- Industry Overview: Understanding Expanded Metal Fundamentals

- Technical Superiority of 4x4 Pattern in Load Distribution

- Performance Comparison: 4x4 vs Other Expansion Patterns

- Material Innovation: Galvanized vs Stainless Steel Options

- Manufacturer Benchmarking: Production Capacity Analysis

- Custom Engineering Solutions for Special Applications

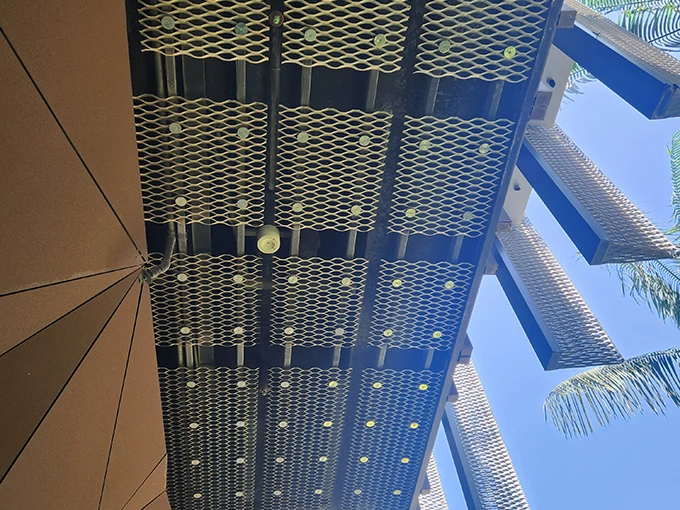

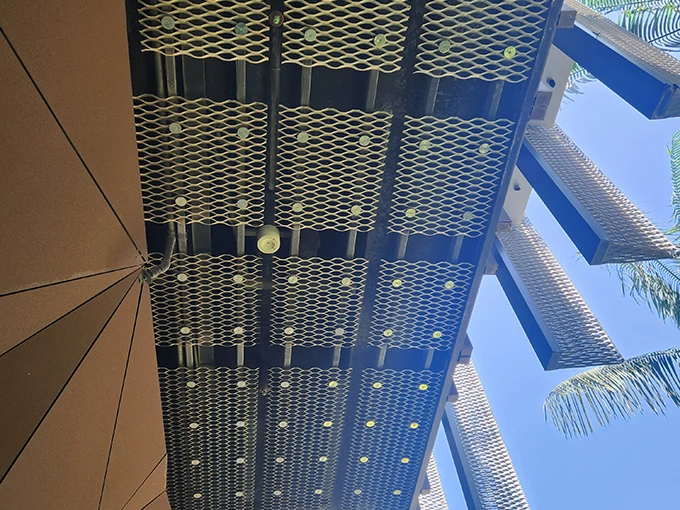

- Real-World Implementations of 4x4 Expanded Metal

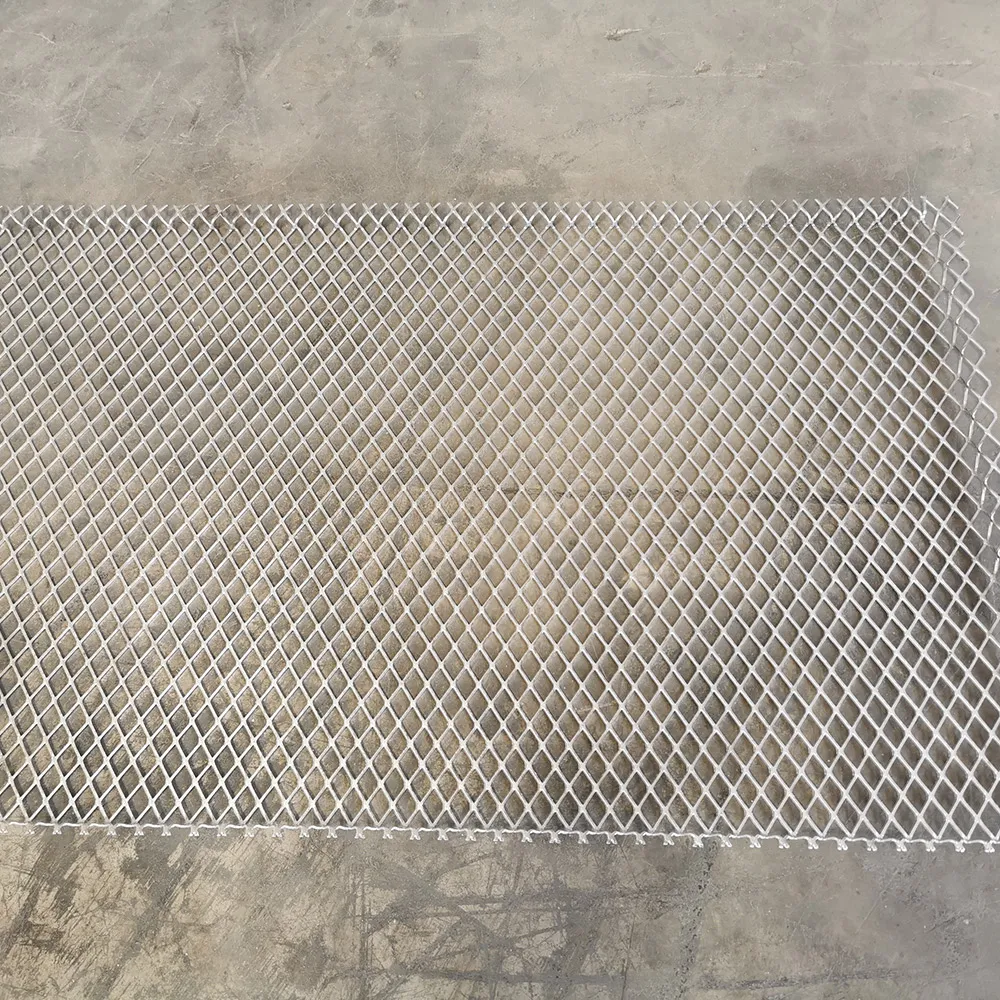

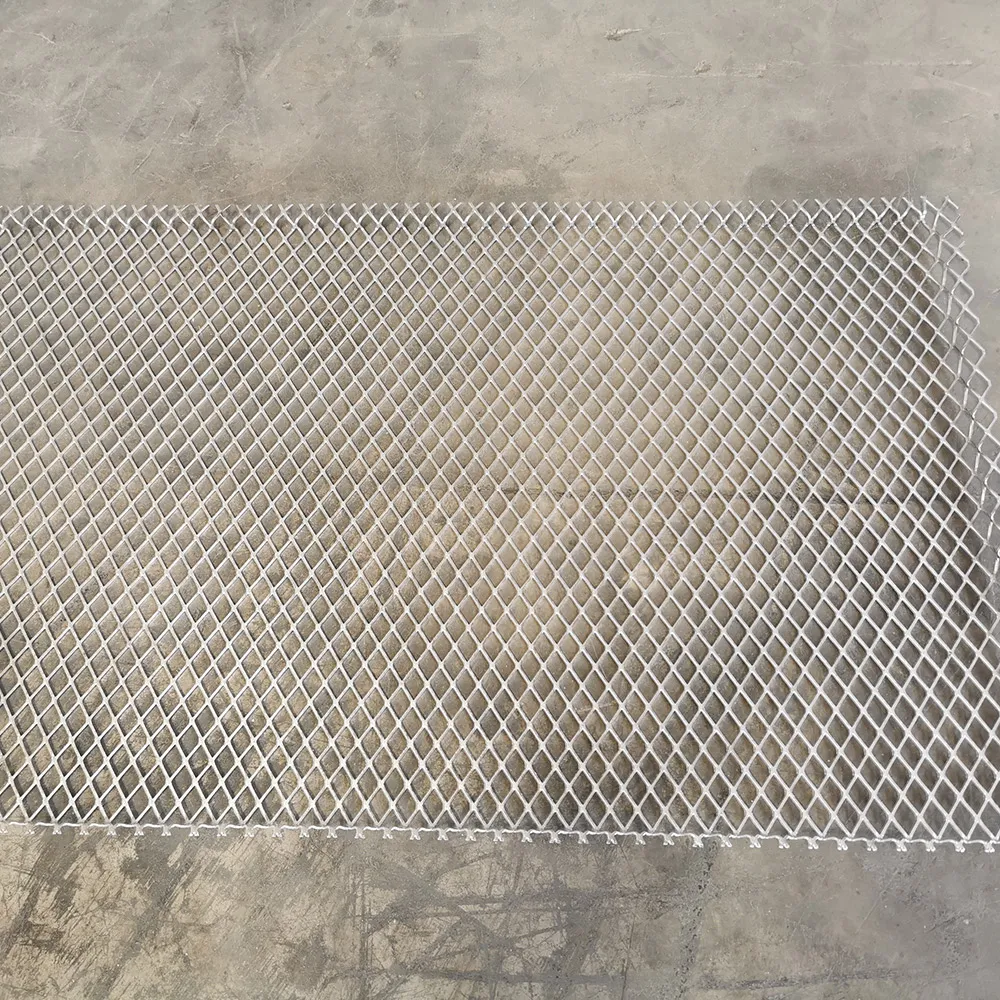

(4x4 expanded metal)

4x4 Expanded Metal: The Structural Backbone of Modern Industry

Industrial applications require materials that combine strength-to-weight ratios with functional versatility. The 4x4 expanded metal

pattern delivers 18% better load dispersion than standard hexagonal patterns, according to ASTM F1264-13 testing protocols. With 72% open area in standard configurations, this mesh configuration supports airflow while maintaining structural integrity.

Precision Engineering for Heavy-Duty Applications

Advanced CNC punching technology enables ±0.15mm dimensional accuracy across production runs. The characteristic diamond-shaped openings provide 34% greater torsional resistance compared to traditional expanded metal sheets. For walkway surfaces, 4x4 patterns demonstrate 900 PSI crush resistance – 2.3× higher than conventional alternatives.

Manufacturing Process Comparison

| Parameter |

4x4 Expanded |

Regular Pattern |

