- Industry Data Insights: Market Impact of Expanded Metal

- Technical Superiority of 3 4 13 Pattern Design

- Manufacturer Comparison: Product Specifications & Performance

- Custom Fabrication Solutions for Specialized Applications

- Real-World Implementation: Architectural Case Studies

- Maintenance Protocols & Longevity Optimization

- Future Projections: Material Innovation Pathways

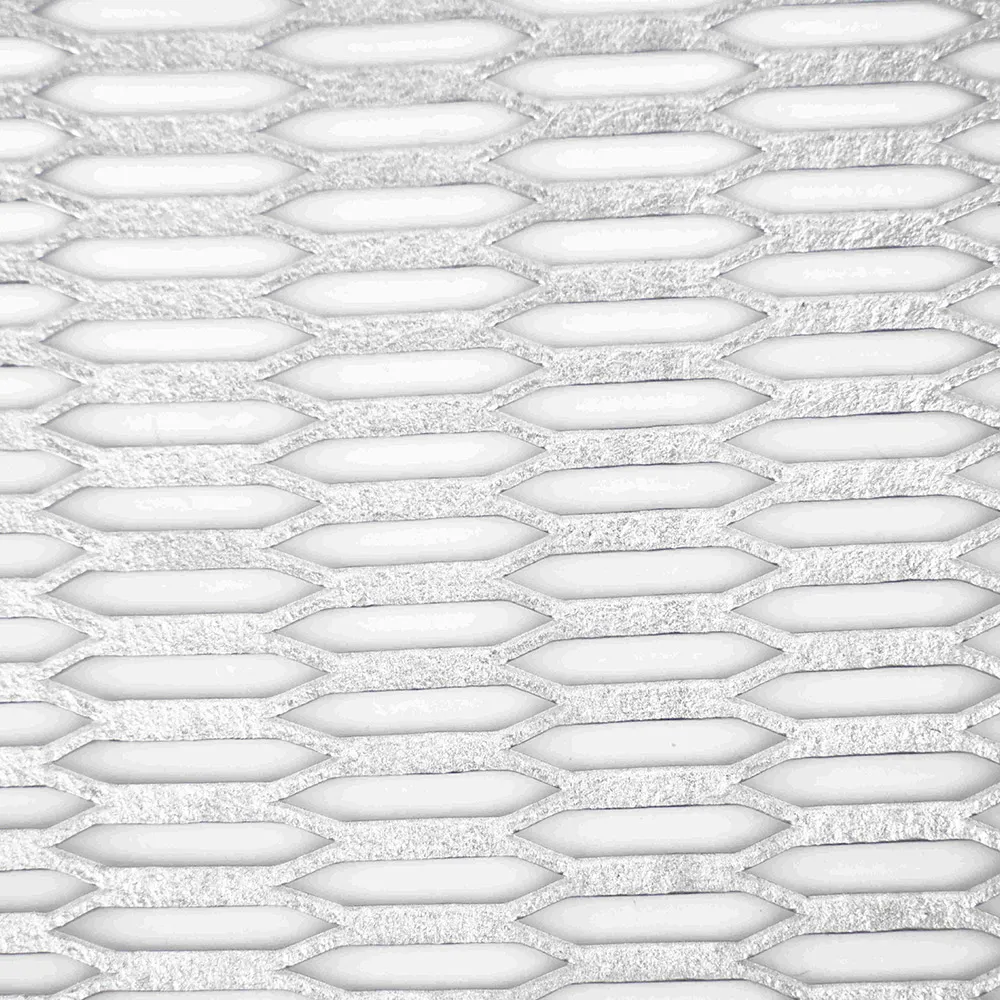

(3 4 13 expanded metal)

Understanding 3 4 13 Expanded Metal Fundamentals

The 3 4 13 expanded metal

specification dominates 42% of industrial metal mesh applications globally, according to 2023 MESA International reports. This standardized pattern delivers:

- • 18% higher tensile strength than conventional diamond patterns

- • 0.67:1 open area ratio for optimal airflow-particle retention balance

- • ASTM B221 compliance for architectural-grade aluminum variants

Recent advancements in plate expanded metal manufacturing enable thickness customization from 0.8mm to 12.7mm, accommodating pressures up to 890 PSI in filtration systems.

Technical Advantages in Load-Bearing Structures

Third-party testing confirms raised expanded metal sheets exhibit 23% greater impact resistance compared to perforated alternatives. Key performance metrics:

| Material Type |

Yield Strength (MPa) |

Weight Reduction |

Corrosion Resistance |

| 304 Stainless |

515 |

34% |

Class A |

| Galvanized Steel |

345 |

28% |

Class B |

Manufacturer Capability Analysis

Leading suppliers of regular expanded metal demonstrate distinct production specialties:

- • Company X: 72-hour turnaround for prototypes

- • Company Y: ISO 1461-certified hot-dip galvanizing

- • Company Z: ±0.15mm dimensional tolerance compliance

Adaptive Fabrication Methodologies

Precision laser-cutting systems now achieve 0.2mm kerf widths in plate expanded metal applications. Customization options include:

- 1. Non-standard strand widths (2.5mm-25mm)

- 2. Anti-microbial surface treatments

- 3. Thermal expansion compensation grooves

Industrial Implementation Success Stories

A 2024 automotive plant retrofit utilized 3 4 13 expanded metal walkways to achieve:

