- Introduction: Understanding Perforated Metal Sheet Thickness

- Technical Advantages of Varying Sheet Thickness

- Manufacturing Processes and Thickness Controls

- Comparative Analysis of Leading Manufacturers

- Customization Options for Perforated Metal Thickness

- Real-World Applications: Case Studies by Industry

- Conclusion: Selecting the Optimal Perforated Metal Sheet Thickness

(perforated metal sheet thickness)

Introduction: Understanding Perforated Metal Sheet Thickness

Perforated metal sheet thickness plays a critical role in industrial and architectural applications. The integrity, performance, and appearance of a finished product are directly affected by the chosen thickness—commonly ranging from 0.3mm to 15mm, depending on material and intended use.

With the global market for perforated sheets exceeding $2.8 billion in 2023 and projected to grow at over 5% CAGR, designers and engineers are increasingly focused on how thickness parameters affect strength, weight, airflow, and acoustics. The three principal terms—perforated metal sheet thickness

, perforated sheet thickness, and perforated metal thickness—are often used interchangeably, but nuanced differences exist in technical standards and applications. This guide explores the technical and commercial implications of selecting the correct thickness for your project.

Technical Advantages of Varying Sheet Thickness

Adjusting perforated metal thickness offers several technical advantages that influence project success. Thicker sheets provide enhanced mechanical resistance and load-bearing capability, making them ideal for heavy-duty protection panels, industrial machinery guards, or infrastructure cladding. For example, a 3mm steel sheet can withstand over 180 MPa of stress before deformation, compared to 0.5mm sheets, which are mainly used in filtration or decorative applications.

On the other hand, reducing the thickness improves ductility and lowers weight, often critical in aerospace and automotive industries. Thinner perforated sheets also provide greater design freedom, supporting intricate hole patterns and finer mesh creation suitable for noise control or air diffusion. Moreover, choosing the right thickness impacts corrosion resistance—thicker sheets typically support advanced surface treatments, further extending their lifespan in challenging environments.

Manufacturing Processes and Thickness Controls

The manufacturing process directly affects the attainable perforated sheet thickness. Most suppliers use precision technologies such as CNC punching, laser cutting, or rotary pin perforation. Depending on material (aluminum, stainless steel, galvanized iron), manufacturers guarantee tolerances as narrow as ±0.05mm for premium-grade sheets.

For example, in stainless steel perforation, sheets between 0.8mm and 6mm are standard due to their ability to balance formability with structural stability. The table below illustrates typical production ranges established by leading equipment:

| Material |

Min. Thickness (mm) |

Max. Thickness (mm) |

Process Tolerance (mm) |

| Aluminum |

0.5 |

10.0 |

±0.08 |

| Stainless Steel |

0.8 |

6.0 |

±0.05 |

| Mild Steel |

0.6 |

12.0 |

±0.10 |

| Galvanized Steel |

0.7 |

8.0 |

±0.09 |

Thickness uniformity is rigorously monitored during production, supported by real-time digital calipers and automated inspection software, minimizing product deviation and ensuring compliance with ISO 9001:2015 standards.

Comparative Analysis of Leading Manufacturers

Manufacturers differentiate themselves by offering a combination of advanced machining capability, material availability, and precision controls. Here’s a comparative overview of renowned global suppliers regarding supported sheet thickness, customization, and quality certifications:

| Manufacturer |

Max Sheet Size (mm) |

Thickness Range (mm) |

ISO Certification |

Customization Capability |

| RMIG Group |

2000 x 6000 |

0.5–15.0 |

ISO 9001, 14001 |

Advanced CNC, High-Precision, Bespoke Designs |

| Graepel |

1500 x 3000 |

1.0–10.0 |

ISO 9001 |

Modular Systems, Fast Prototyping |

| PerfoTec |

1000 x 2500 |

0.8–8.0 |

ISO 9001 |

Food-Grade Materials, Micro-Perforation |

| McNichols |

1220 x 2440 |

0.6–12.7 |

ISO 9001 |

Standard and Custom Hole Configurations |

These variations in perforated metal sheet offerings allow project managers to align supplier capabilities with project requirements, optimizing both cost and technical performance.

