|

Items

|

Beskriuwing

|

|

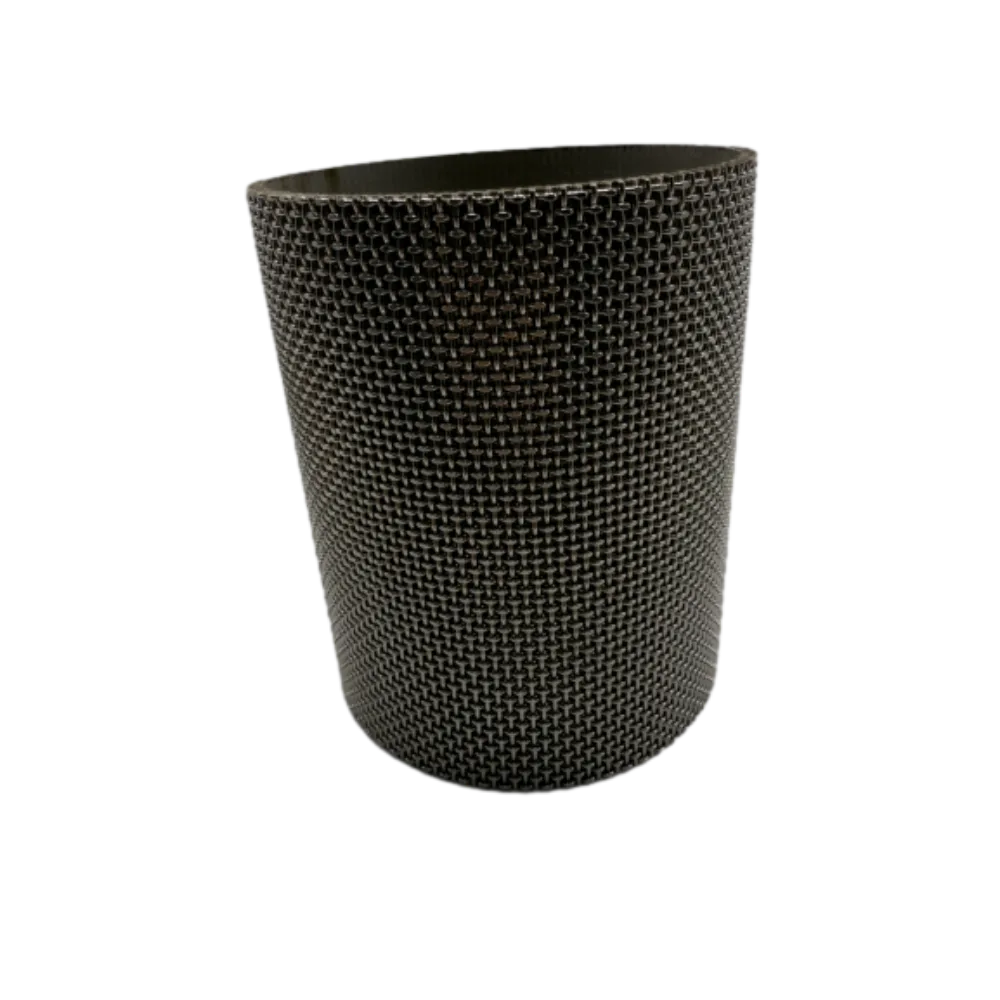

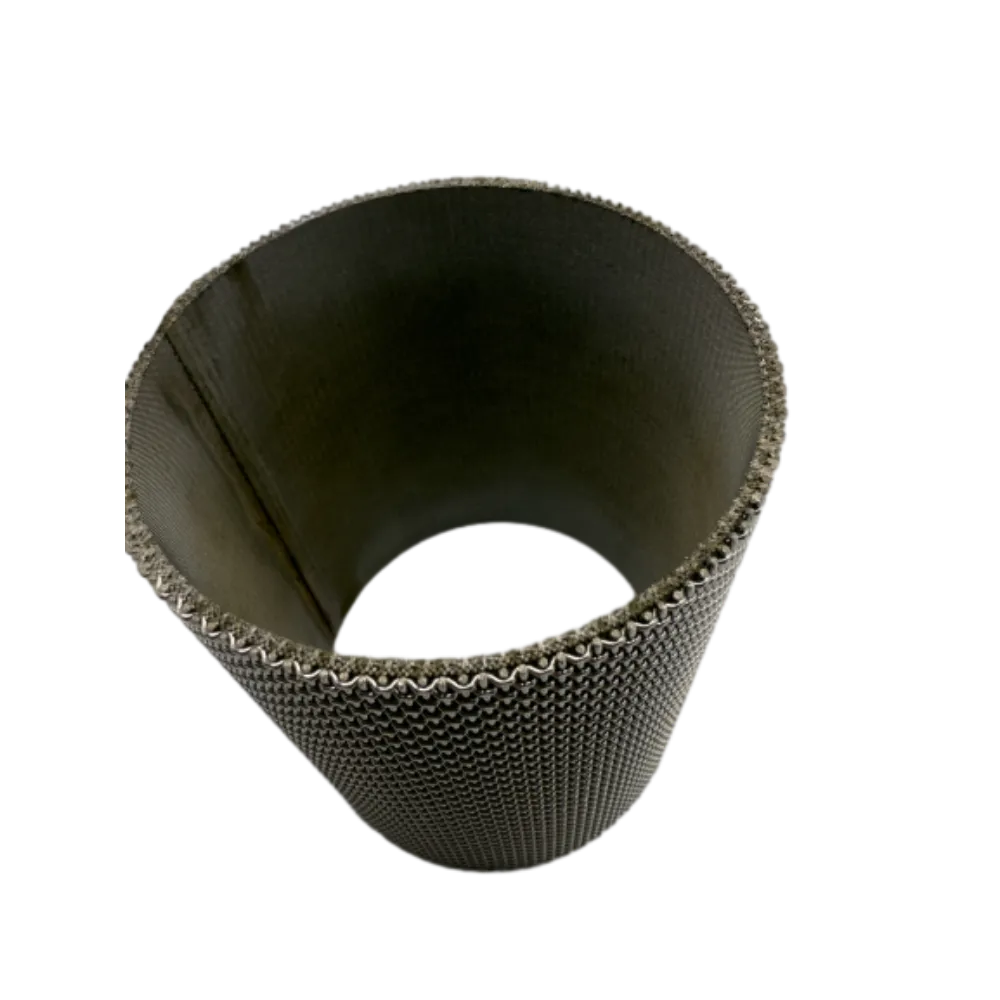

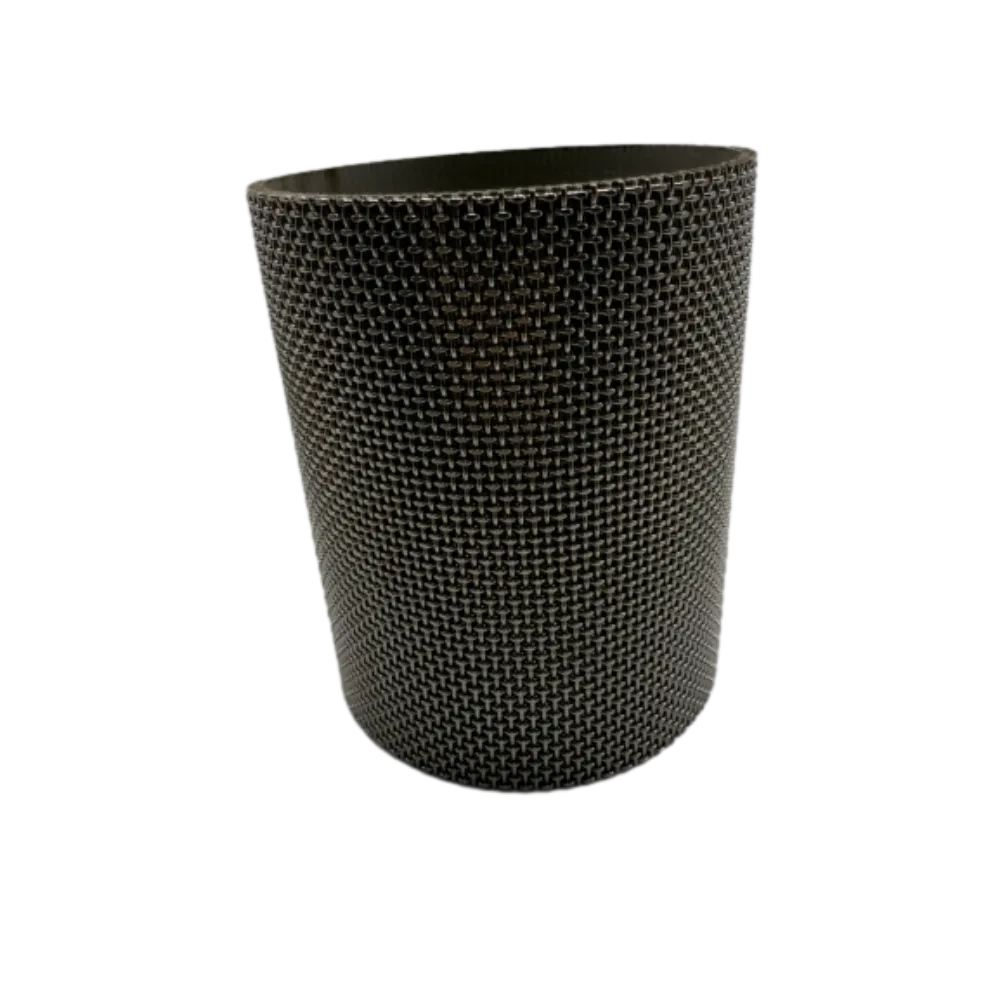

Produkt Namme

|

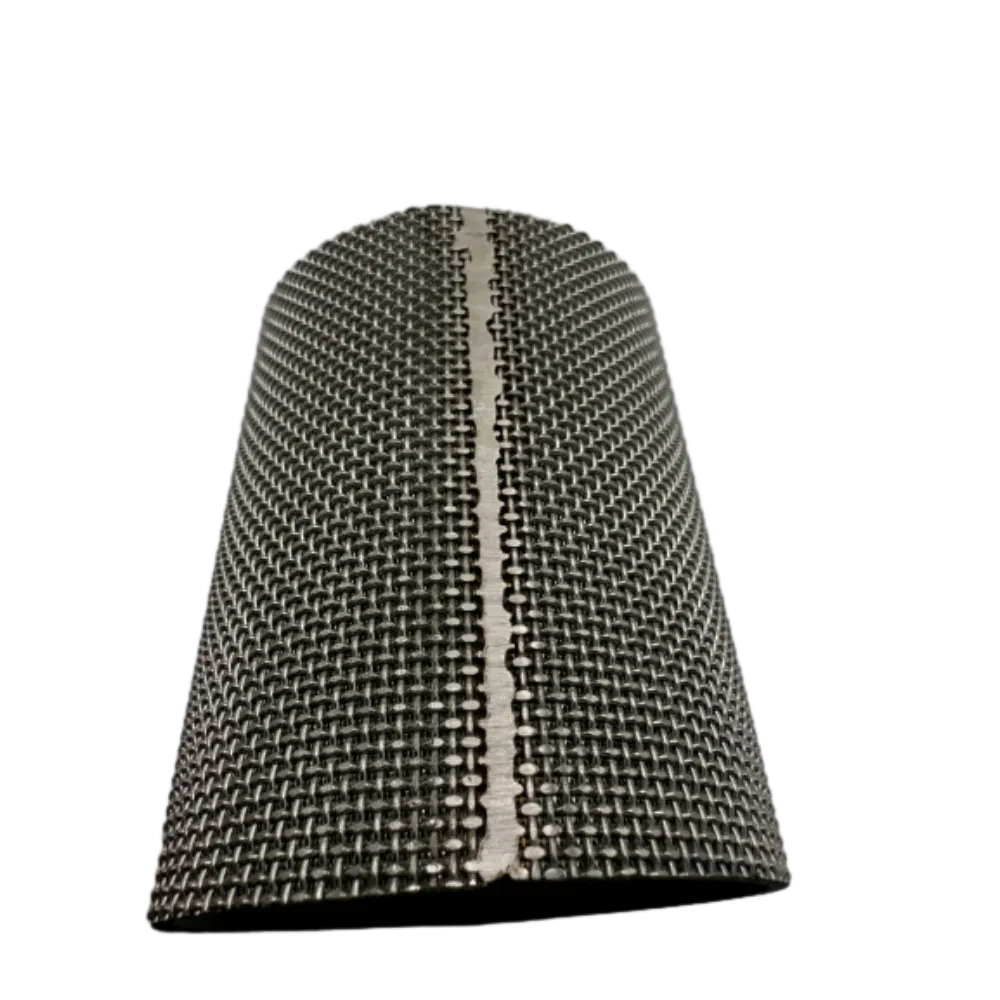

Sintered Wire Mesh Tube

|

|

Manufacturing Process

|

1. Sintering: By hege temperatueren bindet de diffusion fan metalen dieltsjes it metalen gaas byinoar om in gearhingjende struktuer te foarmjen

2. Rolling: Troch hege druk rolling, elke mesh laach is strak ferbûn te garandearjen syn dikte uniformiteit.

3. Laser Cutting / Plasma Cutting: Cutting Sintered Wire Mesh, Soargje derfoar dat de cutting is presys yn grutte en foarm.

