11111

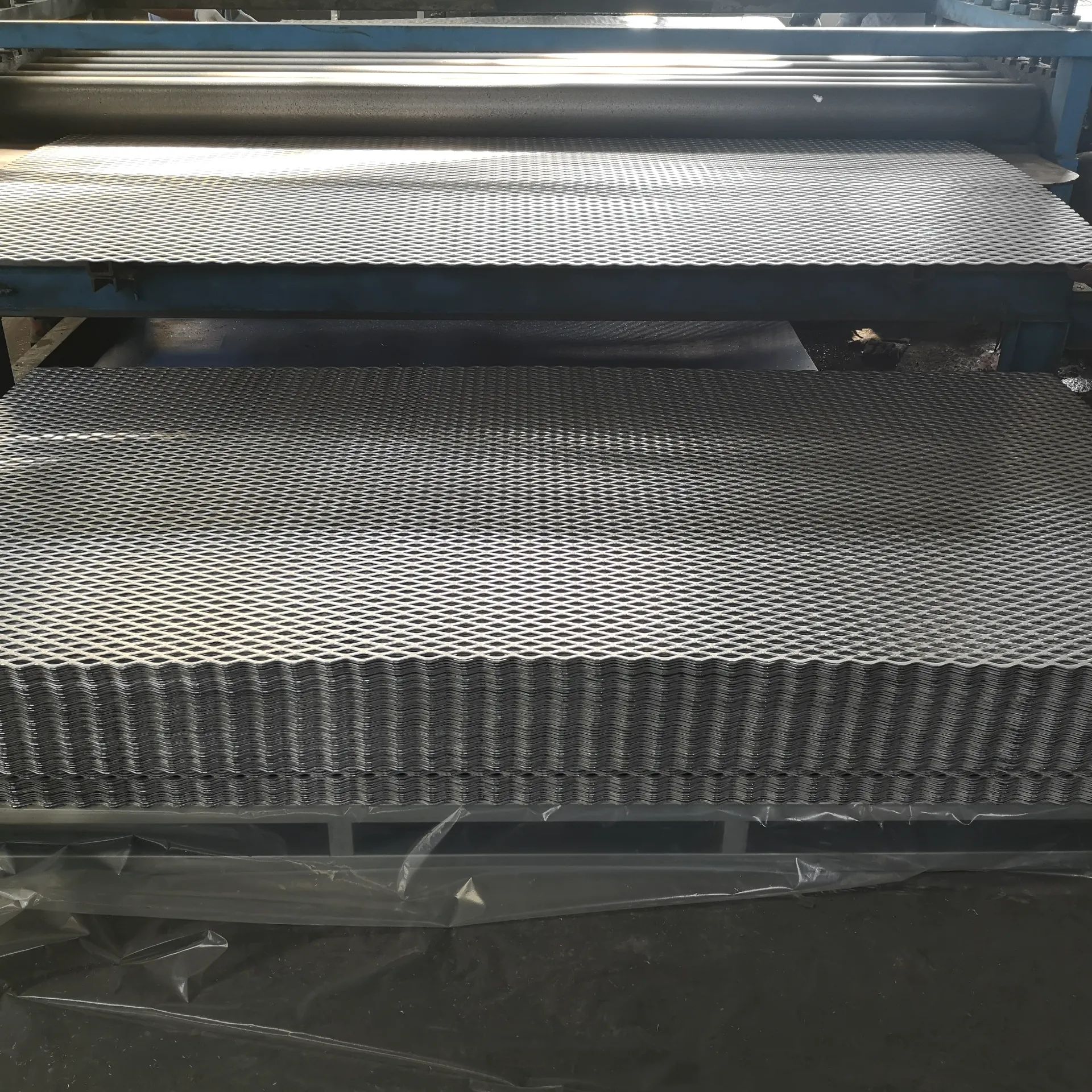

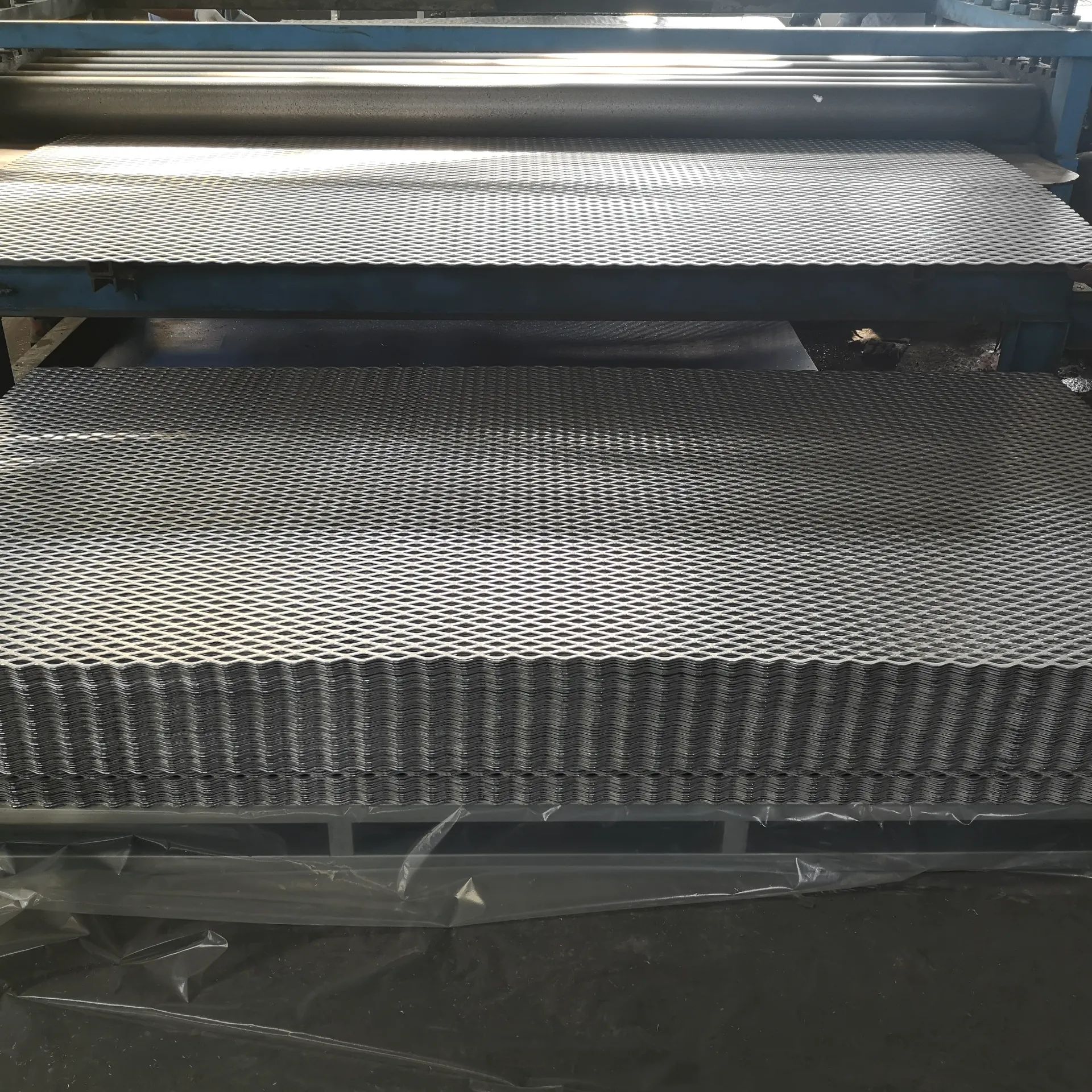

In the realms of architecture, manufacturing, and beyond, expanded metal has emerged as a versatile material praised for its strength, durability, and adaptability. Among its various forms, black expanded metal, 1 8 expanded metal, aluminum expanded metal mesh, expanded metal mesh panels, and steel expanded metal sheet stand out as key variants that cater to diverse functional and aesthetic needs. This exploration delves into their characteristics, applications, and the factors that make them indispensable in contemporary settings.

The Allure of Black Expanded Metal

Black expanded metal combines visual appeal with robust functionality. Often coated with a protective layer, such as powder coating or galvanization, this variant offers enhanced corrosion resistance while adding a sleek, modern aesthetic. In architectural projects, black expanded metal is frequently used for facade cladding, room dividers, or decorative screens, where its dark finish complements minimalist or industrial design themes. For example, in urban commercial spaces, black expanded metal can be shaped into intricate patterns, providing both privacy and a striking visual element. Its durability also makes it suitable for outdoor applications, such as fencing or security barriers, where the black coating withstands weathering while deterring unauthorized access.

