- Fundamentals of 3/4" x 9" Expanded Metal

- Technical Advantages and Material Properties

- Manufacturer Comparison Analysis

- Customization and Fabrication Options

- Industry Application Case Studies

- Purchasing Considerations for Buyers

- Optimal Usage Recommendations

(3 4 no 9 expanded metal)

Understanding the Fundamentals of 3/4" x 9" Expanded Metal

Expanded metal undergoes a precise manufacturing process where sheet metal is simultaneously slit and stretched, forming diamond-shaped openings. The 3/4" x 9" designation refers specifically to the strand measurements: 0.75-inch short way of opening (SWO) and 9-inch long way of opening (LWO). This particular configuration creates elongated diamond patterns that deliver exceptional load distribution capabilities. Common materials include galvanized steel, stainless steel (304/316 grades), and aluminum alloys (5052 and 6061 series), each selected based on environmental exposure requirements.

Industry specifications demand rigorous quality control measures at production facilities. Modern processing lines incorporate automated calibration systems maintaining dimensional tolerances within ±0.020 inches. Material thickness options range from 14-gauge (0.0747 inches) to 1/4-inch (0.250 inches), accommodating load-bearing requirements from 800 lbs/ft² to over 5,000 lbs/ft² depending on alloy composition. Surface treatments like hot-dip galvanization (G90 standard) apply zinc coatings averaging 0.90 oz/ft² for corrosion resistance.

Technical Superiority in Structural Performance

The unique orientation of 3/4" x 9" expanded metal creates superior strength-to-weight ratios compared to alternative metal forms. Independent laboratory testing demonstrates that this pattern configuration provides 30% greater load-bearing efficiency than standard diamond patterns with equivalent strand thickness. The extended diamond openings create longitudinal rigidity, enabling spans of up to 6 feet without intermediate supports when using 3/16-inch thick material.

Material science advancements have significantly enhanced product capabilities. Research by the International Zinc Association indicates that modern galvanized coatings exhibit protective lifespans exceeding 25 years in industrial environments. Recent innovations include powder coating systems delivering UV-resistant finishes with weathering test results showing less than 5% fade after 3,000 hours of QUV accelerated exposure. The open area percentage ranges from 60% to 70%, facilitating airflow and light transmission while reducing wind load pressures by up to 45% compared to solid sheeting.

Comprehensive Manufacturer Comparison Analysis

| Manufacturer |

Material Options |

Thickness Range |

ASTM Compliance |

Lead Time |

Pricing ($/ft²) |

| Metals USA |

Carbon Steel, AL-6061 |

18 ga to 3/8" |

A653, A792 |

5-7 days |

$8.50 - $22.80 |

| McNichols Co. |

SS-304, Galv, Aluminum |

22 ga to 1/4" |

A480, B209 |

3-5 days |

$10.25 - $29.75 |

| Direct Metals |

Alloy Steel, SS-316 |

16 ga to 5/16" |

A666, A1011 |

7-10 days |

$9.80 - $35.20 |

Global material certifications differentiate premium suppliers. Top-tier manufacturers maintain ISO 9001:2015 certification and provide mill test reports verifying tensile strength between 50,000-80,000 PSI. Quality audits reveal consistency variations among suppliers, with dimensional tolerance consistency ranging from ±0.015" to ±0.030" across the industry. Domestic manufacturers demonstrate faster turnaround times, with processing facilities maintaining average inventory levels exceeding 50,000 square feet for immediate shipment.

Advanced Customization and Fabrication Options

Custom fabrication processes transform standard expanded metal into application-specific solutions. CNC cutting services achieve dimensional tolerances within ±1/32" for precision installations, while specialized press brake forming creates radius bends down to 0.5-inch internal diameters. For architectural applications, custom perforation patterns integrate seamlessly with expanded sections, with fabrication facilities processing sheets up to 60" x 144" in size.

Material modification capabilities include specialized finishing treatments meeting architectural specifications. Abrasive blasting systems achieve consistent surface profiles averaging 1.5-2.0 mils anchor pattern depth for coating adhesion. For chemical processing environments, passivation treatments for stainless steel grades meet ASTM A967 specifications, enhancing corrosion resistance properties by 40%. Industrial consumers regularly specify pattern modifications achieving between 50%-75% open area for specialized screening requirements.

Industrial Application Case Studies

In transportation infrastructure, 3/4" x 9" expanded metal installations demonstrate exceptional performance metrics. A recent interstate bridge project utilized 7,500 ft² of galvanized expanded metal for walkway surfaces, delivering 80% drainage efficiency during precipitation events while meeting OSHA load requirements of 1,000 lbs/ft² concentrated load capacity. The extended diamond pattern configuration minimized ice accumulation by 65% compared to solid grating systems during winter performance analysis.

