|

Item

|

Description

|

|

Product Name

|

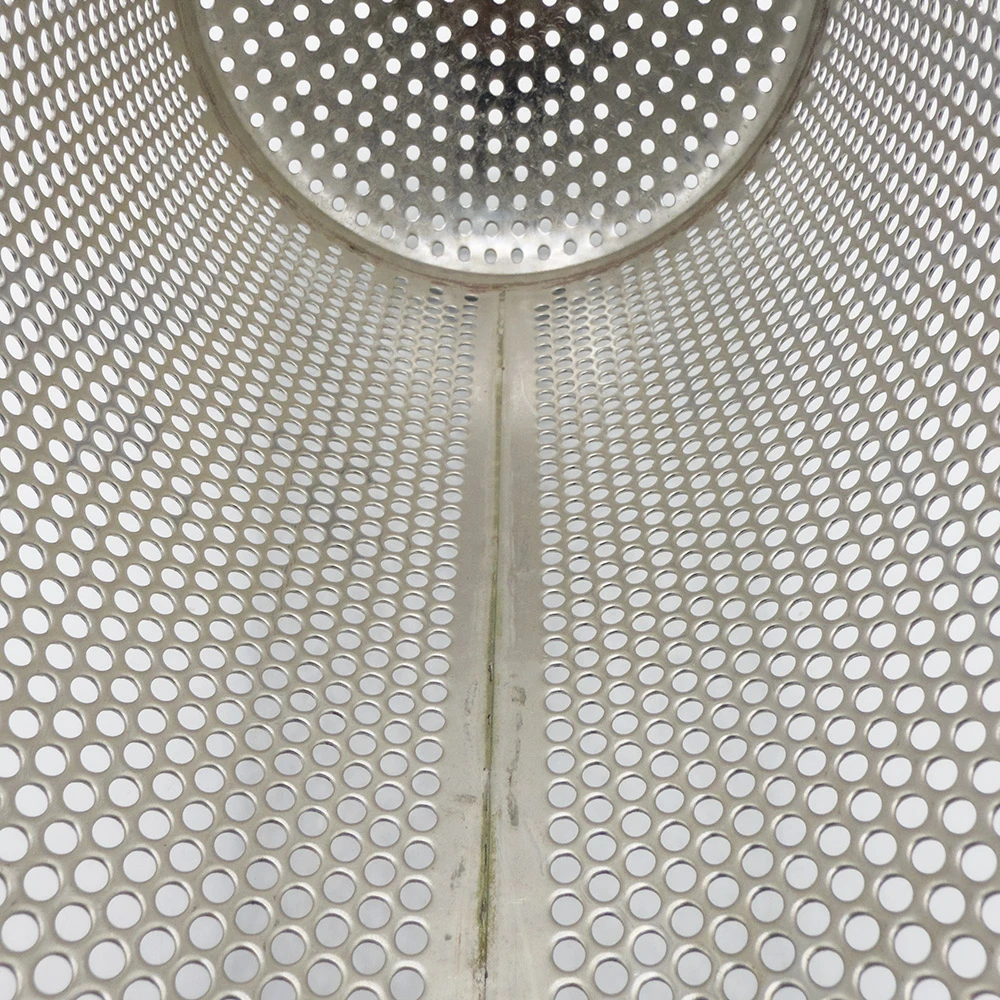

Stainless Steel Perforated Filter (Bag Filtration/Filter System)

|

|

Material

|

Stainless Steel 304/316L (Corrosion-resistant, suitable for food and chemical industries)

|

|

Structure

|

Cylindrical perforated metal mesh, with optional inner support layer and flange connection

|

|

Filtration Accuracy

|

Aperture size: 0.5mm - 20mm (Customizable)

|

|

Dimensions

|

Customizable (Common sizes: Diameter 100-1000mm, Height 100-11000mm)

|

|

Thickness

|

0.3mm - 10mm (Customizable)

|

|

Hole Type

|

Round holes, hexagonal holes, oblong holes (Adaptable to different fluid characteristics)

|

|

Example of Filtration Precision (μm)

|

|

Aperture Size (mm)

|

Filtration Precision (μm)

|

Application

|

|

5.0

|

5000

|

large particle removal

|

|

2.0

|

2000

|

suitable for large debris removal

|

|

1.0

|

1000

|

removing larger solid impurities

|

|

0.5

|

500

|

capturing liquid particles

|

|

0.1

|

100

|

Ultra-fine filtration

|

|

For higher precision filtration (1-50μm), an additional fine filter bag or inner lining can be integrated with the stainless steel perforated mesh to achieve superior performance.

Would you like a recommendation for the optimal aperture size and material based on your application? Let me know your required filtration standard (μm)!

|

|

|

Open Area Ratio

|

20% - 60% (Optimized for flow efficiency)

|

|

Connection Type

|

Flange, clamp, or threaded connection (Compatible with various filtration systems)

|

|

Operating Temperature

|

-50°C to 500°C (Suitable for high-temperature environments)

|

|

Pressure Resistance

|

Up to 30 MPa (Depends on material and thickness)

|

|

Surface Treatment

|

1. Pickling(Stainless steel (304, 316L), carbon steel, nickel-based alloy (Monel, Hastelloy)

2. Electrolytic Polishing(Stainless steel (304, 316L), nickel-based alloy (Monel, Hastelloy))

Etc

|

|

Corrosion Resistance

|

Acid and Alkali Resistant, High-Temperature Resistant, Oxidation Resistant

|

|

Applicable Media

|

Water, oil, air, chemical solutions, food liquids, etc.

|

|

Application Industries

|

Food processing, chemical filtration, pharmaceuticals, wastewater treatment, petroleum refining, metal processing, etc.

|

|

Features

|

1. High strength – Perforated stainless steel mesh structure, impact-resistant, suitable for high-pressure environments

2. Corrosion-resistant – Made of 304/316L stainless steel, suitable for acidic and alkaline environments

3. Reusable & Washable – Long service life, reducing filtration costs

4. Excellent flow performance – High open area ratio, minimizing fluid resistance and improving filtration efficiency

5. Easy installation – Standardized flange or threaded connections, compatible with various systems

|

|

Customization Options

|

Sizes, aperture sizes, materials, thickness, and connection types can be customized

|

|

Packaging

|

Plastic bag + Carton + Wooden crate (Moisture-proof and rust-proof for international shipping)

|

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)