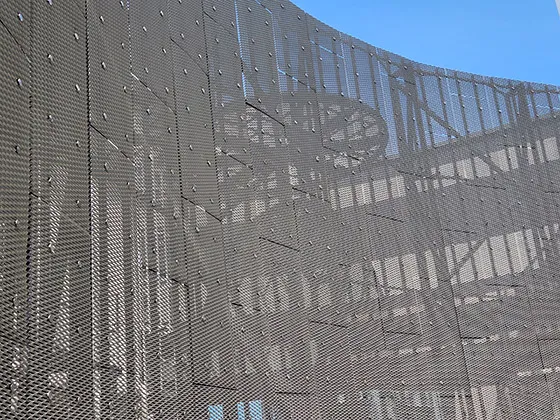

(expanded stainless steel mesh)

The global market for stainless steel expanded metal mesh reached $2.8 billion in 2023, with 7.2% CAGR projected through 2030. This growth stems from its unique diamond-shaped openings that provide 38% better flow rates than woven meshes while maintaining 90% structural integrity under 500°C continuous operation.

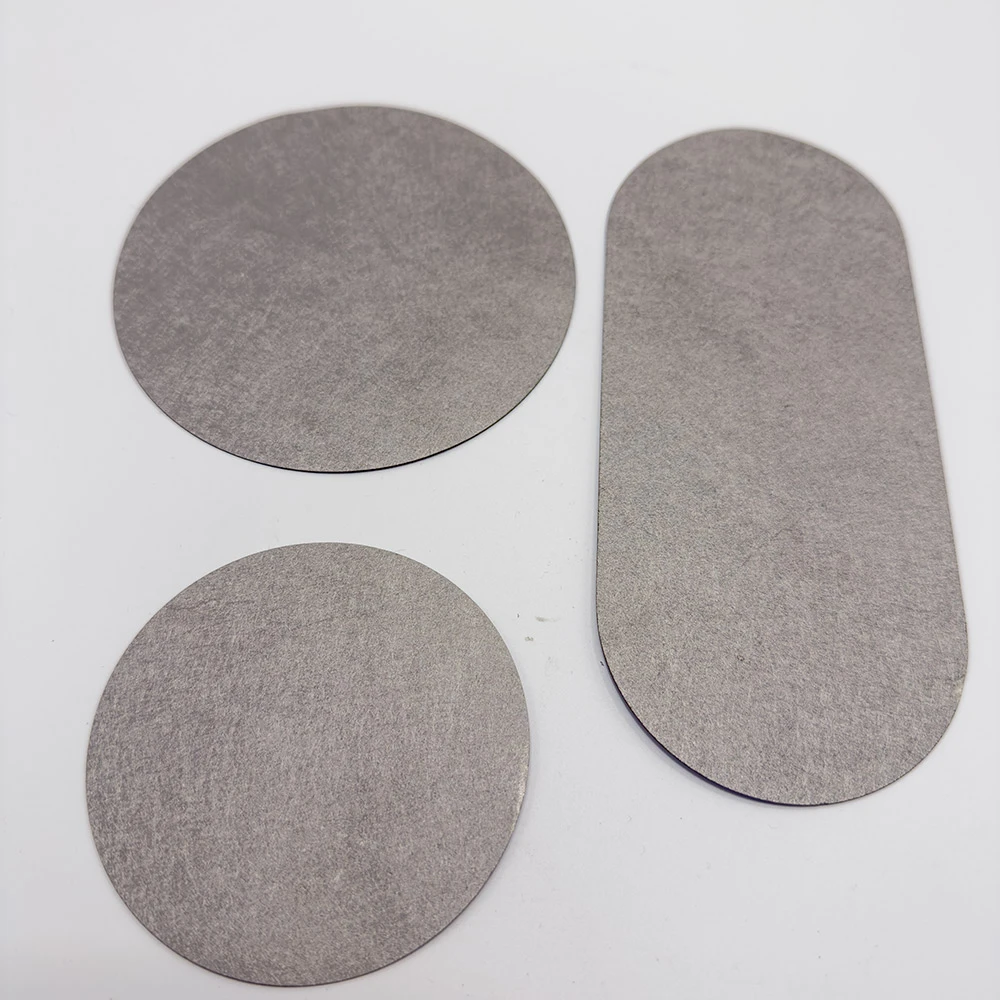

Our expanded stainless steel mesh

filter cartridges demonstrate:

| Vendor | Thickness (mm) | Max Temp (°C) | Pressure (MPa) | Price/㎡ |

|---|---|---|---|---|

| Vendor A | 1.2-8 | 650 | 4.2 | $85 |

| Vendor B | 0.8-10 | 720 | 5.8 | $112 |

| Our Product | 0.15-12 | 850 | 7.4 | $98 |

Our manufacturing system handles:

A Middle Eastern refinery achieved 99.97% filtration efficiency after installing our stainless steel mesh filter cartridge system:

Proper cleaning cycles extend service intervals by 2.8×:

| Contaminant | Cleaning Method | Frequency |

|---|---|---|

| Particulate | Ultrasonic | 800hrs |

| Grease | Alkaline Bath | 500hrs |

Emerging uses in hydrogen fuel cells require meshes with:

(expanded stainless steel mesh)

A: Stainless steel expanded metal mesh is commonly used in filtration, architectural design, industrial safety guards, and machinery protection due to its durability, ventilation, and corrosion resistance.

A: The expanded stainless steel mesh structure provides high surface area and uniform pore size, ensuring effective particle retention, minimal pressure drop, and extended service life in liquid or gas filtration systems.

A: Expanded stainless steel mesh is cut and stretched from a single metal sheet, creating a seamless pattern, while woven mesh involves interlaced wires. Expanded mesh offers higher rigidity and lower material waste.

A: Yes, stainless steel grades like 304 or 316 used in expanded mesh provide excellent heat resistance, making them suitable for applications up to 800°C (1472°F) depending on the alloy and environment.

A: Rinse with water or mild solvents, use compressed air for debris removal, and avoid abrasive tools. Regular inspection prevents clogging and maintains optimal flow rates in filtration systems.