11111

In the realm of architectural, industrial, and decorative applications, expanded metal products have emerged as versatile solutions, blending functionality with innovation. The expanded metal mesh sheet, expanded aluminum grating, copper expanded metal, expanded copper mesh, and extruded steel mesh each offer unique properties, catering to diverse needs across sectors. This exploration delves into their characteristics, applications, and the factors that make them indispensable.

Understanding the Basics of Expanded Metal Mesh Sheet

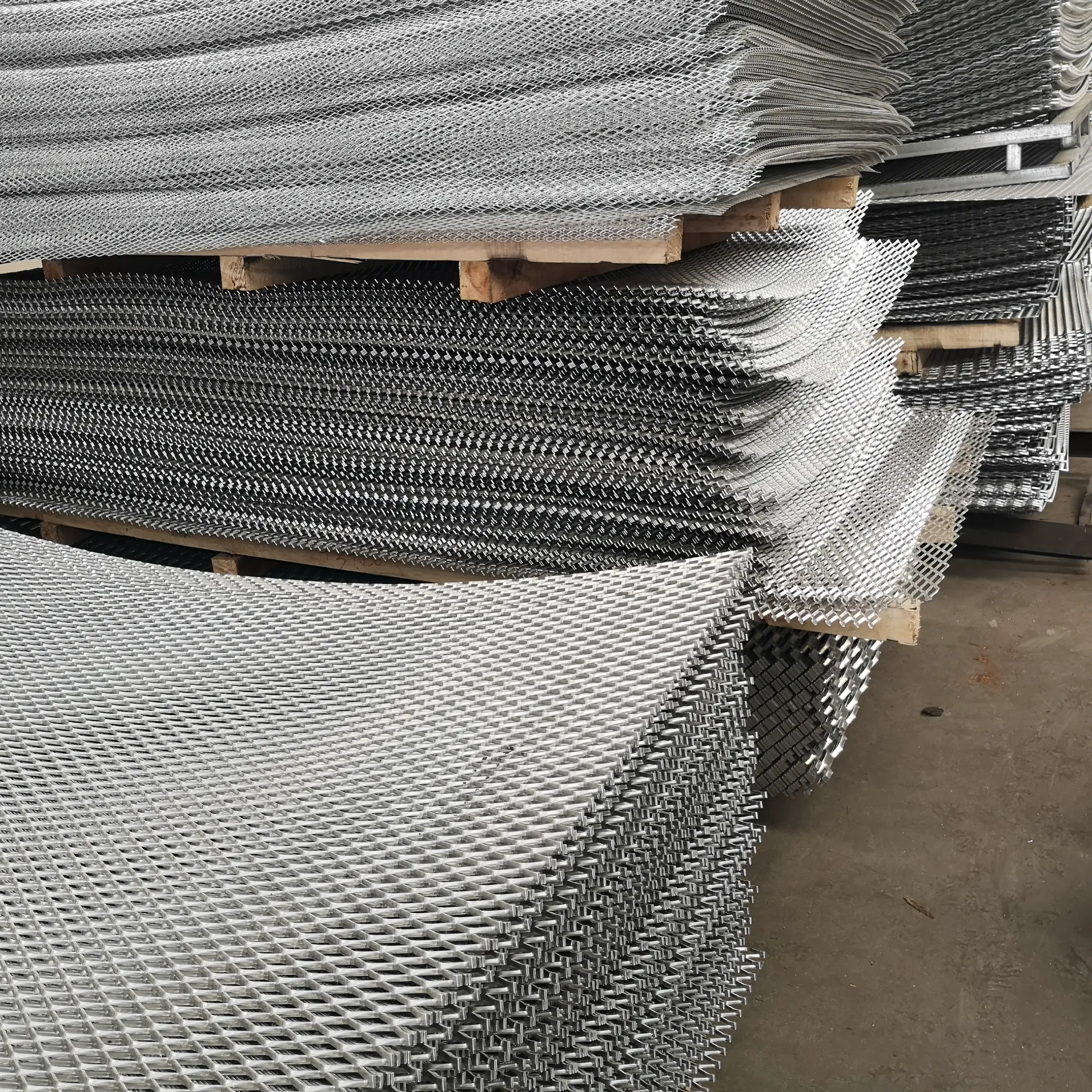

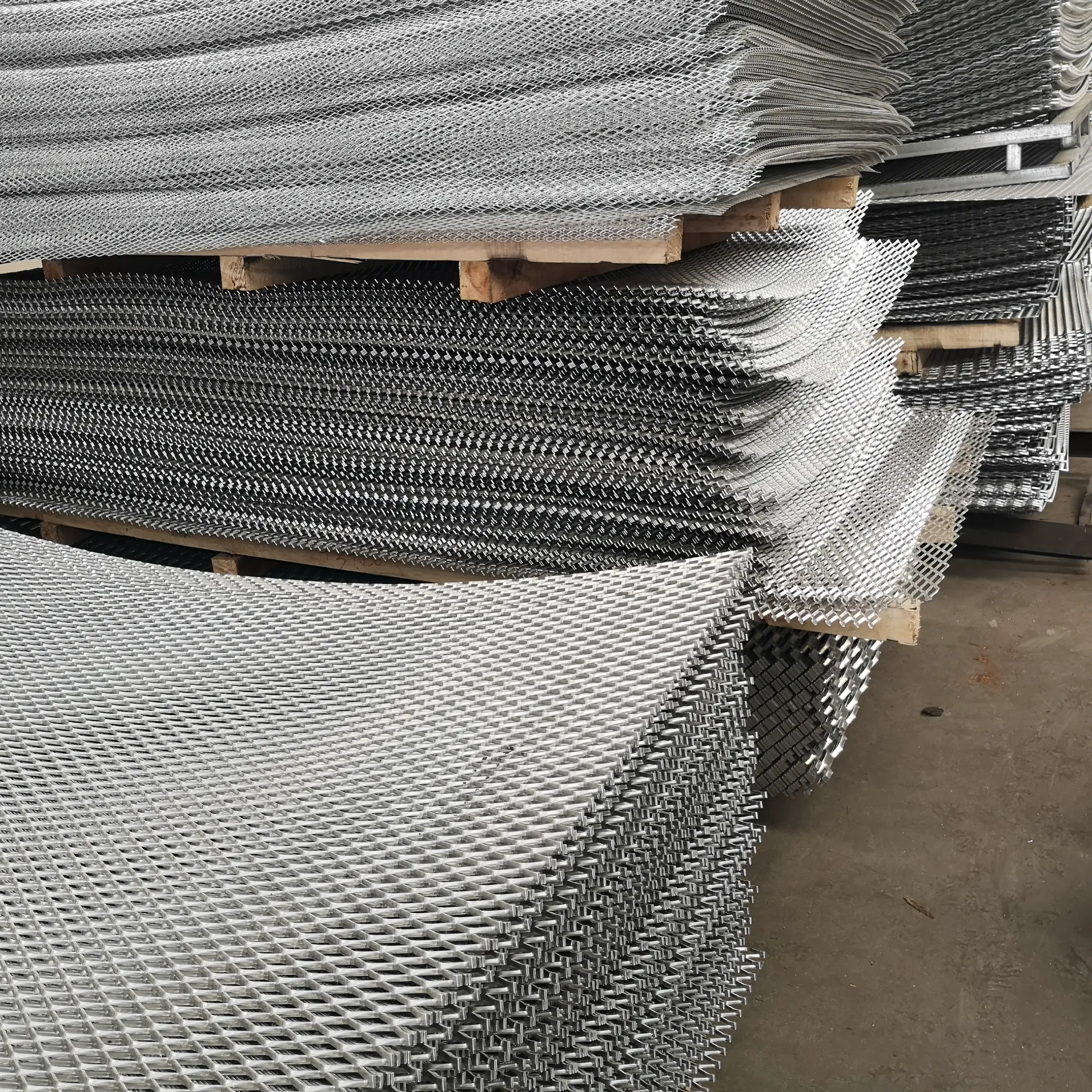

An expanded metal mesh sheet is created through a process of slitting and stretching a metal sheet, forming a network of interconnected diamonds or other patterns. This design provides strength while maintaining lightness and air permeability. In architectural projects, expanded metal mesh sheet is often used for facades, room dividers, or railing infills, adding a modern aesthetic while allowing natural light and airflow. For example, in commercial buildings, a perforated expanded metal mesh sheet can serve as both a security barrier and a decorative element, enhancing the structure’s visual appeal without compromising functionality. The versatility of this product makes it suitable for both indoor and outdoor use, with materials ranging from steel to aluminum.