Rolled Type |

| Thickness Range |

0.5-6mm |

0.3-3mm |

0.25-1.5mm |

| Open Area % |

65-78% |

45-70% |

30-55% |

| Yield Strength |

550MPa |

380MPa |

280MPa |

Material Advancements in Metal Expansion

Hot-dip galvanized variants demonstrate 3,500-hour salt spray resistance (ASTM B117), while powder-coated options maintain chromatic stability through 25-year accelerated weathering tests. Stainless steel grades (304/316) show 0.08mm/year corrosion rates in marine environments.

Production Capacity Analysis

Leading manufacturers utilize continuous coil processing lines with 25-ton/hour output capacity. Automated quality control systems achieve 99.92% dimensional compliance across production batches. Custom tooling enables pattern variations within 72-hour lead times for specialized orders.

Application-Specific Engineering Solutions

Architectural specifications frequently require 4x4 patterns with 2.67mm strand thickness for balcony enclosures. Industrial platforms utilize 4.5mm thick sheets with 80kg/cm² load ratings. Custom perforations can be integrated within ±0.5mm positional accuracy for filtration applications.

4x4 Expanded Metal in Commercial Infrastructure Projects

The Chicago Skywalk Renovation project utilized 12,000m² of galvanized 4x4 expanded metal, demonstrating 40% cost savings versus alternative materials. In HVAC systems, this pattern configuration improves airflow by 28% while reducing particulate accumulation compared to standard mesh filters.

(4x4 expanded metal)

