In the intricate world of industrial filtration, separation, and architectural design, the choice of material and construction is paramount. Among the myriad options, Stainless Steel Weave Wire Mesh stands out as a material of unparalleled versatility, strength, and corrosion resistance. This detailed exploration delves into its multifaceted applications, technical specifications, manufacturing prowess, and the critical factors that make it an indispensable component across a diverse range of sectors.

The global market for wire mesh, particularly that made from stainless steel, is experiencing robust growth, driven by escalating demand in key sectors like chemical processing, oil & gas, food & beverage, and environmental protection. According to a report by Grand View Research, the global industrial wire mesh market size was valued at USD 5.1 billion in 2022 and is projected to expand at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is largely attributable to the increasing need for efficient filtration systems, enhanced safety standards, and durable materials capable of withstanding harsh operating environments. The inherent properties of stainless steel, such as its exceptional corrosion resistance, high tensile strength, and hygienic attributes, position Stainless Steel Weave Wire Mesh as a preferred choice over traditional materials in many critical applications.

Furthermore, the push towards sustainable manufacturing and the circular economy has amplified the appeal of stainless steel due to its recyclability and long service life, reducing waste and material consumption over time. Advancements in weaving technologies, including the development of finer meshes and specialized weave patterns, are also expanding the potential applications for this material, from micro-filtration in pharmaceuticals to aesthetic architectural facades.

