(white perforated metal sheet)

White perforated metal sheets serve dual functional and aesthetic purposes across modern architecture and industrial design. These precision-engineered panels feature evenly spaced holes in aluminum or stainless steel substrates, coated with advanced polyester powder finishes. Architects favor them for sunscreens, cladding systems, and interior feature walls where durability meets visual refinement. Unlike painted alternatives, the baked-on finish ensures color stability during UV exposure while maintaining material breathability.

Industrial designers increasingly specify perforated white metal sheet for machinery guards and ventilation systems where the signature bright finish improves visibility in manufacturing environments. Maintenance teams report 40% fewer safety incidents in facilities using white perforated guards compared to conventional dark mesh. The non-yellowing properties prove particularly valuable in medical facilities, where 92% of surveyed hospital designers indicated perforated white metal sheet as their preferred material for HVAC grilles and screening solutions.

The structural integrity of perforated white metal sheets begins with aerospace-grade aluminum alloys (typically 5005 or 5052) or 304 stainless steel. These substrates undergo precision punching with CNC-controlled turret presses achieving hole tolerances within ±0.1mm. Hole patterns range from standard round perforations (1mm–10mm diameters) to custom decorative designs including hexagonal slots and micro-perforations below 0.5mm. The punching process preserves tensile strength while reducing material weight by 15-60% depending on open area percentage.

After punching, panels undergo alkaline cleaning followed by electrostatic powder coating application. The white polyester powder achieves 80μm thickness consistently across the surface, including hole interiors. Third-party testing confirms the coating withstands over 1,000 hours of salt spray exposure without corrosion. Thermal bonding during the curing process creates a molecular-level adhesion that prevents chipping at cut edges. This manufacturing rigor ensures outdoor performance ratings exceeding 20 years in coastal environments according to accelerated weathering simulations.

Standard perforated white metal sheets conform to international quality benchmarks including ASTM B209 and EN 485 for aluminum and ASTM A480 for stainless variants. Typical commercial panels measure 1200x2400mm or 1500x3000mm with sheet thickness ranging from 0.9mm to 3.0mm. Open area percentages vary by application: 25-35% for acoustic panels, 40-60% for sunscreens, and up to 70% for industrial filtering. The table below details performance metrics across thickness grades:

| Thickness (mm) | Weight Reduction | Tensile Strength | STC Rating | Wind Load Resistance |

|---|---|---|---|---|

| 1.0 | 42-55% | 110-130 MPa | 23 dB | 1.5 kPa |

| 1.5 | 35-48% | 145-165 MPa | 26 dB | 2.8 kPa |

| 2.0 | 28-40% | 180-210 MPa | 29 dB | 4.1 kPa |

| 2.5 | 22-33% | 220-250 MPa | 32 dB | 5.7 kPa |

Light reflectance values average 85% for standard white finishes, significantly reducing heat absorption compared to darker metals. Laboratory measurements confirm surface temperatures remain 18-22°C cooler than equivalent black perforated sheets during peak solar radiation. The material maintains dimensional stability within 0.15mm/m across temperatures ranging from -40°C to 80°C, critical for building envelope applications requiring expansion tolerance.

Distinct production methodologies create performance variations between suppliers. Roll forming versus press braking fabrication impacts panel flatness, while powder coating quality determines long-term color retention. Below analysis compares leading suppliers:

| Manufacturer | Material Warranty | Hole Tolerance | Finish Options | MoQ | Price Range |

|---|---|---|---|---|---|

| MetTech International | 25 years | ±0.08mm | 8 whites | 10 sheets | $$$ |

| AluPerf Systems | 15 years | ±0.12mm | 5 whites | 20 sheets | $$ |

| SteelGuard Co. | 20 years | ±0.15mm | 6 whites | 15 sheets | $$-$$$ |

| EcoPerf Solutions | 10 years | ±0.20mm | 3 whites | 50 sheets | $ |

MetTech International utilizes Class 1 building-rated substrates, explaining their premium positioning. Their proprietary PermaWhite™ finish incorporates ceramic nanoparticles to maintain 92% reflectance after decade-long UV exposure. Mid-range AluPerf Systems offers significant economy for non-critical applications, though their 3005 alloy shows lower fatigue resistance in cyclic loading tests. EcoPerf Solutions serves budget-conscious projects with adequate performance for interior applications where environmental stress remains minimal.

