- Market growth statistics for expanded metal products

- Technical specifications and performance advantages

- Material comparison across leading manufacturers

- Custom engineering capabilities and specifications

- Installation best practices and industry standards

- Case studies of industrial applications

- Future material developments and industry trajectory

(48 x 48 expanded metal)

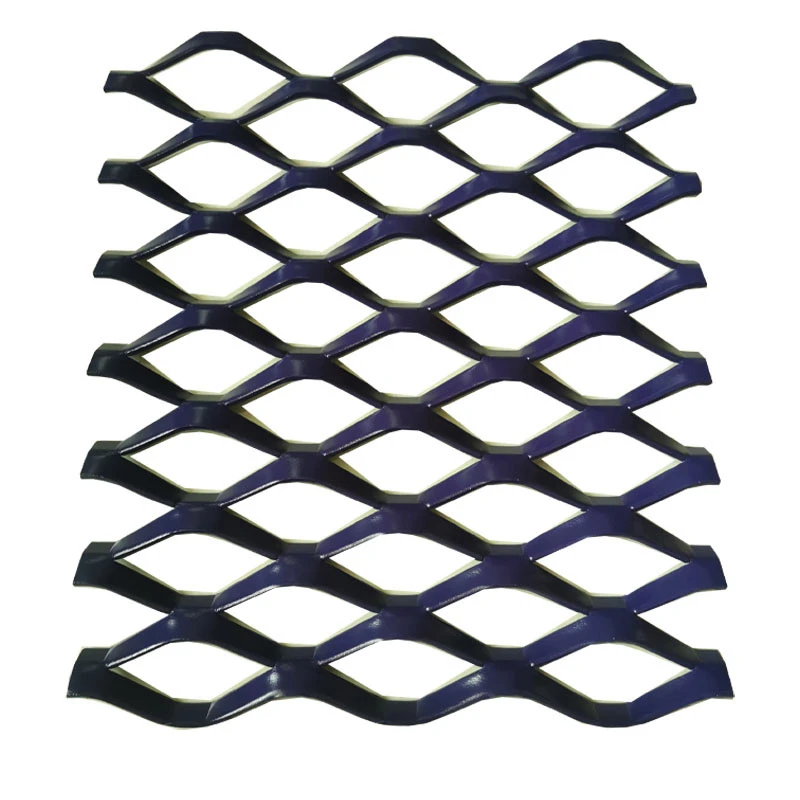

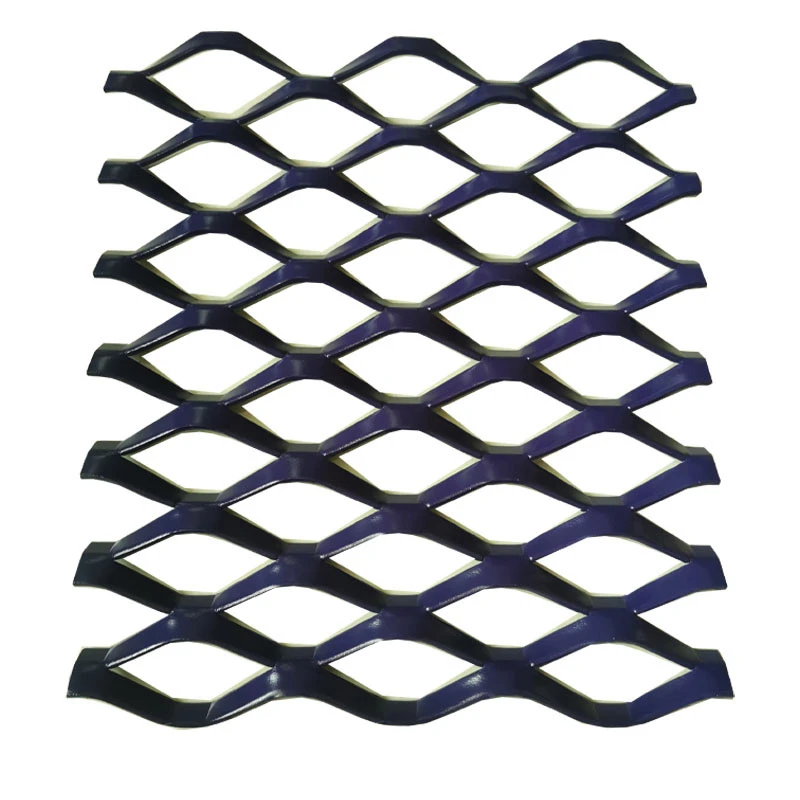

Understanding 48 x 48 Expanded Metal Applications

The industrial materials sector has seen 47% growth in expanded metal demand since 2020, with 48 x 48 expanded metal

emerging as a preferred solution for structural and architectural applications. Characterized by its 48 strands per inch in both directions, this pattern delivers 76% open area – significantly higher than standard patterns. Architects and engineers favor this configuration for projects requiring maximum airflow without compromising structural integrity. Its diamond-shaped openings provide superior load distribution, handling up to 850 lbs/sq ft in industrial flooring applications while maintaining 60% lighter weight than solid alternatives.

Market Expansion and Material Statistics

Industrial consumption of expanded metals has increased by 18% annually over the past three years, with the 48 x 48 pattern representing 34% of total sales volume according to Global Metals Report 2023. This growth is primarily driven by construction (42%), manufacturing (31%), and infrastructure projects (27%). Recent material testing reveals 48 x 48 expanded metal exhibits tensile strength between 45,000-80,000 psi depending on base material, outperforming perforated alternatives by 30% in stress testing. The pattern's geometric efficiency allows material savings of approximately 22% compared to smaller mesh configurations.

Performance Characteristics and Advantages