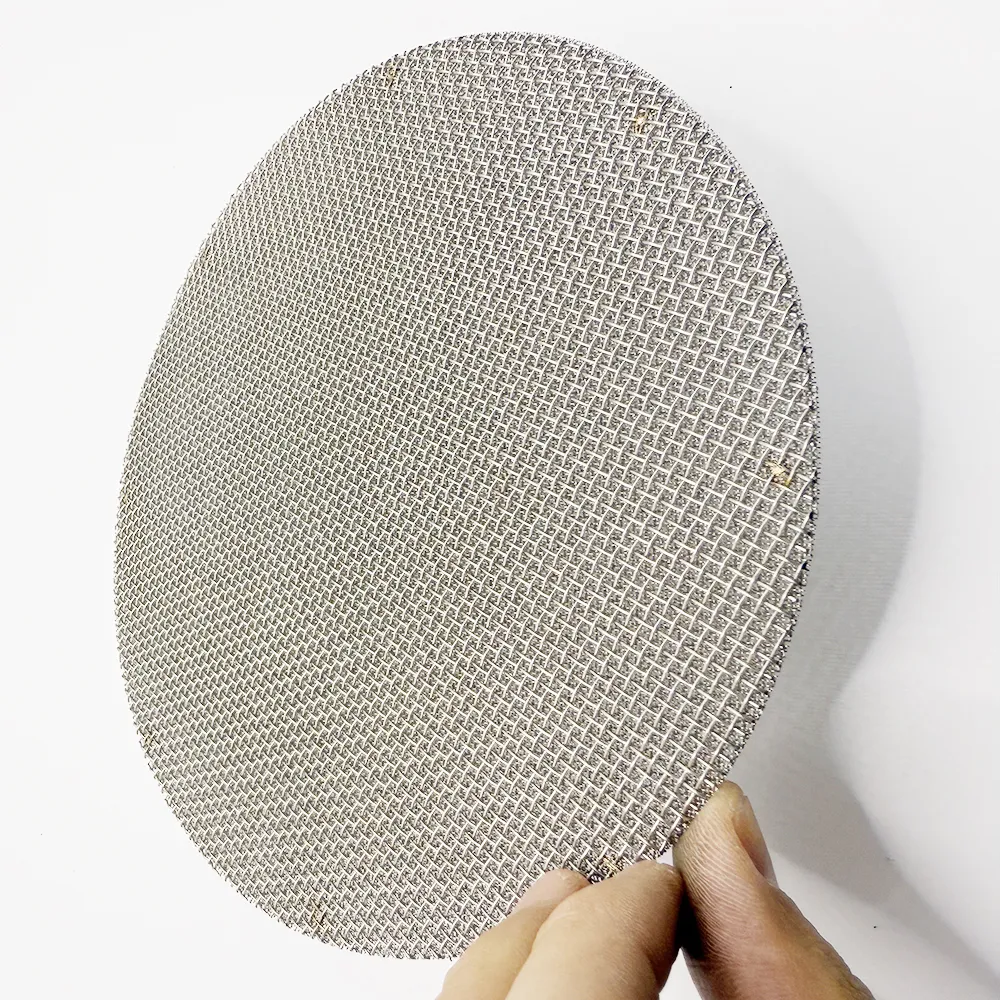

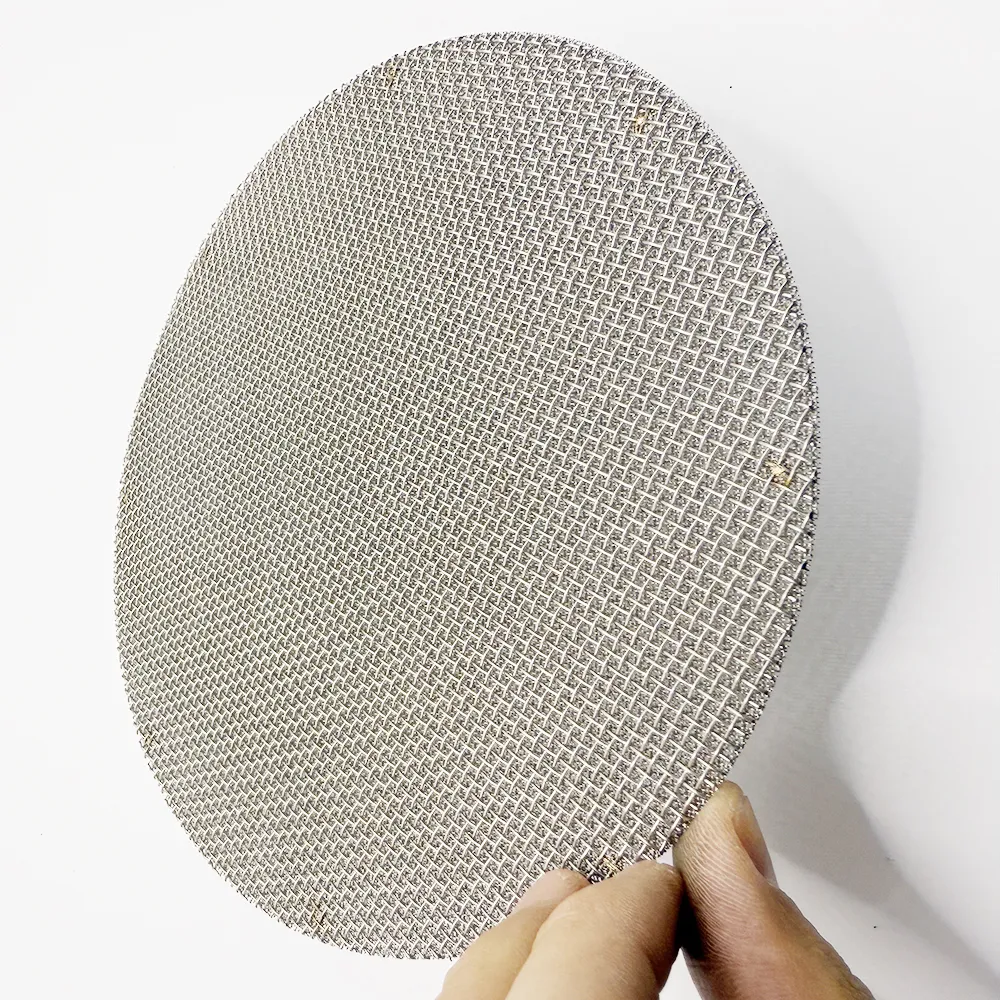

The performance of Stainless Steel Weave Wire Mesh is defined by a series of critical technical parameters. These specifications determine its suitability for specific applications, influencing factors such as filtration efficiency, flow rate, structural integrity, and aesthetic appeal. Key parameters include:

| Parameter | Common Range | Unit | Significance |

|---|---|---|---|

| Material Grade | SS304, SS316, SS316L | - | Corrosion resistance, strength, cost |

