In the demanding landscape of modern industrial processes, the need for superior filtration, diffusion, and structural integrity is paramount. This is where sintered felt emerges as a game-changer. Unlike conventional filtration media, this advanced material, often comprising sintered metal fiber felt, offers unparalleled performance characteristics derived from its unique three-dimensional porous structure. It represents a sophisticated blend of material science and engineering, critical for sectors ranging from petrochemical and aerospace to pharmaceutical and energy. Its robust design ensures prolonged operational life, exceptional filtration efficiency, and resilience under extreme conditions, making it an indispensable component for optimizing efficiency and product purity in high-stakes environments.

The increasing complexity of industrial operations, coupled with stringent environmental regulations and the drive for energy efficiency, underscores the growing demand for materials like metal fiber felt. Industry trends indicate a significant shift towards durable, high-performance filter media that can withstand corrosive chemicals, high temperatures, and high pressures while maintaining precise filtration capabilities. This article delves into the intricate manufacturing processes, key technical parameters, diverse application scenarios, and the inherent advantages that position sintered fiber felt as a leading solution for complex industrial challenges. We will explore how these materials contribute to energy savings, enhanced safety, and superior product quality across various sectors.

The creation of sintered felt is a meticulously controlled multi-stage process that leverages advanced metallurgical techniques to achieve its distinctive properties. It typically begins with the selection of ultra-fine metal fibers, commonly stainless steel (e.g., 316L, 304L), but also nickel-based alloys, FeCrAl alloys, or titanium, chosen for their specific chemical resistance, high-temperature tolerance, and mechanical strength. These fibers, often less than 10 micrometers in diameter, are crucial for achieving high porosity and uniform pore distribution.

The manufacturing process unfolds as follows: Firstly, metal fibers are carefully drawn to achieve the desired diameter and length. These fibers are then processed into a non-woven web or mat through advanced techniques such as air-laying, wet-laying, or paper-making methods, ensuring a homogeneous distribution and interconnected pore structure. This preliminary structure is then subjected to a crucial sintering process. Sintering involves heating the compacted fiber mat in a controlled atmosphere (typically vacuum or inert gas) to a temperature below the melting point of the metal. During this stage, metallurgical bonds form at the fiber contact points, creating a robust, stable, and highly porous structure without fully melting the fibers. This bonding imparts exceptional mechanical strength, rigidity, and resistance to deformation, which are critical for high-pressure and high-temperature applications.

