintered felt solutions that precisely fit your needs. Our Polymer Sintered Felt can be tailored in several aspects:

- Material Selection: Beyond standard 316L stainless steel fiber felt, we offer customization with various high-performance alloys such as 304L, 904L, Hastelloy, Inconel, and Titanium, chosen based on the chemical compatibility, temperature resistance, and mechanical strength required for your specific operating environment.

- Pore Size & Porosity: Our manufacturing process allows for precise control over the fiber density and sintering parameters, enabling us to achieve desired pore sizes (from sub-micron to hundreds of microns) and porosity levels, optimizing filtration efficiency and flow characteristics.

- Dimensions & Configurations: Whether you need flat sheets, seamless tubes, pleated cartridges, discs, or complex geometries, we can fabricate sintered fiber felt elements to your exact specifications. Our CNC machining capabilities ensure high precision in custom shapes and sizes.

- Multi-Layer Composites: For applications requiring enhanced strength, specific filtration profiles, or combined functionalities, we can produce multi-layered sintered felt structures, including combinations with sintered wire mesh for added mechanical support or pre-filtration stages.

Our engineering team works closely with clients from conceptualization to delivery, providing expert consultation to design and deliver the optimal sintered felt solution for even the most challenging applications. This collaborative approach ensures that the final product not only meets but often exceeds performance expectations.

Application Cases: Sintered Felt in Action

Here are illustrative examples demonstrating the impact and effectiveness of sintered felt in real-world industrial scenarios:

Case Study 1: Enhanced Catalyst Recovery in a Petrochemical Plant

A major petrochemical company faced significant losses due to inefficient recovery of a precious catalyst from a high-temperature, corrosive gas stream. Their existing ceramic filters frequently clogged and required expensive, time-consuming replacements. We proposed replacing their filtration units with custom-designed Polymer Sintered Felt cartridges made from 316L stainless steel fiber felt.

- Solution Implemented: Installation of multi-layered sintered felt filter cartridges optimized for sub-micron particle retention and high-temperature resistance.

- Results:

- Increased Catalyst Recovery: Filtration efficiency improved from 95% to over 99.5%, leading to a substantial reduction in catalyst loss, saving millions annually.

- Reduced Downtime: The sintered felt elements could be effectively back-flushed in-situ, reducing cleaning cycles by 70% and nearly eliminating filter replacement downtime.

- Extended Lifespan: Filters now last 3-5 years compared to 6 months for the old ceramic elements, drastically cutting maintenance costs.

Case Study 2: Ultrapure Water Production for a Semiconductor Manufacturer

A leading semiconductor fabrication plant required ultrapure water free of any particulate matter down to 0.1 microns to prevent defects in microchip production. Traditional membrane filters struggled with consistent flow rates and frequent clogging.

- Solution Implemented: Integration of fine-pore sintered fiber felt pre-filters upstream of their RO system.

- Results:

- Improved Water Quality: The sintered felt effectively removed even the finest suspended solids, significantly reducing the load on the RO membranes and improving overall water purity.

- Extended Membrane Life: The lifespan of expensive RO membranes was extended by over 50% due to reduced fouling.

- Stable Flow Rates: The high porosity and consistent permeability of the sintered felt ensured stable and optimal flow rates, crucial for continuous production.

Ensuring Trust: Our Commitments and Support

Trust is built on transparency, reliability, and unwavering support. As a leading provider of sintered felt solutions, we are committed to upholding the highest standards of trustworthiness throughout our engagement with you.

Frequently Asked Questions (FAQ) about Sintered Felt

- Q1: What is the primary difference between Polymer Sintered Felt and traditional woven filters?

- A1: Polymer Sintered Felt, a type of sintered metal fiber felt, offers a much more uniform pore size distribution and a complex, tortuous path for filtration compared to woven filters. This results in superior filtration efficiency, absolute particle retention, higher dirt-holding capacity, and significantly greater mechanical strength and resistance to high temperatures and corrosive environments. Unlike woven filters, it does not shed fibers.

- Q2: Can sintered felt be cleaned and reused, and what methods are recommended?

- A2: Absolutely. One of the major advantages of sintered felt is its excellent cleanability and reusability. Common methods include back-flushing (reversing fluid flow), ultrasonic cleaning, chemical cleaning (using appropriate solvents or acids), and even high-pressure water jets. The specific method depends on the nature of the contaminants and the application.