The Advantages of Expanded Aluminum Grating

Expanded aluminum grating stands out for its lightweight nature and corrosion resistance, making it ideal for applications where durability and ease of installation are crucial. In industrial settings, such as walkways, platforms, or drainage covers, expanded aluminum grating offers reliable support while resisting rust and environmental damage. Its non - conductive properties also make it a safe choice for electrical environments. For instance, in marine applications, expanded aluminum grating is used on ship decks, as it withstands saltwater exposure better than traditional steel gratings. The material’s malleability allows for custom shapes and sizes, ensuring a perfect fit for unique project requirements.

Copper - Based Solutions: Expanded Copper Metal and Mesh

Copper expanded metal and expanded copper mesh are valued for their high conductivity, corrosion resistance, and aesthetic appeal. In electrical applications, expanded copper mesh is used in grounding systems, shielding, or heat dissipation components, leveraging copper’s excellent electrical and thermal properties. For decorative purposes, copper expanded metal adds a touch of elegance to interior designs, such as wall panels or room dividers, where its warm tone and unique texture create a striking visual effect. Additionally, in outdoor installations, copper’s natural patina formation over time adds character while protecting the material from further corrosion, making it a durable choice for landscape features or architectural accents.

Industrial - Grade Strength with Extruded Steel Mesh

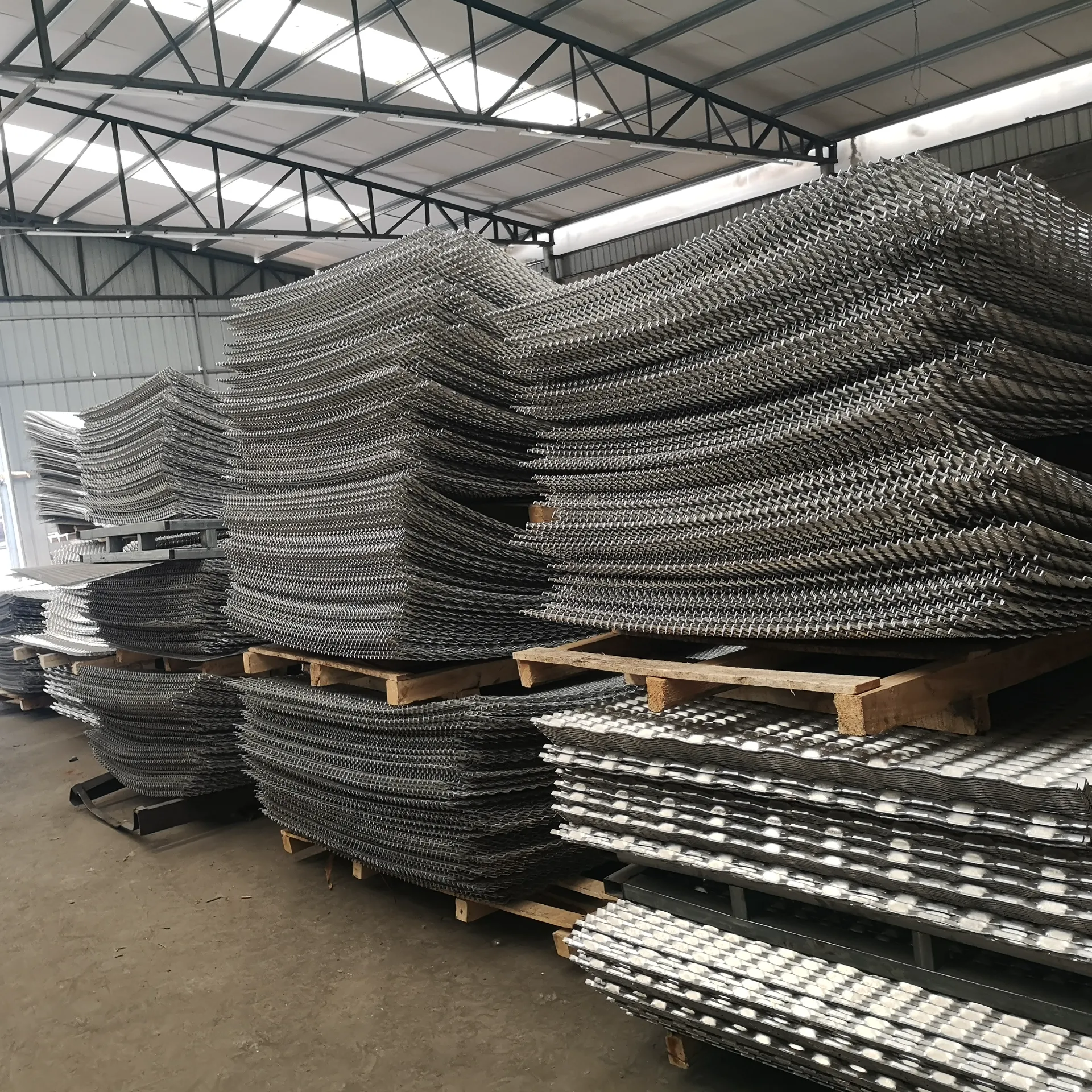