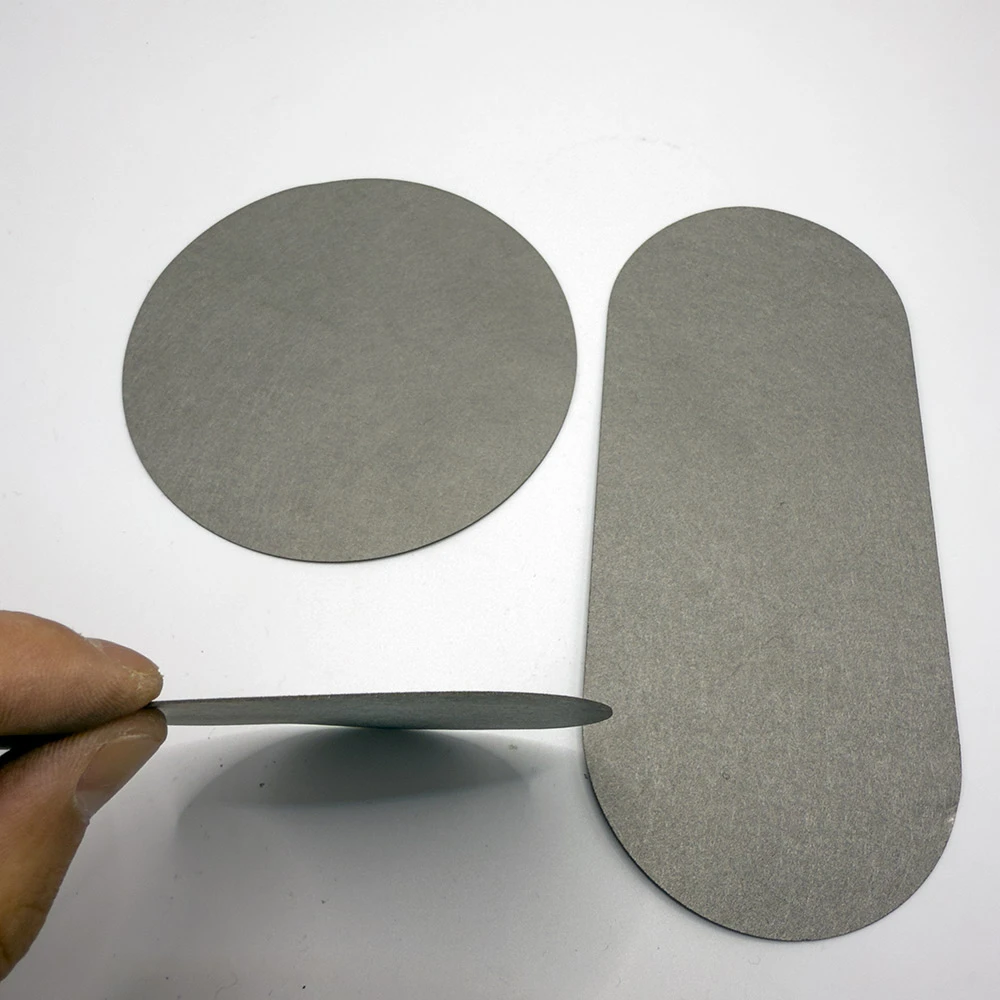

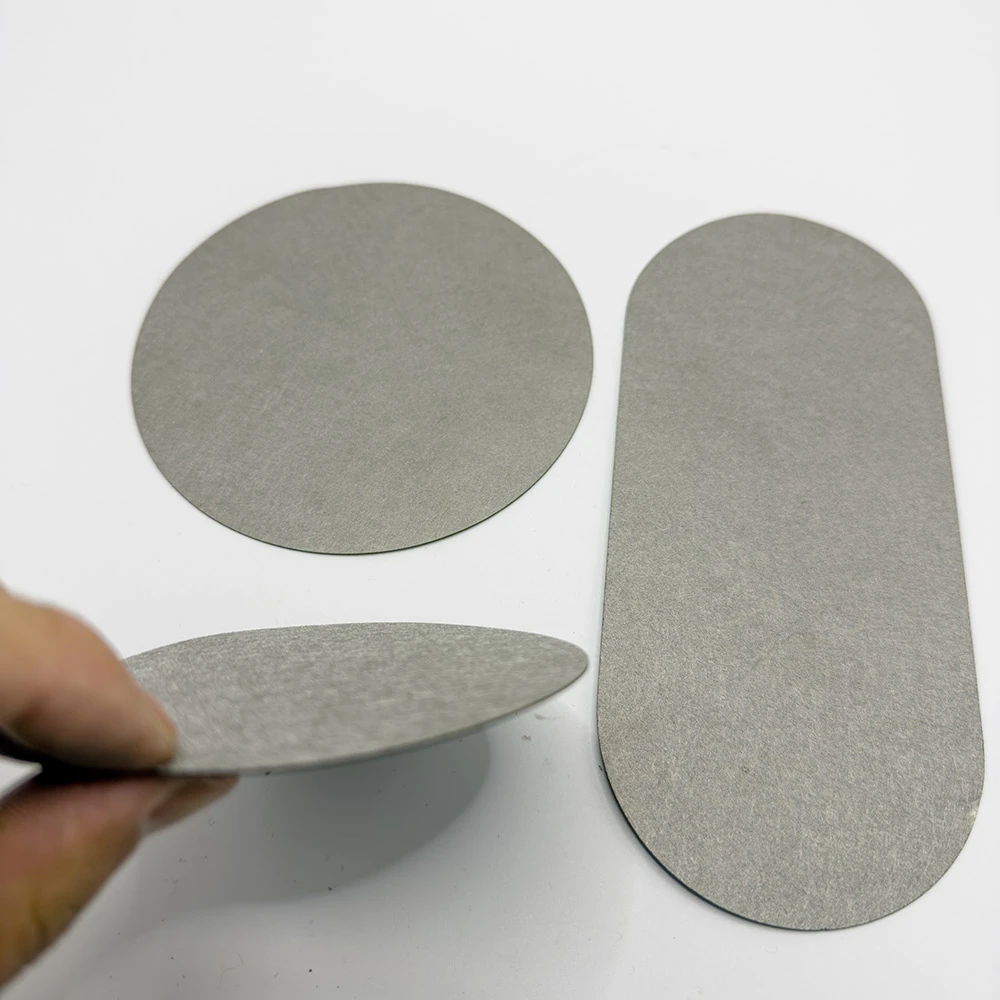

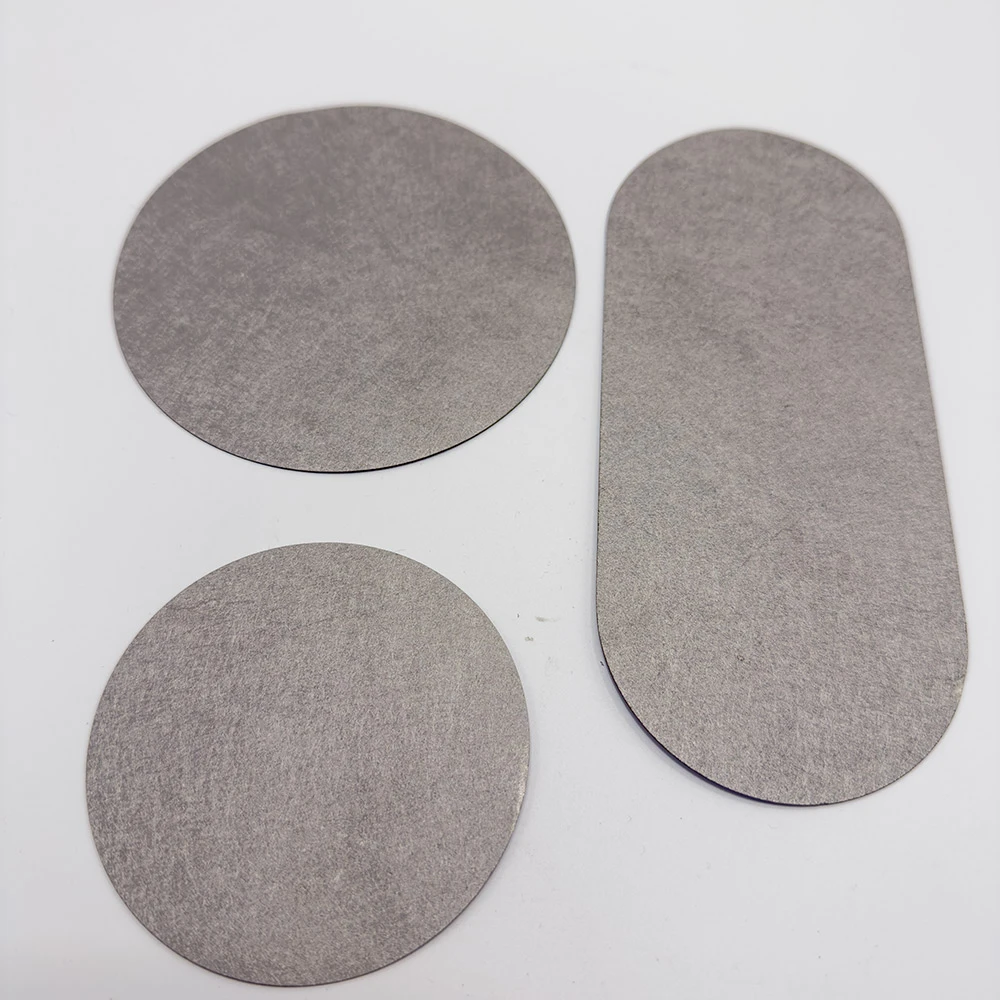

Post-sintering, the material undergoes various finishing processes, including calendering to control thickness and porosity, and precise cutting or forming to meet specific application requirements. Throughout this entire process, stringent quality control measures are implemented, adhering to international standards such as ISO and ASTM, to ensure consistent pore size, permeability, mechanical integrity, and corrosion resistance. This rigorous approach guarantees the reliability and long service life of sintered metal fiber felt products across diverse and challenging industrial environments like petrochemical processing, metallurgy, and water treatment, where their non-shedding nature and high dirt-holding capacity offer significant advantages in terms of energy saving and anti-corrosion properties.

The performance of sintered felt is defined by a suite of critical technical parameters, each contributing to its suitability for specific industrial applications. Understanding these parameters is essential for engineers and decision-makers to select the optimal material for their needs.

