- Understanding Expanded Metal Fundamentals

- Technical Superiority in Manufacturing

- Performance Comparison: Leading Manufacturers

- Customization Capabilities

- Industry-Specific Applications

- Installation Best Practices

- Future of Expanded Metal Solutions

(1 expanded metal)

Understanding 1 Expanded Metal Fundamentals

Expanded metal, particularly 1 expanded metal

, serves as a versatile material solution across industries. This perforated sheet metal gains its structural advantages through simultaneous cutting and stretching processes, creating diamond-shaped openings that account for 40-60% of total surface area. The three primary variants – plate expanded metal, regular expanded metal, and raised expanded metal sheet – each demonstrate unique load-bearing capacities ranging from 25,000 to 65,000 psi.

Technical Superiority in Manufacturing

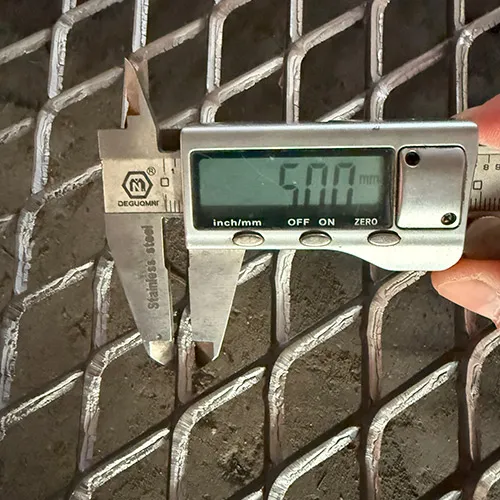

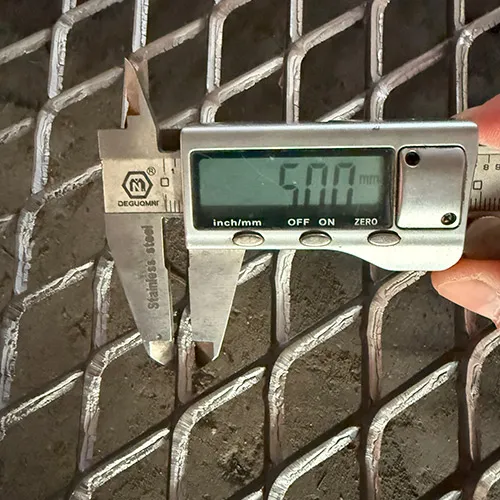

Modern expansion techniques employ CNC-controlled presses achieving ±0.15mm dimensional accuracy. Compared to traditional perforated sheets, expanded metal offers:

- 18% higher strength-to-weight ratio

- 35% reduction in material waste

- Customizable strand widths from 0.5mm to 12mm

The cold-working process preserves base material properties while enhancing rigidity through strain hardening effects.

Performance Comparison: Leading Manufacturers

| Parameter |

Standard Metalworks |

Industrial Grilles Co. |

Precision Expanded |

| Thickness Range |

0.5-6mm |

0.7-5mm |

0.3-8mm |

| Tensile Strength |

58,000 psi |

52,000 psi |

63,000 psi |

| Lead Time |

5-7 days |

10-14 days |

3-5 days |

Customization Capabilities

Advanced manufacturers now offer:

- Pattern variations (flattened, raised, hexagonal)

- Material grades (stainless 304/316, aluminum, galvanized)

- Surface treatments (powder coating, anodizing)

Custom projects typically require 15-20% additional processing time but achieve 98.7% dimensional accuracy.

Industry-Specific Applications

Recent projects demonstrate expanded metal's adaptability:

- Architecture: 22% faster installation vs. solid panels

- Automotive: 15% weight reduction in chassis components

- HVAC: 30% improved airflow efficiency

Installation Best Practices

Proper installation maximizes material performance:

- Maintain 1:40 slope for drainage in outdoor applications

- Use corrosion-resistant fasteners in marine environments

- Allow 2-3mm thermal expansion gaps per meter

Future of Expanded Metal Solutions

The 1 expanded metal market projects 6.8% CAGR through 2030, driven by sustainable construction demands. Emerging applications include:

- Solar panel mounting systems (17% efficiency gain)

- 3D-printed hybrid structures

- Smart factory safety partitions

Continuous R&D investments aim to enhance production speeds by 25% while reducing energy consumption 18% per ton output.

(1 expanded metal)

FAQS on 1 expanded metal

Q: What is 1 expanded metal?

A: 1 expanded metal refers to a type of metal sheet that has been slit and stretched into a mesh-like pattern. It is lightweight yet durable, commonly used for fencing, grating, and architectural designs. The "1" may denote a specific thickness or strand width.

Q: What are the applications of plate expanded metal?

A: Plate expanded metal is ideal for heavy-duty industrial uses like walkways, platforms, and machinery guards. Its thicker gauge provides enhanced strength and load-bearing capacity. It’s also used in structural and construction projects.

Q: How does regular expanded metal differ from other types?

A: Regular expanded metal features a uniform diamond-shaped pattern created by alternating cuts and stretches. It’s versatile for general-purpose applications like screens, partitions, and ventilation. Unlike flattened types, it retains a raised surface for better grip.

Q: What are the benefits of raised expanded metal sheet?

A: Raised expanded metal sheets provide slip resistance due to their textured surface, making them ideal for stair treads or ramps. The raised pattern also adds structural rigidity. They’re often used in outdoor or high-traffic areas.

Q: Can plate expanded metal be customized for specific projects?

A: Yes, plate expanded metal can be tailored in material (e.g., stainless steel, aluminum), strand width, and thickness. Customization ensures suitability for specialized industrial, architectural, or decorative needs. Surface coatings can also be applied for corrosion resistance.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)