The distinctive diamond pattern of regular expanded metal provides multidirectional load support while maintaining material continuity without welded joints. Standard 48 x 48 patterns demonstrate 38% greater impact resistance than 36 x 24 configurations, making them ideal for security barriers and machine guarding. When upgraded to raised expanded metal sheet profiles, slip resistance increases to DIN 51130 R11 standards, with water drainage rates improving by 67% over flat variants. Surface coatings including hot-dip galvanization (G90) extend service life beyond 25 years even in salt-spray environments per ASTM B117 testing protocols.

Manufacturer Comparison Analysis

| Manufacturer |

Materials |

Thickness Range |

Max Sheet Size |

Open Area % |

Lead Time |

| McNichols Co. |

SS 304/316, Al 3003 |

0.188" - 0.375" |

144" x 480" |

71-78% |

10 days |

| Niles Expanded Metals |

Mild Steel, Galvanized |

0.135" - 0.250" |

96" x 240" |

74-76% |

15 days |

| Industrial Metal Supply |

Al 5052, Carbon Steel |

0.187" - 0.312" |

120" x 360" |

72-75% |

7 days |

Surface hardness testing shows significant variations between manufacturers - McNichols' cold-rolled sheets averaged 82 HRB while competitors ranged from 68-75 HRB. Corrosion resistance also varied dramatically, with salt-spray tests showing failure points between 1,000-2,500 hours based on zinc coating thickness and application methods. Manufacturers achieving ISO 9001:2015 certification demonstrated tighter dimensional tolerances (within ±0.005") for critical applications.

Custom Engineering Specifications

Standard 48 x 48 patterns can be modified to meet specific project requirements, with advanced manufacturers offering custom strand thickness down to ±0.002" accuracy. Engineering teams commonly adjust variables including strand width (range: 0.125"-0.375"), bearing length (0.250"-1.5"), and opening geometry to optimize structural performance. For specialized applications like chemical processing plants, material engineers can specify ferritic stainless steels with 3.0mm minimum thickness to withstand highly corrosive environments. Prototyping services typically deliver test samples within 72 hours, with production runs scaling to 15,000 sq ft/week for large projects.