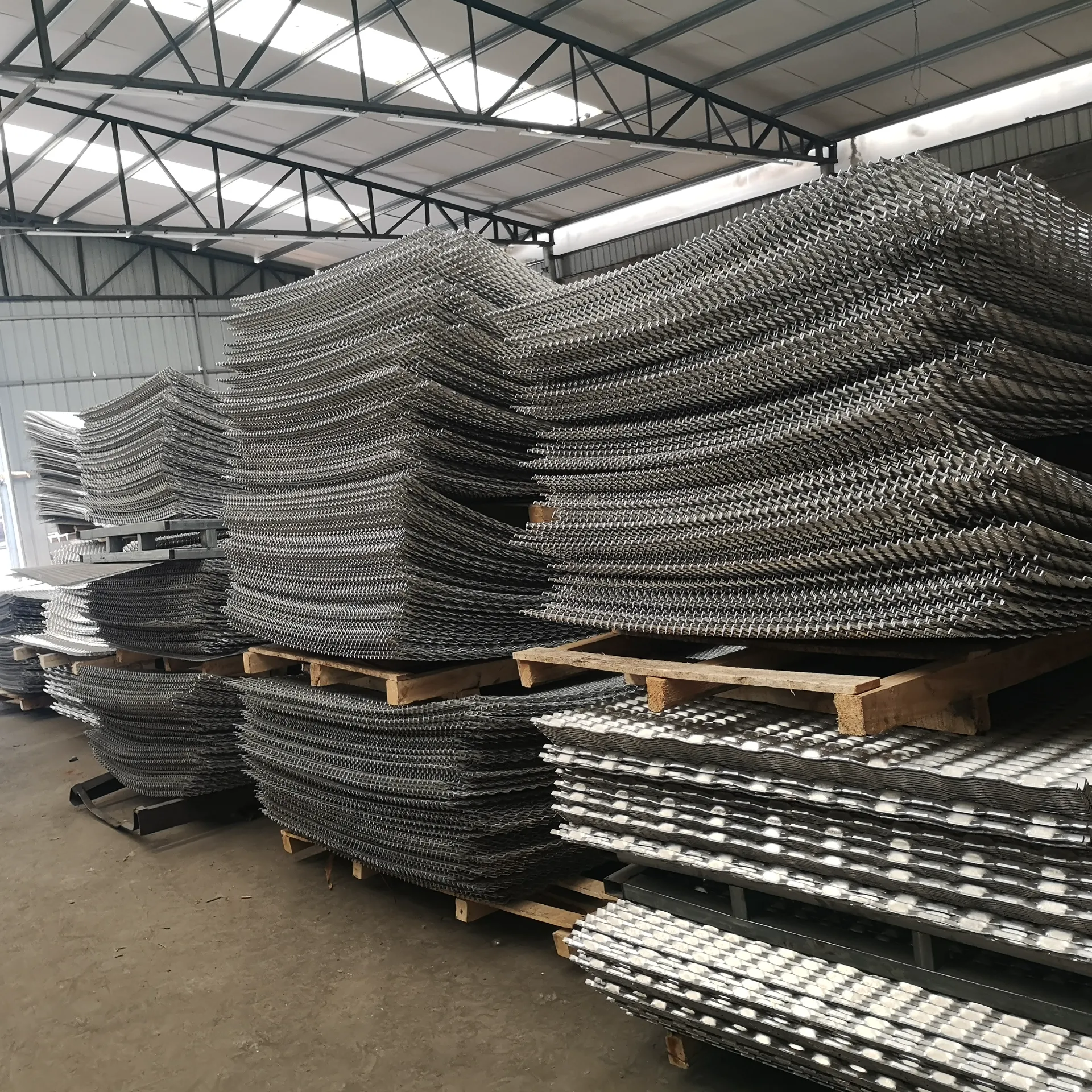

Extruded steel mesh is engineered for heavy - duty applications that require exceptional strength and durability. Manufactured by extruding steel through dies to form precise mesh patterns, this product is commonly used in mining, construction, and agricultural settings. For example, in mining operations, extruded steel mesh is used as safety barriers, rock fall protection, or conveyor belt components, capable of withstanding harsh conditions and heavy loads. In construction, it serves as reinforcement in concrete structures or as security fencing for industrial sites. The high tensile strength of steel, combined with the mesh’s open design, makes extruded steel mesh a reliable choice for applications where safety and longevity are non - negotiable.

FAQ: Key Insights into Expanded Metal Products

How to choose the right material for an expanded metal project?

Selecting the appropriate material—such as steel, aluminum, or copper—depends on the project’s requirements. For outdoor or corrosive environments, expanded aluminum grating or galvanized steel options are preferable. For electrical applications, copper expanded metal or expanded copper mesh is ideal due to their conductivity. Heavy - duty industrial uses often require extruded steel mesh for its strength, while architectural designs may prioritize the aesthetic appeal of expanded metal mesh sheet in various finishes.

What maintenance is required for expanded metal products?

