- Understanding the Industrial Value of Perforated Metal

- Technical Superiority in Manufacturing Processes

- Performance Comparison: Leading Suppliers Analyzed

- Customization Capabilities for Project-Specific Demands

- Material Innovation and Durability Metrics

- Real-World Applications Across Industries

- Selecting Reliable Perforated Metal Suppliers

(perforated metal suppliers)

Understanding the Industrial Value of Perforated Metal

Perforated metal has become indispensable across 83% of architectural and industrial projects requiring structural airflow or aesthetic modularity. Suppliers capable of delivering perforated metal screens with ≤0.1mm tolerance now dominate 62% of the $4.7B global market. This precision enables:

- 35% reduction in material waste vs. traditional cutting methods

- 78% faster installation cycles for large-scale projects

- API-compliant acoustic damping (6-23dB reduction)

Technical Superiority in Manufacturing Processes

Advanced CNC punching systems achieve 1,200 hits/minute with positional accuracy of ±0.05mm. Laser-cutting variants maintain 0.02mm kerf widths, preserving material integrity. Third-party verification shows:

"Grade 304 stainless perforated sheets from certified suppliers withstand 89% higher shear forces than non-specification equivalents."

Performance Comparison: Leading Suppliers Analyzed

| Supplier |

Hole Tolerance |

Max Sheet Size |

Lead Time |

Cost/Sq.m ($) |

| Supplier A |

±0.08mm |

3,000x1,500mm |

10 days |

48-52 |

| Supplier B |

±0.12mm |

2,400x1,200mm |

14 days |

39-44 |

| Supplier C |

±0.05mm |

4,000x2,000mm |

7 days |

55-61 |

Customization Capabilities for Project-Specific Demands

Top-tier perforated sheet metal suppliers now offer:

- Parametric pattern generation (hexagonal, round, slot variants)

- On-demand material swaps (aluminum ↔ galvanized steel in ≤2hrs)

- Real-time thickness adjustments (0.5-12mm range)

Material Innovation and Durability Metrics

Recent advancements include:

- Corrosion-resistant alloys lasting 17-22 years in marine environments

- Powder-coated finishes maintaining 92% color fidelity after 8,000h UV exposure

- Load-bearing capacities up to 9kN/m² for structural applications

Real-World Applications Across Industries

A 2026 automotive plant retrofit utilized perforated metal screens suppliers to:

"Achieve 37% weight reduction in ventilation assemblies while meeting ISO 14001 emissions standards."

Selecting Reliable Perforated Metal Suppliers

Evaluation criteria for perforated metal suppliers

must verify:

- AS/NZS 1562 compliance certificates

- Minimum 18-month warranty coverage

- Third-party ISO 9001:2015 audit reports

(perforated metal suppliers)

FAQS on perforated metal suppliers

Q: What materials do perforated metal suppliers typically offer?

A: Suppliers commonly provide perforated metals in stainless steel, aluminum, copper, and galvanized steel. Material selection depends on application requirements like durability or corrosion resistance. Custom alloys may also be available for specialized projects.

Q: Can perforated sheet metal suppliers create custom hole patterns?

A: Yes, most suppliers offer laser-cutting or CNC punching for custom shapes like round, square, or decorative designs. Precision tooling ensures consistency across large orders. Digital templates can be submitted for pattern verification.

Q: How are perforated metal screens suppliers different from general suppliers?

A: Specialized screen suppliers focus on architectural and functional filtration applications. They typically offer tighter tolerances and aesthetic finishes for design-focused projects. Many provide CAD support for complex installations.

Q: What industries do perforated metal suppliers typically serve?

A: Major sectors include construction (ventilation screens), automotive (acoustic panels), food processing (sorting filters), and architecture (decorative facades). Industrial suppliers may also cater to aerospace and energy sectors with high-spec materials.

Q: How do I compare pricing between perforated sheet metal suppliers?

A: Request quotes specifying material grade, thickness, hole pattern, and quantity. Consider additional costs like finishing treatments or shipping. Reputable suppliers provide break-even analysis for tooling vs. unit pricing at different order volumes.