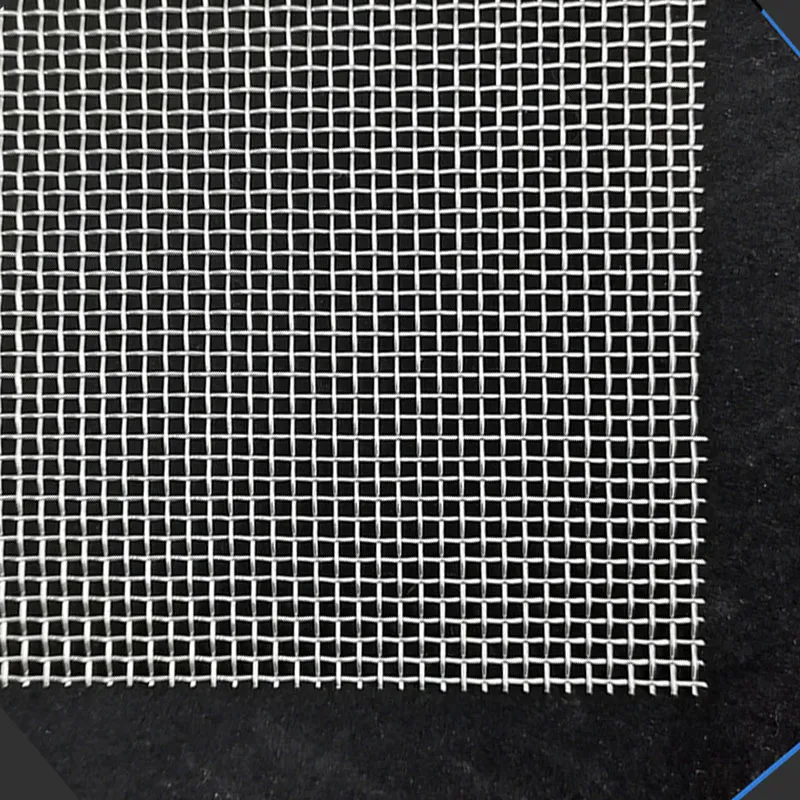

| Mesh Count | 2 to 635 | Wires/inch | Filtration precision, particle retention |

| Wire Diameter | 0.02 mm to 4.0 mm | mm / inch | Strength, durability, open area |

| Aperture Size | 20 µm to 12.0 mm | µm / mm | Max particle size passing, filtration rating |

| Open Area | ~10% to 90% | % | Flow rate, pressure drop |

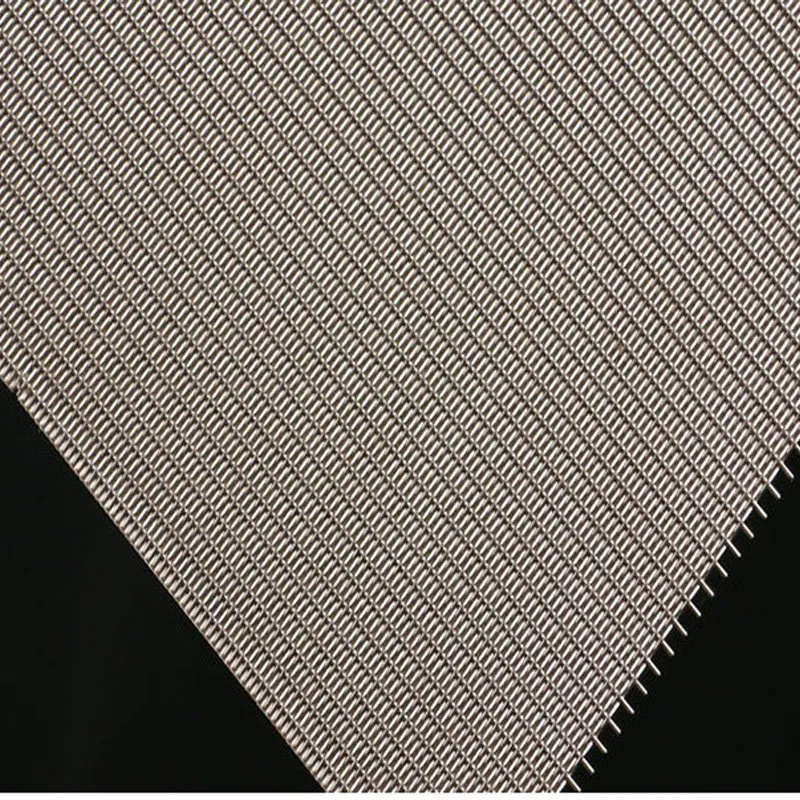

| Weave Type | Plain, Twill, Dutch | - | Strength, filtration characteristics, stability |