| Parameter | Typical Range / Description | Significance |

|---|---|---|

| Material Composition | 316L Stainless Steel, 304L Stainless Steel, Nickel Alloys (e.g., Inconel, Hastelloy), Titanium, FeCrAl | Determines corrosion resistance, high-temperature stability, and chemical compatibility. |

| Pore Size / Filtration Rating | 0.5 μm to 200 μm (Absolute) | Crucial for filtration precision; dictates particle retention capability. Lower values indicate finer filtration. |

| Porosity | 70% to 90% | High porosity ensures low pressure drop, high flow rates, and excellent dirt-holding capacity. |

| Permeability | High (varies with pore size and thickness) | Indicates ease of fluid flow through the material; directly related to flow rate capability at given pressure drop. |

| Temperature Resistance | Up to 900 °C (1650 °F) for stainless steel, higher for specialty alloys | Ability to maintain structural integrity and performance in extreme heat environments. |

| Corrosion Resistance | Excellent against acids, alkalis, and various chemical agents | Withstands aggressive chemical environments, extending lifespan in harsh applications. |

| Mechanical Strength | High tensile strength, good flexural rigidity | Resists deformation under pressure differences and mechanical stress, crucial for structural support. |

| Specific Surface Area | High (due to intricate fiber network) | Beneficial for applications requiring catalytic support or high-efficiency mass transfer. |

These parameters collectively define the superior performance of sintered metal fiber felt. For instance, its high porosity directly translates to a significantly lower pressure drop compared to conventional filter media, leading to reduced energy consumption in fluid processing systems. The combination of high temperature and corrosion resistance makes sintered fiber felt indispensable in harsh chemical processes or high-temperature gas filtration, where polymeric or ceramic materials would fail. Its precise and absolute filtration rating ensures consistent product quality and protects downstream equipment from contamination, offering a long service life under challenging operational conditions.

The versatility and robust performance of sintered felt make it an ideal choice across a broad spectrum of industries, addressing critical challenges in filtration, separation, and flow management. Its unique properties are leveraged in applications where conventional materials fall short.

These diverse applications underscore the technical advantages of sintered felt: its exceptional filtration efficiency, high dirt holding capacity, resistance to extreme conditions, and prolonged service life. These features translate directly into operational benefits such as energy savings due to lower pressure drops, reduced maintenance costs through less frequent filter changes, and enhanced safety by preventing contamination and equipment failure.

The inherent technical advantages of sintered felt distinguish it from conventional filtration and porous media, providing superior performance and cost-efficiency in the long run. Its unique structure, formed by the sintering of fine metal fibers, imparts properties that are critical for demanding industrial environments.

Recognizing that every industrial application has unique requirements, leading manufacturers offer extensive customization capabilities for sintered felt products. This includes:

This level of customization, combined with deep technical expertise and collaborative engineering support, ensures that clients receive optimal filtration solutions perfectly matched to their operational needs, leading to enhanced performance, reduced operational costs, and superior process outcomes.

For B2B decision-makers, choosing a supplier for advanced materials like sintered felt goes beyond product specifications; it's about establishing trust in a partnership. Our commitment to excellence is reflected not only in the superior quality of our sintered metal fiber felt but also in our comprehensive customer support, rigorous quality assurance, and proven track record in diverse industrial applications. We adhere to stringent international standards, including ISO 9001 for quality management systems, ensuring that every batch of sintered felt meets the highest benchmarks for performance and reliability.

Our technical team provides expert consultation, assisting clients in selecting or customizing the optimal sintered fiber felt solution for their specific operational challenges. From initial design and prototyping to production and post-sale support, we ensure a seamless experience. Delivery cycles are optimized through efficient manufacturing processes and robust supply chain management, ensuring timely delivery even for large-scale projects. Furthermore, our products typically come with a comprehensive warranty against manufacturing defects, underscoring our confidence in their durability and performance. Customer testimonials often highlight the significant improvements in process efficiency, reduced maintenance costs, and enhanced product purity achieved by integrating our sintered stainless steel fiber felt into their systems.

The evolution of sintered felt technology has marked a significant advancement in industrial filtration and porous media applications. Its unparalleled combination of high porosity, precise filtration capabilities, mechanical robustness, and resilience to extreme conditions—be it high temperatures, corrosive chemicals, or high pressures—positions sintered metal fiber felt as a critical material for optimizing operational efficiency and product quality across a myriad of sectors. From enhancing energy efficiency in chemical processing to ensuring sterile environments in pharmaceuticals, the advantages of sintered fiber felt are clear and quantifiable.

As industries continue to push the boundaries of performance and sustainability, the demand for sophisticated materials like stainless steel fiber felt will only intensify. Future innovations are likely to focus on even finer filtration capabilities, novel alloy compositions for more extreme environments, and advanced manufacturing techniques for greater cost-effectiveness and broader applicability. The long service life, cleanability, and superior performance of sintered felt not only offer immediate operational benefits but also contribute to long-term sustainability goals by reducing waste and resource consumption. Embracing this advanced technology is a strategic investment for any enterprise aiming for peak performance and reliability in its most critical processes.

PREV:

This is the last article