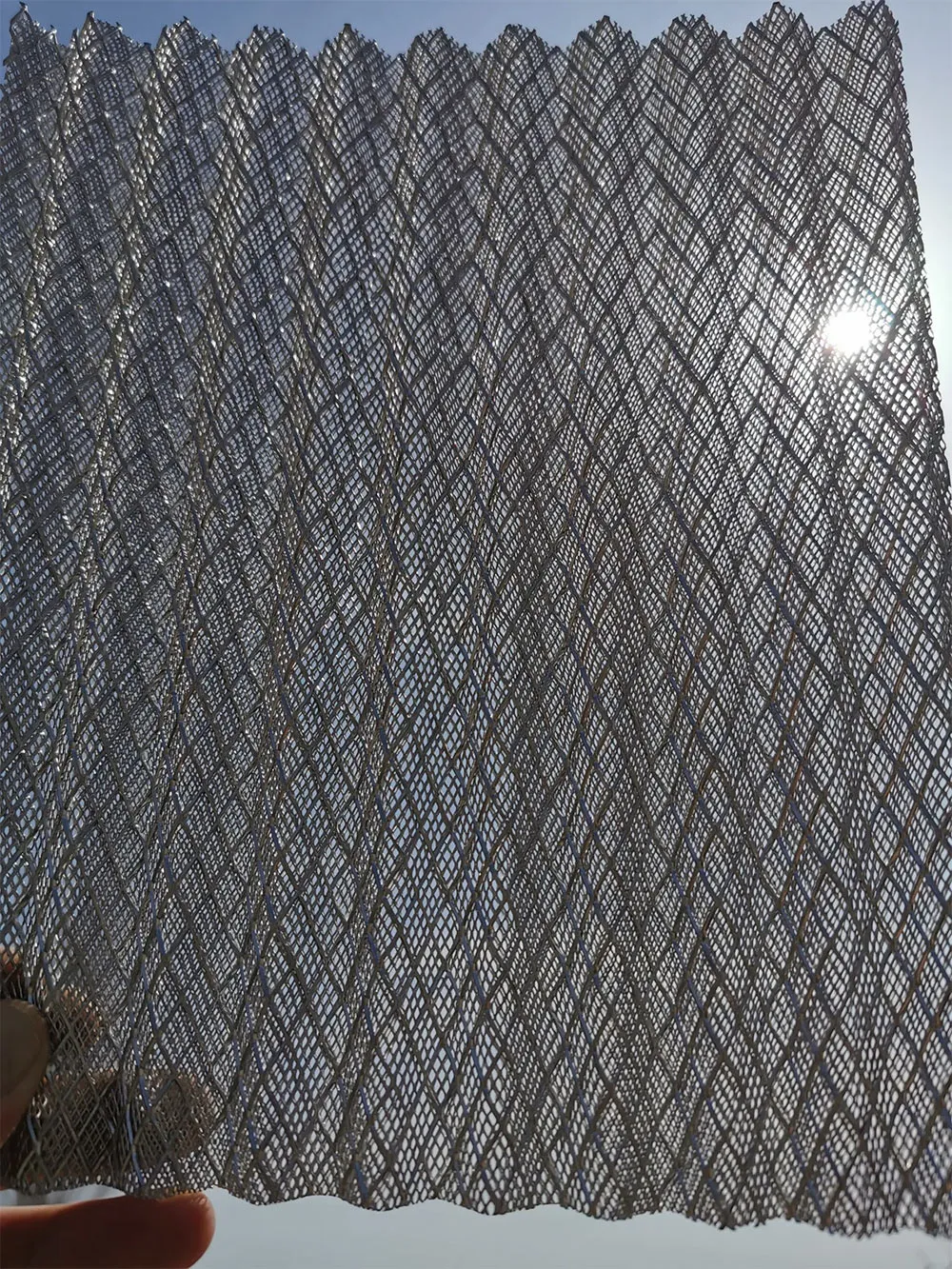

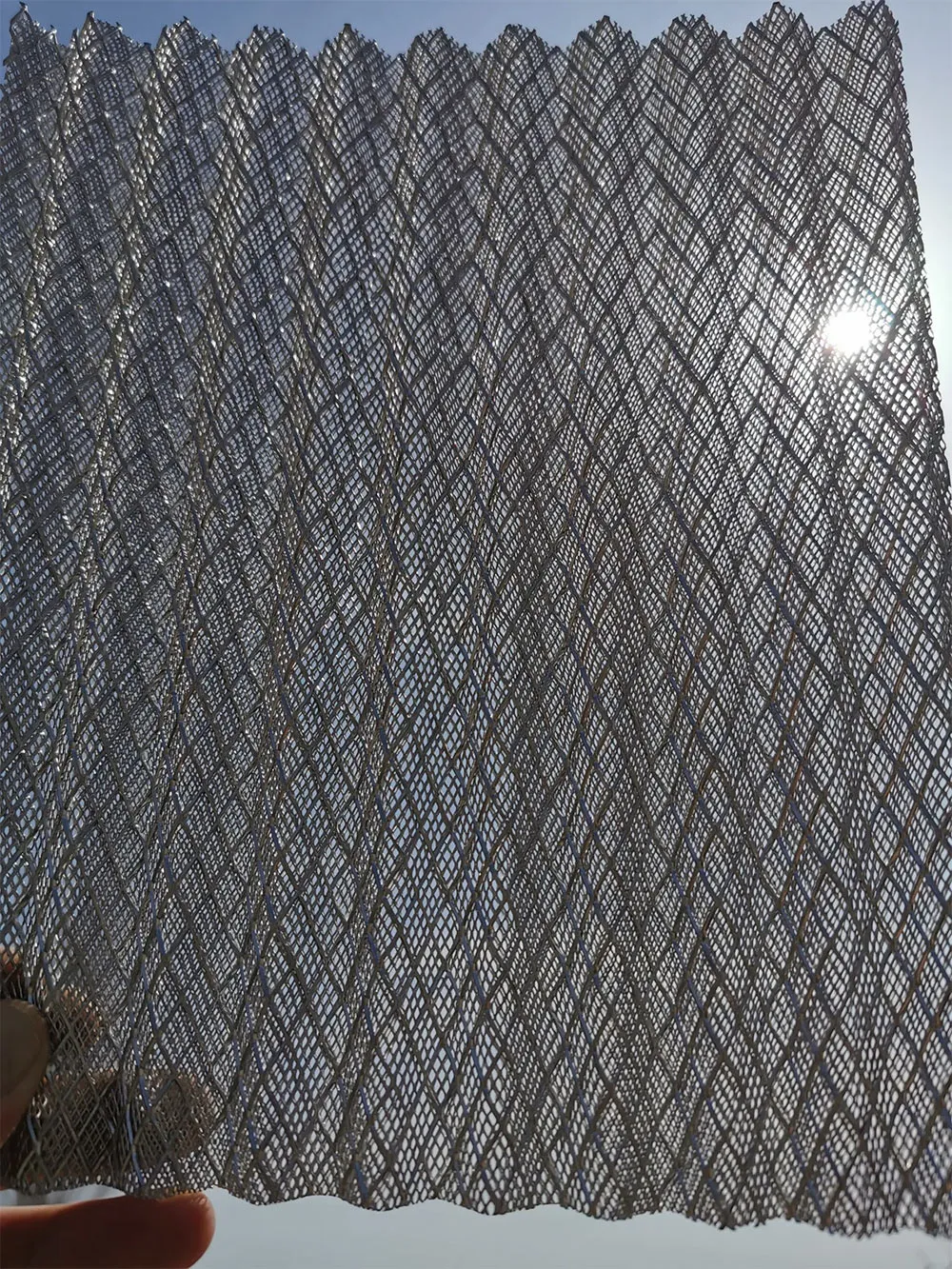

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)