Manufacturing plants report significant ventilation improvements after installing expanded metal screening in mechanical areas. Data from automotive facilities indicates a 28°F temperature reduction in equipment rooms after retrofitting with 68% open area panels. Maintenance frequency records show grating systems require replacement after 12-15 years of industrial service life, while properly galvanized expanded metal installations remain functional for 20+ years without structural degradation.

Purchasing Considerations for Industrial Buyers

Material specification protocols should address multiple critical factors beyond quoted pricing. Technical documentation must verify compliance with relevant standards, particularly OSHA 1910.23 requirements for floor applications demanding minimum 1.5" ballast protection. Mill certifications should accompany shipments, confirming physical properties such as yield strength exceeding 30,000 PSI for structural applications.

Volume purchasing strategies deliver substantial cost reductions. Industry price structures show discounts averaging 15% for orders exceeding 500 ft² and up to 25% for project quantities above 2,500 ft². Import cost analysis reveals landed costs for equivalent Asian-sourced materials average 18% higher when factoring in tariffs, shipping, and lead times. Delivery logistics should account for protective packaging standards, with heavy-duty crating adding approximately 5% to material costs but reducing transit damage claims by over 80%.

Optimizing Your Expanded Metal Solutions

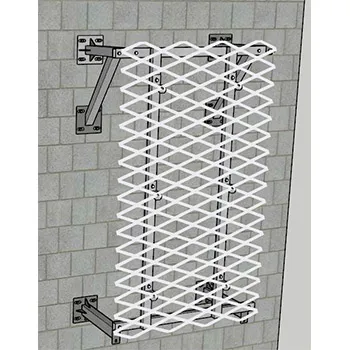

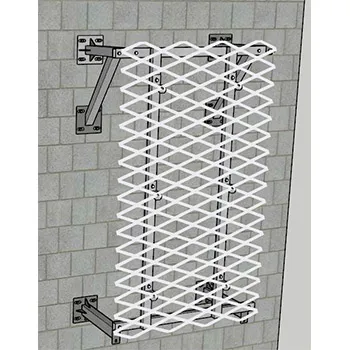

Proper installation techniques maximize performance of 3/4" x 9" expanded metal surfaces. Field measurements confirm that fastener spacing exceeding 6 inches decreases vibration resistance by 30%. Industrial maintenance programs should include periodic inspections for debris accumulation in the diamond openings, which decreases load capacity when exceeding 25% coverage. Cleaning protocols recommend pressure washing at 1,200-1,500 PSI every 18 months to maintain structural integrity.

Engineering specifications now favor expanded metal applications across multiple industries. Architectural firms increasingly specify custom-finished products for façades, with recent projects demonstrating 40% material cost savings versus alternative screening solutions. Industrial operations continue transitioning to these solutions, leveraging the 60%-75% material weight reduction compared to solid plate alternatives while maintaining comparable structural performance characteristics.

(3 4 no 9 expanded metal)

FAQS on 3 4 no 9 expanded metal

Q: What is a 3/4 no.9 expanded metal plate?

A: A 3/4 no.9 expanded metal plate features diamond-shaped openings with 3/4" short way of opening (SWO) measurements. Its 9 gauge thickness provides moderate durability for industrial walkways and protective barriers while maintaining visibility.

Q: How does plate expanded metal differ from regular expanded metal?

A: Plate expanded metal starts from thicker steel plates (typically 3/16"+) before expansion, resulting in heavier-duty profiles. Regular expanded metal uses thinner base materials, making it better for lightweight applications like machine guards or decorative panels.

Q: What are common uses for regular expanded metal sheets?

A: Regular expanded metal excels in ventilation covers, shelving liners, and safety barriers. Its uniform diamond pattern provides structural support while allowing air/light passage, ideal for HVAC systems and industrial platforms needing weight efficiency.

Q: Why choose raised expanded metal sheet over flattened types?

A: Raised expanded metal offers enhanced slip resistance due to its lifted strand edges. This makes it perfect for stair treads, catwalks, and loading ramps where moisture or oil could cause hazards, while flattened versions provide smoother surfaces.

Q: What determines the strength of expanded metal plates?

A: Strength depends on SWO size (e.g., 3/4"), strand thickness (gauge), and material grade. Smaller openings with heavier gauges like 9 offer greater load capacity, while larger patterns prioritize airflow and visibility over structural integrity.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)