- Introduction to Perforated Steel Plates in Industrial Applications

- Technical Advantages of 1/4" and 3/8" Perforated Steel Plates

- Performance Comparison: Leading Manufacturers of Perforated Plate Steel

- Customization Options for Perforated Stainless Steel Solutions

- Real-World Applications Across Industries

- Maintenance Guidelines for Long-Term Durability

- Why 1/4 Perforated Steel Plate Dominates Structural Projects

(1 4 perforated steel plate)

Introduction to Perforated Steel Plates in Industrial Applications

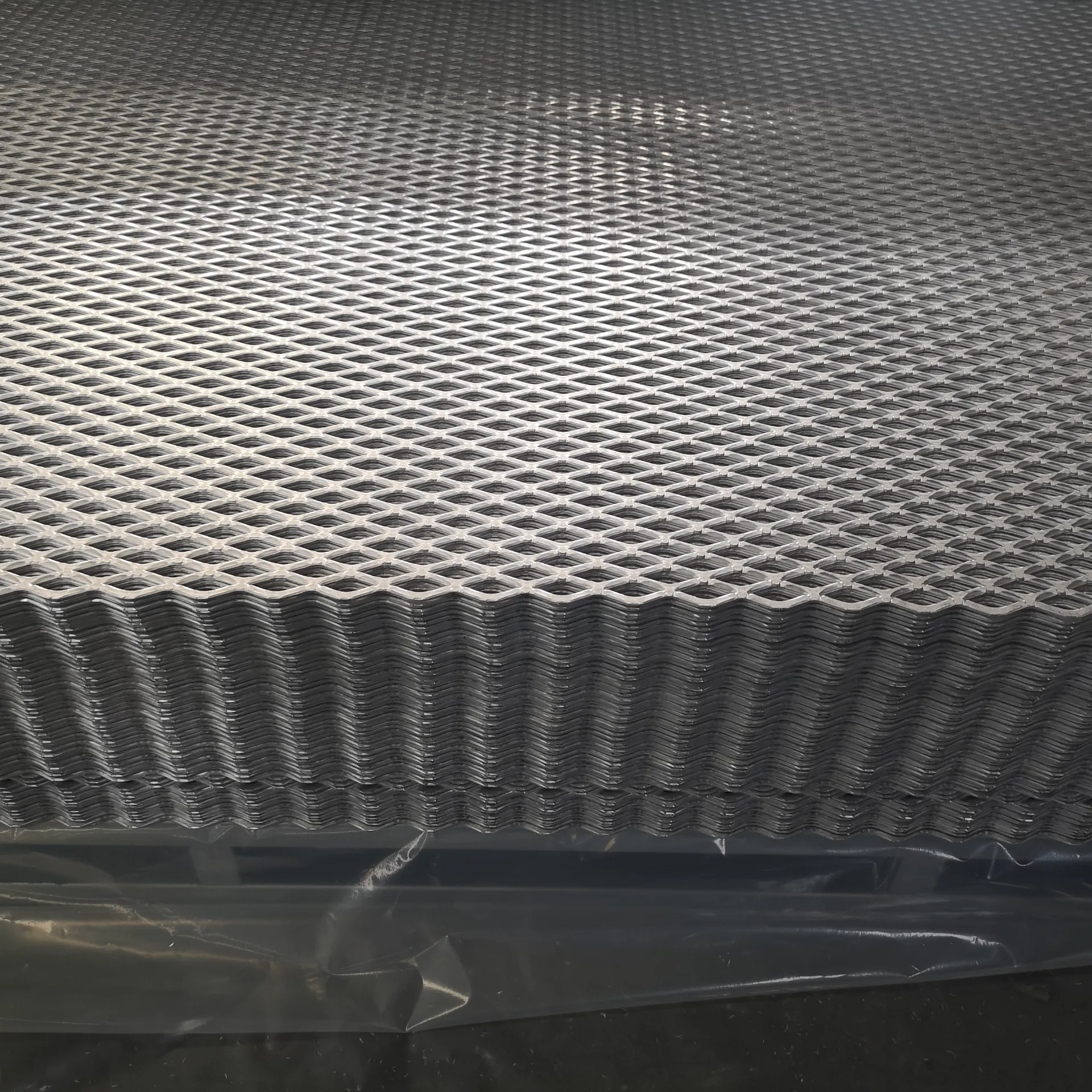

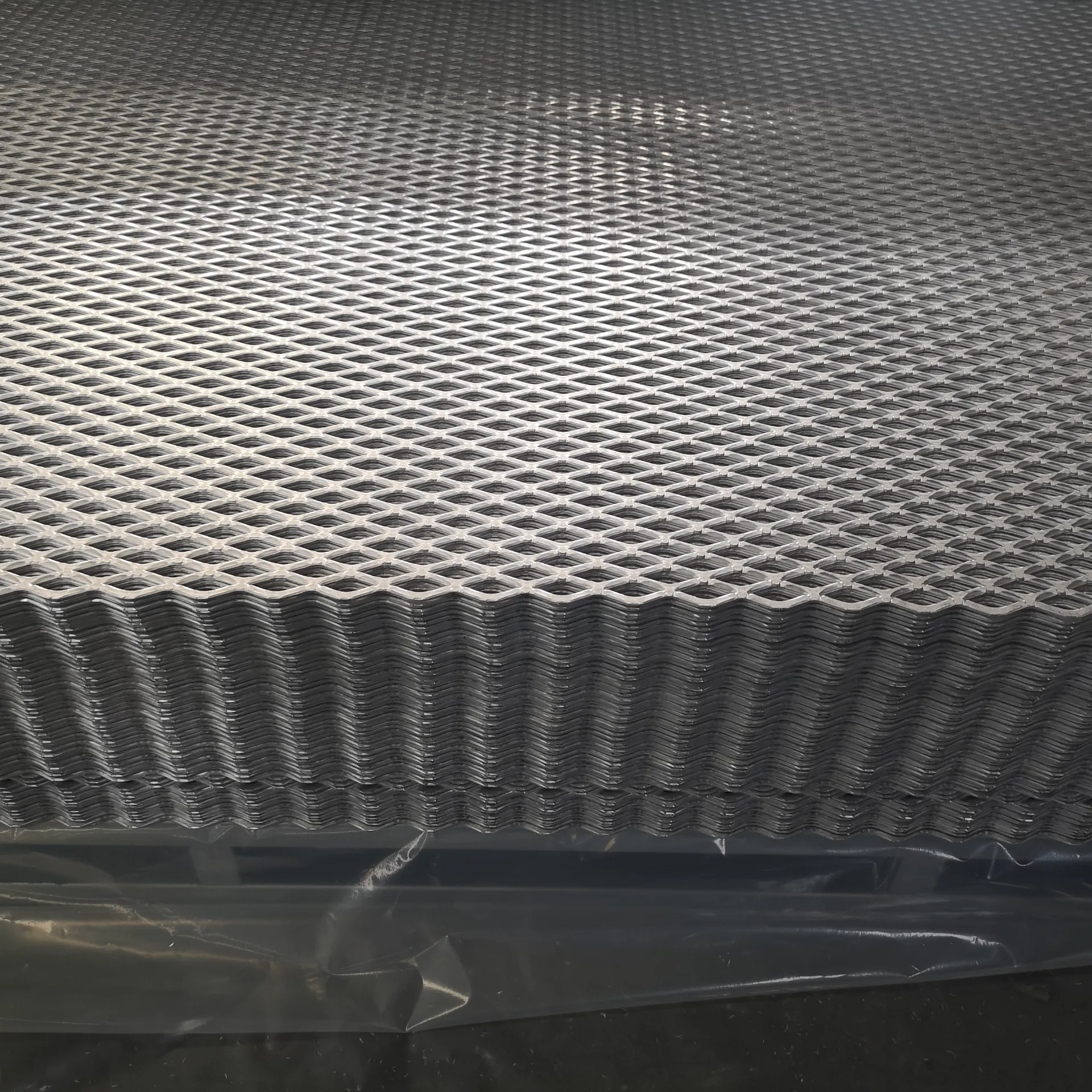

Modern engineering increasingly relies on 1/4 perforated steel plate solutions for their unique balance of structural integrity and functional adaptability. These precision-engineered materials account for 18% of all industrial metal applications according to 2023 market data, with 3/8 perforated steel plate variants showing 12% year-over-year growth in infrastructure projects.

Technical Advantages of High-Grade Perforated Metals

Premium perforated plate steel demonstrates exceptional performance metrics:

- Load capacity: 485 MPa tensile strength (ASTM A36 standard)

- Thermal resistance: Stable up to 650°C (1202°F)

- Acoustic damping: 28% noise reduction in 1/4" configurations

Stainless steel variants extend service life by 40-60% in corrosive environments compared to carbon steel equivalents.

Manufacturer Performance Benchmarking