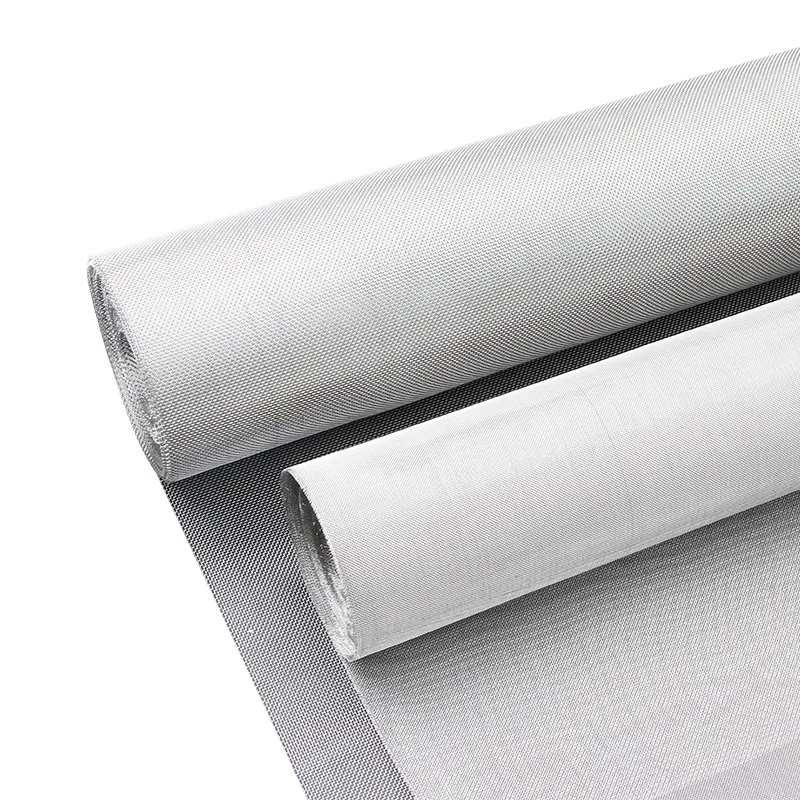

| Roll Width | 0.5m to 2.0m | meter | Manufacturing efficiency, handling |

The creation of high-quality Stainless Steel Weave Wire Mesh is a meticulous process that combines advanced machinery with precise material control. Unlike casting or forging, wire mesh is produced through a specialized weaving technique that transforms individual wires into a coherent, strong, and precise filtration or structural medium. The primary process involves:

High-grade stainless steel rods are drawn through a series of progressively smaller dies to achieve the desired wire diameter. This cold working process increases tensile strength. Following drawing, the wires undergo annealing – a heat treatment process that softens the material, making it more ductile and suitable for weaving. This step is crucial for preventing cracking during weaving and ensuring the finished mesh has optimal flexibility and durability.

Annealed wires are straightened to ensure uniform tension and prevent defects during weaving. Depending on the specific weaving machine and final product form (e.g., specific cut pieces or continuous rolls), wires are either precisely cut to length for warp wires or spooled onto bobbins for weft wires.

The core of the manufacturing process involves specialized wire weaving looms. These highly precise machines interlace the warp (longitudinal) wires and weft (transverse) wires according to the specified weave pattern (plain, twill, Dutch, etc.). Modern looms are computer-controlled to ensure extreme accuracy in mesh count, aperture size, and tension, critical for maintaining consistent quality and performance.

Specific Weaving Sub-processes:

After weaving, the mesh rolls undergo thorough cleaning to remove any residual lubricants, oils, or contaminants from the manufacturing process. This often involves degreasing and ultrasonic cleaning to ensure a pristine surface, especially vital for applications in food processing, medical, or high-purity environments. Depending on the application, further finishing processes like annealing (stress relief after weaving), slitting, or calendering (to flatten the mesh) might be applied.

Every roll or cut piece of Stainless Steel Weave Wire Mesh undergoes rigorous quality control. This includes visual inspection for defects, dimensional checks (mesh count, wire diameter, aperture size, width, length), and material composition verification using spectroscopy. Adherence to international standards such as ISO 9001:2015 for quality management and specific product standards like ASTM E2016-11 (Standard Guide for Industrial Woven Wire Cloth) and ASTM E2814-11 (Standard Guide for Industrial Woven Wire Filter Media) is strictly maintained. Advanced imaging systems are used to verify aperture uniformity and detect wire breaks or weaving inconsistencies. This stringent inspection ensures the mesh meets the required specifications for its intended application and has a long, reliable service life.

