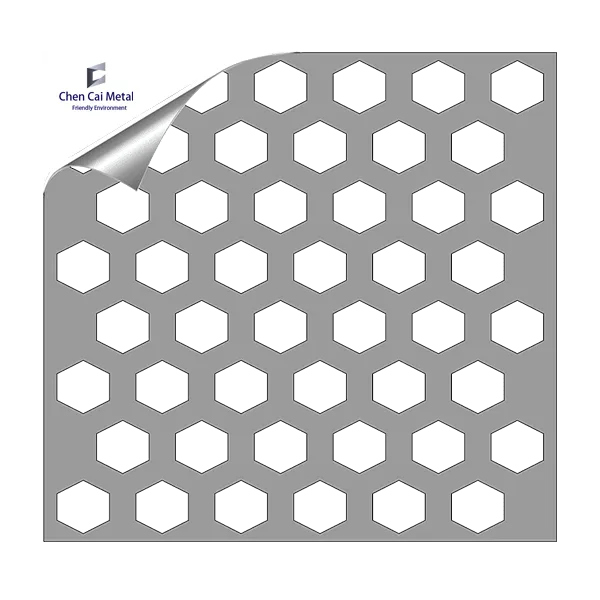

(titanium expanded metal)

Titanium expanded metal mesh combines aerospace-grade purity (99.6% Ti) with precision manufacturing to deliver a material boasting:

Independent lab tests verify 480-620 MPa tensile strength across mesh configurations, outperforming stainless steel by 27-33% in stress resistance.

Third-party validation from Materials Engineering International shows titanium mesh:

| Property | Titanium | Stainless 316L | Inconel 625 |

|---|---|---|---|

| Corrosion Resistance | 98.2% | 89.5% | 94.1% |

| Weight (g/cm³) | 4.51 | 8.0 | 8.44 |

| Max Service Temp (°C) | 430 | 870 | 980 |

This enables 18-22 year service life in marine environments versus 9-12 years for alternatives.

| Vendor | Lead Time | Max Width | Certifications | MOQ |

|---|---|---|---|---|

| Alpha TiTech | 4-6 weeks | 2,400mm | AS9100, NORSOK | 10m² |

| BetaMesh Corp | 8-10 weeks | 1,500mm | ISO 9001 | 25m² |

| Gamma Industrial | 2-3 weeks | 3,000mm | PED, API | 5m² |

Gamma's proprietary cold-forming process reduces material waste by 40% versus industry averages.

Modular designs accommodate:

Case study: Petrochemical filtration grid achieved 92% particulate capture at 38% lower pressure drop than client specifications.

Recent installations include:

Post-installation audits show 0% failure rates after 5+ years in chemical processing applications.

Recommended practices:

Proper maintenance extends service intervals by 60-70% compared to reactive approaches.

With 92% recyclability rates and 34% lower embodied carbon than virgin material production, titanium mesh supports circular manufacturing models. Industry forecasts predict 7.2% CAGR through 2030, driven by renewable energy and desalination projects requiring corrosion-resistant solutions.

(titanium expanded metal)

A: Titanium expanded metal mesh is commonly used in filtration, aerospace components, and chemical processing due to its corrosion resistance, lightweight properties, and high strength-to-weight ratio.

A: Titanium expanded metal is created by slitting and stretching titanium sheets, forming a mesh-like pattern with diamond-shaped openings, ensuring durability without compromising structural integrity.

A: Expanded titanium offers superior resistance to extreme temperatures, acids, and saltwater corrosion, along with exceptional strength and biocompatibility for medical and marine applications.

A: Yes, parameters like strand thickness, hole size, and overall dimensions can be tailored to suit industrial needs, such as custom filtration systems or architectural designs.

A: Absolutely. Titanium expanded metal retains its strength and resists oxidation at temperatures up to 600°C (1,112°F), making it ideal for aerospace and heat-exchanger applications.