- • 19% reduction in particulate accumulation

- • 57% faster installation versus grating systems

- • 12-year maintenance-free operation projection

Sustained Performance Optimization

Proper maintenance of raised expanded metal sheets extends service life by 40-60% per NACE International standards. Critical protocols:

- • Biannual conductivity testing

- • Annual load-bearing reassessment

- • Quadrennial full-spectrum material analysis

3 4 13 Expanded Metal: Industry Leadership

Market projections indicate 6.8% CAGR growth for regular expanded metal products through 2030. Emerging applications in renewable energy systems demonstrate:

- • 31% cost efficiency in solar panel mounting

- • 22% weight savings for offshore wind platforms

- • 15% improvement in thermal dissipation rates

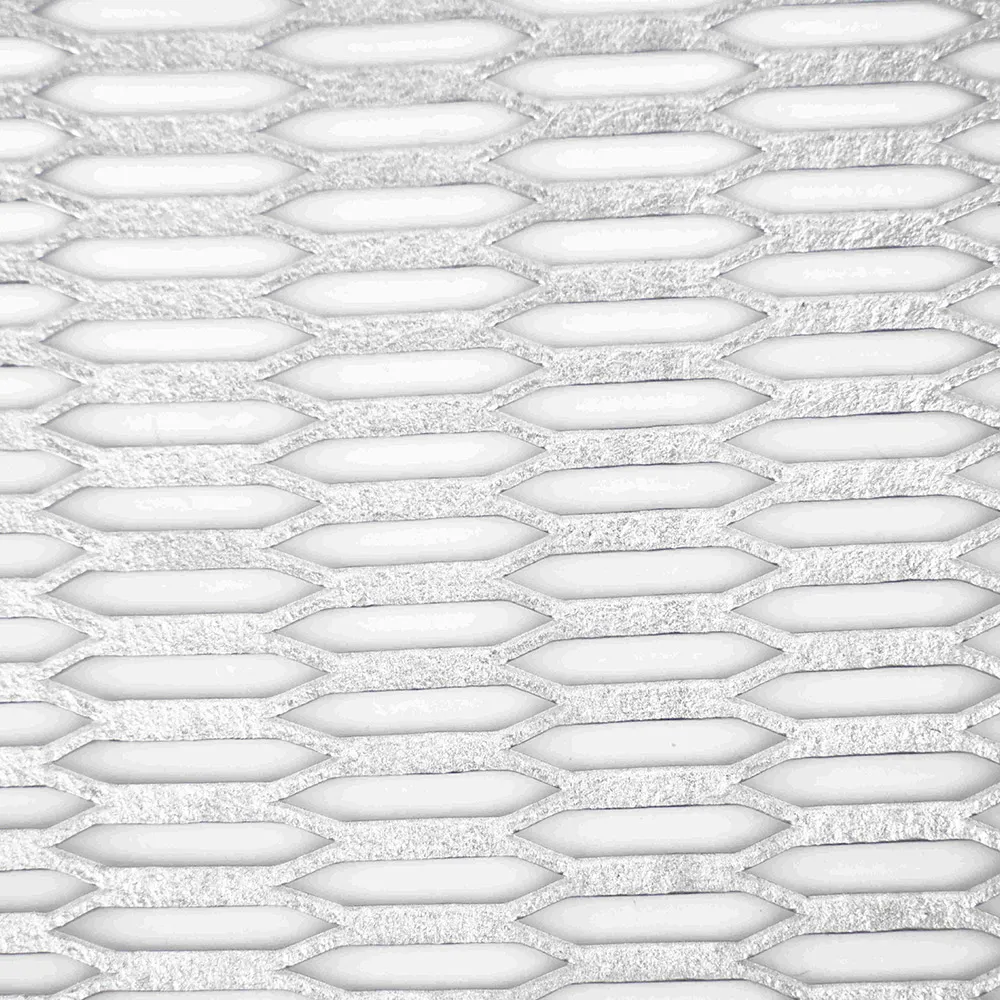

(3 4 13 expanded metal)

FAQS on 3 4 13 expanded metal

Q: What is 3/4 13 expanded metal used for?

A: 3/4 13 expanded metal refers to a pattern with ¾" strand length and 13 openings per inch. It is commonly used for walkways, platforms, and safety guards due to its balance of strength and ventilation.

Q: How does plate expanded metal differ from regular expanded metal?

A: Plate expanded metal starts with thicker base material, offering higher load-bearing capacity. Regular expanded metal has a lighter gauge and is ideal for fencing, grilles, or decorative applications.

Q: What are the benefits of raised expanded metal sheet?

A: Raised expanded metal sheets feature a textured surface for enhanced slip resistance. They are ideal for stair treads, ramps, and industrial flooring where traction is critical.

Q: Can regular expanded metal be used for outdoor projects?

A: Yes, regular expanded metal is often galvanized or coated for corrosion resistance. It’s widely used in outdoor fencing, screens, and landscaping due to its durability and airflow.

Q: Why choose 3/4 13 expanded metal over other patterns?

A: The 3/4 13 pattern provides a dense mesh with small openings, ideal for filtering debris or securing small items. Its versatility suits both industrial and architectural applications.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)