Finally, the finished mesh is carefully packaged to prevent damage during transit. This often involves wrapping in moisture-proof paper or plastic film, then securing in wooden crates or cardboard tubes, ensuring the product arrives in perfect condition at the client's site.

Throughout this entire process, advanced automated systems and skilled technicians work in tandem to ensure precision, consistency, and the highest quality output for every batch of Stainless Steel Weave Wire Mesh.

The exceptional properties of Stainless Steel Weave Wire Mesh make it indispensable across a vast array of industries. Its resistance to corrosion, high temperatures, and wear, combined with its precise filtration capabilities, allow it to excel where other materials fail.

In a real-world scenario, a large municipal water treatment plant upgraded its primary filtration system with Stainless Steel Weave Wire Mesh filters (SS316L, 100 mesh, Twill Weave). This upgrade resulted in a 25% reduction in filter cleaning cycles due to improved particle capture efficiency and a 15% decrease in overall maintenance costs over a two-year period, demonstrating significant operational advantages and energy savings.

Choosing Stainless Steel Weave Wire Mesh offers a distinct set of advantages that translate into superior performance and cost-effectiveness over the product's life cycle.

Selecting the right manufacturer for Stainless Steel Weave Wire Mesh is as crucial as understanding the product itself. A reliable manufacturer offers not just a product, but a partnership built on quality, reliability, and technical support. Here's a comparative overview of factors to consider when evaluating potential suppliers, exemplified by a hypothetical comparison:

| Feature/Criterion | Manufacturer A (High-End Specialist) | Manufacturer B (Mid-Market Generalist) | Manufacturer C (Budget Provider) |

|---|---|---|---|

| Quality Certifications | ISO 9001, ASTM E2016, REACH, RoHS, FDA Compliant | ISO 9001, Basic Material Certs | Limited or No Certs |

| Material Traceability | Full mill certifications, batch tracking for all materials (e.g., SS316L from specific mills) | Batch certs available on request for major grades | Limited or no traceability |

| Customization Capability | High: Special weaves, precise custom apertures (down to 5µm), custom alloys, fabrication services (welding, cutting, framing) | Moderate: Standard custom sizes, some weave variants | Low: Primarily standard sizes and common weaves |

| R&D and Innovation | Dedicated R&D, new product development, process optimization (e.g., new weaving technologies, surface treatments) | Limited R&D, focus on process efficiency | Minimal R&D, focus on cost reduction |

| Lead Time (Standard Orders) | 2-4 weeks (precision manufacturing) | 3-6 weeks | 4-8 weeks (volume dependent) |

| Technical Support & Expertise | Excellent: Dedicated engineers, application specialists, post-sales support, on-site consultation | Good: Sales support with product knowledge | Basic: Order processing only |

| Typical Industries Served | Pharma, Aerospace, High-End Filtration, Advanced Chemical | General Industrial, Food & Bev, Water Treatment | Construction, Basic Filtration, Agricultural |

| Price Point | Premium | Mid-Range | Budget-Friendly |

| Warranty & Guarantee | Comprehensive, multi-year product and performance guarantee | Standard 1-year product warranty | Limited or implied warranty |

When selecting a manufacturer for your Stainless Steel Weave Wire Mesh needs, prioritize those with demonstrable expertise and a track record of quality, especially for mission-critical applications. A reputable supplier like CCMETALMESH (as implied by the product URL) typically falls into the 'High-End Specialist' or 'Mid-Market Generalist' category, offering a balance of quality, customization, and reliable support.

