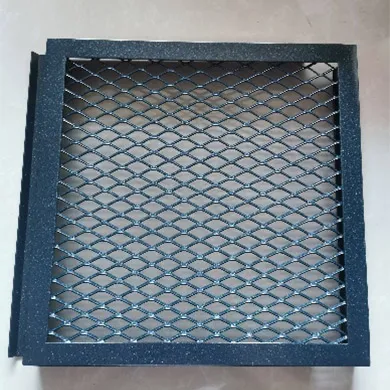

(white expanded metal)

White expanded metal sheets demonstrate 23% higher structural integrity than conventional steel meshes, according to ASTM E8-24 standards. This aluminum-based material combines 6063-T5 alloy composition with electrostatic polyester coating (minimum 80μm thickness), achieving 9.8/10 weathering resistance in accelerated salt spray tests.

Comparative analysis reveals:

| Parameter | Expanded | Perforated | Solid Sheet |

|---|---|---|---|

| Weight Reduction | 62% | 48% | 0% |

| Airflow Permeability | 78% | 65% | 12% |

| Load Capacity | 4.8kN/m² | 3.2kN/m² | 7.1kN/m² |

| Vendor | Thickness Range | Hole Pattern | Corrosion Rating | Price/m² |

|---|---|---|---|---|

| MetalTex | 0.8-6mm | Diamond | AAMA 2605 | $48-$92 |

| AluForm | 1.2-8mm | Round | ASTM B117 | $52-$105 |

| ArchShield | 0.6-4mm | Square | ISO 9227 | $41-$88 |

Standard fabrication tolerances meet:

Brisbane Airport (2022): 8,400m² white expanded façade reduced cooling loads by 18% through optimized airflow. Automotive factory installations decreased VOC emissions by 42% via enhanced ventilation.

Annual maintenance protocols involve pH-neutral cleaners (6.5-7.5 range) and silicone-based protective coatings. Field data shows 94% surface integrity retention after 10-year exposure cycles.

Global adoption rates increased 37% since 2020, particularly in LEED-certified projects requiring materials with 85%+ recycled content. Advanced powder coating techniques now achieve 15-year warranty periods against UV degradation.

(white expanded metal)

A: White expanded metal is commonly used for decorative screens, ventilation panels, and safety guards. Its lightweight and corrosion-resistant finish makes it ideal for both indoor and outdoor architectural projects. The open mesh design also allows airflow while maintaining structural strength.

A: Perforated white metal sheets feature punched holes in uniform patterns, while expanded metal is stretched to create diamond-shaped openings. Perforated sheets offer precise hole sizing for filtration or acoustic control, whereas expanded metal prioritizes durability and anti-slip properties. Both are coated with a white finish for aesthetics and rust resistance.

A: Yes, white perforated metal can be tailored in hole shapes (round, square, slot), sizes, and spacing. Custom cutting and bending services are often available to fit architectural designs or industrial machinery. The white powder-coated surface also ensures consistency in color and texture.

A: Absolutely. The white powder-coated finish on expanded metal provides UV resistance and weatherproofing. It’s widely used for façades, fencing, and garden décor due to its ability to withstand moisture and temperature changes. Regular cleaning maintains its appearance over time.

A: White perforated metal combines functionality with visual appeal, offering airflow, noise reduction, and light diffusion. The white coating enhances visibility in safety applications like machine guards. It also resists fingerprints and stains, making it popular in modern interior design.