- Q3: What are the typical service life expectations for Polymer Sintered Felt products?

- A3: With proper selection, installation, and regular cleaning, Polymer Sintered Felt products made from robust materials like stainless steel fiber felt can have a service life ranging from several months to many years (3-5 years or more is common). Factors like operating conditions (temperature, pressure, contaminant load), fluid chemistry, and cleaning frequency significantly influence lifespan.

- Q4: How does sintered felt handle high temperatures and corrosive chemicals?

- A4: Due to its metallic composition and the high-temperature sintering process, sintered felt exhibits exceptional thermal stability. Materials like 316L stainless steel can operate reliably up to 700°C (1292°F). For corrosive chemicals, specialized alloys such as Hastelloy, Inconel, and Titanium are used, offering superior resistance to acids, alkalis, and other aggressive media where plastic or fabric filters would fail.

- Q5: What is "absolute filtration" in the context of sintered felt?

- A5: Absolute filtration refers to the ability of a filter to capture virtually all particles larger than a specified micron rating, typically with an efficiency of 99.9% or higher. Unlike "nominal" ratings which indicate an average, sintered felt, with its controlled and rigid pore structure, can provide absolute filtration, critical for applications requiring extremely high purity.

- Q6: What certifications or standards should I look for when purchasing sintered felt?

- A6: Reputable manufacturers adhere to international quality standards. Look for ISO 9001 certification for quality management. For product performance, relevant standards include ASTM F316 (Standard Test Method for Pore Size Characteristics of Membrane Filters by Bubble Point and Mean Flow Pore Test), ISO 2942 (Fluid power systems – Filter elements – Verification of fabrication integrity and determination of the first bubble point), and potentially industry-specific certifications like FDA compliance for food and beverage or pharmaceutical applications.

- Q7: Can sintered felt be customized for specific applications?

- A7: Yes, customization is a key strength of sintered felt. Manufacturers can tailor the material (e.g., metal fiber felt from different alloys), pore size, porosity, thickness, and final shape/dimensions (e.g., cylinders, discs, pleated cartridges) to perfectly match the unique requirements of your process, including specific flow rates, pressure drops, and contaminant types.

Delivery and Support Commitments

- Delivery Cycle: Our standard delivery times for Polymer Sintered Felt vary based on product complexity and customization. Typically, custom orders are fulfilled within 4-6 weeks after design approval, with expedited options available for urgent requirements. We maintain a stock of common configurations for quicker dispatch.

- Quality Assurance & Warranty: All Polymer Sintered Felt products undergo stringent quality checks at every stage of manufacturing, adhering to ISO 9001 standards. We provide a comprehensive warranty against manufacturing defects, ensuring your investment is protected. Specific warranty terms are provided with each quotation.

- Customer Support: Our dedicated technical support team is available to assist you with product selection, system integration, troubleshooting, and maintenance guidance. We offer pre-sales consultation, on-site technical assistance (where feasible), and prompt after-sales support to ensure the optimal performance of our sintered felt solutions throughout their lifecycle.

Concluding Thoughts: The Future of Sintered Felt

Sintered felt technology represents a significant leap forward in material science, offering robust, efficient, and sustainable solutions for myriad industrial challenges. Its unique combination of high porosity, mechanical strength, and resistance to extreme conditions positions it as an indispensable material in advanced filtration, fluidization, and other high-performance applications. As industries continue to evolve, the demand for sophisticated materials like Polymer Sintered Felt will only intensify, driving further innovation in its development and application.

The commitment to quality, customization, and comprehensive customer support ensures that industries can confidently integrate these advanced solutions, leading to enhanced operational efficiency, reduced environmental impact, and superior product quality. The journey of sintered metal fiber felt from concept to critical industrial component is a testament to continuous engineering excellence and a vision for a cleaner, more efficient industrial future.

References and Further Reading:

- "Sintered Metal Fiber Media: Properties, Applications, and Design Considerations" - A comprehensive review from the Journal of Materials Science. (Source Link)

- "Advances in Filtration Technology for High-Temperature Gas Streams" - Insights from the AIChE Journal, discussing the role of advanced metallic filters. (Relevant Journal Home Page - Specific article access may require subscription)

- "Market Analysis Report: Metal Fiber" by Grand View Research - Provides market size, share, and trends for metal fibers, including those used in sintered felt. (Source Link)