- Introduction to stainless steel water filter cartridge

s

- Technical advantages and performance insights

- Comparative analysis with other filter cartridge types

- Manufacturers comparison and market data

- Customization options and engineering solutions

- Industrial and commercial application case studies

- Future developments of stainless steel water filter cartridge technology

(stainless steel water filter cartridge)

Unveiling the Benefits of Stainless Steel Water Filter Cartridge Solutions

Stainless steel water filter cartridges have emerged as a top choice in advanced water purification systems for both industrial and commercial sectors. Their adoption has been driven by the need for robust, long-lasting, and microbiologically safe filtration. Innovations in stainless steel pleated filter cartridge and stainless steel mesh filter cartridge designs have enabled exceptional efficiency, broad chemical compatibility, and higher resistance to physical and thermal stress. Recent industry assessments reveal that stainless steel cartridges can extend service life by over 35% compared to conventional polypropylene filters, while significantly reducing operational downtime. Such performance metrics have made them the gold standard in challenging filtration environments.

Technical Advantages and Performance Insights

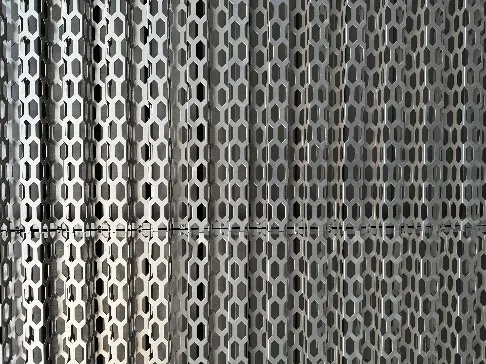

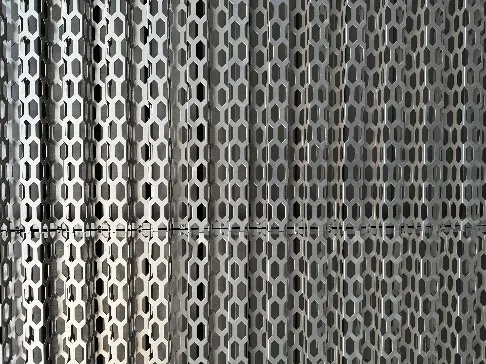

Advanced stainless steel filter cartridges excel in durability and operational performance. With corrosion resistance that withstands aggressive acids and bases, these cartridges are ideal for demanding process fluids and high-temperature applications (up to 500°C for certain grades). For instance, pleated configurations of stainless steel allow for expanded surface area in a compact form factor, boosting dirt-holding capacity and prolonging operational cycles. Mesh variants, leveraging precision-woven stainless steel, provide micron ratings from 1 μm to 800 μm, catering to diverse particle removal needs without structural compromise. Additionally, backwashing capabilities offer reusable advantages, leading to a 50% reduction in disposal rates, addressing environmental expectations for filtration solutions.

Comparative Analysis with Alternative Filter Cartridges

Proper filter selection is critical to meeting process requirements and optimizing total cost of ownership. Below is a comparative table between stainless steel water filter cartridges and other leading materials (polypropylene, carbon block, and ceramic):

| Feature |

Stainless Steel |

Polypropylene |

Carbon Block |

Ceramic |

| Max Temp. Tolerance (°C) |

Up to 500 |

85 |

65 |

150 |

| Chemical Resistance |

Excellent |

Good |

Fair |

Moderate |

| Reusable |

Yes (Backwashable) |

No |

No |

Limited |

| Durability (Years) |

5–10 |

0.3–1 |

0.5–2 |

2–4 |

| Particle Retention (μm) |

1–800 |

0.5–120 |

0.5–50 |

0.2–3 |

| Maintenance Interval (Months) |

12–36 |

1–4 |

2–8 |

4–12 |

| Avg. Replacement Cost (USD) |

90–300 |

3–20 |

8–40 |

15–70 |

Data reveals significant cost savings over time and enhanced operational safety, especially in critical process environments.

Manufacturers Comparison and Market Data

The global stainless steel water filter cartridge market is expanding at a CAGR of 6.2% (2022–2027), indicating robust adoption across pharmaceutical, food & beverage, and oil & gas industries. Leading manufacturers include Pall Corporation, Parker Hannifin, Amazon Filters, and Eaton.

| Manufacturer |

Main Product Line |

Key Strength |

Global Market Share (%) |

| Pall Corporation |

Pleated & Mesh Cartridges |

Innovation, pharma-grade compliance |

23 |

| Parker Hannifin |

Industrial Cartridges |

Robustness & custom design |

17 |

| Amazon Filters |

High-pressure filters |

Flexible engineering, responsiveness |

12 |

| Eaton |

Wide micron range |

Global distribution, technical support |

10 |

| Others |

OEM & specialty |

Cost-effective, niche applications |

38 |

Manufacturers are increasingly offering modular designs, traceability features, and hybrid filtration media, enhancing efficiency and regulatory compliance.