4. Welding: Wurdt brûkt foar welding yn in silindryske foarm

|

|

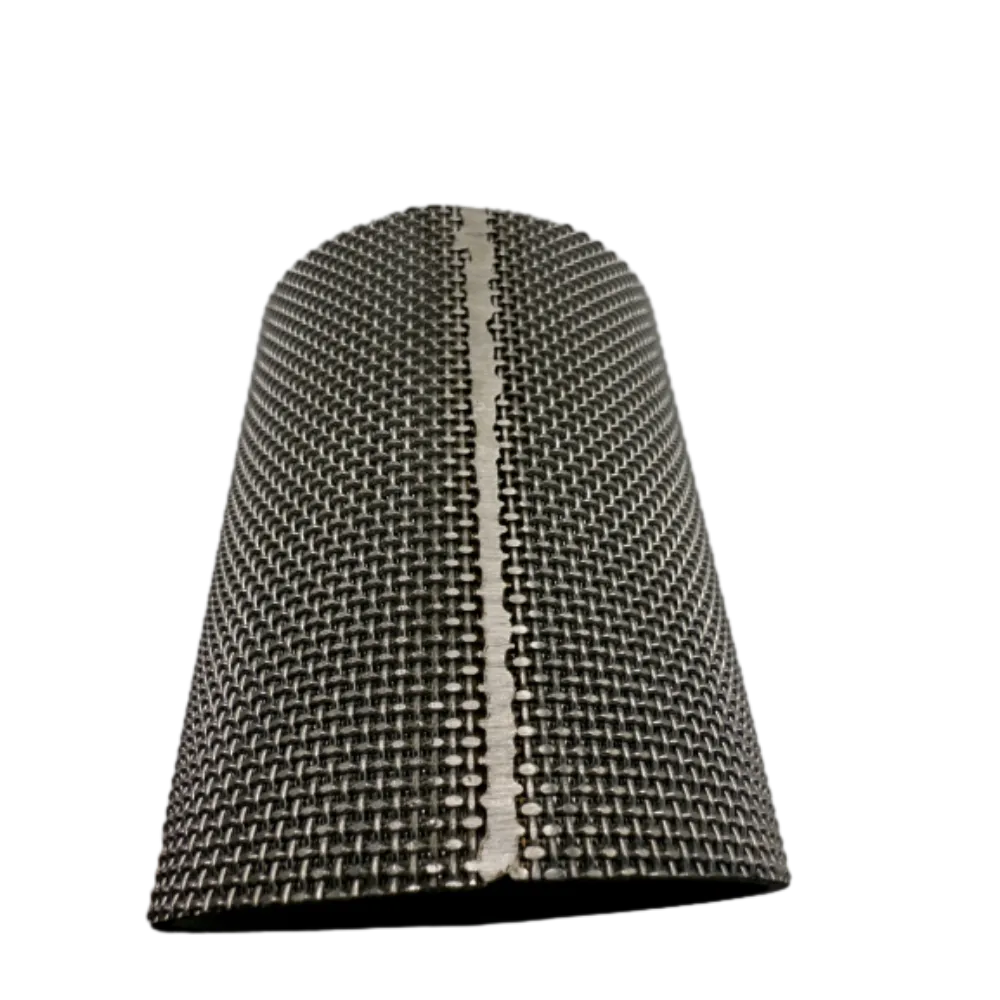

Geweven manier fan woven wire gaas

|

1. Plain Weave (De meast foarkommende weaving metoade hat unifoarme gaas gatten en is geskikt foar algemiene filtration)

2. Twill Weave (Hegere filternoyaktichheid, strakkere struktuer, geskikt foar hege-precision filtering)

3. Dutch Weave (In hege tichtheid filterstruktuer wurdt foarme troch interweaving grof warp triedden en fyn weft triedden, faak brûkt foar ultrafine filtration)

4. Reverse Dutch Weave (Hat hegere sterkte en load-bearing kapasiteit, geskikt foar hege-druk filtration)

|

|

Materiaal Alternativen

|

1. RVS (304, 316, 316L)

2. Nikkellegering (Monel, Hastelloy, Inconel)

3. Titanium Mesh

ETC

|

|

Oantal lagen

|

3, 5, 7 lagen (as oanpaste multi-laach struktuer)

|

|

Filtraasje accuracy

|

1μm - 200μm (oanpasber)

|

|

Dikte Range

|

0.5mm - 5mm (feroaret troch it oantal lagen)

|

|

Gat Grutte Distribúsje

|

Gradientpoarûntwerp foar effisjinte filtraasje en floeistofstream

|

|

Surface behanneling

|

Acid beitsen (Rustfrij stiel / koalstof stiel),

Elektrolytysk polearjen (RVS)

Nikkel plating (RVS / Carbon Steel)

Anodisearjen (aluminium) ensfh.

|

|

Operating Temperatuer

|