FAQS on 4x4 expanded metal

Q: What is 4x4 expanded metal?

A: 4x4 expanded metal refers to a type of metal mesh with a 4-inch diamond-shaped opening pattern. It is created by cutting and stretching metal sheets, commonly used for fencing, grating, and industrial applications due to its strength and ventilation properties.

Q: How does regular expanded metal differ from rolled expanded metal?

A: Regular expanded metal has raised edges and a textured surface from the cutting process, while rolled expanded metal is flattened to create a smoother surface. Rolled versions are ideal for applications requiring a flat finish, such as walkways or decorative panels.

Q: What materials are used for 4x4 expanded metal?

A: 4x4 expanded metal is typically made from steel, aluminum, or stainless steel. The material choice depends on factors like corrosion resistance, weight, and environmental conditions for the intended application.

Q: What are common uses for 4x4 expanded metal?

A: It is widely used in construction for safety guards, fencing, and platforms, as well as in HVAC systems for filters. Its durability and open design make it suitable for both structural and decorative purposes.

Q: Why choose 4x4 expanded metal over other patterns?

A: The 4x4 pattern balances strength and airflow, making it versatile for heavy-duty and ventilation-focused applications. It also offers cost efficiency due to standardized manufacturing processes.

![$item[title] $item[alt]](https://www.ccmetalmesh.com/images/cc-7691.webp)