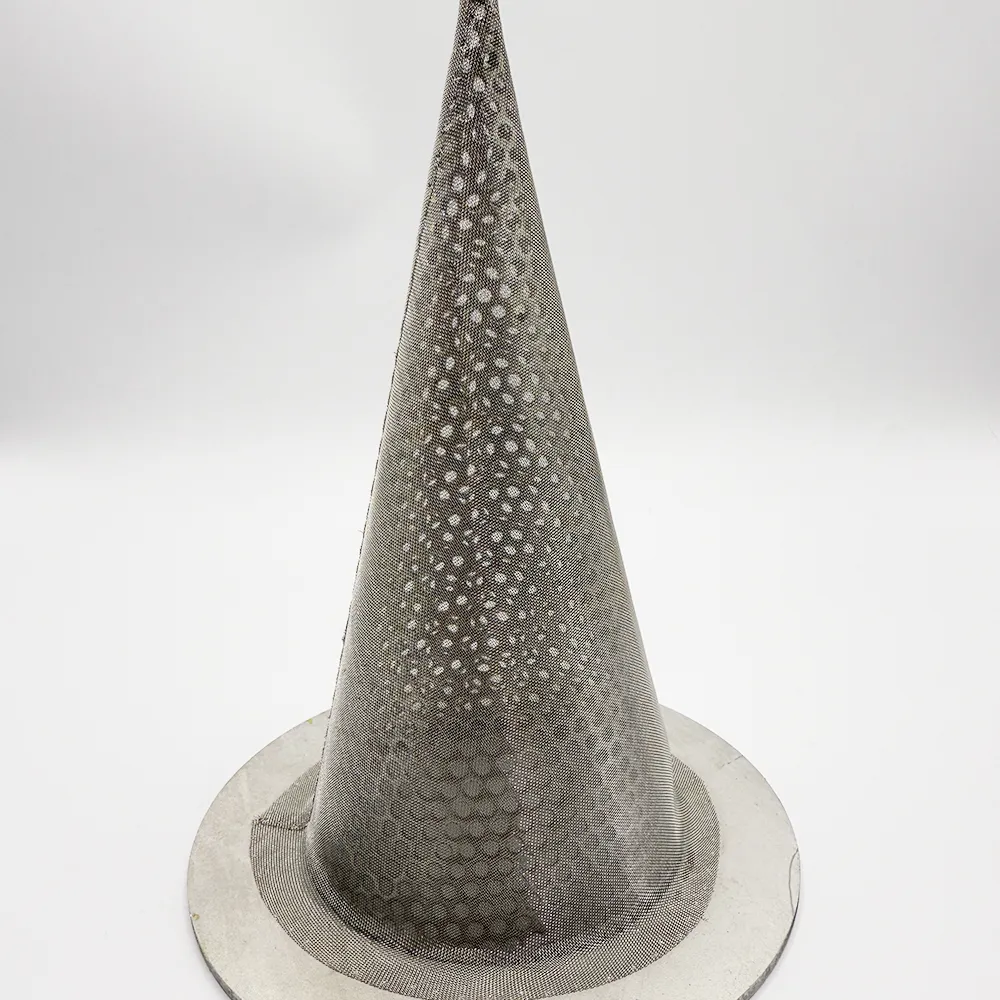

Standard Stainless Steel Weave Wire Mesh products often suffice, but many industrial and specialized applications demand bespoke solutions. Customization allows for optimal performance, ensuring the mesh perfectly integrates with existing systems and meets precise operational requirements. Key customization options include:

A recent project involved a pharmaceutical company needing a filter for a highly corrosive solvent. Standard SS316L mesh degraded too quickly. The solution was a custom-woven Stainless Steel Weave Wire Mesh from a specialized Hastelloy C-276 alloy with a specific twill-dutch weave pattern. This tailored approach increased the filter's service life by over 300%, reducing both material consumption and downtime for filter changes, showcasing the power of customized solutions.

The practical application of Stainless Steel Weave Wire Mesh vividly illustrates its value and versatility across diverse industries. Here are a few compelling case studies:

Challenge: A major petrochemical plant faced frequent clogging and premature failure of conventional filters in its crude oil distillation unit due to abrasive particles and high operating temperatures (up to 400°C). This led to significant downtime and maintenance costs.

Solution: The plant replaced its filters with high-performance Stainless Steel Weave Wire Mesh made from SS316, featuring a robust Twill Weave with a specific mesh count to handle the flow dynamics and particle size distribution. The mesh was further enhanced with a specialized edge treatment to withstand vibration.

Result: Over 18 months of operation, the new stainless steel mesh filters demonstrated a 70% reduction in clogging incidents and a 45% extension in filter service life. This translated to an estimated annual saving of $250,000 in replacement parts and labor, alongside a substantial increase in operational uptime and product throughput.

Challenge: A large-scale bakery required ultra-fine sieving of flour and sugar to prevent lumps and ensure consistent product quality. Existing nylon mesh sieves suffered from frequent tearing and did not meet stringent hygiene standards, leading to cross-contamination risks and premature replacement.