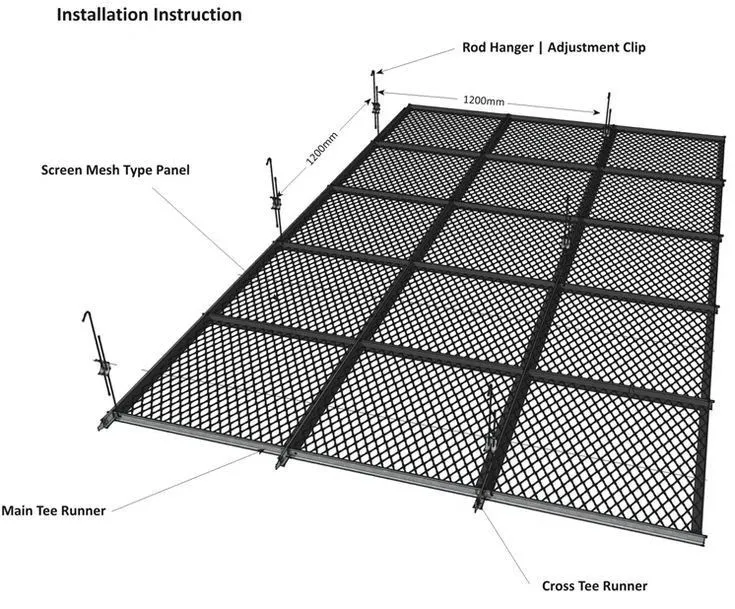

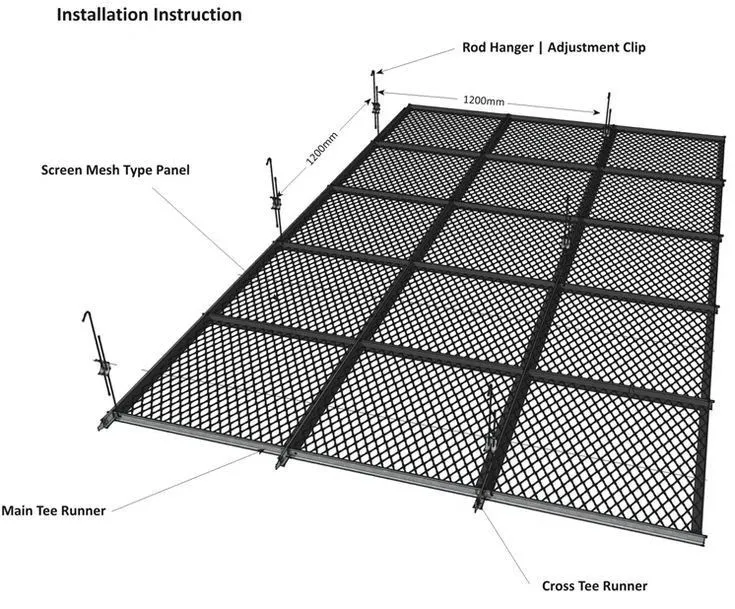

Customization Options for Perforated Metal Thickness

Bespoke fabrication is increasingly common, given the highly specialized needs across industries such as automotive, agricultural machinery, and acoustic engineering. Customization covers the precise selection of perforated sheet thickness, hole size and pattern, material alloy, and surface finishing. High-volume orders may also involve pre-coating, anodizing, or anti-fingerprint treatments, offered on specific thickness ranges to ensure coating durability and aesthetic quality.

For projects requiring exact gauge compliance—such as non-slip walkways, advanced filtration systems, or heat shields—manufacturers work closely with clients to determine optimal design, considering:

- Load and impact resistance targets

- Air permeability or fluid flow rates

- Acoustic performance metrics

- Environmental and corrosion challenges

Some suppliers use proprietary software to simulate sheet behavior across thickness options, enabling data-driven recommendations early in the specification stage. This approach significantly reduces prototyping cycles and material waste.

Real-World Applications: Case Studies by Industry

Practical examples illustrate how adjusting perforated metal thickness meets unique project challenges:

Industrial Architecture: In the Mercedes-Benz Arena façade (Germany), 4mm anodized aluminum perforated panels offered a blend of lightweight installation and high wind-load resistance.

Automotive: OEMs such as BMW use 1.2–1.5mm stainless steel sheets for exhaust system heat shields, balancing weight reduction with thermal protection.