Understanding 1 8 Expanded Metal Specifications

1 8 expanded metal refers to a specific mesh size, where the distance between the centers of adjacent openings (pitch) is 1.8 inches. This 规格 (specification) balances openness and structural integrity, making it ideal for applications that require moderate visibility and airflow while maintaining strength. In industrial settings, 1 8 expanded metal is commonly used as walkway gratings or platform flooring, as the mesh size prevents small objects from falling through while allowing liquid and debris to drain. For agricultural purposes, this variant can serve as livestock fencing, providing enough space for animals to move while restricting their escape. The versatility of 1 8 expanded metal lies in its ability to meet both functional requirements and design preferences across different sectors.

The Lightweight Strength of Aluminum Expanded Metal Mesh

Aluminum expanded metal mesh is valued for its high strength - to - weight ratio, making it an excellent choice for projects where weight is a critical factor. Constructed from aluminum alloys, this mesh is corrosion - resistant, non - magnetic, and easy to fabricate, making it suitable for aerospace, marine, and automotive applications. In aircraft interiors, aluminum expanded metal mesh can be used as lightweight storage panels or ventilation grilles. For marine environments, its resistance to saltwater corrosion ensures longevity in applications like ship decks or offshore platform fencing. Additionally, in residential and commercial buildings, aluminum expanded metal mesh is often used for ceiling panels or ventilation covers, combining functionality with a modern, airy aesthetic.

The Practicality of Expanded Metal Mesh Panels

Expanded metal mesh panels offer pre - fabricated solutions that simplify installation and enhance project efficiency. These panels are available in various materials, including steel, aluminum, and stainless steel, and can be customized in size, mesh pattern, and finish to meet specific project requirements. In construction, expanded metal mesh panels are used as formwork for concrete structures, providing reinforcement while allowing excess concrete to drain, resulting in a textured surface. For security applications, these panels can be integrated into fences or gates, offering a robust barrier against impact and forced entry. Their modular design also makes them easy to transport and install, reducing labor costs and project timelines in both industrial and residential settings.

The Robustness of Steel Expanded Metal Sheet

Steel expanded metal sheet is synonymous with durability and heavy - duty performance. Made from carbon steel or stainless steel, these sheets are capable of withstanding high loads, making them essential in industrial and infrastructure projects. In manufacturing facilities, steel expanded metal sheet is used as machine guards or safety barriers, protecting workers from moving parts while allowing visibility. For outdoor applications like bridge gratings or railway platforms, the strength of steel ensures long - term reliability even in high - traffic or harsh weather conditions. Additionally, steel expanded metal sheets can be coated with zinc or paint to enhance corrosion resistance, extending their lifespan in outdoor and marine environments.

FAQ: Key Insights into Expanded Metal Solutions

How to select the right material for an expanded metal project?

Choosing between black expanded metal, aluminum, or steel depends on factors like environment, load requirements, and aesthetics. For outdoor or corrosive environments, aluminum or galvanized steel (such as black expanded metal with protective coatings) is ideal. For heavy - duty loads, steel expanded metal sheet is preferable, while aluminum suits lightweight, high - visibility applications like aluminum expanded metal mesh in aerospace designs.

What maintenance is required for expanded metal products?

Most expanded metal variants require minimal maintenance. For black expanded metal or coated steel, occasional cleaning with a mild detergent to remove debris and checking for coating damage are sufficient. Aluminum mesh may benefit from periodic rinsing in marine environments to prevent salt buildup. Avoid using abrasive tools that could scratch the surface or compromise protective coatings.

Can expanded metal mesh panels be customized for unique designs?

Yes, expanded metal mesh panels are highly customizable. Manufacturers can adjust mesh size, sheet dimensions, material thickness, and surface finishes (such as powder coating or embossing) to meet design specifications. This flexibility allows for creative applications, from artistic architectural screens to specialized industrial components like 1 8 expanded metal with specific pitch requirements.

What are the primary advantages of using expanded metal over traditional materials?

Expanded metal offers several key benefits: its open design provides ventilation and light transmission while maintaining structural strength; it is cost - effective due to efficient material use during production; and its durability reduces long - term replacement costs. Variants like aluminum expanded metal mesh and steel expanded metal sheet also offer corrosion resistance and adaptability to diverse climates and loads.

How does mesh size impact the performance of expanded metal?

Mesh size, such as 1 8 expanded metal, directly affects a product’s load - bearing capacity, visibility, and airflow. Smaller mesh sizes offer higher strength and security but may restrict airflow, while larger sizes enhance openness but reduce load capacity. For example, fine mesh is suitable for security screens, while larger mesh like 1 8 expanded metal is ideal for drainage or livestock fencing where moderate openness is required.

![$ element [ady] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)