Solution: The bakery upgraded to food-grade Stainless Steel Weave Wire Mesh (SS304L, Plain Weave, 200 mesh) for its sieving machines. The mesh was electropolished to achieve an exceptionally smooth surface, minimizing particle adhesion and facilitating easy cleaning, thereby complying with FDA CFR 21 Part 177.2600 (Rubber articles intended for repeated use) and other food contact material standards (though SS is metal, electropolishing ensures a non-reactive surface appropriate for food contact).

Result: The new stainless steel sieves provided consistent, lump-free product, significantly reducing waste. Their inherent durability and ease of sanitation led to a 90% reduction in replacement frequency and an improvement in food safety audit scores by 15%. The initial investment was recouped within 8 months due to operational efficiencies and reduced material costs.

Challenge: A commercial building in a hot climate sought a sustainable solution to reduce solar heat gain while maintaining natural light and an open aesthetic.

Solution: An innovative architectural facade was designed using large panels of Stainless Steel Weave Wire Mesh (SS316, custom open area, interwoven with larger wires for structural rigidity). The mesh was strategically angled to deflect direct sunlight while allowing diffused light to enter.

Result: The mesh facade contributed to a 20% reduction in cooling energy consumption during peak summer months, as independently verified by an energy audit. Beyond energy savings, the building gained a distinctive, modern aesthetic, enhancing its market value and showcasing a commitment to sustainable design principles. This project highlighted how Stainless Steel Weave Wire Mesh can contribute to both functional and aesthetic goals, aligning with green building initiatives (e.g., LEED certification criteria for material selection and energy performance).

At CCMETALMESH, our commitment extends beyond delivering high-quality Stainless Steel Weave Wire Mesh. We pride ourselves on building lasting relationships through unparalleled customer service and technical support. Here’s what some of our clients have to say:

"We've partnered with CCMETALMESH for our filtration needs for over five years. Their Stainless Steel Weave Wire Mesh is consistently superior, and their technical team is incredibly responsive. We had a challenging requirement for a specific chemical process, and they delivered a customized solution that exceeded our expectations in terms of corrosion resistance and lifespan. Their quick delivery and comprehensive support make them an invaluable supplier."

"For our food processing lines, hygiene and consistency are non-negotiable. CCMETALMESH's food-grade Stainless Steel Weave Wire Mesh has been a game-changer. It's easy to clean, highly durable, and meets all our regulatory standards. The product quality speaks for itself, but their commitment to on-time delivery and detailed product certifications truly sets them apart."

"As an architectural firm, we push boundaries with materials. The team at CCMETALMESH helped us realize our vision for a unique building facade. Their expertise in customizing Stainless Steel Weave Wire Mesh to our exact aesthetic and performance specifications was instrumental. The final result is not only visually stunning but also highly effective in energy management. We appreciate their collaborative approach and deep product knowledge."

Our service commitment includes: Rapid Prototyping for custom orders, Global Logistics Support ensuring timely delivery regardless of location, Comprehensive Technical Datasheets for every product, and a Dedicated After-Sales Support Team to address any queries or challenges post-delivery. Our average delivery cycle for standard orders is 2-4 weeks, with expedited options available for urgent requirements. All our products come with a 2-year quality assurance warranty, reflecting our confidence in their durability and performance.

Q1: What are the primary differences between SS304 and SS316 Stainless Steel Weave Wire Mesh?

A1: SS304 is the most common grade, offering good corrosion resistance and is cost-effective for general applications. SS316 (and its low-carbon variant, SS316L) contains molybdenum, which significantly enhances its resistance to pitting and crevice corrosion, especially in chloride environments (e.g., saltwater, some industrial chemicals). For highly corrosive environments, SS316/316L is typically preferred.

Q2: How is "mesh count" determined, and why is it important?

A2: Mesh count refers to the number of openings per linear inch, measured from the center of one wire to the center of the next. It's a crucial parameter as it directly dictates the size of particles that can be filtered or screened. A higher mesh count means finer openings and better filtration efficiency for smaller particles.

Q3: Can Stainless Steel Weave Wire Mesh be welded?

