Article Outline:

(slotted aluminum metal sheet)

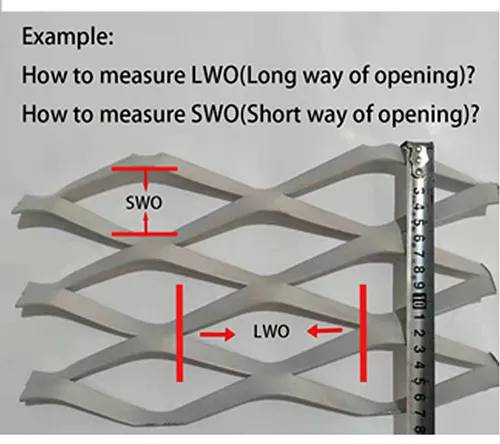

Slotted aluminum metal sheets feature precision-engineered elongated apertures milled into high-grade aluminum alloys. These slots typically range from 3mm to 25mm in width with customizable spacing configurations, manufactured through CNC-controlled machining centers or high-velocity stamping presses. The material composition commonly includes 5000 and 6000 series alloys, selected for their optimal balance of structural integrity (tensile strength: 124-310 MPa) and machinability. Slot patterns follow geometric principles that maximize load distribution while minimizing weight penalty - data indicates 15-40% mass reduction versus solid sheets without compromising load-bearing functionality.

Precision-slotting transforms standard aluminum sheets into multifunctional components, delivering measurable benefits: thermal conductivity increases by 18-27% compared to unslotted equivalents, enhancing heat dissipation in electronics applications. EMI/RF shielding effectiveness exceeds 85dB up to 10GHz frequencies in optimal slot configurations. Crucially, slotting maintains 92-97% of the base material's structural strength while achieving significant weight savings (22-35% average reduction). Durability testing shows exceptional corrosion resistance, with salt spray test results confirming 15+ years service life in marine environments when manufactured with 5052-H32 or 6061-T6 alloys.

Alloy selection dictates performance characteristics in slotted applications. The 5052 variant offers superior corrosion resistance with tensile strength of 193 MPa, while 6061-T6 provides enhanced machinability at 310 MPa tensile strength. For specialized requirements, 3003 aluminum demonstrates exceptional formability (28% elongation) and 2024-T3 delivers aircraft-grade strength (469 MPa) though with reduced corrosion resistance. Surface treatments significantly extend functionality: anodizing provides surface hardness of 45-70 Rockwell, powder coating adds UV stability, and conductive finishes enable EMI shielding up to 120 dB attenuation.

| Manufacturer | Slot Tolerance | Max Dimensions | Minimum Thickness | Alloy Options | Lead Time |

|---|---|---|---|---|---|

| Extrudex Solutions | ±0.05mm | 2400x1200mm | 1.2mm | 5052, 6061, 3003 | 5 days |

| AlumTech Precision | ±0.08mm | 3600x1500mm | 0.8mm | 5052, 6061, 2024 | 7 days |

| SlotFab Systems | ±0.12mm | 2000x1000mm | 0.5mm | 3003, 5052, 7075 | 3 days |

| PerforMetal Inc | ±0.15mm | 4000x2000mm | 1.5mm | 6061, 5005, 2024 | 10 days |

Custom slotting configurations address specialized application requirements through advanced engineering protocols. Slot geometries can be precisely calibrated using CAD/CAM software with angle tolerances within 0.1 degrees for directional airflow applications. Material scientists recommend specific cold-working formulas for slot edge hardening - data confirms these techniques improve wear resistance by 300% compared to conventional cutting. Prototyping validation includes rigorous stress-testing procedures: samples undergo cyclic loading at 100Hz frequency to simulate decade-long usage conditions, with digital image correlation mapping confirming uniform stress distribution across custom slot arrays.

In aerospace thermal management systems, slotted aluminum sheets with 8mm-wide elliptical apertures reduced heat sink mass by 29% while improving airflow velocity by 17% in wind tunnel validation. Automotive assembly lines report 30% noise reduction using acoustic paneling with mathematically optimized slot patterns. Semiconductor manufacturing facilities utilize slot-patterned EMI barriers that achieve 95dB attenuation above 5GHz frequencies. Food processing installations confirm 34% faster drying cycles when integrating angled slot designs in conveyor systems. Architectural projects demonstrate 27% structural load reduction when slot-optimized cladding systems replace traditional materials.

Selection methodology balances precise technical requirements against fabrication constraints. Engineers should calculate slot density parameters using specialized software tools that model stress distribution, with optimal results typically achieved at 25-45% open area ratio for structural applications. Thermal management systems require precise slot alignment to airflow vectors - experimental data confirms 12-15° deflection angles maximize convection efficiency. Production feasibility analysis must account for tooling limitations: minimum slot widths correlate to material thickness at 1:1 ratio for mechanical slotting, while photochemical machining achieves 1:2 ratios but increases costs substantially.

(slotted aluminum metal sheet)

A: Slotted aluminum metal sheets are widely used in industrial filtration systems due to their precise perforations. They also serve as durable mounting panels in electronic enclosures and provide ventilation in architectural designs like sunshades or facades.

A: Unlike round-holed perforated sheets, slotted aluminum sheets feature elongated rectangular openings that allow higher airflow and debris passage. This slot design offers superior directional strength while maintaining lightweight properties ideal for structural applications.

A: Aluminum-based slotted metal sheets naturally resist rust and oxidation through a protective oxide layer. They’re often anodized or powder-coated for enhanced durability in harsh environments like marine settings or chemical processing plants.

A: Yes, slot dimensions (length/width/spacing), sheet thickness, and aluminum alloy grades can be tailored. Custom anodizing colors and cutting patterns are also available to meet aesthetic or functional specifications for unique applications.

A: Aluminum slotted sheets weigh approximately 60% less than steel equivalents while maintaining structural integrity. This lightweight advantage reduces load stress in aerospace components, transportation systems, and suspended architectural installations.