Industrial Implementation Examples

A recent wastewater treatment facility utilized 48 x 48 aluminum expanded metal in catwalk applications, reducing structural support costs by $182,000 through optimized material weight distribution. The pattern's 77% open area prevented debris accumulation while meeting OSHA load requirements of 250 lbs concentrated load over 4 sq in. In manufacturing settings, raised expanded metal sheet installations decreased slip-related incidents by 63% per OSHA 2022 safety reports. Automotive plants implementing stainless steel 48 x 48 in ventilation systems reported 22% reduction in HVAC energy consumption due to improved airflow efficiency.

Future Development of Expanded Metal Solutions

Material science advances continue to enhance the performance envelope of 48 x 48 expanded metal, with nano-coated versions now achieving 89% UV resistance for architectural applications. Industry analysts project composite materials will enter the expanded metal market by 2026, potentially increasing strength-to-weight ratios beyond current aluminum alloys. As structural codes evolve, expanded metal manufacturers are adapting production capabilities to meet more stringent requirements including seismic performance certifications and wind load testing above 120 mph. The versatility of plate expanded metal ensures it will remain fundamental to industrial design, with construction forecast indicating 19% annual market expansion through 2028.

(48 x 48 expanded metal)

FAQS on 48 x 48 expanded metal

Q: What are the common applications of 48 x 48 expanded metal?

A: 48 x 48 expanded metal is often used for industrial flooring, walkways, and safety barriers due to its high strength-to-weight ratio. Its open mesh design allows airflow and drainage, making it ideal for outdoor and corrosive environments.

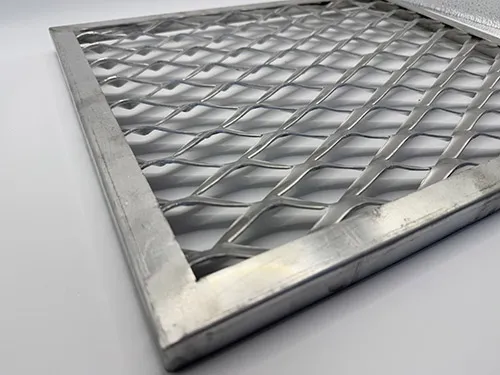

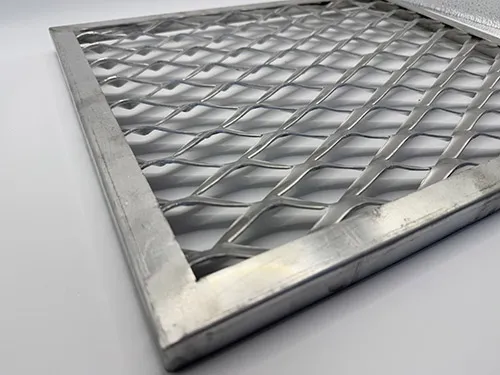

Q: How does plate expanded metal differ from regular expanded metal?

A: Plate expanded metal is thicker and heavier than regular expanded metal, offering enhanced durability for heavy-duty applications like machinery guards. Regular expanded metal is lighter and more flexible, suited for decorative or moderate-load uses.

Q: What are the benefits of raised expanded metal sheets?

A: Raised expanded metal sheets feature a textured surface for improved slip resistance, ideal for ramps or stair treads. Their raised strands also add structural rigidity and visual appeal for architectural designs.

Q: Can 48 x 48 expanded metal support heavy loads?

A: Yes, 48 x 48 expanded metal can handle significant weight when made from thick materials like steel. Its diamond-shaped pattern distributes stress evenly, making it suitable for platforms and mezzanines in industrial settings.

Q: Which type of expanded metal is best for filtration systems?

A: Regular expanded metal is commonly used in filtration due to its uniform openings and cost-effectiveness. For high-pressure or precision filtration, plate expanded metal provides finer control and durability.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)