A3: Yes, Stainless Steel Weave Wire Mesh can be welded using various techniques like spot welding, TIG (Tungsten Inert Gas) welding, or resistance welding. The choice of welding method depends on the mesh configuration, desired strength, and application. Proper welding ensures structural integrity and enables the mesh to be incorporated into larger assemblies like filter baskets or framed screens.

Q4: What is the typical lifespan of Stainless Steel Weave Wire Mesh?

A4: The lifespan of Stainless Steel Weave Wire Mesh is highly dependent on the application, environmental conditions (e.g., exposure to corrosive agents, abrasion), and operational stresses (e.g., pressure, temperature). However, due to its inherent durability and corrosion resistance, stainless steel mesh can last for many years, often decades, significantly longer than alternative materials, especially when properly maintained and selected for the specific environment.

Q5: Is Stainless Steel Weave Wire Mesh suitable for high-temperature applications?

A5: Absolutely. Stainless steel exhibits excellent heat resistance. For example, SS304 can typically withstand continuous temperatures up to 870°C (1600°F) and intermittent temperatures up to 925°C (1700°F). SS316 offers similar thermal resistance. For even higher temperatures or specific thermal cycling conditions, specialized high-temperature stainless steel alloys or superalloys might be used in the mesh.

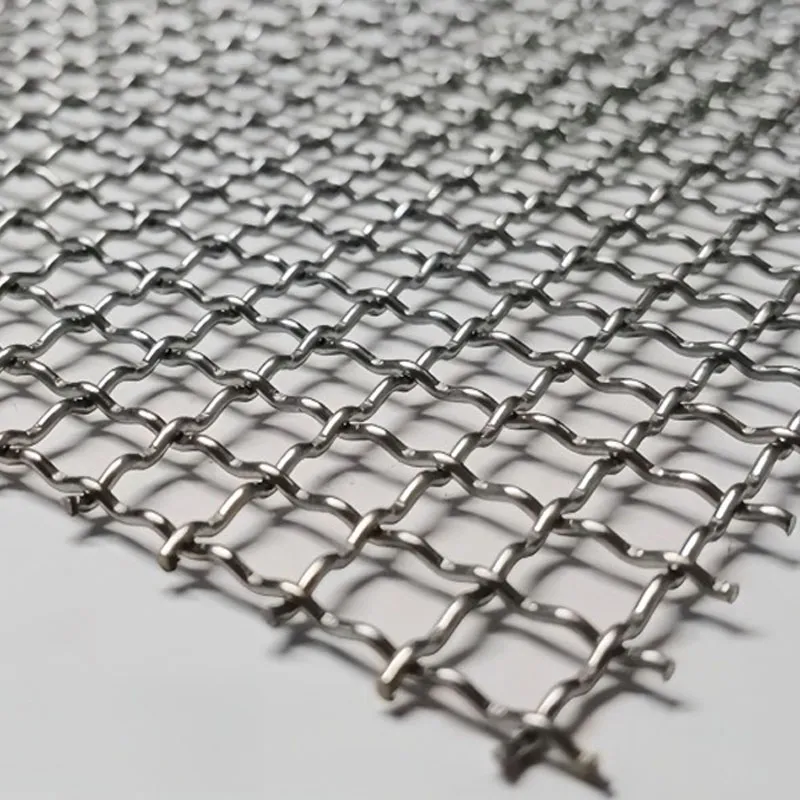

Q6: What is "Dutch Weave" and its advantage over "Plain Weave"?

A6: In a Plain Weave, warp and weft wires have the same diameter and are interlaced one over, one under, creating square openings. Dutch Weave, however, uses larger warp wires and smaller, more densely packed weft wires. This creates a dense, strong mesh with tapered, irregular openings and no straight-through holes, making it ideal for very fine filtration (e.g., 20 microns) where high strength and flow resistance are required. It offers superior filtration efficiency for very small particles under pressure.

Q7: How do I ensure I choose the correct mesh for my specific application?

A7: Choosing the correct Stainless Steel Weave Wire Mesh involves considering several factors: the material to be filtered (particle size, corrosivity, temperature), the desired flow rate, environmental conditions, mechanical stress, and budget. It is highly recommended to consult with technical experts from the mesh manufacturer who can analyze your specific requirements and recommend the optimal material grade, weave type, mesh count, and wire diameter for your application.

Ready to enhance your operations with high-performance Stainless Steel Weave Wire Mesh?

Explore Our Products & SolutionsPREV:

This is the last article