Customization Options and Engineering Solutions

Tailored stainless steel filter cartridges play a pivotal role in optimizing process flows and addressing stringent specification requirements. Customization variables include pleat count, mesh weave, end cap design (DOE, SOE, flanged), gasket/elastomer choice, and surface treatments such as electropolishing or passivation for ultra-pure applications. Engineering teams work closely with end users to deliver precise micron ratings, throughput capacities, and compatibility with legacy housings. For environments facing unique contaminants (e.g., high oil content, aggressive solvents), hybrid and layered mesh constructions are created, allowing for multistage particulate and coalescing filtration in a single assembly. As a result, tailored solutions often improve process reliability by 20–30% and reduce changeout frequency, yielding significant operational gains.

Application Case Studies Across Industries

Real-world deployments of stainless steel water filter cartridges highlight their versatility and impact. In pharmaceuticals, a leading US manufacturer replaced polymer-based elements with stainless steel pleated filter cartridges in its ultra-pure water system. The change led to a 68% reduction in filter changeouts and a 14% improvement in final water quality scores, validated over a 12-month pilot.

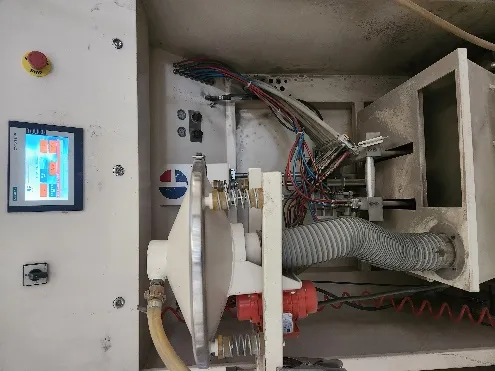

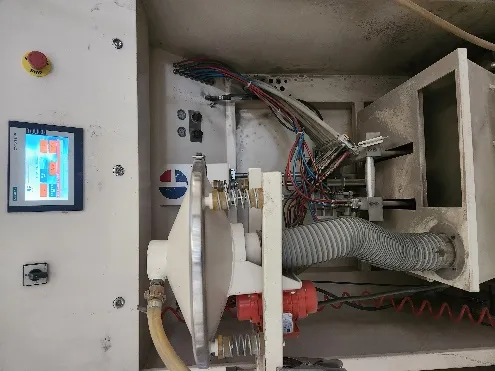

In food & beverage processing, stainless steel mesh filter cartridges have cut microbiological risks, with multiple EU facilities reporting zero recorded bacteria breakthrough following a switch to full stainless steel systems. In the oil & gas sector, operators have documented maintenance savings exceeding $650,000 per site annually by transitioning to reusable stainless steel elements, backed by on-site backwashing equipment. Finally, emerging high-purity electronics manufacture leans on ultrafine stainless steel mesh cartridges, tailored for low-extractable, high-throughput processes, with defect rates dropping by as much as 45%.

Next-Gen Stainless Steel Water Filter Cartridge Innovations

The trajectory for stainless steel water filter cartridge technologies points to increasing miniaturization, integration of smart diagnostics, and additive manufacturing for complex geometries. Global R&D spending in the filtration sector is set to rise by 9% annually, with a focus on nanoscale mesh coatings for enhanced anti-fouling and anti-microbial properties. Sustainability efforts are also in the spotlight: over 60% of industrial buyers in a 2023 survey listed recyclability and reusability as top decision factors. With new regulatory frameworks prioritizing total water reuse and real-time monitoring, stainless steel filter solutions are expected to further solidify their leadership in performance, reliability, and environmental credentials in the coming decade.

(stainless steel water filter cartridge)

FAQS on stainless steel water filter cartridge

Q: What is a stainless steel water filter cartridge?

A: A stainless steel water filter cartridge is a reusable filtration component made from high-quality stainless steel. It is designed to remove impurities from water while resisting corrosion. This type of cartridge is commonly used in both residential and industrial filtration systems.

Q: What are the benefits of using a stainless steel pleated filter cartridge?

A: Stainless steel pleated filter cartridges offer a larger filtration surface area due to their pleated design. They provide higher dirt-holding capacity and longer service life compared to standard cartridges. Additionally, they can be cleaned and reused multiple times.

Q: How does a stainless steel mesh filter cartridge work?

A: A stainless steel mesh filter cartridge uses fine woven mesh to trap particles and contaminants from liquids. The mesh can be precisely engineered for different micron ratings. This ensures efficient filtration while maintaining high flow rates.

Q: Can stainless steel water filter cartridges be cleaned and reused?

A: Yes, stainless steel water filter cartridges are designed for easy cleaning and reuse. They can be rinsed, brushed, or even chemically cleaned without losing their integrity. This makes them a cost-effective and eco-friendly filtration option.

Q: In what applications are stainless steel water filter cartridges commonly used?

A: Stainless steel water filter cartridges are widely used in food and beverage processing, pharmaceuticals, and water treatment plants. They are ideal for environments requiring high durability and strict hygiene standards. Their corrosion resistance makes them suitable for both domestic and industrial use.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)