-200 ℃ oant 600 ℃ (ôfhinklik fan materiaal)

|

|

Druk Resistance

|

Oant 30MPa of heger (feroaret basearre op meshlagen en dikte)

|

|

Permeability / Flow Resistance

|

Leech ferset en hege permeabiliteit, geskikt foar gas- en floeistoffiltraasje

|

|

Corrosie Resistance

|

Resistint foar soeren, alkalis, sâlt spray, en oksidaasje yn hurde omjouwings

|

|

Cleaning Metoaden

|

Backwashing, Ultrasone skjinmeitsjen, Hege temperatuer bakken, Chemical cleaning, en werbrûkber

|

|

Manufacturing Process

|

Hege temperatuer fakuüm sintering, Rolling, Welding, Stamping

|

|

Beskikbere foarmen

|

Silindrysk, fjouwerkant, blêd, plissé, oanpaste foarmen beskikber

|

|

Ferbining Metoaden

|

Flensferbining, Welding, Threaded ferbining, Clamping

|

|

Tapasbere Fluids

|

Geskikt foar floeistoffen, gassen, oaljes, stoom, ensfh.

|

|

Applikaasje fjilden

|

Petrochemical, Food & Beverage, Pharmaceuticals, Environmental Water Treatment, Aerospace, Automotive Industry, ensfh.

|

|

Produkt Foardielen

|

1. Hege krêft en druk ferset, net maklik te ferfoarmjen

2. Repeatable cleaning, lange libben

3. Precision filtration, unifoarm pore grutte ferdieling

4. Hege temperatuer en corrosie ferset, oanpasber oan hurde omjouwings

|

![$item[titel] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)