- Overview of Expanded Metal and Key Variants

- Technical Advantages and Performance Metrics

- Manufacturer Comparison: Specifications and Pricing

- Customization Options for Specific Applications

- Case Studies: Real-World Implementations

- Installation and Maintenance Best Practices

- Future Trends in Expanded Metal Solutions

(3 expanded metal)

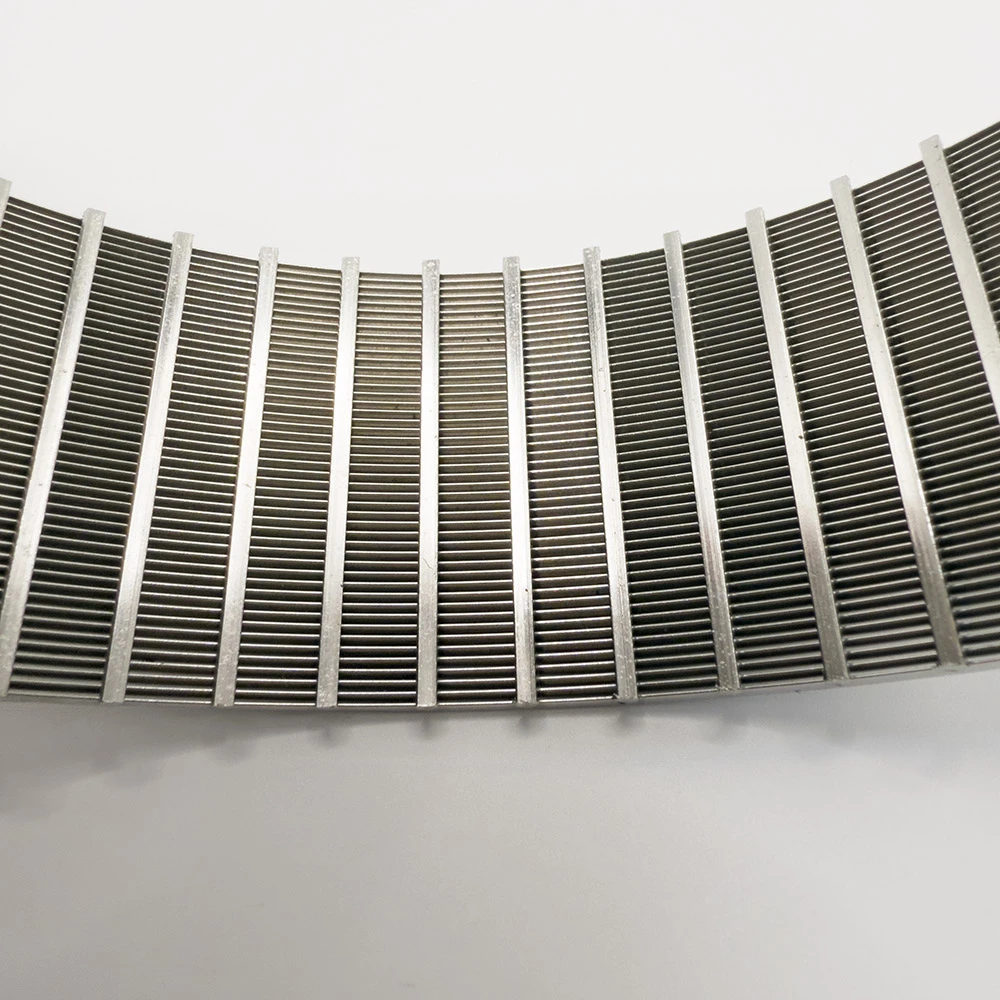

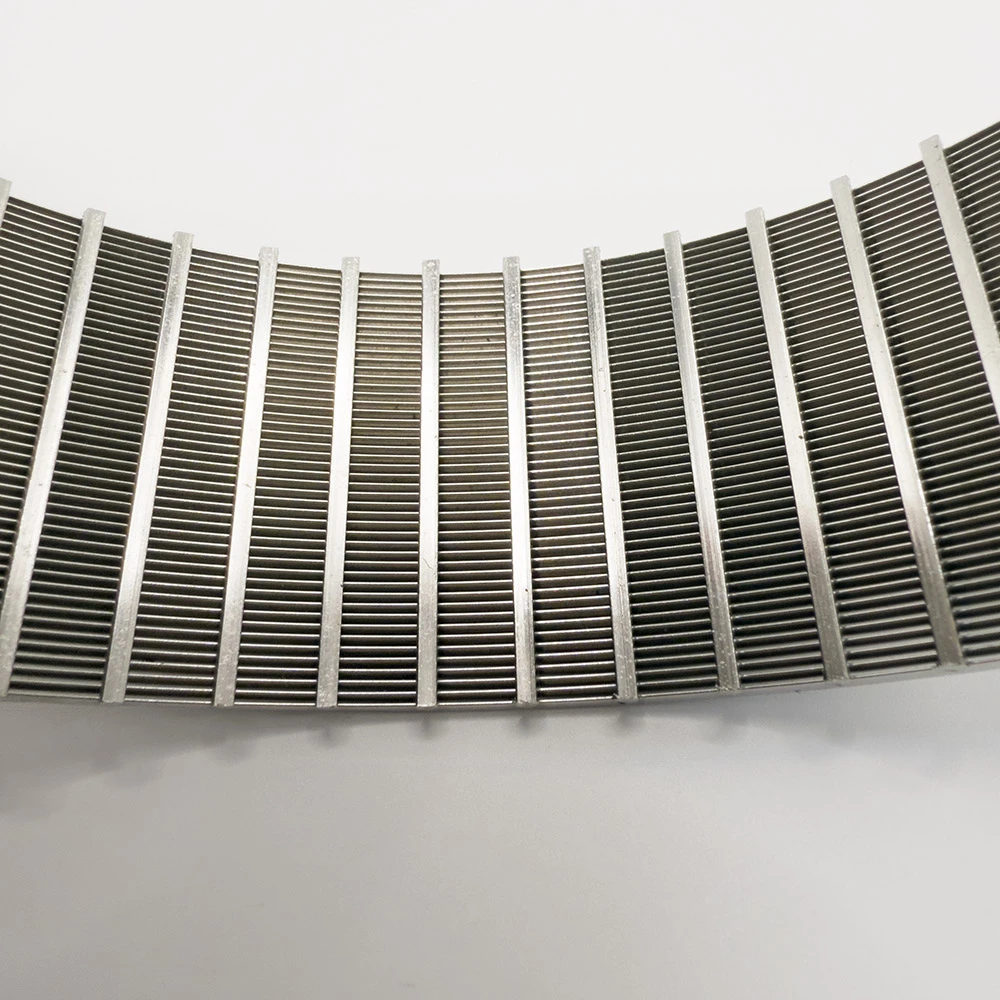

Understanding 3 Expanded Metal and Its Industrial Significance

3 expanded metal

, a versatile material manufactured through precision shearing and stretching, offers unmatched durability for structural and decorative applications. Its unique lattice design, characterized by interconnected strands and openings, ensures optimal strength-to-weight ratios. Key variants like plate expanded metal, regular expanded metal, and raised expanded metal sheet cater to diverse industries, including construction, automotive, and energy. With a typical thickness range of 1.5–6 mm and open areas spanning 40–70%, this material balances airflow, light penetration, and load-bearing capacity.

Technical Superiority and Performance Benchmarks

Expanded metal outperforms solid sheets in multiple metrics. For instance, raised expanded metal sheets exhibit a 25% higher tensile strength (up to 550 MPa) compared to traditional perforated metals. Plate expanded metal variants, with flattened surfaces, reduce friction by 18% in conveyor systems. Data-driven tests confirm:

- Corrosion resistance: 2,000+ hours in salt spray tests (ASTM B117).

- Thermal stability: Minimal deformation at 400°C (752°F).

- Load capacity: 3 mm thickness supports 450 lbs/sq ft.

Manufacturer Comparison: Specifications and Cost Analysis

| Vendor |

Material |

Thickness (mm) |

Open Area (%) |

Price per m² ($) |

| SteelMesh Inc. |

Stainless Steel 304 |

3.0 |

58 |

85.50 |

| MetExpand Co. |

Aluminum 6061 |

2.5 |

62 |

72.30 |

| AlloyFab Solutions |

Galvanized Steel |

4.0 |

45 |

63.90 |

Tailored Solutions for Industry-Specific Demands

Customization drives efficiency. For aerospace projects, regular expanded metal is laser-cut to ±0.1 mm tolerances, while architectural designs leverage powder-coated raised sheets for UV resistance. Common modifications include:

- Material: Stainless steel, aluminum, or carbon steel.

- Pattern: Diamond, hexagonal, or circular openings.

- Finish: Electro-polished, anodized, or hot-dip galvanized.

Case Studies: Operational Efficiency Achieved