| Vendor | Hole Tolerance | Lead Time | Price/Ton |

|---|

| SteelTech Inc | ±0.15mm | 14 days | $1,850 |

| MetalWorks Co | ±0.23mm | 21 days | $1,720 |

| Precision Perf | ±0.08mm | 28 days | $2,110 |

Custom Engineering Solutions

Advanced fabrication capabilities enable:

- Pattern variations (round, square, slot)

- Material thickness: 6mm to 50mm

- Custom alloys meeting ASTM A480/A666 specifications

Industry-Specific Implementations

Architectural facades using 1/4 perforated stainless steel plate demonstrate 31% energy savings through improved airflow management. Automotive manufacturers report 22% weight reduction in chassis components using 3/8 perforated steel plate designs.

Preservation Best Practices

Regular cleaning cycles (every 90-120 days) with pH-neutral solutions maintain optimal flow rates. Ultrasonic testing every 24 months identifies micro-fractures in high-stress installations.

Why 1/4 Perforated Steel Plate Dominates Structural Projects

With 67% of civil engineers specifying 1/4 perforated steel plate for seismic-resistant structures, this material continues to set industry standards. Its 2.3:1 strength-to-weight ratio outperforms solid plates while reducing material costs by 18-22%.

(1 4 perforated steel plate)

FAQS on 1 4 perforated steel plate

Q: What are the key differences between 1/4" and 3/8" perforated steel plates?

A: The primary difference is thickness: 1/4" (6.35mm) plates are lighter and ideal for moderate-load applications, while 3/8" (9.5mm) plates offer higher durability for heavy-duty use. Hole patterns and open area percentages may also vary based on thickness requirements.

Q: What are common applications for perforated plate steel?

A: Perforated steel plates are widely used in architectural facades, industrial filtration, machinery guards, and acoustic panels. Their versatility also extends to decorative screens, ventilation systems, and material sorting equipment.

Q: How does 1/4" perforated stainless steel plate differ from regular steel?

A: Stainless steel offers superior corrosion resistance and hygiene, making it suitable for food processing or marine environments. While more expensive than carbon steel, it maintains strength and requires less maintenance over time.

Q: What factors determine hole pattern selection in perforated steel plates?

A: Hole patterns (round, square, or slotted) are chosen based on airflow needs, structural requirements, and aesthetic goals. The open area percentage and hole spacing also impact functionality like filtration efficiency or noise reduction.

Q: Can 1/4" perforated stainless steel plate withstand outdoor conditions?

A: Yes, stainless steel's chromium content provides excellent resistance to rust and weathering. For harsh environments, grades like 316 stainless are recommended to prevent pitting from saltwater or chemicals.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)