Maintenance varies by material. Expanded aluminum grating and copper expanded metal typically require minimal upkeep, such as occasional cleaning with a mild detergent to remove debris. Steel - based products, like extruded steel mesh or expanded metal mesh sheet, may need periodic checks for rust, especially in humid environments, and can be treated with protective coatings if necessary. Regular inspections to ensure no loose components or structural damage are recommended for all types.

Can expanded metal products be customized for specific designs?

Yes, most expanded metal products, including expanded metal mesh sheet and expanded aluminum grating, can be customized. Manufacturers can adjust mesh size, sheet thickness, and finish (such as powder coating or galvanizing) to meet design specifications. Custom shapes and cuts are also possible, making them suitable for unique architectural features or specialized industrial applications.

Are expanded metal solutions environmentally friendly?

Many expanded metal products, such as expanded aluminum grating and steel meshes, are recyclable, contributing to sustainable design practices. Aluminum, in particular, is highly recyclable without losing its properties. Additionally, the open design of expanded metal reduces material usage compared to solid sheets, minimizing waste and environmental impact.

What industries commonly use extruded steel mesh?

Extruded steel mesh is widely used in industries requiring robust materials, such as mining (for safety barriers and 筛分), construction (as reinforcement or fencing), agriculture (for animal enclosures or grain storage), and manufacturing (for machine guards or conveyor systems). Its strength and resistance to wear make it a staple in harsh, high - stress environments.

![$ element [ady] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)