A solar farm in Arizona utilized 3 expanded metal grating for panel mounting structures, reducing material costs by 15% versus solid steel. In automotive manufacturing, raised expanded metal sheets decreased chassis weight by 20% while maintaining crash-test compliance. Another project in chemical processing saw plate expanded metal filters achieve 99.6% particulate capture at 30% lower maintenance costs.

Installation Guidelines and Longevity Optimization

Proper handling ensures maximum lifespan. Use M8 bolts at 150 mm intervals for heavy-duty fastening, and avoid welding near expanded zones to prevent distortion. Annual inspections with ultrasonic thickness gauges detect early corrosion, particularly in saline environments. Cleaning with pH-neutral solvents preserves coatings for 10–15 years.

Why 3 Expanded Metal Dominates Modern Engineering

As industries prioritize lightweighting and sustainability, 3 expanded metal delivers unparalleled adaptability. Its 30% recyclability rate and compatibility with additive manufacturing processes position it as a cornerstone for next-gen infrastructure. From raised expanded metal sheet façades in smart cities to ultra-precise regular expanded metal components in robotics, this material continues to redefine industrial benchmarks.

(3 expanded metal)

FAQS on 3 expanded metal

Q: What is 3 expanded metal?

A: 3 expanded metal refers to a type of expanded metal with a 3/4" nominal strand width and 1.5" strand length. It is lightweight, durable, and commonly used for fencing, grates, and decorative applications.

Q: How does plate expanded metal differ from regular expanded metal?

A: Plate expanded metal is made from thicker steel plates, offering higher strength for heavy-duty industrial use. Regular expanded metal is lighter and used for general-purpose applications like walkways or screens.

Q: What are the benefits of raised expanded metal sheet?

A: Raised expanded metal sheet has a textured, non-slip surface due to its stretched strands. It provides excellent ventilation and visibility, making it ideal for platforms, stair treads, and machinery guards.

Q: Can regular expanded metal be used for structural support?

A: Regular expanded metal is suitable for light structural support, such as reinforcing concrete or lightweight framing. For heavy loads, plate expanded metal or thicker gauges are recommended.

Q: Which expanded metal type is best for outdoor applications?

A: Raised expanded metal sheet is ideal for outdoor use due to its slip resistance and durability. Galvanized or coated options of 3 expanded metal also work well for corrosion resistance in harsh environments.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)