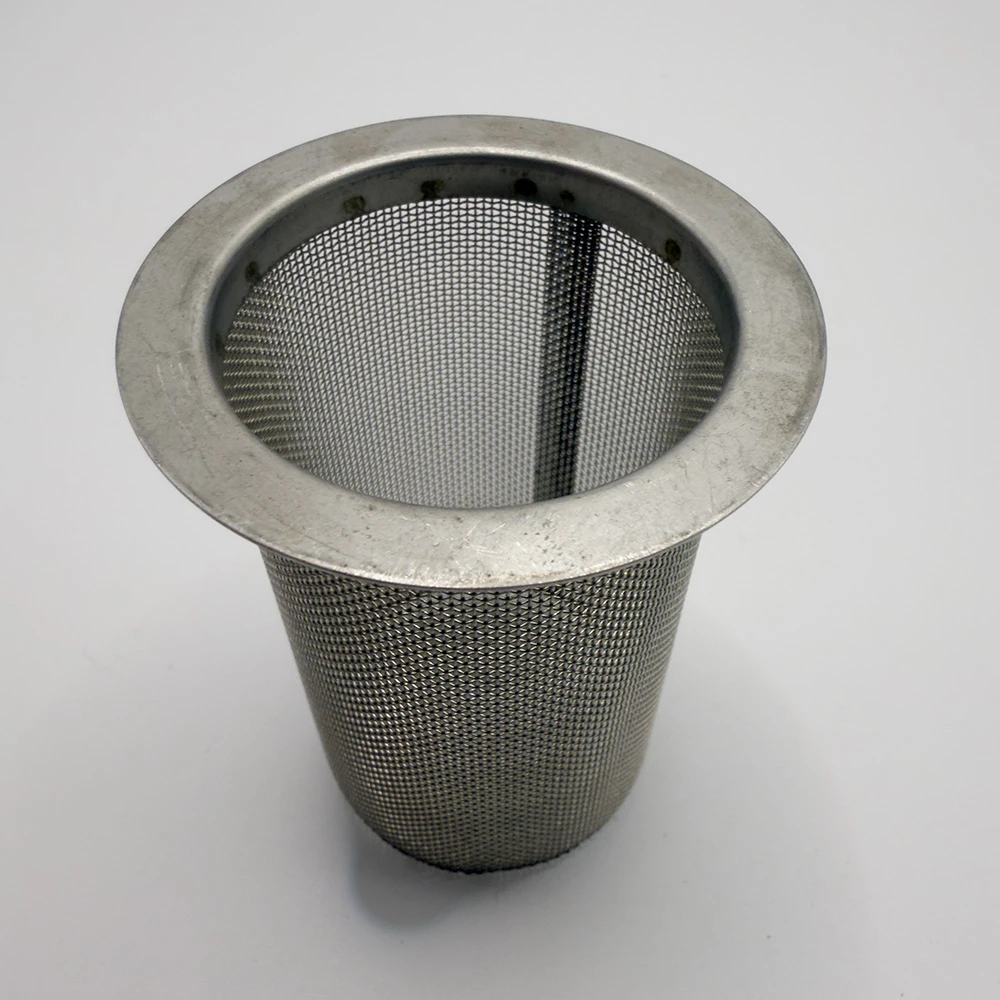

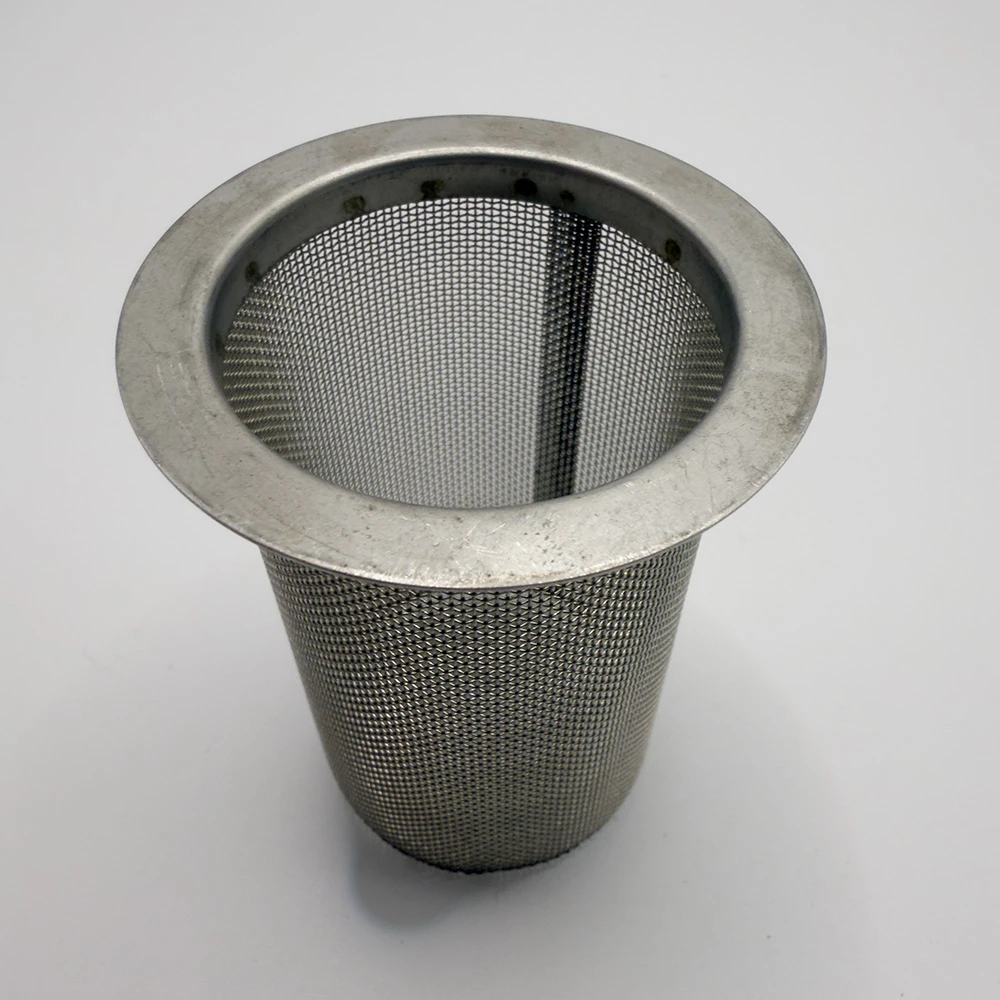

Food Processing: Dairy equipment manufacturers specify 0.8mm micro-perforated sheets to maximize drainage and cleaning efficiency without compromising hygiene standards.

Environmental Technology: In a municipal water treatment upgrade, 2.5mm galvanized perforated plates facilitated high-flow, anti-clog screen structures, reducing downtime by 23%.

The following table demonstrates typical industry-driven choices:

| Industry |

Typical Thickness Range (mm) |

Critical Performance Parameter |

| Architecture |

2.0–6.0 |

Wind Resistance |

| Automotive |

1.0–2.0 |

Thermal Shielding |

| Filtration |

0.3–1.0 |

Permeability |

| Food Equipment |

0.7–1.2 |

Sanitary Design |

| Infrastructure |

3.0–12.0 |

Load Resistance |

Conclusion: Selecting the Optimal Perforated Metal Sheet Thickness

Selecting the ideal perforated metal sheet thickness involves balancing load expectations, environmental exposure, weight limits, and design vision. The decision shouldn't be driven solely by standard stock sizes or price, but by a careful assessment of project-specific technical, operational, and aesthetic requirements. As technology advances, the ability to fine-tune perforated metal thickness enables high-performance, customized solutions—transforming infrastructure, vehicles, and products across industries. By leveraging advanced manufacturing processes, rigorous quality controls, and collaborative design with trusted suppliers, your projects gain from safe, durable, and visually compelling outcomes.

(perforated metal sheet thickness)

FAQS on perforated metal sheet thickness

Q: What is the standard range for perforated metal sheet thickness?

A: Perforated metal sheet thickness typically ranges from 0.3mm to 12mm. The most common thicknesses are between 0.7mm and 6mm.

Q: How can I choose the right perforated sheet thickness for my project?

A: Select the perforated sheet thickness based on the required strength and application. Thicker sheets provide more durability, while thinner sheets are lighter and more flexible.

Q: Does perforated metal thickness affect its load-bearing capacity?

A: Yes, perforated metal thickness directly impacts its strength and load-bearing capacity. Thicker sheets can handle heavier loads.

Q: Are there industry standards for perforated sheet thickness tolerances?

A: Most manufacturers follow ASTM or EN standards for perforated metal thickness tolerances. Always confirm with your supplier for specific tolerances.

Q: Can I customize the perforated metal sheet thickness?

A: Yes, many suppliers offer custom perforated metal sheet thicknesses to meet project requirements. Contact your supplier to discuss customization options.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)