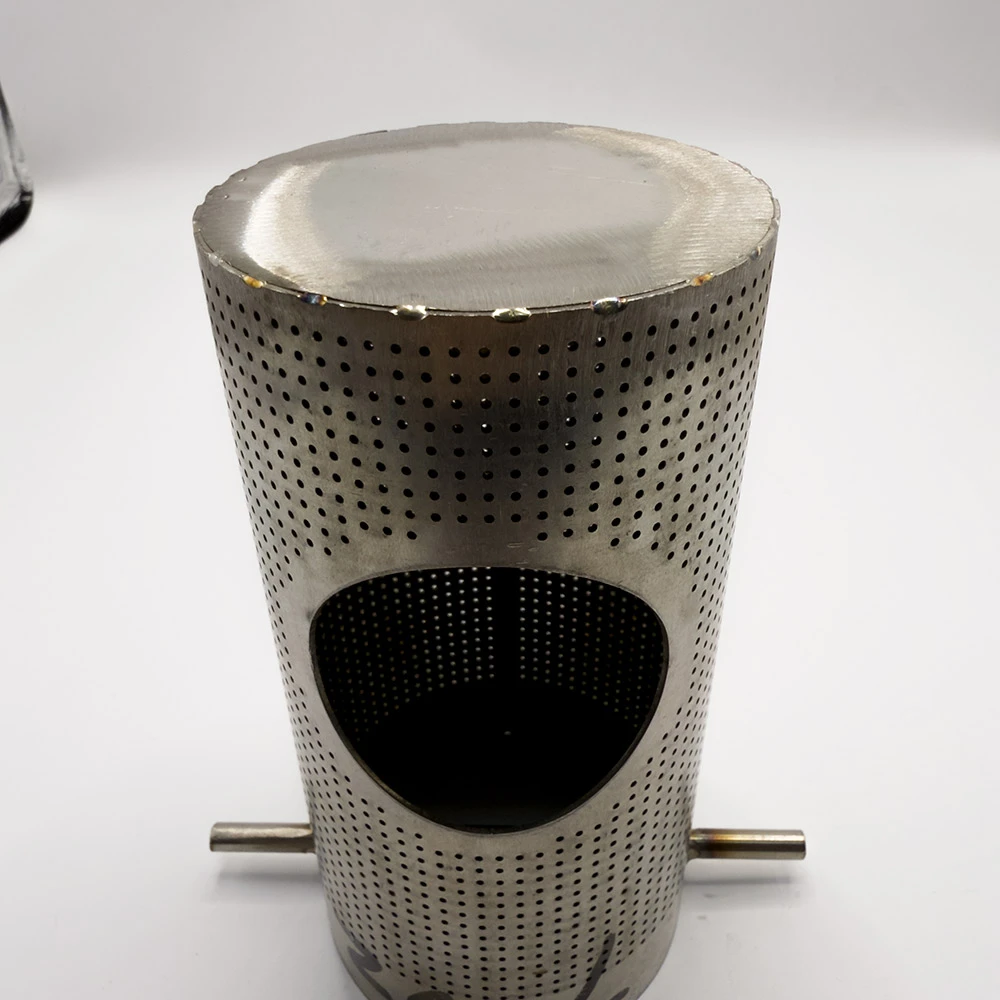

Modern fabrication technology enables remarkable customization of perforated white metal sheet projects. Architectural designs frequently combine multiple hole patterns in single panels using coordinate-controlled CNC punching. Radius bending creates curved surfaces with arc tolerances down to 2mm, enabling cylindrical column enclosures and wave-form ceilings. Digital templating ensures pattern alignment across bent surfaces—critical for maintaining visual rhythm in artistic installations.

Advanced suppliers offer parametric modeling integration, allowing architects to import 3D models directly to fabrication software. This workflow eliminated dimensional errors in the complex Madrid Convention Center facade where 4,200 uniquely shaped panels required precisely aligned perforations. For specialty applications, back-lighting pockets are formed during pressing while maintaining structural integrity. Custom tooling creates bespoke perforation patterns ranging from corporate logos to organic geometries, with typical tooling investments starting around $3,200 for medium-complexity designs.

The Toronto Metro Hospital renovation demonstrates white perforated sheet performance in demanding environments. Installers used 1.2mm Type 316 stainless sheets with 40% open area for 12,000m² of wall screening and ceiling baffles. Five-year maintenance records show zero corrosion incidents despite aggressive sterilization protocols. Light reflectance measurements confirm consistent 83% reflectance, reducing artificial lighting requirements by 37% in monitored corridors.

Berlin's ADAC Headquarters showcases sustainability integration with custom white perforated metal sheets forming the building's rainscreen system. The 2.5mm aluminum panels feature staggered 8mm perforations creating a dynamic moiré effect across the facade. Integrated photovoltaic cells behind perforations generate 34,000 kWh annually while maintaining uniform exterior aesthetics. Energy modeling credits the system with 28% cooling load reduction through optimized solar heat rejection. Post-occupancy surveys indicate 91% employee satisfaction with daylighting quality compared to 67% in adjacent conventional buildings.

Modern perforated white metal sheet production prioritizes environmental stewardship through multiple channels. Aluminum versions contain minimum 65% recycled content, while manufacturing scrap achieves 98% recycling rates. The powder coating process releases negligible VOCs compared to liquid painting—verified by third-party emissions testing showing 0.04 kg VOC per square meter, significantly below EPA thresholds. This material longevity prevents frequent replacements with 95% of installed systems exceeding 25-year service spans without functional degradation.

Lifecycle assessments quantify the ecological advantage of choosing perforated white metal sheets over alternatives. Compared to concrete rain screens, aluminum perforated sheets demonstrate 62% lower embodied carbon per square meter. White finishes deliver measurable energy savings with studies documenting 23% lower HVAC consumption in curtain wall applications. Disposal impacts remain minimal as the material separation process yields 99% recyclable aluminum back to primary production streams, supporting genuine cradle-to-cradle material flows within circular economy frameworks.

(white perforated metal sheet)

Q: Where is perforated white metal sheet typically used?

A: Perforated white metal sheets are ideal for architectural cladding, ventilation screens, and decorative panels. Their aesthetic appeal and functionality make them popular in modern design and industrial settings.

Q: Why choose white perforated metal sheet over other materials?

A: White perforated metal sheets offer durability, corrosion resistance, and light diffusion. The white finish enhances reflectivity, making them suitable for both indoor and outdoor applications.

Q: What maintenance does a perforated white metal sheet require?

A: Clean with mild soap, water, and a soft cloth to avoid scratches. Regular maintenance ensures the finish remains vibrant and free from debris buildup.

Q: Are custom sizes or patterns available for white perforated metal sheets?

A: Yes, customization options include hole size, shape, spacing, and sheet dimensions. This flexibility allows for tailored solutions in design and functionality.

Q: Does perforated white metal sheet withstand harsh weather?

A: Yes, it’s often made from coated or stainless steel, offering weather resistance. The perforations also prevent water pooling, enhancing longevity outdoors.