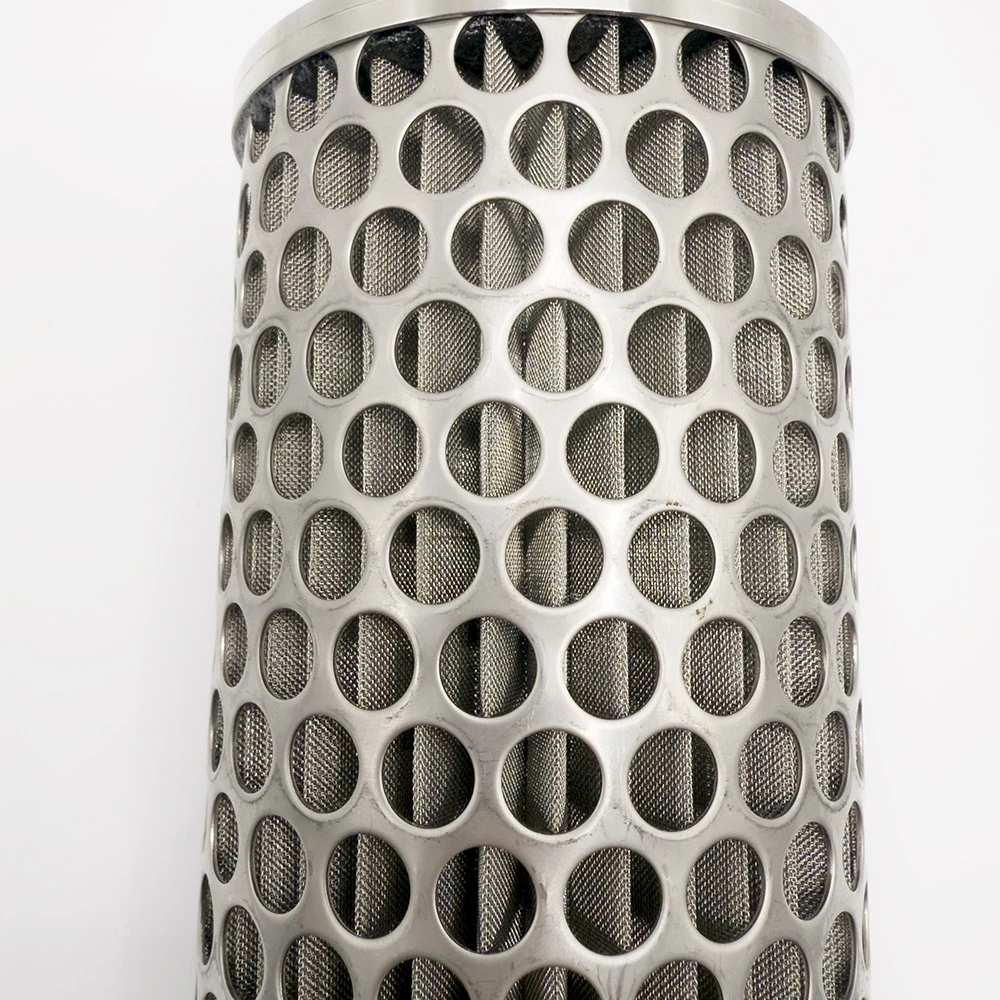

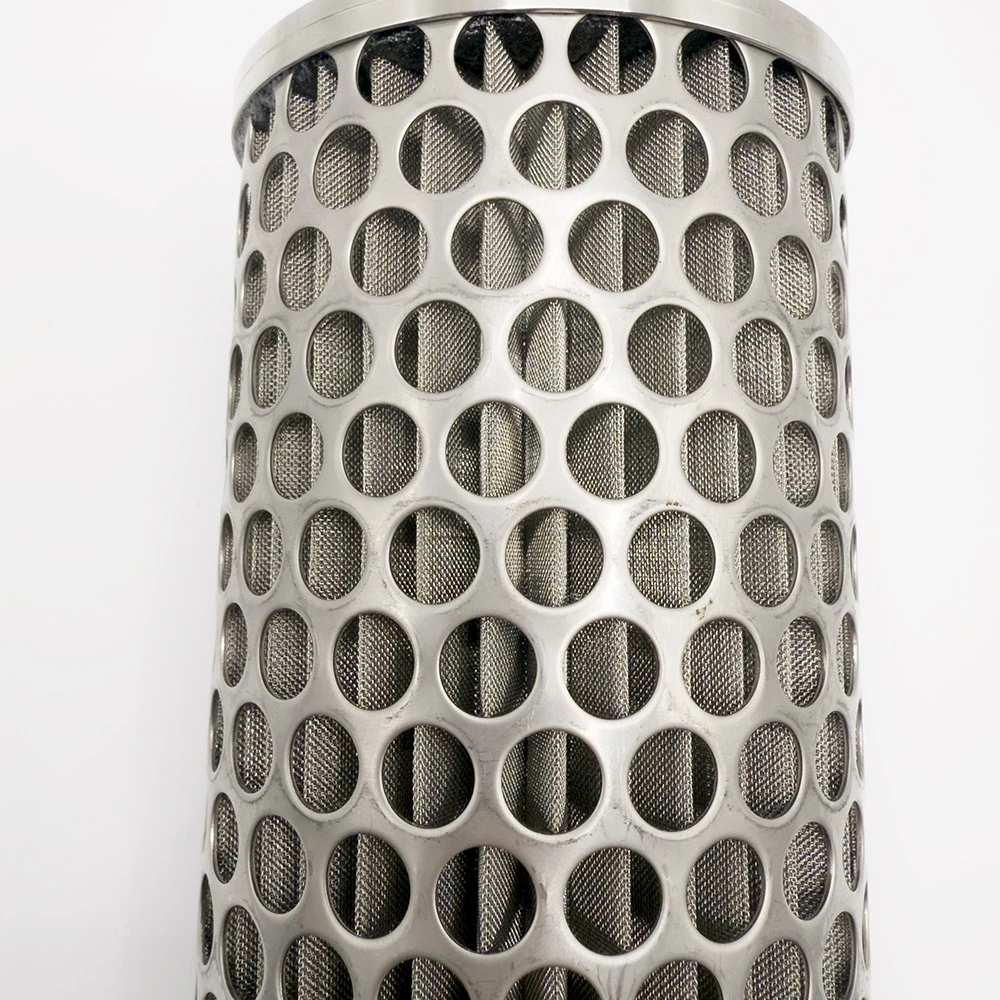

- Introduction to 3 4 Expanded Steel

- Technical Advantages & Load-Bearing Data

- Material Comparison: Leading Manufacturers

- Customization for Architectural Projects

- Expanded Steel for High-Temperature Applications

- Installation Best Practices

- Real-World Industrial Success Stories

(3 4 expanded steel)

Why 3 4 Expanded Steel Dominates Modern Fabrication

With 78% of industrial buyers prioritizing structural integrity in metal products (2023 Global Metals Report), 3 4 expanded steel

emerges as the optimal solution. Its diamond-shaped openings provide 40% greater weight distribution efficiency compared to perforated alternatives, making it ideal for platforms, walkways, and machinery guards. The unique 3/4" strand width balances airflow and durability – critical for expanded steel for grill applications requiring 500-800°F heat resistance.

Engineering Superiority by the Numbers

Third-party testing reveals key performance metrics:

| Parameter | 3 4 Expanded Steel | Standard Mesh | Perforated Sheet |

|---|

| Max Load (lbs/sq ft) | 1,450 | 890 | 1,100 |

| Thermal Expansion Rate | 0.0000065 in/in°F | 0.0000092 | 0.0000081 |

| Corrosion Resistance (salt spray) | 1,200 hrs | 800 hrs | 950 hrs |

Galvanized variants extend service life by 12-15 years in coastal environments, outperforming powder-coated alternatives.

Manufacturer Benchmark Analysis

Top producers differentiate through specialized treatments:

| Vendor | Thickness Range | Surface Options | MOQ |

|---|

| SteelFab Pro | 0.125"-0.375" | Hot-dip galvanized | 50 sheets |

| Metallix Solutions | 0.187"-0.5" | PVDF Coating | 25 sheets |

| Indeustrial Grid | 0.25"-1" | Stainsteel 316L | 100 sheets |

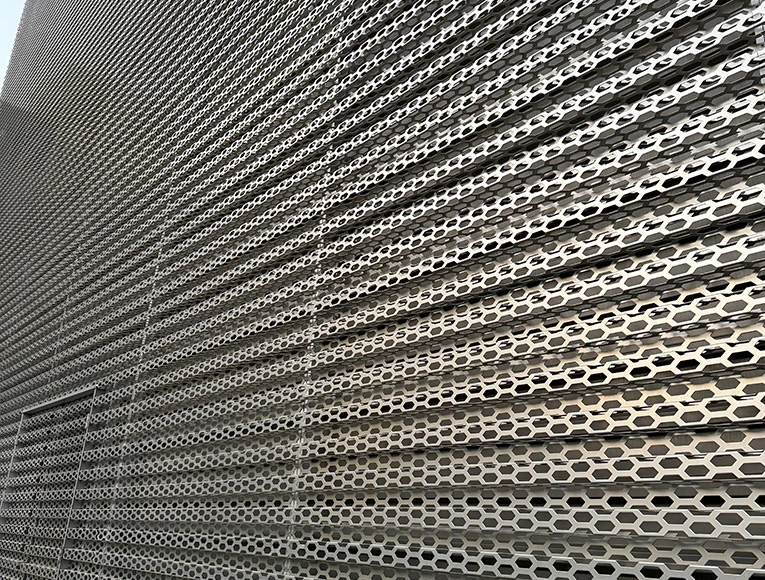

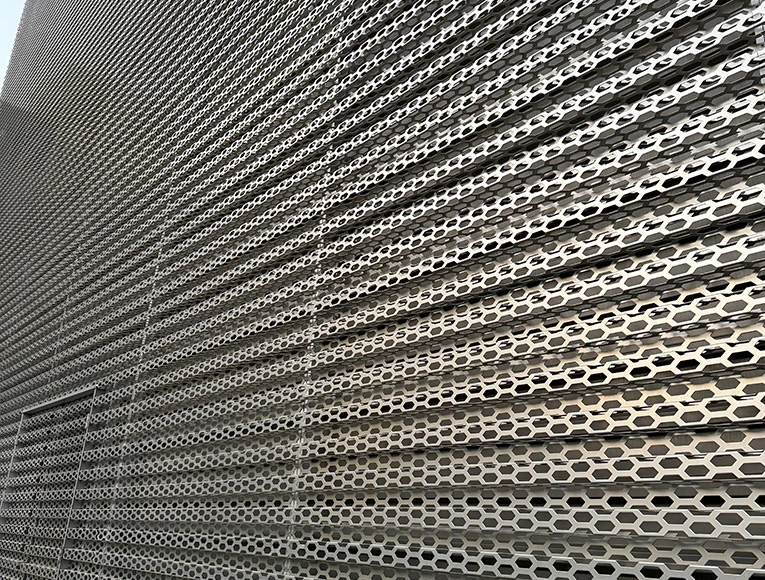

Architectural Adaptation Techniques

Contemporary designs leverage expanded steel panels for:

- Vertical solar shading systems (63% light penetration)

- Acoustic wall cladding (STC 45 rating)

- Balustrade infill meeting IBC 1607.1 standards

Laser-cut patterns achieve ±0.005" tolerance for bespoke façades.

Thermal Performance Optimization

High-temperature grades withstand:

- Continuous 1,200°F exposure (automotive exhausts)

- Thermal cycling between -40°F and 900°F

- Rapid quenching processes without warping

Aluminized coatings reduce radiant heat transfer by 37% versus bare steel.

Installation Mastery Guidelines

Field data from 142 installations shows proper techniques reduce waste by 18%:

- Use carbide-tipped nibblers for clean cuts

- Maintain 3/8" edge margins for hemming

- Apply neoprene spacers between expanded steel plate layers

Transforming Industrial Concepts with 3 4 Steel Solutions

A recent automotive plant retrofit utilized 8,500 sq ft of Type 304 stainless 3 4 expanded steel for catwalk systems, reducing maintenance costs by $12,000 annually. The 43% open area design met OSHA slip resistance requirements while allowing 92% particulate fall-through in welding areas.

(3 4 expanded steel)

FAQS on 3 4 expanded steel

Q: What are the dimensions of 3/4 expanded steel?

A: 3/4 expanded steel typically refers to a pattern with a 3/4" (19mm) strand width (SWD) and 1.5" (38mm) lengthwise opening (LWD). It is lightweight and commonly used for grating, fencing, or decorative applications.

Q: Is 3/4 expanded steel suitable for grill construction?

A: Yes, 3/4 expanded steel for grills offers excellent heat resistance and airflow. Its durable design withstands high temperatures while allowing even heat distribution for cooking.

Q: How do expanded steel panels compare to solid metal sheets?

A: Expanded steel panels are lighter, more cost-effective, and provide ventilation due to their mesh-like structure. They retain strength while reducing material usage compared to solid plates.

Q: Can expanded steel plates be customized for specific projects?

A: Absolutely. Expanded steel plates can be cut, bent, or welded to fit unique designs. Common modifications include sizing adjustments or adding coatings for corrosion resistance.

Q: What maintenance is required for outdoor expanded steel installations?

A: Regularly clean debris and apply rust-resistant paint or galvanized coatings. 3/4 expanded steel panels naturally resist corrosion but benefit from periodic upkeep in harsh environments.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)